Effective Desander Liquid for Removal of Sediment and Debris

By:Admin

The company, founded in 2005, has quickly become a leader in the field of solids control and drilling waste management. Their team of experts has developed a range of products and services to address the challenges faced by the oil and gas industry, including the efficient removal of sand and other solid particles from drilling fluid.

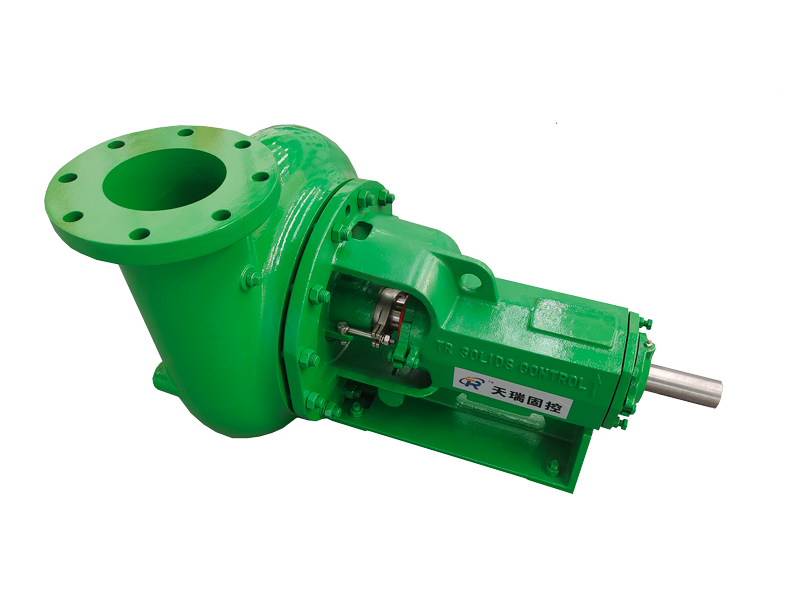

One of the company's flagship products is the Desander Liquid, a state-of-the-art system that effectively separates sand and other solid particles from drilling fluid. This innovative solution not only improves the performance of drilling operations but also reduces the environmental impact of drilling activities. By removing solid particles from drilling fluid, the Desander Liquid helps to minimize the amount of waste generated during drilling operations, leading to a more sustainable and environmentally friendly approach to oil and gas production.

The Desander Liquid is designed to be highly efficient and durable, capable of handling high volumes of drilling fluid while effectively removing solid particles. This results in improved drilling performance, reduced downtime, and lower maintenance costs for drilling equipment. In addition, the Desander Liquid helps to protect downstream equipment and processes by ensuring that the drilling fluid is free from sand and other solid particles.

One of the key features of the Desander Liquid is its ability to adapt to a wide range of drilling conditions. Whether drilling in shallow or deep waters, onshore or offshore, in arctic or tropical climates, the Desander Liquid can be customized to meet the specific requirements of each drilling operation. This adaptability makes it an ideal solution for oil and gas companies operating in diverse and challenging environments.

In addition to its innovative products, Desander Liquid also provides a range of services to support the oil and gas industry. Their team of experts offers consulting, training, and technical support to help companies optimize their drilling operations and minimize environmental impact. By working closely with their clients, Desander Liquid ensures that their solutions are tailored to meet the unique needs of each drilling operation.

Desander Liquid has built a strong reputation for delivering high-quality products and services that improve the efficiency, sustainability, and environmental performance of drilling operations. Their commitment to innovation, quality, and customer satisfaction has earned them the trust and loyalty of some of the world's leading oil and gas companies.

As the oil and gas industry continues to face increasing pressure to improve environmental performance and reduce costs, the innovative solutions offered by Desander Liquid are likely to play a crucial role in driving the industry forward. By providing efficient and sustainable solutions for separating sand and other solid particles from drilling fluid, Desander Liquid is helping to pave the way for a more sustainable and environmentally friendly future for the oil and gas industry.

