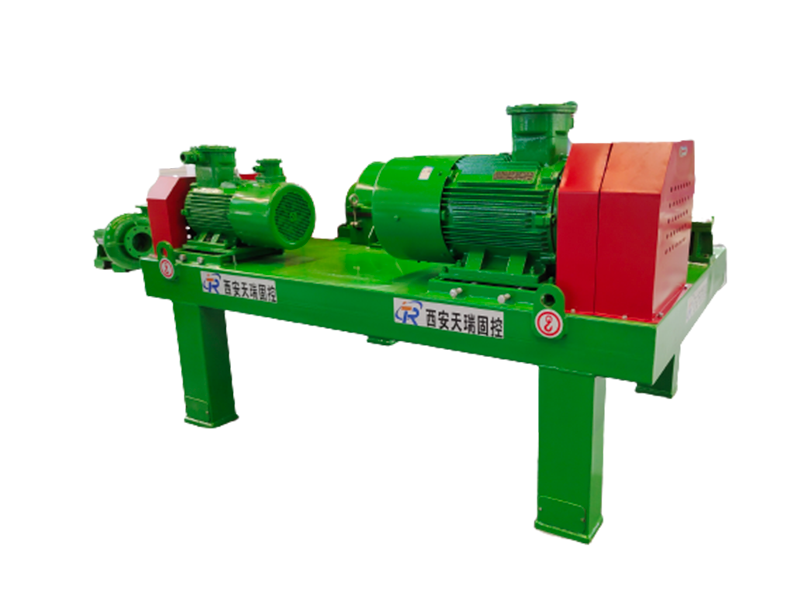

Effective Desanding Equipment for Industrial Use

By:Admin

Established in [year], the company has been a pioneer in providing high-quality equipment and services to the oil and gas sector. With a strong commitment to innovation and customer satisfaction, they have built a reputation for delivering reliable and efficient solutions to the industry's most challenging problems.

The desanding equipment, which is an essential component in oil and gas production, has garnered attention for its advanced features and superior performance. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that the equipment meets the highest industry standards.

One of the key features of the desanding equipment is its ability to effectively remove sand and other solid particles from wellstreams, preventing damage to downstream equipment and ensuring the efficient production of oil and gas. This not only results in cost savings for the operators but also minimizes downtime and maintenance requirements.

Moreover, the equipment is designed for easy installation and operation, making it a valuable asset for oil and gas producers. Its compact design and user-friendly interface enable seamless integration into existing production facilities, reducing the need for extensive modifications or additional equipment.

In addition to its outstanding performance, the desanding equipment is also known for its durability and low maintenance requirements. Built to withstand the harsh operating conditions of the oil and gas industry, the equipment is designed for long-term reliability and trouble-free operation.

Furthermore, the company's commitment to environmental sustainability is evident in the design and operation of the desanding equipment. By removing solid particles from wellstreams, the equipment helps minimize the environmental impact of oil and gas production, ensuring compliance with stringent regulatory requirements.

The company's team of experienced engineers and technical specialists provides comprehensive support and services for the desanding equipment, including installation, commissioning, and after-sales support. This ensures that customers receive the necessary assistance to maximize the performance and longevity of the equipment.

The desanding equipment has already gained traction in the market, with numerous operators choosing it for their oil and gas production facilities. Its proven track record of reliability and efficiency has made it a preferred choice for companies looking to enhance the performance of their operations.

Overall, the desanding equipment offered by [company name] is a testament to the company's commitment to innovation and excellence in the oil and gas industry. With its advanced technology, superior performance, and comprehensive support services, the equipment is poised to play a significant role in the optimization of oil and gas production worldwide.

As the demand for reliable and efficient equipment continues to grow in the oil and gas industry, [company name] remains at the forefront of providing cutting-edge solutions that meet the evolving needs of the industry. With its unparalleled expertise and dedication to customer satisfaction, the company is set to continue driving innovation and advancements in oil and gas production for years to come.

