Efficient Mud Mixing Hopper Utilizing Venturi Technology

By:Admin

In the realm of oil and gas drilling, efficiency and effectiveness are key components to success. This is where the Mud Mixing Hopper Venturi comes into play – a crucial tool in the process of creating a consistent and effective drilling mud. With the enhancement of this vital piece of equipment, drilling companies can expect improved drilling performance and efficiency.

The Mud Mixing Hopper Venturi, a product of a leading drilling equipment manufacturer, is designed to create a high level of suction that draws drilling mud into the mixing hopper and efficiently mixes it with other additives. This process ensures that the drilling mud is consistent and well-mixed, ultimately leading to a smoother and more efficient drilling operation.

The Venturi's recent enhancements have further improved its functionality and reliability. With upgraded materials and advanced engineering, the Venturi is now more durable and efficient than ever before. This means that drilling companies can rely on this important piece of equipment to perform at a high level, even in the most challenging drilling conditions.

One of the key advantages of the enhanced Mud Mixing Hopper Venturi is its ability to improve drilling efficiency. By ensuring that the drilling mud is well-mixed and consistent, the Venturi contributes to smoother drilling operations, reducing the risk of downtime and delays. This not only saves time and money for drilling companies but also enhances overall productivity.

Moreover, the enhanced Venturi is designed to be user-friendly, allowing for easy installation and maintenance. This means that drilling crews can quickly and efficiently set up the equipment and keep it in optimal working condition, further contributing to a streamlined drilling process.

The manufacturer of the Mud Mixing Hopper Venturi is a well-established company with a reputation for producing high-quality and reliable drilling equipment. With decades of experience in the industry, the company has a deep understanding of the needs and challenges faced by drilling companies. This insight has driven the development of innovative and practical solutions, such as the enhanced Mud Mixing Hopper Venturi, to address these needs and improve drilling operations.

In addition to the Mud Mixing Hopper Venturi, the company offers a wide range of other drilling equipment and solutions, including mud pumps, shale shakers, and centrifuges. This comprehensive product lineup allows drilling companies to rely on a single trusted source for all their equipment needs, ensuring consistency and reliability across their operations.

The company's commitment to quality and innovation is reflected in its stringent quality control processes and ongoing research and development efforts. This ensures that all products, including the Mud Mixing Hopper Venturi, meet the highest standards of performance and reliability, providing drilling companies with the confidence to tackle even the most challenging drilling projects.

With the enhanced Mud Mixing Hopper Venturi, drilling companies can expect improved drilling performance, efficiency, and reliability. This crucial piece of equipment, combined with the company's dedication to quality and innovation, represents a significant step forward in the quest for smoother and more efficient drilling operations.

In conclusion, the enhanced Mud Mixing Hopper Venturi is poised to make a meaningful impact on the drilling industry. Its improved functionality and reliability, combined with the company's commitment to quality and innovation, underscore its potential to enhance drilling operations and drive efficiency in the field. As drilling companies continue to seek ways to improve their performance, the Mud Mixing Hopper Venturi stands out as a valuable tool in their arsenal.

