Effective Mud Cleaning System for Efficient Drilling Operations

By:Admin

The company behind MCS is dedicated to delivering top-quality products and services to its clients. With a team of experienced professionals and industry experts, the company has established itself as a leader in the field of mud cleaning technology. It is committed to delivering innovative solutions that are tailored to the specific needs of its clients, and its commitment to excellence has earned it a solid reputation in the industry.

MCS is a game-changer for the oil and gas industry. By utilizing advanced technology and state-of-the-art equipment, MCS is able to provide a level of efficiency and effectiveness that is unprecedented in the industry. The system is designed to remove solid particles from drilling mud, ensuring that the mud is clean and free from contaminants. This not only improves the efficiency of the drilling process, but also ensures that the environment is protected from harmful pollutants.

Furthermore, MCS is committed to providing cost-effective solutions for its clients. The company understands the challenges that the oil and gas industry faces, and it is dedicated to delivering solutions that are not only effective, but also affordable. By utilizing innovative technology and cutting-edge equipment, MCS is able to deliver solutions that provide maximum value for its clients.

In addition to its cutting-edge technology, MCS is also dedicated to safety. The company takes the safety of its employees and clients seriously, and it has implemented strict safety protocols to ensure that its operations are conducted in a safe and responsible manner. Clients can have peace of mind knowing that MCS is committed to delivering solutions that are not only effective, but also safe for the environment and for the people involved in the drilling process.

MCS is leading the way in the oil and gas industry, and its commitment to excellence has earned it a solid reputation in the field of mud cleaning technology. The company is dedicated to delivering innovative solutions that are tailored to the specific needs of its clients, and its cutting-edge technology is setting new standards for efficiency and safety. With a team of experienced professionals and industry experts, MCS is poised to continue its success and lead the industry into a new era of excellence.

In conclusion, Mud Cleaning System is revolutionizing the oil and gas industry with its cutting-edge technology and commitment to excellence. The company is dedicated to providing cost-effective solutions that are tailored to the specific needs of its clients, and its commitment to safety and efficiency has earned it a solid reputation in the industry. As the industry continues to evolve, MCS is poised to lead the way with its innovative solutions and game-changing technology.

Company News & Blog

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

Exploring the Latest Innovations in Mud Pumps for Drilling in China

China Mud Pump and Mud Pump for Drilling: Revolutionizing the Drilling IndustryThe drilling industry has been evolving over the years, primarily due to the significant advancements in technology. The use of machinery in drilling operations has increased the efficiency and effectiveness of the process, allowing for more accurate and faster execution.One of the integral components of drilling machinery is the mud pump, which is responsible for the circulation of drilling fluid or mud in the borehole. With the advent of China Mud Pump and Mud Pump for Drilling, the industry is witnessing a transformation in its operations.China Mud PumpChina Mud Pump is a company that specializes in the production and distribution of mud pumps. Established in 2005, it is a subsidiary of Tianjin Dong Fang Xian Ke Petroleum Machinery Co., Ltd, a leader in the oil and gas equipment manufacturing industry.With over 15 years of experience, China Mud Pump has built a reputation for providing high-quality products and excellent customer service. The company has a team of experts who handle the production process, ensuring that every pump meets the required standards.China Mud Pumps are known for their durability, efficiency, and low maintenance costs. The pumps are manufactured using high-quality materials, and the company employs the latest technology in their production process to ensure that they meet the changing needs of the industry.Mud Pump for DrillingMud Pump for Drilling is a vital component of drilling machinery used in the oil and gas industry. It is responsible for the circulation of drilling fluid or mud in the borehole, which helps in cooling the drill bit, clearing debris, and maintaining the pressure of the well.Mud Pump for Drilling is designed to operate under high pressure and is subjected to intense wear and tear. Therefore, it is important to invest in a mud pump that is durable, efficient, and easy to maintain.China Mud Pump for Drilling is a product that satisfies all these requirements. It is designed to operate under high pressure, making it suitable for use in various drilling environments. The pump is also manufactured using high-quality materials that can withstand the rigors of drilling operations.Advantages of China Mud Pump and Mud Pump for DrillingThe use of China Mud Pump and Mud Pump for Drilling offers numerous advantages to the drilling industry. Some of these benefits include:1. Durability: The pumps are designed to withstand the intense wear and tear associated with drilling operations. They are manufactured using high-quality materials, ensuring that they can last for years without requiring significant maintenance.2. Efficiency: China Mud Pumps are designed to operate under high pressure, making them suitable for use in various drilling environments. The pumps are also equipped with features that improve their efficiency, such as high-speed triplex plungers and fluid end modules.3. Low maintenance costs: The pumps are easy to maintain, and their low-maintenance requirements translate to significant cost savings for drilling companies.4. Customization: China Mud Pump and Mud Pump for Drilling can be customized to meet the specific needs of drilling companies. The pumps can be designed to operate in different environments and to handle various drilling fluids.ConclusionThe drilling industry is undergoing a revolution, and the use of advanced technology is at the heart of this transformation. China Mud Pump and Mud Pump for Drilling are leading the way in this movement, providing high-quality, durable, and efficient mud pumps that are transforming the drilling operations.Investing in China Mud Pump and Mud Pump for Drilling offers numerous benefits to drilling companies, including lower maintenance costs, improved efficiency, and customization options. As the industry continues to evolve, it is clear that the use of China Mud Pump and Mud Pump for Drilling will be an integral component in the success of drilling operations worldwide.