Company News & Blog

How to Manage Waste for a Cleaner Environment

Waste management is an essential part of ensuring a clean and sustainable environment. Proper waste management not only helps in reducing pollution and environmental impact but also promotes a healthier and safer living environment for everyone.In recent years, the issue of waste management has gained significant attention as the world continues to face the challenge of managing increasing amounts of waste. With a growing population and urbanization, the amount of waste generated has also increased, putting pressure on existing waste management systems.This is where the [Company] comes in. [Company] is a leading waste management company with a strong commitment to sustainability and environmental responsibility. The company offers a wide range of waste management solutions, including collection, transportation, recycling, and disposal services. With a focus on innovation and efficiency, [Company] is dedicated to providing effective and sustainable waste management solutions to its customers.One of the key aspects of [Company]'s waste management services is its emphasis on recycling and sustainability. The company is dedicated to maximizing the recovery and recycling of waste materials to minimize the amount of waste sent to landfills. By promoting a circular economy through the reuse and recycling of materials, [Company] is contributing to the conservation of natural resources and the reduction of environmental impact.In addition to its commitment to recycling, [Company] also prioritizes the safe and responsible disposal of waste. The company's waste disposal facilities are designed to meet the highest environmental and safety standards, ensuring that waste is handled and disposed of in a way that minimizes harm to the environment.Furthermore, [Company] is also invested in exploring and implementing new technologies and solutions for waste management. The company understands the importance of innovation in addressing the challenges of waste management, and it continuously invests in research and development to improve its services and reduce its environmental footprint.One of the recent initiatives undertaken by [Company] is the implementation of advanced waste management technologies, such as waste-to-energy and biogas generation. These technologies not only aid in the efficient management of waste but also contribute to the generation of renewable energy, further supporting the transition towards a more sustainable and circular economy.In addition to its waste management services, [Company] also places a strong emphasis on community outreach and education. The company believes that raising awareness about waste management and sustainability is crucial in creating a positive impact on the environment. Through educational programs and community engagement, [Company] seeks to empower individuals and businesses to make more sustainable choices and actively participate in waste reduction and recycling efforts.With its commitment to sustainability, innovation, and community engagement, [Company] continues to play a crucial role in the advancement of waste management practices. The company's dedication to environmental responsibility and its efforts to promote a circular economy make it a key player in the waste management industry.As the demand for effective waste management solutions continues to grow, [Company] remains committed to providing sustainable and efficient waste management services. The company's focus on recycling, technological innovation, and community involvement sets it apart as a leader in the industry, and it continues to be at the forefront of driving positive change in waste management practices.In conclusion, effective waste management is essential for the health and well-being of our planet, and [Company] is dedicated to leading the way towards a more sustainable and eco-friendly future. Through its commitment to recycling, innovation, and community engagement, [Company] is making a significant impact in the waste management industry and contributing to the preservation of our environment for future generations.

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

Mastering the Art of Efficient Drilling with Advanced Drilling Machines

Title: Revolutionary Drilling Machine Revolutionizes the IndustryIntroduction:In a groundbreaking development, a leading company in the manufacturing sector has unveiled an innovative Drilling Machine that is set to transform drilling operations across industrial sectors worldwide. This cutting-edge technology is poised to minimize costs, increase efficiency, and enhance precision, placing the company at the forefront of the drilling industry.Body:1. Redefining the Drilling Industry:The newly introduced Drilling Machine marks a significant breakthrough in the industry, promising to revolutionize the way drilling operations are conducted. Built upon cutting-edge technology and the latest industry know-how, this innovative solution sets itself apart by offering unmatched drilling efficiency and precision.2. Enhanced Efficiency and Productivity:The advanced features of the Drilling Machine are designed to streamline operations and optimize productivity. Incorporating powerful motors and state-of-the-art control mechanisms, this machine can perform drilling tasks with unrivaled speed and accuracy. Additionally, its automated functions and intelligent control system minimize the need for manual intervention, ensuring seamless and efficient operations.3. Precision Engineering at its Best:Precision is paramount in drilling operations, and this Drilling Machine does not disappoint. Equipped with high-precision sensors and advanced guidance systems, it allows for drilling operations to be conducted with utmost accuracy. This not only reduces the risk of errors but also ensures consistent quality and reliability in creating holes of varying depths and diameters.4. Diverse Applications across Industries:With its versatility and adaptability, the Drilling Machine finds application across a range of industries. From construction and manufacturing to oil and gas exploration, this innovative solution caters to the diverse needs of different sectors, offering a comprehensive drilling solution that meets the highest industry standards.5. Cost-Effective and Sustainable:This state-of-the-art Drilling Machine not only improves efficiency but also promotes sustainability. It integrates energy-saving features that help reduce power consumption, making it an environmentally friendly choice for companies looking to lower their carbon footprint. Moreover, its durability and resilience ensure minimal maintenance costs and long-term operational effectiveness.6. Ensuring Workplace Safety:The design of the Drilling Machine prioritizes safety as a fundamental aspect. With built-in safety features such as emergency stop buttons, safety alarms, and automatic shut-off mechanisms, operators can carry out drilling tasks confidently and safely. This focus on workplace safety is essential to protect workers and prevent accidents in high-risk environments.7. Revolutionizing Drilling Operations:The implementation of this advanced Drilling Machine is set to revolutionize drilling operations in the industry. Companies within various sectors can look forward to substantial improvements in efficiency, cost-savings, and productivity. Additionally, the focus on precision and safety ensures that end-products meet or exceed the highest quality standards.Conclusion:The introduction of the innovative Drilling Machine is a testimony to the continual advancements in the manufacturing sector. By marrying cutting-edge technology with precision engineering, the company has successfully developed a game-changing solution that is set to redefine the drilling industry. With its unrivaled efficiency, precision, and focus on safety, this Drilling Machine promises to transform drilling operations across numerous industries, bolstering productivity and sustainability while reducing costs.