Company News & Blog

Solids Control: Techniques Used in a Drilling Rig to Separate Solids in Drilling Fluids

Title: Solids Control: An Essential Technique for Efficient Drilling OperationsIntroductionSolids control is a vital technique utilized in drilling rigs to effectively separate solids from drilling fluids. It plays a crucial role in maintaining the quality and performance of the drilling fluids, ensuring smooth drilling operations and maximizing well productivity. By utilizing a series of equipment, including the mud tank, shale shaker, vacuum degasser, desander, desilter, and centrifuge, solids control systems help to remove crushed solids generated by the drill bits, preventing them from contaminating the drilling fluids and ultimately reaching the well surface.The Importance of Solids Control in DrillingDuring the drilling process, the drill bits crush rocks and cuttings from the formation, producing a substantial amount of solid particles. If left unaddressed, these solids can significantly impact drilling operations by clogging the drill bit, causing damage to downhole equipment, increasing drilling costs, and reducing overall well productivity. Solids control systems efficiently remove these solids, enabling drilling fluids to maintain their desired properties, such as density, viscosity, and lubrication, throughout the drilling process.The Solids Control System Components1. Mud Tank: The mud tank serves as a primary holding and mixing compartment for the drilling fluids. It is designed to allow the settling of larger, coarser solid particles, allowing further separation in subsequent stages.2. Shale Shaker: The shale shaker is the first stage of the solids control system. It utilizes a vibrating screen to separate large solids with a diameter greater than 75 microns. The efficient removal of large solids helps reduce the load on downstream equipment and ensures the drilling fluids remain clean and free from obstruction.3. Vacuum Degasser: The vacuum degasser is primarily used to remove air or gas bubbles that may enter the drilling fluids during the drilling process. By eliminating these unwanted elements, the degasser helps maintain the stability and consistency of the drilling fluids.4. Desander: The desander is responsible for removing solids with a diameter ranging from 45 to 74 microns. By utilizing centrifugal forces in a hydrocyclone, the desander effectively separates the finer cuttings and solids before further processing.5. Desilter: The desilter, similar to the desander, operates through hydrocyclone technology. It specifically targets solids with a diameter between 15 and 44 microns, ensuring that even smaller particles are efficiently removed from the drilling fluids.6. Centrifuge: The centrifuge is the final stage in the solids control system. It utilizes high-speed rotation to further separate the fine solids remaining after the desilter stage. This process ensures ultra-fine solids, down to a few microns, are effectively eliminated before the drilling fluids return to the borehole.Achieving Efficiency and Clean Drilling FluidsBy integrating all the stages mentioned above, solids control systems significantly improve the overall efficiency and performance of drilling operations. These systems enable drilling companies to achieve higher rates of penetration, reduce the risk of equipment failure, and optimize drilling fluid properties. The removal of solids at various stages also helps extend the lifespan of the drilling fluids, reducing costs associated with its disposal and replacement.Furthermore, solids control systems play a pivotal role in upholding environmental standards by minimizing the discharge of solids into surrounding ecosystems. Proper solid control practices ensure that drilling operations conform to regulations, preventing environmental contamination and protecting fragile ecosystems.ConclusionSolids control is an indispensable technique in modern drilling operations that safeguards drilling fluid quality, equipment longevity, and overall well productivity. By effectively separating solid particles at various stages, the solids control system optimizes drilling efficiency, reduces costs, and maintains environmental compliance. As the exploration of natural resources expands, solids control continues to play a pivotal role in the development of sustainable drilling practices.

