Essential Tips for Efficient Solids Control in Drilling Operations

By:Admin

SCD's comprehensive range of products and services includes shale shakers, mud cleaners, centrifuges, and degassers, all designed to help companies manage drilling fluids and control solids effectively. In addition, SCD offers on-site technical support and training to ensure that its clients are able to maximize the performance of their equipment.

The company's commitment to quality and reliability has made it a preferred choice for many of the world's leading oil and gas companies. SCD's equipment is known for its durability and efficiency, helping companies to minimize downtime and reduce operational costs.

SCD's success can be attributed to its talented team of engineers and technicians, who are constantly developing new and improved solutions to meet the evolving needs of the industry. By staying ahead of the curve, SCD is able to offer cutting-edge technology that helps its clients to stay competitive in a challenging market.

In addition to its world-class products, SCD prides itself on its exceptional customer service. The company works closely with its clients to understand their specific requirements and provide tailored solutions that deliver tangible results. SCD's dedication to customer satisfaction has earned it a reputation for reliability and trustworthiness.

With a global presence, SCD is able to serve clients in various locations around the world. The company's extensive network of distributors and service centers ensures that its clients receive prompt and efficient support wherever they are located.

Through its commitment to excellence and innovation, SCD continues to set the standard for solids control and drilling fluid management. The company's focus on quality, reliability, and customer satisfaction has firmly established it as a leader in the industry.

In conclusion, SCD's dedication to providing cutting-edge technology, exceptional customer service, and reliable solutions has made it a trusted partner for companies in the oil and gas industry. As the industry continues to evolve, SCD remains committed to staying at the forefront of innovation and delivering superior value to its clients.

Company News & Blog

Top Drilling Fluid Equipment to Enhance Your Operations

Drilling Fluid Equipment (DFE) has been a leading provider of high-quality drilling fluid equipment and services for the oil and gas industry for over 20 years. With a commitment to innovation, reliability, and customer satisfaction, DFE has become a trusted partner for major drilling operations around the world.The company offers a wide range of drilling fluid equipment, including shale shakers, desanders, desilters, mud cleaners, centrifuges, and more. DFE's products are designed to effectively remove solid particles from drilling fluids, ensuring optimal drilling efficiency and safety. In addition to equipment sales, DFE also provides maintenance, repair, and technical support services to ensure that their clients' operations run smoothly.One of DFE's flagship products is their patented shale shaker, which is known for its exceptional performance in separating solids from drilling fluids. This innovative equipment is designed to withstand high temperatures and harsh operating conditions, making it ideal for both onshore and offshore drilling operations. With a wide range of screen options available, DFE's shale shaker can be tailored to meet the specific needs of each project.In addition to their high-quality equipment, DFE is also known for their commitment to environmental sustainability. The company has developed a range of environmentally friendly drilling fluid products that help reduce the environmental impact of drilling operations. By using biodegradable additives and recyclable materials, DFE is helping their clients minimize their carbon footprint while maintaining high drilling performance.With a global presence, DFE has established a strong reputation for excellence in the oil and gas industry. The company has successfully completed projects in various regions, including North America, South America, the Middle East, and Asia. DFE's team of experienced engineers and technicians are dedicated to delivering top-notch solutions to their clients, ensuring that their drilling operations are efficient, cost-effective, and environmentally responsible.As part of DFE's commitment to customer satisfaction, the company places a strong emphasis on research and development. By continuously investing in new technologies and product improvements, DFE ensures that their equipment meets the highest standards of performance and reliability. This dedication to innovation has enabled DFE to stay ahead of the competition and maintain its position as a leader in the drilling fluid equipment market.In recent news, DFE has announced the launch of a new line of advanced drilling fluid equipment, aimed at meeting the evolving needs of the oil and gas industry. The company's latest offerings include state-of-the-art desanders and desilters, designed to enhance drilling fluid performance and streamline the solids control process. With improved efficiency and durability, these new products are set to further solidify DFE's reputation as a trusted provider of drilling fluid solutions."We are excited to introduce our latest line of drilling fluid equipment, which represents the culmination of years of hard work and dedication to meeting the needs of our clients," said a spokesperson for DFE. "These new products are the result of our ongoing commitment to innovation and excellence, and we are confident that they will deliver significant value to our customers."With their proven track record of delivering high-quality products and services, DFE is well-positioned to continue serving as a key partner for the global oil and gas industry. As the demand for reliable drilling fluid equipment continues to grow, DFE remains committed to providing cutting-edge solutions that drive efficiency, safety, and environmental sustainability in drilling operations. As they look to the future, DFE is poised to maintain their leadership in the market and expand their reach to new regions and industry sectors.