China Expands Shale Shaker and Drilling Rig Capabilities, Boosting Oil Extraction Efforts

China Drill Shale Shaker and Drilling Rig Manufacturing Company Strengthens Position in Global MarketChina's drill shale shaker and drilling rig manufacturing industry is steadily growing, with one prominent company leading the charge. Operating at the forefront of innovation, this company has successfully established itself as a key player in the global market. With a diverse range of products and a commitment to quality, they continue to pave the way for the future of drilling technology.Driven by a dedication to meeting the evolving needs of the industry, this Chinese company has adopted a customer-centric approach, focusing on delivering cutting-edge solutions tailored to their clients' specific requirements. By combining advanced technology with extensive research and development, they have been able to create industry-leading drilling equipment that excels in performance, reliability, and cost-effectiveness.The company's flagship product, the shale shaker, has become renowned for its superior efficiency in separating solids from drilling fluid, thus optimizing the drilling process. Utilizing a high-frequency vibration system, the shale shaker effectively removes unwanted debris, ensuring the smooth operation of drilling rigs in even the most challenging environments. With a strong emphasis on durability, this product showcases the company's commitment to quality, enabling customers to increase operational efficiency and reduce maintenance costs.In addition to shale shakers, the company also offers a wide range of drilling rigs that are designed to meet the diverse needs of the industry. These rigs are equipped with state-of-the-art hydraulic systems, advanced control panels, and user-friendly interfaces, allowing for precise control and ease of operation. Combined with their exceptional durability, these drilling rigs offer an unmatched level of performance, enabling operators to tackle demanding drilling projects with ease.Recognizing the importance of sustainability and environmental conservation, this Chinese company has also made significant strides in developing eco-friendly drilling solutions. By incorporating energy-efficient technologies and reducing emissions, they aim to minimize the environmental impact of drilling operations while ensuring optimal performance.A key contributing factor to the company's success lies in their comprehensive after-sales support system. With a global network of service centers, they offer timely assistance, technical advice, and spare parts supply, ensuring that customers receive prompt and reliable support throughout the lifespan of their equipment. This commitment to customer satisfaction has garnered them an excellent reputation and a loyal customer base, further solidifying their position in the industry.Having established a strong presence in the domestic market, the company has set its sights on expanding its reach globally. With an increasing demand for their products in various regions, they have successfully exported their drilling equipment to numerous countries, earning international acclaim for their quality and performance. By actively participating in international exhibitions and establishing partnerships with distributors worldwide, they continue to strengthen their position and gain recognition on a global scale.The success of China's drill shale shaker and drilling rig manufacturing industry is undoubtedly bolstered by this prominent Chinese company. With their commitment to innovation, customer satisfaction, and environmental responsibility, they are set to lead the way in the global market. As drilling technology continuously evolves, this company remains at the forefront, ensuring that they are continuously delivering cutting-edge solutions that exceed customer expectations.