Food Grade Air Operated Diaphragm Pump for Milk and Grease Transfers

Shanghai GL Environmental Technology Co., Ltd. has released a new product – the Food Grade Grease Milk Transfer Air Operated Diaphragm Pump. This new pump is specifically designed for the transfer of milk and other food-grade substances. With its easy-to-use air-operated design, this pump is a perfect addition to any food or beverage production facility.The Food Grade Grease Milk Transfer Air Operated Diaphragm Pump is made with high-quality materials to ensure that it meets the strictest safety and sanitation standards. The pump is constructed with food-grade stainless steel, which is not only durable but also non-toxic.Furthermore, the pump is designed to prevent contamination of the product it is transferring. It has a special diaphragm that separates the product from the pump's moving parts, which ensures that there is no chance of contamination.The pump also has a simple design that makes it easy to disassemble and clean. This is a critical feature that ensures the pump is always in its optimal condition for use. Additionally, this pump is easy to maintain, which is a significant advantage for facilities that have multiple pumps.The Food Grade Grease Milk Transfer Air Operated Diaphragm Pump is also very versatile. It can transfer a wide range of food and beverage products, including milk, juice, and other liquid foods. This versatility makes it an ideal choice for food and beverage production facilities of any size.The air-operated design of the pump is another incredible feature that makes it easy to use and maintain. The pump's motor is powered by compressed air instead of electricity, which ensures that the pump is safe and easy to use. The air-operated motor also reduces the risk of fire, making this pump an ideal choice for facilities with strict safety requirements.The Food Grade Grease Milk Transfer Air Operated Diaphragm Pump comes with different discharge and suction ports sizes, accommodating varying transfer quantities. The pump is an affordable investment for businesses that process food or beverage, ensuring that they always have an efficient, versatile, and easy-to-use pump.Shanghai GL Environmental Technology Co., Ltd.(removed brand name), the manufacturer behind this innovative pump, has vast experience and expertise in the production of food-grade pumps. The company has been in the business of developing pumps that meet the highest standards for many years. They have a reputation for producing high-quality pumps that are affordable and easy to maintain.In conclusion, the Food Grade Grease Milk Transfer Air Operated Diaphragm Pump is a game-changer for facilities that produce food and beverage products. Its unique features, including its air-operated design, versatility, and ease of use and maintenance, make it a must-have for any food and beverage production facility. Shanghai GL Environmental Technology Co., Ltd. has proved yet again that they are an industry leader in the development of food-grade pumps.

