High-Efficiency Sludge Agitator for Effective Waste Management

By:Admin

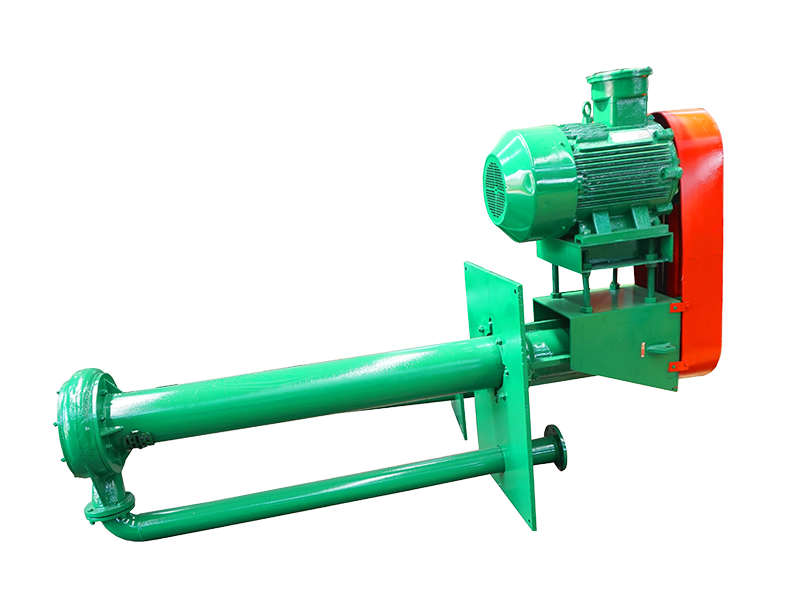

In response to the growing demand for effective waste treatment solutions, the renowned company {} has recently unveiled its latest innovation – the Sludge Agitator. This state-of-the-art equipment is designed to significantly enhance the efficiency of waste treatment processes, ultimately contributing to a more sustainable and environmentally-friendly approach to waste management.

The Sludge Agitator, a revolutionary solution developed by {}, is set to revolutionize the way in which sludge is treated in industrial and municipal wastewater treatment facilities. By effectively mixing and agitating the sludge, this equipment offers an efficient and cost-effective method for optimizing the treatment process, ultimately leading to improved overall performance.

The primary function of the Sludge Agitator is to prevent the settling of solids within the sludge, which can lead to uneven treatment and reduced efficiency. By constantly agitating the sludge, this innovative equipment ensures that the solids remain in suspension, allowing for better treatment and separation of the waste materials.

One of the key features of the Sludge Agitator is its versatility and adaptability to different types of waste treatment systems. Whether it is used in activated sludge processes, anaerobic digesters, or other treatment facilities, this equipment is designed to seamlessly integrate into existing infrastructure, providing a seamless and efficient solution for optimizing waste treatment operations.

Furthermore, the Sludge Agitator is equipped with advanced control and monitoring capabilities, allowing operators to easily adjust the agitation intensity and duration to suit specific treatment requirements. This level of control not only enhances the overall performance of the equipment but also ensures that the treatment process is optimized for maximum efficiency and effectiveness.

In addition to its technical capabilities, the Sludge Agitator also offers notable benefits in terms of environmental sustainability. By improving the overall efficiency of waste treatment processes, this equipment can help reduce the environmental impact of industrial and municipal operations, leading to lower energy consumption, reduced waste generation, and ultimately, a more sustainable approach to waste management.

The introduction of the Sludge Agitator is a testament to {}'s commitment to developing innovative solutions that address the evolving needs of the waste treatment industry. With a proven track record of delivering high-quality and reliable equipment, the company continues to spearhead advancements in waste management technology, setting new standards for efficiency, reliability, and sustainability.

As a leading provider of waste treatment solutions, {} is dedicated to supporting its customers in achieving their environmental and operational goals. The introduction of the Sludge Agitator represents yet another milestone in the company's ongoing efforts to drive positive change in the waste treatment industry, offering a tangible solution for improving efficiency and sustainability in waste management operations.