Compact Mixing Tank for Efficient Blending

[Company Introduction]{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more.We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry. Our state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing us to produce top-of-the-line products that deliver superior performance and efficiency.[News Content]{City, Country} – {Date} – {Company Name} is pleased to announce the launch of the new Small Mixing Tank, further expanding our product line and offering our customers a versatile and efficient solution for their mixing needs.The Small Mixing Tank is designed to meet the demands of businesses that require a compact and portable mixing solution. With a capacity of {X} liters, this tank is perfect for small-scale production or research and development purposes. The tank is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion, making it suitable for a wide range of applications.One of the key features of the Small Mixing Tank is its integrated agitator system, which is designed to provide thorough and efficient mixing of various substances. The agitator is powered by a robust motor that delivers consistent and reliable performance, allowing for precise control of the mixing process. Additionally, the tank is equipped with a control panel that enables the operator to adjust the speed and mixing time according to the specific requirements of the application.The compact design of the Small Mixing Tank makes it easy to transport and install, providing flexibility to users who may need to move the equipment between different locations or integrate it into existing production setups. The tank is also equipped with safety features such as a secure lid and safety interlocks, ensuring the protection of the operator and the integrity of the mixing process.“We are thrilled to introduce the Small Mixing Tank to our product line, as it represents our commitment to providing innovative and practical solutions to our customers,” said {Spokesperson’s Name}, the {Job Title} of {Company Name}. “This tank is designed to meet the needs of businesses that require a small-scale mixing solution without compromising on performance and quality. We believe that it will be a valuable addition to our customers' operations, offering enhanced efficiency and productivity.”In addition to the Small Mixing Tank, {Company Name} offers a comprehensive range of mixing equipment and process solutions to suit the diverse needs of different industries. Our team of experts is dedicated to providing personalized support and guidance to our customers, helping them find the most suitable solution for their specific requirements.For more information about the Small Mixing Tank and other products offered by {Company Name}, please visit our website or contact our sales team directly.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more. We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry.

Importance of Mud Recycling Systems for Efficient Drilling Processes

GN Solids America Provides High-Quality Drilling Mud Recycling System with CE and ATEX StandardsThe drilling process is an essential part of oil and gas exploration, and the mud recycling system plays a vital role in maintaining the drilling mud properties at an optimal level. It removes the unnecessary large-sized solids and protects the drilling equipment from being damaged by large solids. GN Solids America is a leading provider of high-quality drilling mud recycling systems that meet Europe CE standard and ATEX explosion-proof standard.The mud recycling system consists of 2 centrifugal pumps, 2 mixing pumps, and 20 agitators. It acts as the heart and blood of the rig, making sure that all the components work together in perfect harmony. Without a reliable mud recycling system, the drilling process would be inefficient and expensive.GN Solids America is committed to providing its customers with the best quality solid control equipment at a competitive price. The shale shakers' G force can reach up to 8 G, making it possible to discharge drier solids that meet environmental requirements. Moreover, GN Solids America's new and upgraded shaker screen possesses better performance, longevity, and can store longer than ever before. During the drilling process, the shaker screens undergo significant wear and tear. Hence, GN Solids America's composite screen is the perfect solution, lasting longer than other screens.Customers from Europe and North America appreciate the quality of GN Solids America's products, and are buying them in increasing numbers. GN Solids America aims to provide its customers with the best quality products at an affordable cost."We are pleased to provide our customers with high-quality drilling mud recycling systems that meet CE and ATEX standards. We are committed to ensuring our customers' satisfaction by providing them with reliable and cost-effective products," said the spokesperson for GN Solids America.In conclusion, GN Solids America is a reliable provider of high-quality drilling mud recycling systems that meet international standards. Its products are top-notch and cost-effective, making them ideal for various applications in the oil and gas industry. GN Solids America's commitment to quality and customer satisfaction is what sets it apart from other solid control equipment providers in the market. Visit the website www.gnsolidsamerica.com. For more information, send your inquiries to [email protected].