High Quality Industrial Centrifuges - Everything You Need to Know

A leader in the field of separation technology, {company} has announced the launch of its latest innovation in the form of Decanter Centrifuges – a cutting-edge addition to its already impressive lineup of centrifugation solutions. With a strong focus on delivering efficient and reliable separation processes for various industries, {company} has once again proven its commitment to driving progress and pushing the boundaries of what is possible in the world of separation technology.Decanter Centrifuges are a vital component in the process of separating various liquids and solids from each other. They are commonly used in industries such as wastewater treatment, oil and gas, food and beverage, and chemical processes. The main function of a Decanter Centrifuge is to separate solid materials from liquids through the principles of sedimentation and centrifugal force. This makes them an essential tool in ensuring the efficient and cost-effective processing of a wide range of substances.The Decanter Centrifuges offered by {company} are equipped with state-of-the-art features that set them apart from other products in the market. One of the key advantages of {company}'s Decanter Centrifuges is their ability to handle a wide range of materials with varying viscosities, densities, and concentrations. This versatility makes them highly adaptable to the diverse needs of different industries, providing a robust solution for various separation challenges.In addition, {company}'s Decanter Centrifuges are designed to deliver optimal performance while minimizing energy consumption and operational costs. This is achieved through the integration of advanced control systems and precision engineering, which ensure that the centrifuges operate at peak efficiency at all times. As a result, businesses can expect to see a notable improvement in their bottom line as a direct result of implementing {company}'s Decanter Centrifuges into their operations.Furthermore, the Decanter Centrifuges offered by {company} are built to withstand the rigors of continuous operation in demanding industrial environments. This is made possible by the utilization of high-quality materials and components, as well as rigorous quality control measures that guarantee the reliability and durability of the centrifuges. As a result, businesses can have confidence in the longevity and performance of {company}'s Decanter Centrifuges, knowing that they are built to last.It is also worth noting that {company} offers comprehensive support and maintenance services for its Decanter Centrifuges, ensuring that customers can maximize the uptime and effectiveness of their equipment. This includes expert installation, training, and ongoing technical assistance, all of which are designed to help businesses get the most out of their investment in {company}'s cutting-edge separation technology.Overall, the introduction of Decanter Centrifuges to {company}'s product range represents a significant advancement in the field of separation technology. With their exceptional performance, efficiency, and reliability, these centrifuges are set to make a tangible impact on a wide range of industries, providing a powerful solution for the challenges associated with liquid-solid separation.For businesses looking to enhance their separation processes and improve their overall operational efficiency, {company}'s Decanter Centrifuges are a compelling choice that offers tangible benefits. With their proven track record of excellence and innovation, {company} has once again demonstrated its position as a leader in the field of separation technology, setting the standard for excellence in this critical area of industrial processing.

Essential Tips for Efficient Solids Control in Drilling Operations

Solids Control Drilling (SCD) is a leading provider of drilling fluid management and solids control equipment for the oil and gas industry. With a focus on innovation and customer satisfaction, SCD has become a trusted partner for companies looking to optimize their drilling operations.SCD's comprehensive range of products and services includes shale shakers, mud cleaners, centrifuges, and degassers, all designed to help companies manage drilling fluids and control solids effectively. In addition, SCD offers on-site technical support and training to ensure that its clients are able to maximize the performance of their equipment.The company's commitment to quality and reliability has made it a preferred choice for many of the world's leading oil and gas companies. SCD's equipment is known for its durability and efficiency, helping companies to minimize downtime and reduce operational costs.SCD's success can be attributed to its talented team of engineers and technicians, who are constantly developing new and improved solutions to meet the evolving needs of the industry. By staying ahead of the curve, SCD is able to offer cutting-edge technology that helps its clients to stay competitive in a challenging market.In addition to its world-class products, SCD prides itself on its exceptional customer service. The company works closely with its clients to understand their specific requirements and provide tailored solutions that deliver tangible results. SCD's dedication to customer satisfaction has earned it a reputation for reliability and trustworthiness.With a global presence, SCD is able to serve clients in various locations around the world. The company's extensive network of distributors and service centers ensures that its clients receive prompt and efficient support wherever they are located.Through its commitment to excellence and innovation, SCD continues to set the standard for solids control and drilling fluid management. The company's focus on quality, reliability, and customer satisfaction has firmly established it as a leader in the industry.In conclusion, SCD's dedication to providing cutting-edge technology, exceptional customer service, and reliable solutions has made it a trusted partner for companies in the oil and gas industry. As the industry continues to evolve, SCD remains committed to staying at the forefront of innovation and delivering superior value to its clients.