Company News & Blog

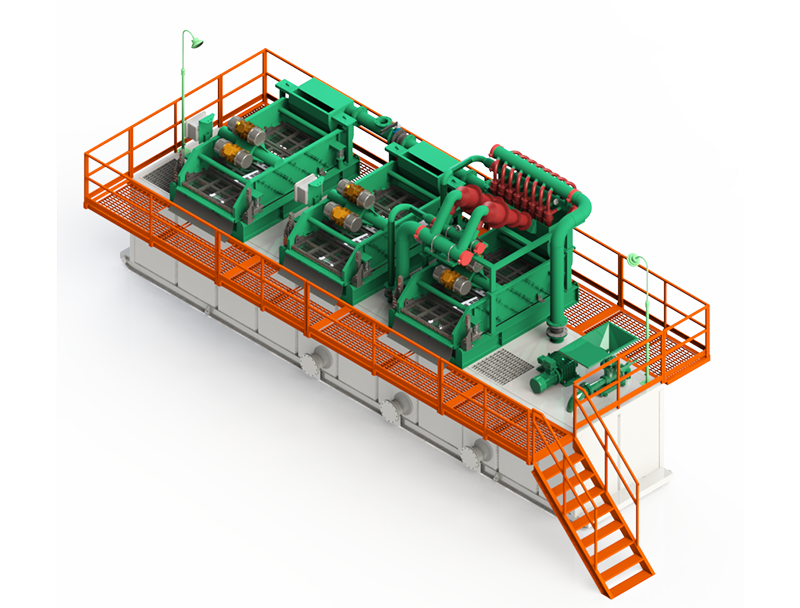

Innovative Mud Mixing System for Efficient Operations

Mud Mixing System Enhances Drilling Efficiency for [Company Name][City, State] - [Company Name] is proud to announce the integration of their state-of-the-art mud mixing system into their drilling operations. This innovative technology is designed to enhance drilling efficiency and productivity, allowing [Company Name] to deliver superior results for their clients in the oil and gas industry.The mud mixing system is a crucial component of the drilling process, as it is used to create the necessary drilling fluid that is essential for maintaining stability and lubrication during drilling operations. The system is capable of mixing a variety of additives and chemicals to create a customized drilling fluid that meets the specific requirements of each drilling project.By incorporating this advanced mud mixing system into their operations, [Company Name] is able to streamline their drilling processes and achieve greater precision and consistency in the creation of drilling fluid. This ultimately leads to improved drilling efficiency and performance, allowing the company to deliver exceptional results for their clients.In addition to enhancing drilling efficiency, the mud mixing system also offers environmental and cost-saving benefits. The system is designed to minimize the waste of drilling fluid additives, reducing the overall environmental impact of drilling operations. This not only aligns with [Company Name]'s commitment to sustainability, but also helps their clients minimize their environmental footprint.Furthermore, the system's precise mixing capabilities help to optimize the use of drilling fluid additives, leading to cost savings for both [Company Name] and their clients. This cost-effective approach to drilling operations allows [Company Name] to deliver value-driven solutions to their clients, while maintaining the highest standards of quality and performance.[Company Name] is recognized for their dedication to innovation and continuous improvement in the oil and gas industry. The integration of the mud mixing system is a testament to their commitment to investing in the latest technologies to enhance their capabilities and deliver superior results for their clients. This ensures that [Company Name] remains at the forefront of the industry, setting the standard for excellence in drilling operations.With the integration of the mud mixing system, [Company Name] is well-positioned to take on a wide range of drilling projects, from conventional to complex and challenging environments. The system's versatility and adaptability make it an ideal solution for addressing the diverse needs of their clients, while maintaining the highest levels of performance and efficiency.As [Company Name] continues to grow and expand their operations, the integration of the mud mixing system further solidifies their position as a leading provider of drilling services in the oil and gas industry. By leveraging the latest technologies and innovations, [Company Name] remains dedicated to delivering exceptional results and exceeding the expectations of their clients.The integration of the mud mixing system is a significant milestone for [Company Name], and it represents their ongoing commitment to driving progress and innovation in the oil and gas industry. With this advanced technology at their disposal, [Company Name] is poised to continue delivering superior drilling solutions that meet the evolving needs of their clients, while setting the standard for excellence in the industry.