Understanding the Function of a Desilter: What You Need to Know

The desilter is a crucial component of a mud system that is used in the oil and gas industry. Its function is to remove the fine solids that are present in the drilling fluid, ensuring that the fluid is in the best possible condition for use in the drilling operation. This is achieved through a process of filtration, which separates the solids from the liquid and allows for the clean fluid to be reused in the drilling process.One company that specializes in the design and manufacture of desilters is {}. With over 20 years of experience in the industry, they have established themselves as a leading provider of high-quality equipment for mud systems. Their desilters are designed to efficiently remove solids from drilling fluid, allowing for the smooth and efficient operation of the drilling process.The desilters produced by {} are known for their reliability and durability, making them the go-to choice for many drilling operations around the world. The company takes pride in the quality of their products, ensuring that they are built to withstand the harsh conditions of the oil and gas industry. This commitment to quality has earned them a reputation as a trusted and dependable provider of desilter equipment.In addition to their high-quality products, {} also offers excellent customer service and support. Their team of experts is available to provide assistance and guidance to their clients, ensuring that they are able to make the most out of their desilter equipment. With a focus on customer satisfaction, the company has built strong and lasting relationships with their clients, becoming a preferred choice for many drilling operations.The desilter equipment offered by {} is designed to be efficient and cost-effective, helping to improve the overall performance of a mud system. By removing fine solids from the drilling fluid, the desilter helps to maintain the properties of the fluid, ensuring that it remains in the best possible condition for use in the drilling process. This not only leads to better drilling performance but also helps to reduce the overall cost of the operation.One of the key benefits of using {} desilters is their ability to improve the overall efficiency of a drilling operation. By removing solids from the drilling fluid, the desilter helps to reduce the risk of equipment damage and downtime, leading to a smoother and more productive drilling process. This can ultimately lead to cost savings and improved profitability for the operation.In conclusion, the desilter is an essential component of a mud system in the oil and gas industry, and {} has established itself as a leading provider of high-quality desilter equipment. With a focus on quality, reliability, and customer satisfaction, they have become a trusted choice for many drilling operations around the world. Their efficient and cost-effective desilters are designed to improve the overall performance of a mud system, leading to smoother and more productive drilling operations. With a commitment to excellence, {} continues to be a preferred provider of desilter equipment in the industry.

Quality Sand Investment Casting and Coated Sand Investment Castings in China

China Sand Investment Casting and Coated Sand Investment Castings have become increasingly popular in the manufacturing industry due to their superior quality and cost-effectiveness. With the rise of demand for precision-engineered components in various industries, the investment casting process has become an integral part of the production of high-quality and complex parts.Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating a wax pattern that is coated with a ceramic material. This pattern is then melted, leaving a hollow ceramic shell that is filled with molten metal to create the final part. This process allows for the production of parts with intricate shapes, thin walls, and fine details, making it a preferred method for the production of components in industries such as aerospace, automotive, and marine.China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise in the production of high-quality precision components. With state-of-the-art facilities and a highly skilled workforce, they are able to meet the most demanding requirements of their customers, providing cost-effective solutions for complex and critical components.The investment casting process offers numerous benefits, including the ability to produce parts with tight tolerances, excellent surface finish, and complex geometry. This makes it a preferred choice for manufacturers looking to produce high-performance components that meet stringent quality standards.China Sand Investment Casting and Coated Sand Investment Castings specialize in the production of a wide range of components, including turbine blades, impellers, and other complex parts used in the aerospace and automotive industries. Their expertise in producing components with high temperature and corrosion resistance makes them a trusted partner for manufacturers requiring precision-engineered parts for critical applications.In addition to traditional investment casting, China Sand Investment Casting and Coated Sand Investment Castings also offer coated sand investment casting, a process that involves coating sand with a refractory material to create a mold for casting. This process is particularly suitable for the production of large and heavy parts, offering cost-effective solutions for manufacturers looking to produce components with complex shapes and structures.The company's commitment to quality and innovation has made them a preferred choice for manufacturers looking for reliable and cost-effective investment casting solutions. With a strong focus on research and development, they continue to invest in new technologies and processes to ensure that they are at the forefront of the industry, offering their customers the best possible solutions for their production needs.With a global presence and a strong reputation for quality and reliability, China Sand Investment Casting and Coated Sand Investment Castings are well-positioned to meet the growing demand for precision-engineered components in various industries. Their commitment to excellence and customer satisfaction has made them a trusted partner for manufacturers worldwide, providing them with the high-quality components they need to stay competitive in today's market.In conclusion, China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise to meet the most demanding requirements of their customers. With a strong focus on quality, innovation, and customer satisfaction, they are well-positioned to continue their success and remain a preferred partner for manufacturers looking for cost-effective and reliable solutions for their production needs.