High Quality Shaker Screens for Improved Processing Efficiency

Shaker screens are an integral part of the oil and gas drilling process, helping to separate solids and fluids and ensure smooth and efficient operations. One company at the forefront of shaker screen technology is {}. They have been providing high-quality, reliable shaker screens to the oil and gas industry for many years, and their commitment to innovation and excellence has made them a trusted partner for drilling companies around the world.{} is known for their advanced shaker screen designs, which are carefully engineered to maximize efficiency and performance. Their screens are made from durable materials that can withstand the harsh conditions of drilling operations, and they undergo rigorous testing to ensure that they meet the highest standards of quality and reliability.One of the key advantages of using {} shaker screens is their ability to improve the overall efficiency of the drilling process. By effectively separating solids from fluids, their screens help to reduce waste and minimize downtime, ultimately leading to cost savings for drilling companies. In addition, {} screens are designed to be easy to install and maintain, further enhancing their value to their customers.Recently, {} introduced a new line of shaker screens that have been met with great enthusiasm from the industry. These screens feature advanced technology that allows for even greater efficiency and performance, and they have been carefully designed to meet the specific needs of today's drilling operations. With this new line of shaker screens, {} continues to demonstrate their commitment to innovation and their ability to stay ahead of the curve in the rapidly evolving oil and gas industry.In addition to their cutting-edge shaker screens, {} is also known for their exceptional customer service. They work closely with their clients to understand their unique needs and challenges, and they are dedicated to providing customized solutions that deliver real results. Whether it's recommending the right type of shaker screen for a particular drilling operation or providing technical support and assistance, {} goes above and beyond to ensure that their customers have the support they need to succeed.{}'s reputation for excellence in the shaker screen industry has made them a go-to choice for drilling companies looking for reliable, high-performance equipment. Their commitment to quality, innovation, and customer service sets them apart from their competitors, and they continue to be a driving force in the evolution of shaker screen technology.As the demand for oil and gas continues to grow, the need for efficient and reliable drilling equipment becomes increasingly important. With {}'s advanced shaker screens and dedication to excellence, they are well-positioned to meet the needs of the industry and continue to be a leader in the field. Their continued innovation and commitment to their customers make them a valuable partner for drilling companies around the world, and they are poised to make even greater contributions to the oil and gas industry in the years to come.

Top Tank Agitator Models and Uses in Industrial Processes

Today, we are excited to introduce a new tank agitator, designed and manufactured by our company. This innovative product is set to revolutionize the industry with its advanced technology and unparalleled efficiency. The tank agitator is an essential tool for mixing and blending various substances in industrial processes, and our new product is poised to set a new standard for performance and reliability.Our company has been a leading provider of industrial equipment and machinery for over 20 years. We have a strong reputation for delivering high-quality products and exceptional customer service. Our team of engineers and designers are constantly working to develop new and improved solutions to meet the evolving needs of our clients. With our state-of-the-art manufacturing facilities and cutting-edge technology, we are able to bring innovative products to the market that offer superior performance and value.The new tank agitator is a testament to our commitment to innovation and excellence. It is equipped with the latest in agitation technology, allowing for precise control and optimal mixing capabilities. The agitator is designed to handle a wide range of viscosities and densities, making it versatile enough for a variety of applications. Whether it's blending liquids, suspending solids, or promoting chemical reactions, our tank agitator delivers consistent and reliable results.One of the key features of our tank agitator is its robust construction and durability. We understand the demanding nature of industrial processes, and our product is built to withstand the toughest operating conditions. With quality materials and solid engineering, our tank agitator is built to last, minimizing downtime and maintenance costs for our customers.In addition to its performance capabilities, our tank agitator is also designed with user convenience in mind. It is easy to install, operate, and maintain, allowing for seamless integration into existing production systems. Our goal is to provide our customers with a hassle-free experience, and our tank agitator is a reflection of that commitment.Furthermore, our company provides comprehensive support and service for all of our products, including the new tank agitator. We offer technical assistance, maintenance, and repair services to ensure that our customers get the most out of their investment. Our team is dedicated to helping our clients achieve their production goals and maximize efficiency with our equipment.As we look to the future, we are confident that our new tank agitator will make a significant impact in the industry. Its advanced technology, reliability, and user-friendly design set it apart from the competition, and we are excited to see the positive results it will bring to our customers. We will continue to innovate and deliver cutting-edge solutions to meet the evolving needs of the industrial sector, and the tank agitator is just the beginning of what's to come.