Innovative PWP Screen Technology Revolutionizes the Industry

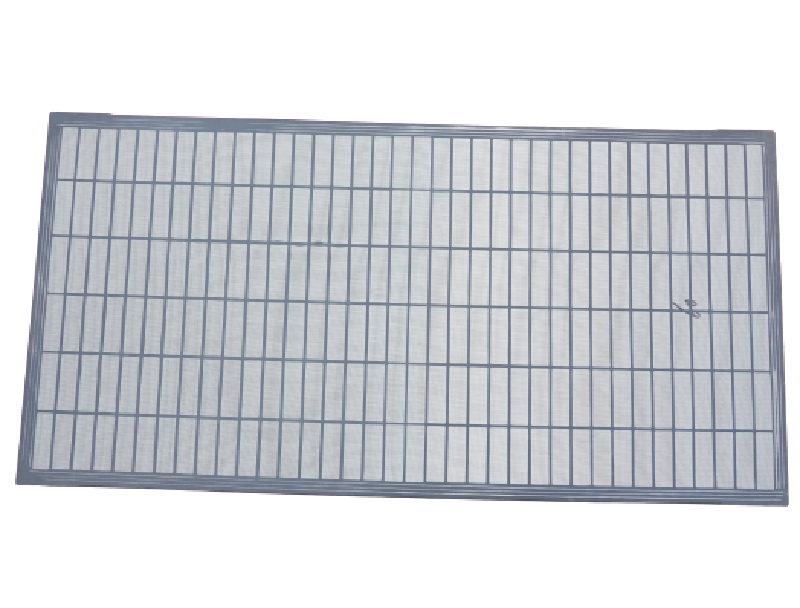

Hyperpool PWP Screen, a cutting-edge product in the field of oil and gas solids control, has been making waves in the industry with its innovative design and superior performance. Developed by a leading company in the oil and gas equipment manufacturing sector, this product is set to revolutionize the way drilling operations are conducted, providing a more efficient and cost-effective solution for managing drilling waste.The company behind Hyperpool PWP Screen is a renowned name in the industry, known for its commitment to quality and excellence. With years of experience and expertise in oil and gas equipment manufacturing, the company has established itself as a leader in providing innovative solutions for drilling operations. Its extensive portfolio of products and services includes a wide range of equipment designed to enhance the efficiency and effectiveness of drilling processes.Hyperpool PWP Screen is the latest addition to the company's product lineup, and it has already garnered significant attention for its impressive features and benefits. The screen is designed to effectively remove solids from drilling fluids, ensuring a clean and consistent flow that is essential for optimal drilling performance. Its high-quality construction and durable materials make it a reliable and long-lasting solution for solids control, reducing downtime and maintenance costs for drilling operations.One of the key features of Hyperpool PWP Screen is its advanced design, which is engineered to maximize the use of available screen area and prolong the service life of the screen. This ensures that the screen delivers superior performance over an extended period, offering a cost-effective solution for managing drilling waste. Its high flow rates and exceptional solids removal capability make it an ideal choice for demanding drilling applications, where efficient solids control is crucial for successful operations.In addition to its exceptional performance, Hyperpool PWP Screen also offers easy installation and maintenance, reducing the overall operational costs for drilling companies. Its user-friendly design and compatibility with a wide range of drilling equipment make it a versatile and practical solution for various drilling operations. Furthermore, the screen is designed to withstand the harsh conditions of drilling environments, ensuring reliable performance even in the most challenging situations.The company behind Hyperpool PWP Screen is committed to providing exceptional support and service to its customers, ensuring that they receive the highest level of satisfaction with their investment. With a global network of service centers and technical experts, the company is well-equipped to provide prompt assistance and maintenance for its products, further enhancing the overall value of Hyperpool PWP Screen for its customers.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, Hyperpool PWP Screen is well positioned to become a leading choice for drilling companies around the world. Its innovative design, exceptional performance, and reliable support make it a compelling solution for improving drilling operations and reducing operational costs.With its strong reputation and commitment to excellence, the company behind Hyperpool PWP Screen is set to further solidify its position as a leader in providing innovative and reliable solutions for the oil and gas industry. As it continues to expand its product offerings and enhance its capabilities, the company is poised to play a key role in shaping the future of drilling operations and solids control.