Effective Drilling Mud Management Techniques for Oil and Gas Industry

As a global leader in the energy industry, {company} has been at the forefront of providing cutting-edge solutions for the oil and gas sector. The company has a strong track record of delivering innovative technologies and services to streamline operations and maximize efficiency.One of the key challenges in the oil and gas industry is the management of drilling mud. Drilling mud, also known as drilling fluid, is a critical component in the drilling process. It is used to lubricate the drill bit, carry cuttings to the surface, control wellbore pressure, and provide stability to the wellbore. However, the proper management of drilling mud is essential to ensure the success of drilling operations and minimize environmental impact.To address this challenge, {company} has developed a state-of-the-art Drilling Mud Management system that is designed to optimize the performance of drilling mud while minimizing waste and environmental impact. The system incorporates advanced technologies and best practices to effectively treat, recycle, and dispose of drilling mud, ensuring compliance with environmental regulations and industry standards.One of the key features of {company}'s Drilling Mud Management system is its ability to efficiently separate solids from the drilling mud, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner. This not only reduces waste and lowers operational costs, but also minimizes the environmental footprint of drilling operations.In addition, the system is equipped with advanced filtration and purification technologies to ensure that the recycled drilling mud meets the required specifications for reuse in drilling operations. This not only improves the efficiency of the drilling process but also reduces the need for fresh water, which is a precious resource in many drilling locations.Furthermore, {company}'s Drilling Mud Management system is designed to adapt to the specific requirements of each drilling operation, providing a customized solution that is tailored to the unique challenges and objectives of each project. This ensures that the system can effectively address the complexities of different drilling environments and well conditions, while maximizing the performance and efficiency of drilling mud.Moreover, {company} also offers comprehensive support and services to accompany its Drilling Mud Management system, including engineering expertise, technical assistance, and training programs. This ensures that customers have access to the necessary knowledge and resources to fully leverage the capabilities of the system and achieve optimal results.By implementing {company}'s Drilling Mud Management system, oil and gas companies can benefit from improved operational efficiency, reduced environmental impact, and enhanced regulatory compliance. This not only contributes to the sustainability and responsible stewardship of natural resources but also enhances the overall profitability and competitiveness of drilling operations.It is clear that {company} remains committed to delivering innovative solutions that address the evolving needs of the energy industry. Through its Drilling Mud Management system, the company is empowering oil and gas companies to achieve greater efficiency, minimize waste, and uphold the highest standards of environmental stewardship. With its advanced technologies, industry expertise, and global presence, {company} is poised to continue leading the way in shaping the future of the energy sector.

High-performance Shale Shaker for Oil and Gas Industry

Mongoose Pro Shale Shaker Sets the Standard for Efficiency and Reliability in Shale Shaker TechnologyThe demand for shale shaker technology has been steadily rising in the oil and gas industry, and companies are consistently looking for the most efficient and reliable equipment to meet their needs. This is where the Mongoose Pro Shale Shaker comes in, setting the standard for efficiency and reliability in shale shaker technology.The Mongoose Pro Shale Shaker is a product of innovation and expertise, developed by a leading company in the oil and gas industry. With a commitment to providing top-of-the-line equipment, this company has a proven track record of delivering high-quality products that are designed to meet the demands of the ever-evolving industry.This particular shale shaker is built to withstand the harshest drilling conditions, making it the perfect choice for companies looking to maximize their drilling operations. With its advanced design and cutting-edge technology, the Mongoose Pro Shale Shaker is able to effectively separate solids from drilling fluid, resulting in improved efficiency and reduced operating costs.One of the key features of the Mongoose Pro Shale Shaker is its adjustable G-force, allowing for optimal performance in various drilling conditions. This, in combination with its high-capacity composite screen panels, ensures that the shaker is able to handle a wide range of drilling fluids and produce consistently high-quality results.In addition to its impressive performance capabilities, the Mongoose Pro Shale Shaker is also built with ease of use in mind. Its user-friendly interface and simple maintenance requirements make it an ideal choice for companies looking to streamline their operations and maximize productivity.The Mongoose Pro Shale Shaker is also designed with durability in mind, with rugged construction and high-quality materials that are built to last. This ensures that companies can rely on this equipment to perform consistently, even in the most challenging drilling environments.Furthermore, the Mongoose Pro Shale Shaker is backed by a team of experts who are dedicated to providing top-notch service and support to ensure that customers get the most out of their investment. This level of support is a testament to the company's commitment to customer satisfaction and its dedication to delivering reliable equipment that meets the needs of the industry.Overall, the Mongoose Pro Shale Shaker is a game-changer in the world of shale shaker technology, offering unmatched efficiency, reliability, and performance. With its advanced design, user-friendly interface, and durable construction, it is the ideal choice for companies looking to maximize their drilling operations and achieve optimal results.As the demand for shale shaker technology continues to grow, the Mongoose Pro Shale Shaker stands out as a leader in the industry, providing companies with the equipment they need to stay ahead of the curve. With its proven track record of delivering high-quality products and exceptional customer support, this company is setting the standard for excellence in shale shaker technology.