Essential Software Solutions and Technology Advancements for Effective Exploration Decision-Making

Exploring for minerals and metals is a complex, costly and time-consuming process. However, technology advancements have significantly changed the exploration industry over the past decade by providing innovative solutions that enhance exploration efficiencies. From remote sensing to geophysical surveys, cutting-edge technologies have emerged to increase accuracy and reduce the risks associated with mineral exploration. One aspect of exploration that has benefited from advances in technology is drill cuttings management.Drill cuttings management is a critical aspect of any mining exploration program. It involves collecting and analyzing the rock fragments or cuttings produced during drilling operations. These cuttings can be analyzed to provide essential geological information such as the mineralogy, rock type, and structure of the underlying deposit. Information from drill cuttings is used by geologists and mining engineers to make informed decisions regarding the next drilling location, prioritize targets, and guide further exploration.In the past, the process of managing drill cuttings was time-consuming and human-intensive, which resulted in delays in decision-making and high exploration costs. Nowadays, however, due to advances in digital technologies, the process has become more efficient and cost-effective.One of the leading solutions to drill cuttings management is remote sensing, which relies on the use of unmanned aerial vehicles (UAVs) to capture high-resolution images of the drilled area. The images are then analyzed using machine learning algorithms, which can accurately identify and interpret geological features, automate data processing, and improve the accuracy of the exploration data.Another technology that has transformed drill cuttings management is the use of real-time data analytics. Instead of waiting for samples to be analyzed in a laboratory, real-time data analytics can provide information on the properties of the material being drilled. This technology has the potential to be a game-changer in the exploration industry, improving the efficiency of the exploration program by providing instant feedback to exploration teams while drilling is still in progress.The use of mobile apps is another technology that has revolutionized the management of drill cuttings. Exploration teams can use mobile apps to collect data, input geological information, and track drilling progress. The apps can also be used to upload and analyze the data, which provides an interactive platform for the exploration team to collaborate. The use of mobile apps promotes critical decision-making in real-time, thus reducing the risks associated with mineral exploration.In conclusion, the exploration industry has benefited greatly from technological advancements in drill cuttings management. The use of UAVs, real-time data analytics, mobile apps and machine learning algorithms offer a more efficient and cost-effective approach to exploration. As the exploration industry continues to evolve, it is expected that we will see further advances in drill cuttings management, which will continue to drive efficiencies in the exploration process.

A Guide to Vacuum Pumps and Diaphragm Pumps in China

China-based company, specializing in the production of vacuum pumps and diaphragm pumps, has recently announced the launch of their latest series of innovative and high-performance pumps. With a strong dedication to research and development, the company has established a reputation for delivering top-quality pumping solutions to a wide range of industries, including pharmaceutical, chemical, food and beverage, and more.The new series of vacuum pumps and diaphragm pumps are designed to meet the evolving needs of industrial applications, offering enhanced efficiency, reliability, and performance. These pumps are suitable for a variety of tasks, such as degassing, filtration, distillation, and solvent evaporation, making them an essential component of many production processes.The vacuum pumps are built with advanced technology to provide a high level of vacuum, ensuring optimal performance in the removal of gases and vapors from a sealed space. These pumps are able to operate at low noise levels and are equipped with a stable pumping speed, resulting in consistent and reliable performance. Additionally, the diaphragm pumps feature a robust design and are ideal for applications that require a pulsation-free flow and the ability to handle corrosive and aggressive gases and vapors.The company's commitment to quality and innovation is reflected in the rigorous testing and inspection processes that each pump undergoes before being released to the market. This dedication to quality control ensures that customers receive pumps that are not only technologically advanced, but also reliable and durable.In addition to the new series of pumps, the company also offers a comprehensive range of accessories and spare parts, as well as expert technical support and maintenance services. This holistic approach to customer service ensures that clients have access to everything they need to optimize the performance and longevity of their pumping systems.The company's success can be attributed to its strong emphasis on research and development. By continuously investing in cutting-edge technologies and exploring new materials and manufacturing processes, the company has been able to stay ahead of the curve in the pumping industry. Furthermore, the company's team of experienced engineers and technicians are passionate about pushing the boundaries of pump design and performance, resulting in products that are at the forefront of innovation.With a global presence, the company is well-positioned to provide pumping solutions to customers around the world. Whether it's a small-scale operation or a large industrial plant, the company has the expertise and resources to deliver tailor-made pumping systems that address the unique requirements of each client.As the demand for efficient and reliable pumping solutions continues to grow, the company remains dedicated to pushing the boundaries of pump technology. With a focus on innovation, quality, and customer satisfaction, the company is poised to maintain its position as a leading provider of vacuum pumps and diaphragm pumps in the global market.In conclusion, the latest series of vacuum pumps and diaphragm pumps from the China-based company offers a glimpse into the future of pumping technology. With a strong emphasis on innovation and quality, these pumps are set to deliver exceptional performance and reliability across a wide range of industrial applications. As the company continues to evolve and expand its product offerings, it is clear that they are poised to remain at the forefront of the pumping industry for years to come.