Powerful Cyclone Desander - Protect Your Equipment and Environment

Cyclone Desander, a leading company in the field of cyclonic separation technology, has once again proven its expertise in providing innovative and efficient solutions for the oil and gas industry. With a strong focus on quality and performance, Cyclone Desander has established itself as a reliable partner for companies looking to optimize their drilling operations and enhance overall productivity.Cyclone Desander's latest success comes in the form of a groundbreaking new desanding system that has been specifically designed to effectively remove sand and other solid particles from drilling fluids, thus improving operational efficiency and reducing equipment wear and tear. This innovative solution is set to revolutionize the way companies approach solids control, offering a more cost-effective and environmentally-friendly alternative to traditional methods.One of the key features of Cyclone Desander's new system is its advanced cyclonic separation technology, which enables the efficient removal of solid particles from drilling fluids using centrifugal force. This results in cleaner, more fluid drilling fluids that are better suited for use in the drilling process. By minimizing the presence of abrasive particles in the fluid, the system helps to prolong the lifespan of drilling equipment and reduce the risk of damage during operations.In addition to its superior performance, Cyclone Desander's desanding system also stands out for its compact design and ease of installation. The system can be seamlessly integrated into existing drilling setups, minimizing downtime and ensuring a smooth transition to the new technology. This level of flexibility and adaptability is a testament to Cyclone Desander's commitment to providing practical and user-friendly solutions that meet the evolving needs of the industry.Furthermore, Cyclone Desander places a strong emphasis on sustainability and environmental responsibility. By effectively managing solid waste and reducing the need for chemical additives in drilling fluids, the company's desanding system contributes to a more eco-friendly approach to drilling operations. This focus on sustainability aligns with the growing demand for greener practices within the oil and gas industry, positioning Cyclone Desander as a forward-thinking leader in the field.The success of Cyclone Desander's desanding system can also be attributed to the company's extensive expertise and commitment to research and development. The team at Cyclone Desander comprises highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation and continuously improving their product offerings. This culture of excellence and continuous improvement has enabled Cyclone Desander to stay ahead of the curve in an ever-evolving industry.Moreover, Cyclone Desander's dedication to customer satisfaction is evident in its comprehensive support and after-sales services. The company works closely with its clients to understand their specific needs and challenges, offering customized solutions that deliver tangible results. This collaborative approach has earned Cyclone Desander a reputation for reliability and trustworthiness, with a growing list of satisfied customers who have experienced the benefits of the company's cutting-edge solutions firsthand.Looking ahead, Cyclone Desander is poised to further strengthen its position as a leading provider of desanding and solids control solutions. With a focus on continuous innovation and a commitment to excellence, the company is well-equipped to meet the evolving demands of the oil and gas industry and support its clients in achieving optimal performance and efficiency.In conclusion, Cyclone Desander's latest desanding system represents a significant milestone in the company's ongoing efforts to deliver groundbreaking solutions for the oil and gas industry. With its advanced technology, practical design, and unwavering commitment to customer satisfaction, Cyclone Desander continues to set the standard for excellence in the field of cyclonic separation, solid control, and drilling fluid management. As the industry looks towards a more sustainable and efficient future, Cyclone Desander stands ready to lead the way with its innovative solutions and unwavering dedication to quality and performance.