Powerful Fluid Agitator for Efficient Mixing and Agitation

Fluid agitators play a crucial role in many industries, including chemical, pharmaceutical, food and beverage, and water treatment. These devices are used to mix or agitate fluids in order to achieve a desired consistency, temperature, or chemical reaction. One leading company in the fluid agitator industry, [Company Name], has been making waves in the market with their innovative and high-quality products. With a strong focus on research and development, [Company Name] has established itself as a go-to provider for fluid agitation solutions. The company’s flagship product, the [Product Name] fluid agitator, has garnered widespread acclaim for its superior performance and durability. This state-of-the-art agitator is designed to meet the rigorous demands of modern industrial processes, offering efficient mixing, reliable operation, and easy maintenance. In addition to their impressive product line, [Company Name] also prides itself on providing exceptional customer service and support. Their team of technical experts is always available to assist clients with installation, troubleshooting, and any other inquiries. This commitment to customer satisfaction has helped [Company Name] build strong and long-lasting relationships with their clientele.One of the key factors that sets [Company Name] apart from its competitors is their dedication to sustainability and environmental responsibility. The company utilizes advanced technologies and materials that minimize energy consumption and waste, ensuring that their products have a minimal impact on the environment. By prioritizing eco-friendly practices, [Company Name] has become a preferred choice for businesses looking to reduce their carbon footprint.Furthermore, [Company Name] has recently launched a new line of fluid agitators that are specifically designed for the pharmaceutical and biotech industries. These agitators adhere to the strict regulatory standards of these sectors, providing reliable and precise mixing for sensitive and critical processes. With these innovative solutions, [Company Name] is poised to further expand its presence in these rapidly growing markets.In an effort to stay at the forefront of technological advancements, [Company Name] continues to invest in research and development. Their team of engineers and scientists are constantly exploring new innovations and improvements to enhance the performance and efficiency of their fluid agitators. By staying ahead of the curve, [Company Name] ensures that their products remain competitive and relevant in an ever-evolving industry.Looking ahead, [Company Name] is committed to further strengthening its position as a leader in the fluid agitator market. With a focus on innovation, quality, and customer satisfaction, the company is poised for continued success and growth. As industries continue to evolve and demand increases for efficient fluid mixing solutions, [Company Name] is well-prepared to meet these challenges and exceed the expectations of their clients.In conclusion, the importance of fluid agitators in various industries cannot be overstated, and [Company Name] has proven itself to be a reliable and innovative provider in this sector. With a strong emphasis on quality, sustainability, and customer service, [Company Name] continues to set the standard for fluid agitation solutions. As they continue to expand their product offerings and strive for excellence, it is clear that [Company Name] is poised for a bright future in the global marketplace.