High-Quality Hydraulic Cylinder and Cylinder in China

China Hydraulic Cylinder and Cylinder (CHC), a leading hydraulic cylinder manufacturer in China, has recently announced their expansion into the global market. With a focus on providing high-quality hydraulic cylinders for various industrial applications, CHC has established a strong reputation for excellence in the field of hydraulic technology.Founded in 2005, CHC has quickly grown to become a key player in the hydraulic cylinder industry. Their state-of-the-art manufacturing facilities, advanced technology, and rigorous quality control processes have enabled them to produce a wide range of hydraulic cylinders that meet the highest standards of performance and durability. The company's commitment to innovation and customer satisfaction has set them apart from their competitors and has solidified their position as a trusted supplier in the global market.CHC's hydraulic cylinders are designed to meet the demands of various industries, including construction, agriculture, mining, and automotive. Their products are designed to withstand extreme conditions and provide reliable and efficient performance. Whether it's a standard hydraulic cylinder or a custom-designed solution, CHC's team of engineers and technicians are dedicated to delivering products that exceed customer expectations.The company's dedication to quality goes beyond their products - CHC also provides exceptional customer service and technical support. Their team of experts is readily available to assist customers with selecting the right hydraulic cylinder for their specific needs and to provide guidance on installation and maintenance. CHC's commitment to customer satisfaction has earned them a loyal and satisfied customer base.In addition to their focus on product quality and customer service, CHC is also dedicated to environmental sustainability. They adhere to strict environmental standards in their manufacturing processes and seek to minimize their carbon footprint. By implementing eco-friendly practices, CHC is contributing to a greener and more sustainable future.With their expansion into the global market, CHC aims to bring their superior hydraulic cylinders to customers around the world. Their products will be distributed through a network of authorized dealers and distributors, ensuring that customers have access to CHC's products and support wherever they are located. By expanding their reach, CHC is poised to further solidify their position as a leading global supplier of hydraulic cylinders.As CHC looks to the future, they are committed to continuous improvement and innovation. They are constantly exploring new technologies and materials to enhance the performance and reliability of their hydraulic cylinders. By staying at the forefront of hydraulic technology, CHC is positioned to meet the evolving needs of the global market and to continue to provide industry-leading solutions.In conclusion, China Hydraulic Cylinder and Cylinder (CHC) is a company that has earned a strong reputation in the hydraulic cylinder industry through their dedication to quality, customer service, and environmental sustainability. With their expansion into the global market, CHC is poised to bring their high-quality hydraulic cylinders to customers around the world, further solidifying their position as a trusted and reliable supplier. As they continue to innovate and improve, CHC is well-equipped to meet the evolving demands of the global market for hydraulic cylinders.