Efficient Ways to Use Drilling Machines for Perfect Holes

Title: Cutting-Edge Drilling Technology Revolutionizes the IndustryIntroduction:In a groundbreaking development, a cutting-edge Drilling Machine is set to transform the drilling industry. Designed to increase efficiency and reduce operational costs, this state-of-the-art technology is poised to make a significant impact across multiple sectors. With its superior engineering and innovative features, this cutting-edge drilling machine is set to revolutionize drilling processes and deliver unprecedented results.1. Introduction to the Drilling Machine:The Drilling Machine is a highly advanced piece of equipment developed by a leading engineering company. Drawing upon years of experience and expertise in the field, the company has designed a machine that offers groundbreaking capabilities in drilling operations. This cutting-edge technology is designed to outperform existing drilling machinery, significantly improving productivity and efficiency in various industries.2. Enhanced Efficiency and Precision:The Drilling Machine incorporates advanced technologies and precision engineering to deliver unparalleled efficiency in drilling operations. Equipped with high-powered motors and intelligent controls, this machine ensures optimal drilling performance, irrespective of the terrain or materials involved. Its cutting-edge features allow for greater stability, increased drilling speed, and improved accuracy, resulting in reduced project timelines and enhanced productivity.3. Versatility and Adaptability:Designed to cater to a wide range of drilling requirements, this machine boasts impressive versatility and adaptability. It is capable of drilling through various surfaces, including concrete, rock, and metal, making it suitable for a diverse range of industries such as construction, mining, and oil exploration. Furthermore, the machine's modular design allows for the integration of different components and accessories, enhancing its adaptability to specialized drilling needs.4. Safety and Environmental Considerations:Committed to ensuring the safety of workers and environmental conservation, the Drilling Machine incorporates multiple safety features and eco-friendly mechanisms. The machine is equipped with innovative dust control systems to minimize airborne contaminants, protecting both the environment and the health of operators. Additionally, advanced safety features, including automatic shut-off mechanisms and real-time monitoring, ensure secure and accident-free drilling operations.5. Cost-Effectiveness and Operational Benefits:By optimizing drilling processes and streamlining operational workflows, the Drilling Machine offers exceptional cost-effectiveness. Its superior drilling efficiency reduces labor requirements, thereby minimizing overall project costs. The machine's adaptability to different drilling tasks also eliminates the need for multiple specialized machines, resulting in significant savings for businesses. Moreover, its powerful motor and advanced controls minimize downtime, maximizing operational efficiency and enhancing profitability.6. Longevity and Maintenance:Built to withstand rugged drilling conditions, the Drilling Machine boasts an exceptional lifespan. The machine's robust construction and high-quality components ensure prolonged durability, reducing the need for frequent repairs or replacements. Furthermore, the company's commitment to customer satisfaction extends to after-sales service, providing comprehensive maintenance and support to maximize the longevity and performance of the machine.Conclusion:The launch of the Drilling Machine marks a significant milestone in the drilling industry. With its cutting-edge technology, exceptional efficiency, and versatility, this machine promises to revolutionize drilling operations across multiple sectors. As businesses strive for increased productivity and cost-effectiveness, this innovative drilling solution will pave the way for accelerated growth and enhanced profitability. The Drilling Machine is a testament to human ingenuity and a harbinger of future advancements in the field of drilling technology.

Highly-Durable Mud Gun Nozzle Provides Effective Solutions for Industrial Operations