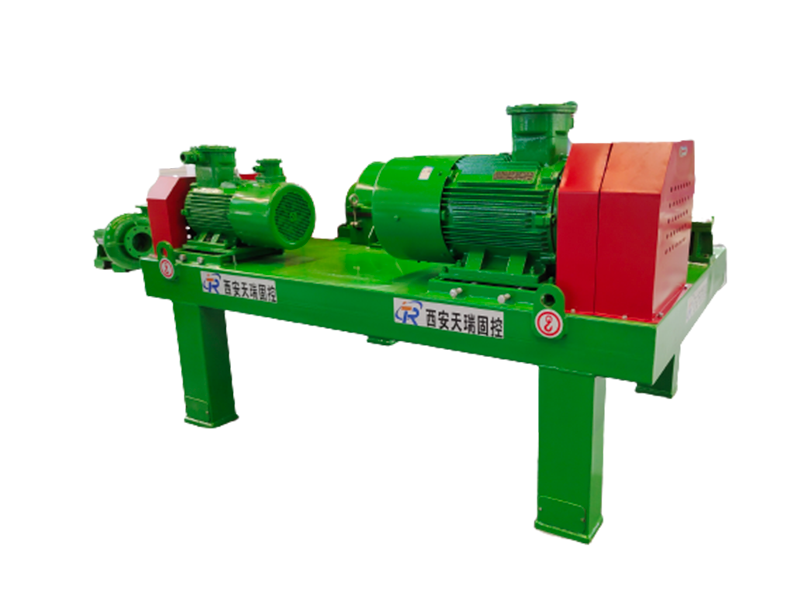

Highly Efficient Mud Mixing Pump for Industrial Use

Mud Mixing Pump: A Game-Changer in the Drilling IndustryIn today’s fast-paced and competitive drilling industry, efficiency and reliability are crucial for success. One company that has been making waves in this field is [company name], a leading manufacturer of drilling equipment and machinery. Their innovative Mud Mixing Pump has proven to be a game-changer in the industry, providing unmatched performance and productivity for drilling operations around the world.The Mud Mixing Pump, developed and manufactured by [company name], is a state-of-the-art piece of equipment designed to streamline the process of mixing drilling mud. Drilling mud, also known as drilling fluid, is a critical component in the drilling process, serving multiple functions such as cooling and lubricating the drill bit, carrying drill cuttings to the surface, and preventing blowouts. Proper mixing and circulation of drilling mud are essential for the success and safety of any drilling operation.With the Mud Mixing Pump, [company name] has revolutionized the way drilling mud is mixed and circulated. The pump is equipped with advanced technology and features that set it apart from traditional mixing pumps. Its high-pressure and high-volume capabilities allow for rapid and efficient mixing of drilling mud, saving valuable time and resources for drilling companies. Additionally, the pump is built to withstand the rigors of the drilling environment, with durable construction and components that ensure long-term reliability and performance.One of the key advantages of the Mud Mixing Pump is its versatility. It is compatible with a wide range of drilling mud formulations and can be easily adapted to different drilling conditions and requirements. This flexibility makes it an ideal choice for drilling operations in various industries, including oil and gas exploration, geothermal drilling, mining, and construction.[company name] takes great pride in the quality and performance of its Mud Mixing Pump, standing behind its product with a commitment to excellence and customer satisfaction. The company’s dedicated team of engineers and technicians continuously strive to improve and enhance the pump’s design and functionality, ensuring that it meets the evolving needs of the drilling industry.With a strong focus on innovation and technology, [company name] has established itself as a trusted leader in the drilling equipment market. The company’s reputation for delivering top-of-the-line products, backed by superior customer service and support, has earned the trust and loyalty of drilling companies and contractors worldwide.In addition to the Mud Mixing Pump, [company name] offers a comprehensive range of drilling equipment and machinery, including drill rigs, mud pumps, shale shakers, and accessories. The company’s extensive product line caters to the diverse needs of the drilling industry, providing solutions for both onshore and offshore drilling operations.As the demand for efficient and reliable drilling equipment continues to grow, [company name] remains at the forefront of the industry, driving innovation and setting new standards for performance and quality. With its unwavering commitment to excellence and its focus on customer satisfaction, the company is well-positioned to meet the evolving needs of the global drilling market.In conclusion, the Mud Mixing Pump from [company name] is a testament to the company’s dedication to innovation and quality in the drilling industry. Its advanced features and exceptional performance make it a valuable asset for drilling operations, offering unmatched efficiency and reliability. As drilling companies continue to seek solutions that improve productivity and safety, [company name] remains a trusted partner in meeting those needs, delivering cutting-edge equipment and support that drive success in the field.