Essential Tips for Efficient Solids Control in Drilling Operations

Solids Control Drilling (SCD) is a leading provider of drilling fluid management and solids control equipment for the oil and gas industry. With a focus on innovation and customer satisfaction, SCD has become a trusted partner for companies looking to optimize their drilling operations.SCD's comprehensive range of products and services includes shale shakers, mud cleaners, centrifuges, and degassers, all designed to help companies manage drilling fluids and control solids effectively. In addition, SCD offers on-site technical support and training to ensure that its clients are able to maximize the performance of their equipment.The company's commitment to quality and reliability has made it a preferred choice for many of the world's leading oil and gas companies. SCD's equipment is known for its durability and efficiency, helping companies to minimize downtime and reduce operational costs.SCD's success can be attributed to its talented team of engineers and technicians, who are constantly developing new and improved solutions to meet the evolving needs of the industry. By staying ahead of the curve, SCD is able to offer cutting-edge technology that helps its clients to stay competitive in a challenging market.In addition to its world-class products, SCD prides itself on its exceptional customer service. The company works closely with its clients to understand their specific requirements and provide tailored solutions that deliver tangible results. SCD's dedication to customer satisfaction has earned it a reputation for reliability and trustworthiness.With a global presence, SCD is able to serve clients in various locations around the world. The company's extensive network of distributors and service centers ensures that its clients receive prompt and efficient support wherever they are located.Through its commitment to excellence and innovation, SCD continues to set the standard for solids control and drilling fluid management. The company's focus on quality, reliability, and customer satisfaction has firmly established it as a leader in the industry.In conclusion, SCD's dedication to providing cutting-edge technology, exceptional customer service, and reliable solutions has made it a trusted partner for companies in the oil and gas industry. As the industry continues to evolve, SCD remains committed to staying at the forefront of innovation and delivering superior value to its clients.

Essential Guide to Drilling Solids Control Equipment - Venturi Hopper

The oilfield industry is an essential sector in any economy, and ensuring that it remains productive and sustainable is critical to maintaining its ongoing success. One of the fundamental aspects of oilfield production is solid control, which is the process of managing the solids that are generated during drilling operations. These solids include drill cuttings, rock fragments, and debris, and it is imperative to remove them efficiently and effectively to preserve the drilling equipment and ensure that the drilling operations can continue smoothly.To achieve this, the oilfield industry relies on various equipment, one of which is the Venturi hopper, a part of the mud mixing pump. This can be made of either carbon steel or stainless steel and is designed to work in combination with the mud mixing pump. The Venturi hopper is an essential component of the oilfield solids control system and plays a critical role in ensuring the proper management of solids during drilling operations.The role of the Venturi hopper in the oilfield solids control system is to mix and agitate the drilling mud, thereby improving the overall efficiency of the mud mixing pump. The hopper works by drawing the drilling mud through a narrow throat, which produces a vacuum effect that causes an increase in the fluid velocity. This increase in velocity leads to the injection of air or dry powder into the mud stream, which results in a more effective mixing process.One of the key benefits of the Venturi hopper is its ability to handle a wide range of drilling fluids, including both low and high-density muds. This makes it an ideal solution for use in a variety of drilling applications, including oil and gas drilling operations, mining operations, and geothermal drilling operations.There are various types of Venturi hoppers available on the market, and each is designed to meet the specific needs of different drilling operations. For example, some hoppers are designed for use in high-pressure applications, while others are suitable for use in low-pressure applications. There are also hoppers available that are specifically designed to handle abrasive drilling fluids, which can cause significant wear and tear on other types of solids control equipment.In addition to its critical role in the solids control system, the Venturi hopper is also an essential component in the overall efficiency and sustainability of oilfield production. By ensuring that solids are effectively and efficiently removed from the drilling fluids, the hopper helps to preserve the drilling equipment, reducing the need for frequent maintenance and repair. This, in turn, helps to reduce the cost of operations and improve the overall profitability of the oilfield industry.Overall, the Venturi hopper is an essential component of the oilfield solids control system, providing a critical function in the proper management of solids during drilling operations. By working in combination with the mud mixing pump, the hopper improves the overall efficiency of the drilling process, reduces the need for costly maintenance and repair, and helps to ensure the ongoing sustainability and success of the oilfield industry. With its versatility and effectiveness, the Venturi hopper is a must-have for any drilling operation, playing a crucial role in the smooth and sustainable operation of the oilfield industry.