Mud Gun Nozzle, a vital component in the oil and gas industry, plays a crucial role in the drilling process. The mud gun nozzle is used to spray drilling mud, a mixture of water, clay, and other chemicals, into the drilling well to lubricate the drill bit, carry rock cuttings to the surface, and maintain pressure in the well. It is an essential tool for optimizing the drilling process and ensuring the success of oil and gas extraction operations.In this context, one company, which is a leading manufacturer of drilling equipment and tools, has recently launched its latest mud gun nozzle, designed to enhance drilling efficiency and reliability. With over 20 years of experience in the industry, the company has become a trusted name in providing high-quality products and innovative solutions for oil and gas exploration and production.The new mud gun nozzle features a cutting-edge design that offers improved performance and durability. Its advanced nozzle configuration allows for better spray coverage and distribution of drilling mud, resulting in more efficient drilling operations. The material used in the construction of the nozzle is highly resistant to corrosion and abrasion, ensuring long-lasting performance even in the harshest drilling environments.Furthermore, the company's mud gun nozzle is engineered to provide easy maintenance and servicing, reducing downtime and operational costs for drilling companies. The design incorporates quick-connect fittings and accessible components, allowing for effortless disassembly and reassembly when necessary. This user-friendly approach reflects the company's commitment to delivering practical and reliable solutions to its customers.In addition to the superior design and functionality, the mud gun nozzle is also backed by the company's renowned technical support and customer service. The company's team of experienced engineers and technicians are available to provide assistance with installation, maintenance, and troubleshooting, ensuring that customers can maximize the performance of the mud gun nozzle and their overall drilling operations.As part of its dedication to quality and customer satisfaction, the company conducts rigorous testing and quality assurance procedures to ensure that its mud gun nozzles meet the highest standards of performance and reliability. This attention to detail and commitment to excellence have earned the company the trust and loyalty of numerous drilling companies around the world.The launch of the new mud gun nozzle represents the company's ongoing efforts to innovate and improve its product offerings to meet the evolving needs of the oil and gas industry. By leveraging its expertise and technical capabilities, the company aims to continue playing a significant role in advancing drilling technologies and supporting the exploration and production activities of its customers.In conclusion, the introduction of the new mud gun nozzle by the company signifies a significant development in the realm of drilling equipment and tools for the oil and gas industry. With its advanced design, exceptional performance, and unwavering commitment to customer support, the company continues to solidify its position as a leading provider of reliable and innovative solutions for drilling operations. As the industry continues to evolve, the company remains poised to meet the challenges and demands of the future, driven by its dedication to excellence and customer satisfaction.

Discover the Power of a Single Stage Vacuum Dielectric Insulating Oil Purifier for Sale

Acoreoilfiltration oil purifier for sale introduces the new Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd, a leading manufacturer of oil purification equipment in China. This new machine is designed to purify and restore the quality of dielectric insulating oil used in high voltage electrical equipment.Dielectric insulating oil plays a vital role in the efficient and safe operation of high voltage electrical equipment such as transformers, circuit breakers, and capacitors. Over time, this oil can become contaminated with impurities such as water, dissolved gases, and particulate matter, reducing its dielectric strength and increasing the risk of equipment failure and power outages.To address this problem, Kongen Oil Purifier Co.,Ltd has developed the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine. This machine uses a combination of vacuum dehydration, degassing, and particulate filtration to remove contaminants from the oil and restore its dielectric strength and chemical stability. The machine can process up to 3000 liters of oil per hour and is suitable for use with mineral, synthetic, and silicone dielectric insulating oils.One of the key features of this machine is its advanced vacuum dehydration system, which removes water and moisture from the oil by exposing it to a vacuum. This process not only removes free and dissolved water but also removes water molecules that are chemically bound to the oil, resulting in a significantly lower moisture content and improved dielectric strength of the oil.The machine also features a high-efficiency degassing chamber, which uses a special vacuum system to remove dissolved gases such as oxygen, nitrogen, and carbon dioxide from the oil. This is important because dissolved gases can contribute to the formation of corrosive compounds and reduce the effectiveness of the oil as an insulator.In addition to oil purification, Kongen Oil Purifier Co.,Ltd also specializes in the production of Deaerator and Vacuum Deaerator equipment. These products are used in a variety of industries, including power generation, petrochemicals, and food processing, to remove excess dissolved gases from liquids and prevent corrosion and other issues.Kongen Oil Purifier Co.,Ltd has been providing high-quality purification and deaeration equipment to customers worldwide for over 20 years. The company is committed to providing innovative and reliable solutions to its customers, using the latest technology and equipment to meet their specific needs.In summary, the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd is a highly effective and efficient solution for purifying and restoring the quality of dielectric insulating oil used in high voltage electrical equipment. Combined with the company's expertise in deaeration technology, Kongen Oil Purifier Co.,Ltd is a trusted leader in the field of oil purification and treatment.