In conclusion, the launch of the Sludge Agitator marks a significant advancement in waste treatment technology, offering a comprehensive solution for enhancing the efficiency and sustainability of waste treatment processes. With its cutting-edge design, advanced capabilities, and environmental benefits, this equipment is poised to make a transformative impact on the waste management industry, setting new standards for operational excellence and environmental responsibility. As the demand for more sustainable waste treatment solutions continues to grow, the Sludge Agitator stands out as a compelling and effective option for organizations looking to optimize their waste treatment operations and minimize their environmental footprint.

Company News & Blog

New High-Performance Screen for Efficient Oil & Gas Separation

Hyperpool Screens: Offering Enhanced Efficiency in Drilling OperationsDrilling operations have become more efficient and productive with the introduction of Hyperpool screens. These screens are specially designed for shale shaker systems and are highly effective in removing solids from drilling fluid. Hyperpool screens, also known as Derrick screens, have become increasingly popular in the oil and gas industry due to their exceptional performance and durability.What are Hyperpool screens?Hyperpool screens are a type of shale shaker screen that are used in the oil and gas industry to filter drilling fluid. They are designed to fit Derrick shale shaker systems, which are used to separate solids and liquids during the drilling process. Hyperpool screens are made using a multi-layered wire mesh cloth and are available in a variety of sizes and configurations to meet specific drilling requirements.Why choose Hyperpool screens?Hyperpool screens offer several advantages over other types of shale shaker screens. For one, they are more durable and long-lasting. The multi-layered wire mesh cloth ensures that the screens can withstand wear and tear from drilling operations. They are also highly effective in removing solids from drilling fluid, resulting in a more efficient and productive drilling process. Hyperpool screens are also easy to install and maintain, reducing downtime and maintenance costs.How do Hyperpool screens work?Hyperpool screens are designed to work with Derrick shale shaker systems. When drilling fluid is pumped into the shaker system, it passes through the screens and is filtered to remove solids. The multi-layered wire mesh cloth traps the solids and allows the clean fluid to pass through. The solids are then removed from the system and disposed of.Benefits of Hyperpool screensHyperpool screens offer several benefits that make them a popular choice for drilling operations. One of the biggest advantages is their efficiency in removing solids from drilling fluid. This results in a more efficient and productive drilling process, as the fluid can be reused and less waste is produced. Hyperpool screens are also more durable and long-lasting, reducing the need for frequent replacements. This saves time and money in the long run. Additionally, they are easy to install and maintain, reducing downtime and maintenance costs.ConclusionHyperpool screens are a vital component of shale shaker systems used in the oil and gas industry. They offer several advantages over other types of shale shaker screens, including enhanced efficiency and durability. Hyperpool screens are designed to filter drilling fluid, removing solids and producing a clean fluid that can be reused. If you’re looking for an effective and reliable solution for your drilling operations, Hyperpool screens are definitely worth considering.Keywords: Derrick Hyperpool screens, shale shaker screens, drilling operations, drilling fluid, multi-layered wire mesh cloth

Top Quality Shale Shakers Available for Sale in China - Find the Best Deals Now

China's Shale Shaker and Shale Shakers for Sale are revolutionizing the oil and gas industry with their innovative technology and high-performance capabilities. These state-of-the-art equipment are designed to efficiently separate drilling cuttings from drilling fluid, providing a crucial step in the process of drilling for oil and gas.One of the leading manufacturers of shale shakers in China, {} has established itself as a trusted provider of high-quality equipment for the oil and gas industry. With a strong focus on research and development, the company has continually advanced the capabilities of their shale shakers, making them some of the most reliable and efficient options on the market.The shale shaker is a critical component in the drilling process. It is responsible for removing large solids from the drilling fluid, which is essential for maintaining the integrity of the fluid and ensuring that it can be reused in the drilling operation. By efficiently separating the solid particles, the shale shaker helps to prolong the life of the drilling equipment and reduce the environmental impact of the drilling operation.In addition to their superior performance, the shale shakers offered by {} are also designed with durability and ease of maintenance in mind. This ensures that they can withstand the harsh conditions of drilling operations and require minimal maintenance to keep them operating at peak efficiency.With a commitment to providing exceptional customer service, {} offers a range of shale shakers for sale to meet the specific needs of their clients. Whether it's a small-scale drilling operation or a large-scale industrial project, the company has a shale shaker solution to suit every requirement.The company's extensive experience in the industry has allowed them to develop a deep understanding of the challenges faced by their clients and the demands of the oil and gas industry as a whole. This has driven their continuous innovation and improvement of their shale shaker technology, ensuring that they remain at the forefront of the industry.In addition to manufacturing shale shakers, {} also provides comprehensive support and technical assistance to their clients. This includes installation, training, and ongoing maintenance services, all aimed at ensuring that their clients are able to maximize the performance and lifespan of their equipment.By combining cutting-edge technology with a customer-centric approach, {} has solidified its position as a leading provider of shale shakers in China and beyond. With a commitment to quality, reliability, and innovation, the company continues to play a crucial role in the success of oil and gas drilling operations around the world.As the demand for oil and gas continues to grow, the need for efficient and reliable drilling equipment becomes increasingly important. {}'s shale shakers are playing a vital role in meeting this demand, providing a crucial piece of equipment that is essential for the success of drilling operations.Overall, {}'s dedication to excellence and innovation has positioned them as a key player in the oil and gas industry, and their shale shakers continue to set the standard for performance and reliability. With a focus on meeting the specific needs of their clients and a commitment to advancing the capabilities of their equipment, the company is poised to continue making a significant impact on the industry for years to come.