Centrifuges for Efficient Sludge Dewatering: The Ultimate Guide

Centrifuges for Sludge Dewatering: A Breakthrough in Waste ManagementIn recent years, the issue of sludge management has become a growing concern for various industries, municipalities, and environmental organizations. Sludge, which is a byproduct of wastewater treatment and industrial processes, poses a significant challenge for disposal and management due to its high moisture content and potential environmental hazards. However, with the advancement of technology and innovation in the field of waste management, new solutions have emerged to address this pressing issue. One such solution is the use of centrifuges for sludge dewatering, which has proven to be a game-changer in the industry.One company at the forefront of this breakthrough is {}. With years of experience in the design, manufacturing, and distribution of industrial separation and filtration equipment, {} has established itself as a leading provider of centrifuges for sludge dewatering. The company's commitment to innovation, efficiency, and environmental sustainability has led to the development of state-of-the-art centrifuge technology that effectively reduces the moisture content of sludge, making it easier and more cost-effective to handle and dispose of.The centrifuges manufactured by {} are designed to achieve maximum dewatering efficiency while minimizing energy consumption and operational costs. This is achieved through the use of advanced centrifuge designs, high-quality materials, and precision engineering. The result is a reliable and high-performance sludge dewatering solution that meets the evolving needs of various industries and organizations.One of the key advantages of {}'s centrifuges is their versatility and adaptability to different types of sludge. Whether it's municipal wastewater sludge, industrial byproducts, or other organic materials, the centrifuges are capable of effectively separating the solids from the liquid phase, resulting in a significant reduction in the volume and weight of the sludge. This not only makes it easier to transport and dispose of the sludge but also reduces the environmental impact and overall costs associated with sludge management.Furthermore, {}'s centrifuges are designed with user-friendly controls and automation features, ensuring ease of operation and maintenance. This not only enhances the overall efficiency of the dewatering process but also allows for seamless integration into existing waste management systems. Additionally, the company offers comprehensive technical support and training to ensure that customers can maximize the performance and lifespan of their centrifuges.In addition to the technological prowess of its centrifuges, {} is committed to sustainability and environmental responsibility. The company strives to minimize the environmental footprint of its products and operations, adhering to stringent quality and environmental management standards. This commitment is reflected in the energy-efficient design of the centrifuges, as well as the company's efforts to promote the recycling and reuse of dewatered sludge, further contributing to a more sustainable waste management approach.As a result of its dedication to excellence and innovation, {} has earned a reputation as a trusted partner for organizations in need of effective sludge dewatering solutions. With a global presence and a diverse customer base, the company has successfully implemented its centrifuge technology in a wide range of industries, including wastewater treatment plants, food processing facilities, chemical and petrochemical plants, and more.The use of centrifuges for sludge dewatering represents a significant step forward in the field of waste management, offering a viable and sustainable solution to the challenges posed by sludge disposal. With {}'s cutting-edge centrifuge technology, industries and municipalities can achieve greater efficiency, cost savings, and environmental compliance in their sludge management practices. As the demand for more effective and sustainable waste management solutions continues to grow, {} remains at the forefront, driving innovation and setting new standards for sludge dewatering technology.