High-Quality Mud Pumps for Effective Drilling in China

The global market for mud pumps for drilling operations is witnessing a significant rise in demand, driven by the growing number of drilling activities globally. As one of the leading manufacturers and suppliers of mud pumps for drilling operations, {Company Name} is poised to capitalize on this increasing demand with its high-quality products.{Company Name} has earned a reputation for excellence within the industry, offering a wide range of mud pumps that are designed to meet the needs of drilling operations in various environments. The company excels in providing reliable and efficient solutions for both onshore and offshore drilling applications, making it a preferred choice for many drilling companies around the world.One of the key products offered by {Company Name} is its China Mud Pump, which has garnered attention for its superior performance and durability. The China Mud Pump is designed to withstand the harsh conditions typically encountered in drilling operations, making it a reliable and cost-effective choice for operators. With a strong focus on quality and reliability, {Company Name} has established itself as a trusted partner for companies seeking high-performance mud pumps for their drilling activities.In addition to the China Mud Pump, {Company Name} also offers a comprehensive range of mud pumps for drilling operations. These products are designed to meet the specific requirements of different drilling environments, providing operators with the flexibility to choose the right solution for their needs. With a commitment to innovation and continuous improvement, {Company Name} ensures that its mud pumps are equipped with the latest technologies to deliver optimal performance and reliability.The company's dedication to quality and customer satisfaction is reflected in its rigorous testing and certification processes. Each mud pump undergoes thorough testing to ensure compliance with industry standards and regulations, giving customers the assurance that they are investing in a reliable and safe product. With a strong focus on customer service, {Company Name} also offers comprehensive support and after-sales services to assist customers in maximizing the performance and lifespan of their mud pumps.As the global demand for energy continues to grow, the need for efficient and reliable drilling equipment has become increasingly important. {Company Name} recognizes the significance of its role in supporting the drilling industry, and is committed to developing innovative solutions that empower operators to achieve their objectives with confidence. By continually investing in research and development, the company aims to stay ahead of the curve in offering cutting-edge mud pumps that deliver superior performance and value.In conclusion, {Company Name} is well-positioned to meet the rising demand for mud pumps for drilling operations, with its high-quality products and commitment to customer satisfaction. With a strong track record of reliability and performance, the company is a trusted partner for drilling companies seeking reliable and efficient solutions for their operations. As the global drilling industry continues to evolve, {Company Name} remains dedicated to delivering innovative and dependable mud pumps that empower operators to achieve their goals safely and efficiently.

Efficient Mud Cleaning System for Improved Operations

Oil and gas drilling operations are a crucial part of the global energy industry. These operations involve the use of various equipment and systems to extract hydrocarbons from the earth. One such essential system is the Mud Cleaning System, which plays a vital role in ensuring the smooth and efficient drilling process.The Mud Cleaning System, also known as a mud recycling system, is designed to remove solids from drilling fluid or mud, while also maintaining the properties of the fluid to meet the required specifications for the drilling operation. This system is an integral part of the drilling process as it helps in controlling the density, viscosity, and pH balance of the drilling fluid, which ultimately aids in the extraction of oil and gas from the wellbore.One company that has been at the forefront of providing state-of-the-art Mud Cleaning Systems is {}. With years of experience and expertise in the oil and gas industry, they have been delivering high-quality and reliable mud recycling systems to drilling companies worldwide.The company's Mud Cleaning Systems are designed to effectively remove solids and other impurities from the drilling fluid, thereby ensuring that the fluid can be reused in the drilling process, reducing waste and overall operational costs. Their systems are equipped with advanced technologies such as shale shakers, hydrocyclones, degassers, and centrifuges, all working in unison to efficiently clean the drilling mud.Furthermore, the Mud Cleaning Systems offered by {} are customizable to meet the specific requirements of different drilling operations. Whether it's an onshore or offshore drilling project, their systems are designed to withstand harsh environmental conditions and provide reliable performance.In addition to providing standard mud recycling systems, the company also offers turnkey solutions that include installation, commissioning, and ongoing technical support. This ensures that their clients can seamlessly integrate the Mud Cleaning System into their drilling operations and maximize its benefits.With a strong emphasis on research and development, {} continues to innovate and improve its Mud Cleaning Systems to meet the evolving needs of the oil and gas industry. They are committed to developing systems that are not only efficient in solids control but also environmentally friendly, promoting sustainability in drilling operations.Furthermore, the company prioritizes safety and compliance with industry standards in all its products. Their Mud Cleaning Systems are designed and manufactured in accordance with international regulations, ensuring that they meet the highest quality and safety requirements.As a global leader in mud recycling technology, {} has established a strong reputation for delivering reliable and cost-effective solutions to the oil and gas industry. Their Mud Cleaning Systems have been deployed in diverse drilling operations, contributing to improved efficiency and operational excellence for their clients.In conclusion, the Mud Cleaning System plays a crucial role in the success of oil and gas drilling operations, and {} has been a trailblazer in providing advanced and reliable solutions in this domain. With their commitment to innovation, quality, and customer satisfaction, they continue to set the benchmark for mud recycling systems in the industry.