High-Quality Drilling Rig Parts and Drawworks in China

China has long been a leader in the oil and gas industry, and their advancements in drilling rig technology have been at the forefront of this. With a commitment to innovation and quality, Chinese companies continue to provide essential parts and equipment for drilling operations around the world.One such company is {}, a leading provider of drilling rig parts and equipment. With a focus on research and development, they have become known for their high-quality products that meet the demands of the industry. From drill drawworks to drilling rig components, {} has established itself as a reliable supplier for companies looking to enhance their drilling operations.In recent years, the demand for drilling rig parts and equipment has continued to grow as the global energy market expands. This has led to increased competition among suppliers, but {} has been able to distinguish itself through its dedication to quality and customer service.One of the key products that {} offers is their drill drawworks. This essential component of a drilling rig is responsible for raising and lowering the drill string, making it a vital part of the overall operation. With a focus on durability and efficiency, {}'s drill drawworks have become a popular choice for companies looking to maximize their drilling capabilities.In addition to drill drawworks, {} also provides a wide range of other drilling rig parts, including mud pumps, top drives, and more. Their comprehensive selection of products makes them a one-stop shop for companies in need of reliable equipment for their drilling operations.One of the major advantages of working with {} is their commitment to customization. They understand that every drilling operation is unique, and they are able to tailor their products to fit the specific needs of their customers. This flexibility has made them a preferred supplier for drilling companies around the world.In addition to their product offerings, {} also provides comprehensive support and services for their customers. This includes technical assistance, maintenance and repair services, and training programs for operators. This commitment to customer satisfaction sets {} apart from other suppliers and has helped them build long-lasting relationships with their clients.With an eye towards the future, {} continues to invest in research and development to further enhance their products and services. They understand the importance of staying ahead of the curve in an ever-evolving industry, and they are dedicated to maintaining their position as a leading supplier of drilling rig parts and equipment.As the global demand for energy continues to rise, the importance of reliable drilling operations has never been greater. Companies like {} play a critical role in supporting these operations by providing high-quality parts and equipment that are essential for success. With their commitment to innovation and customer satisfaction, {} is well-positioned to continue leading the way in the drilling rig industry for years to come.

Maximizing Cost-Effectiveness for Horizontal Directional Drilling Projects: Considerations for Drilling Rigs and Mud Solids Control Systems

Title: Innovations in Horizontal Directional Drilling Rig and Mud Solids Control Systems in ChinaIntroduction:China is witnessing significant advancements in the field of horizontal directional drilling (HDD) rigs and mud solids control systems. With the joint venture between international companies like Vermeer and local manufacturers such as GN Desander Desilter and Drillto, China is becoming a leading player in the HDD market. This article will explore the latest innovations in HDD technology and the importance of balancing budget and quality for maximum effectiveness.Vermeer Navigator HDD Drilling Rig:The Vermeer Navigator series of HDD drills and units are known for their exceptional performance in the underground installation of utilities. These rigs are widely used for gas, electric, water, telecommunication, and soil remediation projects without the need for extensive excavation or trenching. Vermeer's technology ensures accurate and efficient drilling, making it an ideal choice for a wide range of HDD applications.Drillto HDD Machines:Established in 1999, Drillto Trenchless Co., Ltd. is a civilian-owned science-technology enterprise specializing in the research and development of no-dig technology. With Mr. Pengwang leading the team, Drillto has emerged as the fastest-growing HDD machine manufacturer globally. The company boasts a state-of-the-art manufacturing facility equipped with advanced machinery like EDM and CNC Lathe. Their expertise lies in manufacturing HDD rigs, drill pipes, and representing renowned brands in the field.Balancing Budget and Quality:While undertaking an HDD project, achieving the right balance between budget and quality is crucial. By opting for world-renowned manufacturers like Vermeer or their joint venture companies in China, project managers can ensure the use of high-quality drilling rigs. These rigs are designed to offer reliability, efficiency, and accuracy in underground installations, thereby reducing overall project costs.Furthermore, selecting a reliable mud solids control system is equally significant in HDD projects. GN solids control, a reputable supplier in the industry, is highly regarded for its efficient drilling mud processing solutions. Their HDD mud systems have gained recognition from clients worldwide and are being successfully deployed on various projects. By partnering with GN solids control, project managers can achieve optimal drilling performance while maintaining strict quality standards and cost-effectiveness.Conclusion:The horizontal directional drilling industry in China is witnessing remarkable growth with companies like Vermeer, GN Desander Desilter, and Drillto leading the way. With their innovative technologies and focus on quality, these companies are transforming the HDD landscape. Balancing budget and quality is a critical factor for the success of any HDD project. By choosing renowned drilling rig manufacturers and reliable mud solids control system suppliers like GN solids control, project managers can achieve maximum effectiveness while reducing costs.