High-efficiency Drilling Mud Solid Control System for China and Drilling Rig

China’s Drilling Mud Solid Control System and Solid Control System for Drilling Rig are at the forefront of cutting-edge technology in the oil and gas industry, providing innovative solutions for the management and treatment of drilling waste. With a proven track record of excellence, these systems have set a new standard for efficiency and environmental responsibility in the field of drilling operations.The Drilling Mud Solid Control System is designed to effectively remove solid particles from drilling fluids, ensuring the smooth and efficient progress of drilling operations. By utilizing high-performance equipment such as shale shakers, desanders, desilters, and decanting centrifuges, this system is able to separate and treat drilling waste with unparalleled precision and speed. The result is a significant reduction in waste disposal costs and environmental impact, as well as improved drilling fluid properties that enhance overall drilling efficiency.In addition to the Drilling Mud Solid Control System, the Solid Control System for Drilling Rig is a comprehensive solution that encompasses a wide range of equipment and processes for managing drilling waste on-site. Featuring advanced technologies such as mud cleaners, vacuum degassers, and centrifugal pumps, this system is capable of handling the full spectrum of drilling waste management needs, from initial solids removal to the recycling of drilling fluids. Its modular design and customizable configurations make it adaptable to a variety of drilling conditions and project requirements, ensuring maximum operational flexibility.Behind these industry-leading solutions is a company that has established itself as a premier provider of integrated drilling waste management systems. With a focus on research, development, and innovation, the company has consistently pushed the boundaries of what is possible in the field of solid control and waste management. Its team of experienced engineers and technicians are dedicated to delivering top-quality products and services that meet the evolving needs of the oil and gas industry.Moreover, the company’s commitment to environmental stewardship is evident in its emphasis on sustainable practices and the development of eco-friendly technologies. By prioritizing the efficient use of resources and the minimization of waste, the company is playing a proactive role in promoting responsible and sustainable drilling operations. This dedication to sustainability has earned the company recognition as a leader in the industry and a trusted partner for organizations seeking to enhance their environmental performance.In addition to its technical expertise, the company has also cultivated a reputation for exceptional customer service and support. Its global network of sales and service professionals ensures that customers receive prompt and reliable assistance, whether it’s for equipment installation, maintenance, or troubleshooting. This commitment to customer satisfaction has contributed to the company’s long-standing relationships with clients around the world, who rely on its expertise to optimize their drilling operations.Looking ahead, the company remains dedicated to advancing the state of the art in drilling waste management, as it continues to invest in research and development to bring new and improved solutions to market. By staying at the forefront of technological innovation and industry trends, the company is poised to lead the way in shaping the future of solid control and waste management in the oil and gas industry.As the demand for efficient and environmentally responsible drilling waste management solutions continues to grow, China’s Drilling Mud Solid Control System and Solid Control System for Drilling Rig are well-positioned to meet the evolving needs of the industry. With a proven track record of excellence, a commitment to sustainability, and a focus on customer satisfaction, the company is primed to remain a driving force in advancing the standards of drilling operations worldwide.

The Essential Function of Shale Shakers in Drilling Operations

The shale shaker is a vital piece of equipment used in the oil and gas industry for the extraction of hydrocarbons from deep within the earth. It is used to separate drilling cuttings from drilling fluid, also known as mud, in order to keep the fluid free of solids and maintain its proper consistency. This process is crucial in ensuring the efficiency and effectiveness of the drilling operation.One company that has been making significant contributions to the oil and gas industry through its high-quality shale shakers is {}. With years of experience and expertise in the field, {} has become a trusted name in providing top-notch equipment and solutions for the oil and gas sector.The shale shaker manufactured by {} is known for its exceptional performance, durability, and reliability. It is designed to effectively remove solid particles from drilling fluid, ensuring that the fluid is properly cleaned and can be reused in the drilling process. This results in cost savings and a more environmentally friendly drilling operation.The {} shale shaker also boasts a user-friendly design, making it easy to operate and maintain on the drilling site. Its robust construction and efficient performance make it a valuable asset for any drilling operation, whether it is onshore or offshore.In addition to its high-quality equipment, {} also offers excellent customer service and support. The company's team of experts is always ready to provide assistance and guidance to its clients, ensuring that the shale shaker operates at its optimum level at all times.Furthermore, {} is committed to innovation and continuous improvement. The company invests in research and development to enhance its products and develop new technologies that can further improve the efficiency and effectiveness of drilling operations.One of the key developments in the shale shaker technology is the incorporation of advanced vibration technology. By utilizing high-frequency vibrations, the shale shaker can effectively separate fine solids from the drilling fluid, ensuring that the fluid meets the required specifications for the drilling operation.Moreover, {} has also been focusing on the integration of automation and digitalization in its shale shaker systems. This allows for real-time monitoring and control of the equipment, leading to improved efficiency, reduced downtime, and enhanced safety on the drilling site.With its dedication to quality, innovation, and customer satisfaction, {} has established itself as a leading provider of shale shakers in the oil and gas industry. The company's commitment to excellence and its relentless pursuit of technological advancements have earned it a strong reputation among its clients and partners.In conclusion, the shale shaker plays a crucial role in the oil and gas industry, and {} has been at the forefront of providing high-quality equipment and innovative solutions in this field. With its proven track record and commitment to excellence, {} continues to be a trusted partner for companies involved in the exploration and extraction of oil and gas.