Mud Tanks on Drilling Rig: Understanding their Importance and Functionality

Title: Mud Tanks on Drilling Rig: Enhancing Efficiency and Environmental ResponsibilityIntroduction:As the demand for oil and gas continues to rise worldwide, drilling companies are constantly seeking innovative solutions to improve efficiency, reduce costs, and minimize their environmental impact. One crucial aspect of the drilling process is the effective management of drilling fluids, or mud. In this article, we will delve into the significance of mud tanks on drilling rigs, exploring how they contribute to fluid management and the operational success of drilling companies. We will also examine the role of a leading drilling equipment provider in delivering advanced mud tank solutions that prioritize efficiency, safety, and environmental responsibility.Efficient Fluid Management:Mud tanks play a pivotal role in the drilling process, providing a centralized location for the storage, circulation, and treatment of drilling mud. These large tanks are integrated into drilling rigs and are carefully designed to meet the specific operational requirements of each drilling project. By efficiently managing the drilling fluid, mud tanks ensure the integrity of the wellbore, lubricate the drilling bit, and carry cuttings to the surface, thereby enhancing the drilling process's overall efficiency.Safety and Environmental Considerations:With increasing environmental consciousness, drilling companies are under pressure to minimize their environmental footprint. Mud tanks aid in this endeavor by effectively separating the drilling mud from the drill cuttings, allowing for proper treatment and disposal of these byproducts. This system ensures compliance with environmental regulations and facilitates responsible waste management.In addition, mud tanks are equipped with advanced safety features to protect workers and prevent accidents. These features include sensors, alarms, and containment measures that detect and mitigate any potential leaks or spills, preserving the wellbeing of the crew and surrounding environment.The Role of [Drilling Equipment Provider]:[Drilling Equipment Provider], a global leader in drilling solutions, has been at the forefront of developing state-of-the-art mud tank systems. Committed to engineering excellence, they continuously improve their products to meet the evolving needs of the industry. By deploying their cutting-edge mud tank technologies, drilling companies can optimize their operations while adhering to stringent safety and environmental standards.[Drilling Equipment Provider] employs a holistic approach, beginning with comprehensive research and development, and continuing through the manufacturing, installation, and ongoing support phases. Their mud tank systems are designed to deliver high-performance capabilities, ensuring efficient separation of liquid and solids, better fluid control, and enhanced drilling mud treatment.Moreover, [Drilling Equipment Provider]'s mud tank solutions incorporate innovative automation and monitoring features that allow for real-time data analysis. This enables drilling companies to optimize their fluid management, detect any potential issues promptly, and make data-driven decisions to ensure continuous operations.Conclusion:Mud tanks constitute a critical element in the drilling process, playing a significant role in enhancing efficiency, safety, and environmental responsibility. By partnering with industry leaders like [Drilling Equipment Provider], drilling companies can gain access to cutting-edge mud tank systems that optimize fluid management and reinforce their commitment to sustainable practices. With the continuous development of advanced technologies, the integration of highly efficient mud tank systems is ushering in a new era of drilling operations that are both productive and environmentally conscious.

Effective Dust Removal Equipment and Collector Systems in China

China's Dust Removal Equipment and Dust Collector industry is experiencing significant growth and innovation, as companies in this sector are working tirelessly to develop advanced and efficient solutions to combat air pollution and improve environmental quality. One company that is at the forefront of this endeavor is {}. With a strong commitment to research and development, the company has been able to produce state-of-the-art dust removal equipment and dust collectors that are setting new industry standards.Founded in {}, {} has quickly established itself as a leading manufacturer and supplier of dust removal equipment and dust collectors in China. The company's mission is to provide reliable and efficient solutions for controlling air pollution, and it has invested heavily in technology and talent to achieve this goal. Through continuous innovation and improvement, {} has developed a comprehensive range of products that cater to a wide variety of industrial and commercial applications.One of the key factors that sets {} apart from its competitors is its commitment to quality and performance. The company's dust removal equipment and dust collectors are built to the highest standards, using premium materials and cutting-edge technology. This not only ensures the durability and reliability of the products but also guarantees their effectiveness in removing dust and other airborne pollutants from the environment.In addition to its dedication to quality, {} also places a strong emphasis on environmental sustainability. The company understands the importance of reducing air pollution and its impact on public health and the environment. As a result, {} designs its dust removal equipment and dust collectors with energy efficiency and environmental responsibility in mind. By minimizing energy consumption and emissions, these products not only provide effective dust control but also contribute to a cleaner and healthier planet.Furthermore, {} is committed to providing superior customer service and support. The company works closely with its clients to understand their specific needs and requirements, and then offers customized solutions that meet and exceed expectations. With a team of experienced engineers and technicians, {} also provides comprehensive technical assistance, maintenance, and training to ensure that its customers can maximize the performance and longevity of their dust removal equipment and dust collectors.One of the most notable achievements of {} is its continued investment in research and development. The company allocates a significant portion of its resources to advancing the technology and capabilities of its products. This commitment has enabled {} to introduce cutting-edge innovations that have redefined the industry's standards for dust control. As a result, the company's dust removal equipment and dust collectors are known for their efficiency, reliability, and adaptability to various operating conditions.Looking ahead, {} is poised to further expand its influence in the global market. With a proven track record of success and a strong reputation for delivering high-quality solutions, the company is well-positioned to capitalize on the growing demand for advanced dust removal equipment and dust collectors. As air pollution continues to be a pressing concern worldwide, {} is prepared to play a leading role in promoting cleaner and safer environments through its innovative and sustainable products.In conclusion, {} is a trailblazer in the dust removal equipment and dust collector industry, and its contributions to environmental protection and air quality improvement are commendable. With its unwavering commitment to excellence, innovation, and sustainability, {} is set to make a significant impact on the global stage, and the future looks promising for the company and its mission to create a cleaner and healthier world.