New Urethane Panel Screen: A Versatile and Durable Option for Screens

Urethane Panel Screen - The Future of Industrial Separation TechnologyIn the world of industrial separation technology, the use of Urethane Panel Screens has revolutionized the process of screening and separating materials. These screens are designed to provide high performance and efficiency, making them an essential component in a wide range of industries including mining, aggregate, recycling, and more.One of the leading companies in the production of Urethane Panel Screens is {} (Company name). With their state-of-the-art manufacturing facilities and innovative technology, they have been at the forefront of providing high-quality screening solutions for their customers around the globe.The Urethane Panel Screen, which is produced by {}, is known for its durability and longevity. Made from high-quality polyurethane material, these screens are designed to withstand the most demanding applications, ensuring continuous operation and minimal downtime for their customers. This durability is especially important in industries such as mining and aggregate, where the screening process can be harsh and abrasive.In addition to their durability, Urethane Panel Screens from {} are also known for their superior screening performance. Their unique design and construction allow for efficient screening of various materials, ensuring that the desired product specifications are met with precision and accuracy. This results in higher productivity and reduced operating costs for their customers, making these screens a valuable asset in their operations.Another key advantage of {}'s Urethane Panel Screens is their versatility. These screens can be custom-designed to meet specific requirements for different applications, ensuring that they are suitable for a wide range of materials and operating conditions. Whether it is for fine screening, scalping, or dewatering, customers can rely on {} to provide them with the right screening solution for their needs.Furthermore, {}'s commitment to innovation and continuous improvement has led to the development of advanced technologies for their Urethane Panel Screens. With a dedicated team of engineers and researchers, the company is constantly exploring new ways to enhance the performance and durability of their screens, ensuring that they remain at the forefront of industrial separation technology.In addition to their focus on product innovation, {} also places a strong emphasis on customer service and support. They work closely with their customers to understand their specific needs and challenges, providing them with tailored solutions that deliver the best results. This customer-centric approach has earned {} a strong reputation for excellence and reliability in the industry.With a global network of distributors and service centers, {} is able to provide timely and efficient support to their customers, ensuring that they have access to the products and resources they need, wherever they are located. This level of commitment and support has allowed {} to build enduring relationships with their customers, establishing them as a trusted partner in the industry.Looking ahead, the demand for Urethane Panel Screens is expected to continue growing as industries strive for greater efficiency and productivity in their operations. As a leading manufacturer in this field, {} is well-positioned to meet this demand with their advanced screening solutions and unwavering dedication to customer satisfaction.In conclusion, the Urethane Panel Screen from {} represents the future of industrial separation technology, offering unparalleled durability, performance, and versatility for a wide range of applications. With a strong focus on innovation and customer-centricity, {} is set to lead the way in shaping the future of screening technology and delivering value to their customers worldwide.

Effective Mud Gas Separator Design for Oil and Gas Drilling Operations

Mud Gas Separator Design: Enhancing Safety and Efficiency in Oil and Gas OperationsThe oil and gas industry plays a crucial role in meeting the world's energy needs. However, the extraction and processing of these valuable resources come with significant risks and challenges, one of which is the management of hazardous gases such as methane, carbon dioxide, and hydrogen sulfide. To address this issue, companies have been continuously innovating and investing in advanced equipment and technologies, one of which is the mud gas separator (MGS).In recent news, {Company} has unveiled its latest design for the MGS, which promises to enhance safety and efficiency in oil and gas operations. The MGS is a vital piece of equipment used to separate and vent gases from drilling mud, thus preventing the buildup of potentially hazardous gases in the drilling fluid system. With {Company}'s new and improved MGS design, operators can expect enhanced performance and reliability, ultimately contributing to a safer working environment and more streamlined drilling operations.{Company}, a leading provider of oilfield equipment and services, has established itself as a trusted partner for oil and gas companies worldwide. With a strong focus on innovation and engineering excellence, {Company} has been at the forefront of developing cutting-edge solutions to address the industry's most pressing challenges. The company's expertise in the design and manufacturing of oilfield equipment, including MGS, is backed by years of experience and a commitment to delivering high-quality products that meet the evolving needs of its customers.The new MGS design from {Company} incorporates several key features that set it apart from traditional separators. Firstly, the design includes an advanced gas venting system that ensures efficient and reliable separation of gases from the drilling mud. This helps mitigate the risk of gas kicks, a sudden influx of gas into the wellbore that can lead to potential well control issues. Additionally, the MGS is equipped with a durable and corrosion-resistant construction, making it suitable for the harsh and demanding conditions of oil and gas drilling operations.Moreover, the new design also focuses on ease of maintenance and service, with features that allow for quick and hassle-free inspection and cleaning. This is crucial in ensuring the continued performance of the MGS and minimizing downtime during drilling operations. Furthermore, the design is optimized for space efficiency, making it suitable for both onshore and offshore drilling rigs where space is a premium.Incorporating state-of-the-art technology and engineering expertise, {Company} has engineered a MGS that not only meets industry standards but exceeds them. The company's commitment to quality and innovation is reflected in its new MGS design, which offers a compelling solution for oil and gas operators looking to enhance safety and efficiency in their drilling operations.The introduction of this new MGS design comes at a pivotal time for the oil and gas industry, as companies continue to prioritize safety and environmental stewardship. By investing in advanced equipment such as the MGS, operators can effectively manage the risks associated with gas handling during drilling operations while also improving overall efficiency and productivity.At the core of {Company}'s business is a dedication to delivering superior value to its customers. The company's new MGS design exemplifies this commitment, offering a comprehensive solution that addresses the critical challenges of gas management in drilling operations. With safety and efficiency being top priorities for the industry, {Company}'s MGS design is poised to make a significant impact on the way oil and gas companies approach gas separation and handling.In conclusion, the unveiling of {Company}'s new MGS design is a testament to the company's leadership in providing innovative and high-performance equipment for the oil and gas industry. As the industry continues to evolve, companies like {Company} are playing a pivotal role in driving progress and enabling safer, more efficient operations. With its latest MGS design, {Company} has once again demonstrated its ability to deliver cutting-edge solutions that meet the evolving needs of the oil and gas sector.