Understanding the Importance of Drilling Rig Mud Tank Systems

XYZ Drilling Rig Mud Tank System: A Reliable Solution for Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological innovations and advancements. One such innovation that has revolutionized the industry is the drilling rig mud tank system, which plays a crucial role in the drilling process. XYZ Corporation, a leading provider of drilling equipment and solutions, has developed a state-of-the-art mud tank system that has been widely acclaimed for its efficiency and reliability.XYZ Corporation is a global leader in providing drilling solutions to the oil and gas industry. With a strong focus on research and development, the company has been at the forefront of introducing cutting-edge technologies and systems that have helped in enhancing the efficiency and safety of drilling operations. The drilling rig mud tank system is one such example of the company's commitment to innovation and excellence.The mud tank system is an integral part of the drilling process, as it is responsible for the proper management and treatment of drilling fluids. This is crucial for maintaining the stability of the wellbore, controlling pressure, and carrying rock cuttings to the surface. The XYZ mud tank system is designed to effectively handle these tasks, ensuring that the drilling operations are conducted smoothly and efficiently.One of the key features of the XYZ mud tank system is its modular design, which allows for easy customization and adaptation to different drilling environments and requirements. The system can be easily configured to accommodate different volumes of drilling fluids, and its compact design enables it to be easily transported and installed at the drilling site. This flexibility and scalability make the XYZ mud tank system a preferred choice for drilling operators around the world.The mud tank system also incorporates advanced technologies for the treatment and recycling of drilling fluids, minimizing waste and reducing environmental impact. This is in line with XYZ Corporation's commitment to sustainable and eco-friendly drilling practices. The system is equipped with high-performance shakers, centrifuges, and other equipment for efficient solids control and waste management.In addition to its technical capabilities, the XYZ mud tank system is built to withstand the demanding conditions of drilling operations. It is constructed from high-quality materials and undergoes rigorous testing to ensure its durability and reliability. This ensures that the system can perform effectively in the challenging environments commonly encountered in the oil and gas industry.The XYZ mud tank system has gained widespread recognition for its performance and reliability. It has been deployed in numerous drilling projects around the world, where it has consistently delivered excellent results. The system has proven its ability to enhance drilling efficiency, reduce downtime, and minimize operational costs, making it a valuable asset for drilling operators.With its innovative design, advanced technologies, and proven performance, the XYZ mud tank system has set new standards for mud tank systems in the oil and gas industry. It has established itself as a reliable and efficient solution for the challenges faced in drilling operations, and has earned the trust of drilling operators globally.In conclusion, the XYZ drilling rig mud tank system is a testament to XYZ Corporation's commitment to excellence and innovation in the oil and gas industry. Its advanced design, robust construction, and superior performance make it a preferred choice for drilling operators seeking reliable and efficient solutions for their drilling operations. As the industry continues to evolve, the XYZ mud tank system is poised to play a pivotal role in shaping the future of drilling practices. With its proven track record and continuing advancements, XYZ Corporation remains at the forefront of providing cutting-edge solutions for the oil and gas industry's evolving needs.