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

Top Shale Shaker and 55kw Shale Shaker in China - Latest Updates

China Shale Shaker Introduces New 55kw Shale Shaker for Enhanced EfficiencyChina Shale Shaker, a leading provider of drilling fluid management equipment, has recently introduced its new 55kw Shale Shaker to the market. This innovative product is designed to provide enhanced efficiency and performance in drilling operations.The new 55kw Shale Shaker is the latest addition to China Shale Shaker's extensive lineup of high-quality equipment for the oil and gas industry. With its powerful 55kw motor, this shale shaker is capable of handling large capacity and high flow rate drilling operations with ease. It is specifically designed to efficiently separate drilling cuttings and solids from drilling fluid, ensuring optimal performance and cost-effective waste management.China Shale Shaker has built a strong reputation in the industry for providing reliable and durable equipment that meets the highest standards of quality and performance. The company has a team of experienced engineers and technicians who are dedicated to developing cutting-edge solutions for the oil and gas sector. With a commitment to innovation and excellence, China Shale Shaker continues to lead the way in providing advanced equipment for drilling operations.The 55kw Shale Shaker is designed for easy installation and maintenance, making it a cost-effective solution for drilling companies. It is equipped with a user-friendly control system that allows for efficient operation and monitoring of the equipment. Additionally, the shale shaker is built with high-quality materials and components to ensure long-term durability and reliability in the field.China Shale Shaker understands the evolving needs of the oil and gas industry and is continuously working to develop products that address these challenges. The introduction of the 55kw Shale Shaker is a testament to the company's commitment to providing innovative solutions that improve efficiency and productivity in drilling operations. With this new addition to their product line, China Shale Shaker aims to set new standards for performance and reliability in the industry.In addition to the 55kw Shale Shaker, China Shale Shaker also offers a range of other drilling fluid management equipment, including shale shakers, mud cleaners, centrifuges, and degassers. These products are designed to work seamlessly together to provide comprehensive solutions for drilling operations. By offering a complete range of equipment, China Shale Shaker aims to be a one-stop solution provider for oil and gas companies looking to optimize their drilling processes.With a strong focus on customer satisfaction, China Shale Shaker provides comprehensive support and technical assistance to ensure that their equipment meets the specific needs of each client. The company's team of experts is available to provide guidance on equipment selection, installation, and ongoing maintenance to ensure optimal performance and longevity.As the demand for efficient and reliable drilling fluid management solutions continues to grow, China Shale Shaker remains committed to staying at the forefront of innovation in the industry. The introduction of the new 55kw Shale Shaker is a testament to the company's dedication to providing cutting-edge equipment that meets the evolving needs of the oil and gas sector. With a focus on quality, performance, and customer satisfaction, China Shale Shaker is poised to continue leading the way in providing industry-leading solutions for drilling operations.For more information about the 55kw Shale Shaker and other products offered by China Shale Shaker, please visit their website or contact their customer service team for personalized assistance.