The Ultimate Guide to Dewatering Centrifuges: What You Need to Know

Dewatering Centrifuge Revolutionizes Waste Management in Industrial ApplicationsIn the ever-evolving world of industrial waste management, the introduction of the innovative Dewatering Centrifuge has been a game-changer for companies looking to maximize efficiency and minimize their environmental footprint. This cutting-edge technology, developed by a global leader in solid-liquid separation solutions, has garnered widespread acclaim for its ability to effectively separate liquid and solid waste, therefore reducing waste volume and disposal costs.Company A, founded in 2000, has quickly established itself as a leading provider of advanced separation technology, with a commitment to delivering innovative and sustainable solutions to industries worldwide. With a strong focus on research and development, Company A has continuously pushed the boundaries of what is possible in solid-liquid separation, resulting in the creation of the groundbreaking Dewatering Centrifuge.The Dewatering Centrifuge works by using centrifugal force to rapidly separate liquid and solid waste, allowing for the efficient removal of moisture from the waste stream. This technology has proven to be particularly valuable in industries such as mining, chemical processing, and food and beverage production, where the management of solid and liquid waste is a critical aspect of operations.One of the key advantages of the Dewatering Centrifuge is its ability to significantly reduce the volume of waste material, making it easier and more cost-effective to dispose of. This not only results in cost savings for companies but also helps to minimize the environmental impact of waste disposal, as less material ends up in landfills or other waste management facilities.Furthermore, the Dewatering Centrifuge has been praised for its versatility and adaptability, with the ability to handle a wide range of waste materials, including sludge, industrial wastewater, and other high-moisture content substances. This flexibility has made it a valuable asset for companies looking to streamline their waste management processes and improve overall operational efficiency.In addition to its impressive performance capabilities, the Dewatering Centrifuge also boasts a user-friendly design, making it easy to operate and maintain. This has been a significant factor in its widespread adoption by companies of all sizes, as it eliminates the need for extensive training and ensures minimal downtime during maintenance.Company A's commitment to sustainability is evident in all aspects of its operations, and the Dewatering Centrifuge is no exception. By helping companies to reduce their waste volume and disposal costs, this technology supports a more environmentally responsible approach to waste management, aligning with the growing demand for sustainable business practices.Looking ahead, Company A remains dedicated to driving innovation in solid-liquid separation, with ongoing research and development efforts focused on further enhancing the capabilities of the Dewatering Centrifuge. As industrial waste management continues to be a critical consideration for businesses across the globe, the demand for advanced separation technology is expected to grow, making the Dewatering Centrifuge a key player in the evolution of waste management practices.In conclusion, the introduction of the Dewatering Centrifuge by Company A has brought about a paradigm shift in waste management for industrial applications. With its ability to efficiently separate liquid and solid waste, minimize waste volume, and reduce disposal costs, this innovative technology has set a new standard for sustainable and effective waste management. As industries continue to prioritize environmental stewardship and operational efficiency, the Dewatering Centrifuge is poised to play a crucial role in meeting these objectives, driving positive change for businesses and the planet alike.