Top Drilling Fluid Equipment to Enhance Your Operations

Drilling Fluid Equipment (DFE) has been a leading provider of high-quality drilling fluid equipment and services for the oil and gas industry for over 20 years. With a commitment to innovation, reliability, and customer satisfaction, DFE has become a trusted partner for major drilling operations around the world.The company offers a wide range of drilling fluid equipment, including shale shakers, desanders, desilters, mud cleaners, centrifuges, and more. DFE's products are designed to effectively remove solid particles from drilling fluids, ensuring optimal drilling efficiency and safety. In addition to equipment sales, DFE also provides maintenance, repair, and technical support services to ensure that their clients' operations run smoothly.One of DFE's flagship products is their patented shale shaker, which is known for its exceptional performance in separating solids from drilling fluids. This innovative equipment is designed to withstand high temperatures and harsh operating conditions, making it ideal for both onshore and offshore drilling operations. With a wide range of screen options available, DFE's shale shaker can be tailored to meet the specific needs of each project.In addition to their high-quality equipment, DFE is also known for their commitment to environmental sustainability. The company has developed a range of environmentally friendly drilling fluid products that help reduce the environmental impact of drilling operations. By using biodegradable additives and recyclable materials, DFE is helping their clients minimize their carbon footprint while maintaining high drilling performance.With a global presence, DFE has established a strong reputation for excellence in the oil and gas industry. The company has successfully completed projects in various regions, including North America, South America, the Middle East, and Asia. DFE's team of experienced engineers and technicians are dedicated to delivering top-notch solutions to their clients, ensuring that their drilling operations are efficient, cost-effective, and environmentally responsible.As part of DFE's commitment to customer satisfaction, the company places a strong emphasis on research and development. By continuously investing in new technologies and product improvements, DFE ensures that their equipment meets the highest standards of performance and reliability. This dedication to innovation has enabled DFE to stay ahead of the competition and maintain its position as a leader in the drilling fluid equipment market.In recent news, DFE has announced the launch of a new line of advanced drilling fluid equipment, aimed at meeting the evolving needs of the oil and gas industry. The company's latest offerings include state-of-the-art desanders and desilters, designed to enhance drilling fluid performance and streamline the solids control process. With improved efficiency and durability, these new products are set to further solidify DFE's reputation as a trusted provider of drilling fluid solutions."We are excited to introduce our latest line of drilling fluid equipment, which represents the culmination of years of hard work and dedication to meeting the needs of our clients," said a spokesperson for DFE. "These new products are the result of our ongoing commitment to innovation and excellence, and we are confident that they will deliver significant value to our customers."With their proven track record of delivering high-quality products and services, DFE is well-positioned to continue serving as a key partner for the global oil and gas industry. As the demand for reliable drilling fluid equipment continues to grow, DFE remains committed to providing cutting-edge solutions that drive efficiency, safety, and environmental sustainability in drilling operations. As they look to the future, DFE is poised to maintain their leadership in the market and expand their reach to new regions and industry sectors.