Top Quality Screen Mesh and Screen for Various Industries in China

China Screen Mesh and Screen Company, known for its high-quality and durable screen products, has recently announced the launch of a new and improved screen mesh designed to meet the specific needs of various industries. The company, which has been a leader in the screen manufacturing industry for over a decade, has consistently provided innovative and reliable solutions to its customers, and the new mesh is a testament to its commitment to delivering top-notch products.The new screen mesh is constructed using advanced materials and technology, ensuring superior strength and durability. It is designed to withstand harsh environmental conditions, making it suitable for a wide range of applications, including mining, construction, agriculture, and pharmaceuticals. The mesh is available in various sizes and configurations, allowing for customization to meet the specific requirements of different industries.One of the key features of the new screen mesh is its high tensile strength, which enables it to effectively withstand heavy loads and abrasive materials. This makes it ideal for use in mining and construction, where the screens are often subjected to extreme wear and tear. The mesh also offers excellent resistance to corrosion, ensuring long-lasting performance in outdoor and industrial environments.In addition to its physical properties, the new screen mesh is also designed for easy installation and maintenance. Its modular design allows for quick and hassle-free replacement, reducing downtime and increasing productivity. The company has also developed a range of accessories and support systems to facilitate the installation and use of the mesh, further enhancing its overall usability.The launch of the new screen mesh is a result of China Screen Mesh and Screen Company's continuous research and development efforts. The company has a dedicated team of engineers and technicians who are constantly striving to improve and innovate its product offerings. By leveraging the latest technologies and materials, the company is able to stay ahead of the competition and provide cutting-edge solutions to its customers.The company's commitment to quality and customer satisfaction has earned it a strong reputation in the industry. Its products are trusted by businesses and organizations around the world, and the new screen mesh is expected to further solidify its position as a leading provider of screen solutions. With a focus on performance, reliability, and innovation, China Screen Mesh and Screen Company continues to set the bar for the industry.In addition to its product offerings, the company also provides comprehensive technical support and customer service. Its team of experts is available to assist customers with product selection, installation, and troubleshooting, ensuring a seamless experience from start to finish. This level of support has helped the company build long-lasting relationships with its clients and establish itself as a trusted partner in the industry.As China Screen Mesh and Screen Company continues to grow and expand its product line, it remains committed to upholding its core values of quality, innovation, and customer satisfaction. The launch of the new screen mesh is just one example of the company's dedication to providing top-of-the-line solutions to its clients. With its proven track record and forward-thinking approach, China Screen Mesh and Screen Company is poised to remain a driving force in the screen manufacturing industry for years to come.

Refilling Device and Water Supplying Device in China - Latest News

China Refilling Device and Water Supplying Device is a leading company in the field of water management and sustainability. With a focus on providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device has been at the forefront of developing cutting-edge technologies to address the world's growing water challenges.The company's mission is to provide efficient and sustainable water management solutions that can help address the global water crisis. With a strong commitment to research and development, China Refilling Device and Water Supplying Device has been instrumental in developing a range of products and technologies that help conserve and manage water resources effectively.One of the company's key products is the Refilling Device, which is designed to provide a convenient and efficient way for consumers to refill their water containers. This device is equipped with state-of-the-art technology that ensures accurate measurement and dispensing of water, eliminating wastage and promoting water conservation. The Refilling Device is user-friendly and can be easily installed in various locations, including public spaces, offices, and residential areas.In addition to the Refilling Device, China Refilling Device and Water Supplying Device also offers a Water Supplying Device that is designed to provide clean and safe drinking water to communities and businesses. This device uses advanced filtration and purification technologies to ensure that the water supplied meets the highest quality standards. By providing a reliable and sustainable source of drinking water, the Water Supplying Device plays a crucial role in improving public health and hygiene.The company's commitment to sustainability and environmental responsibility is evident in its emphasis on developing products and technologies that minimize water wastage and promote efficient water use. By providing innovative solutions for water management, China Refilling Device and Water Supplying Device is contributing to the global efforts to address water scarcity and ensure the availability of clean and safe water for future generations.China Refilling Device and Water Supplying Device's dedication to research and development has enabled it to stay ahead of the curve in the water management industry. The company continues to invest in cutting-edge technologies and partnerships with leading organizations to further its mission of promoting sustainable water management practices.In addition to its technological innovations, China Refilling Device and Water Supplying Device also places a strong emphasis on education and community engagement. The company regularly conducts outreach programs and workshops to raise awareness about water conservation and the importance of sustainable water management. By empowering individuals and communities with knowledge and resources, China Refilling Device and Water Supplying Device is helping to build a more water-resilient future.The impact of China Refilling Device and Water Supplying Device's work extends beyond its home country, as the company actively collaborates with international partners to share its expertise and technology with the global community. Through its participation in global forums and initiatives, China Refilling Device and Water Supplying Device is contributing to the development of sustainable water management practices on a global scale.As the world continues to face increasing water challenges, the work of companies like China Refilling Device and Water Supplying Device is more important than ever. By providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device is playing a crucial role in ensuring the sustainable use of water resources for generations to come.With its unwavering dedication to sustainability and technological innovation, China Refilling Device and Water Supplying Device is poised to make a significant impact on the global water management landscape. As the company continues to expand its reach and influence, it is likely to play a pivotal role in shaping the future of water management and sustainability worldwide.