Mud Tank In Drilling Rig: What You Need to Know

Mud Tank in Drilling Rig: Ensuring Smooth Drilling OperationsThe mud tank is a crucial component in the drilling rig, playing a pivotal role in the efficient extraction of oil and gas from deep within the Earth. With its ability to store and circulate drilling fluid, the mud tank ensures that the drilling process can be carried out smoothly and effectively. One company that has been leading the way in providing top-notch mud tank solutions is {}. Established in {}, {} has become a renowned name in the oil and gas industry, specializing in the design, manufacturing, and supply of drilling equipment and accessories. With a strong focus on innovation and quality, the company has consistently delivered cutting-edge solutions to its clients, earning a reputation for reliability and excellence. The mud tank is a prime example of a product that has contributed significantly to the success of drilling operations worldwide. A well-designed mud tank provides a centralized location for storing and mixing the drilling fluid, which is essential for maintaining the stability of the borehole, cooling and lubricating the drill bit, and carrying the rock cuttings to the surface. Without a properly functioning mud tank, drilling operations can be hindered, leading to delays and inefficiencies.The mud tank offered by {} is designed with a keen understanding of the demands of the drilling process. It is built to withstand the harsh conditions of the drilling environment, with robust construction that ensures durability and longevity. Additionally, the mud tank is equipped with advanced features to facilitate the smooth circulation of drilling fluid, including agitators, centrifugal pumps, and mud guns that work in unison to maintain the proper consistency and properties of the mud.One of the standout qualities of the {} mud tank is its customizable design. Recognizing that different drilling operations have unique requirements, the company offers tailored solutions to meet the specific needs of its clients. Whether it is a large-scale offshore drilling project or a smaller onshore operation, {} can provide a mud tank that is tailored to fit the available space and accommodate the necessary volume of drilling fluid.Furthermore, {} places a strong emphasis on safety and environmental responsibility in its mud tank designs. The company ensures that its mud tanks are equipped with features that minimize the risk of spills and leaks, as well as systems for the proper disposal of drilling waste. By incorporating these elements into its products, {} enables its clients to adhere to stringent industry regulations and best practices, while also reducing the potential for environmental harm.In addition to the quality of its products, {} is known for its comprehensive support services. The company’s team of experts is readily available to provide assistance with the installation, operation, and maintenance of its mud tanks, ensuring that clients can derive maximum value from their investment. This commitment to customer satisfaction has contributed to the strong relationships that {} has built with its clients, many of whom are repeat customers who continue to rely on the company's expertise.Looking ahead, {} is committed to further advancing its mud tank technology, with a focus on incorporating smart, data-driven features that enable real-time monitoring and optimization of drilling fluid performance. By embracing the latest innovations, {} aims to continue enhancing the efficiency and effectiveness of drilling operations, ultimately contributing to the advancement of the oil and gas industry as a whole.In conclusion, the mud tank is a vital component in the drilling rig, and {} has established itself as a leading provider of high-quality, customized mud tank solutions. With a strong emphasis on innovation, quality, and customer support, the company has solidified its position as a trusted partner for drilling operations around the world. As the industry continues to evolve, {} remains poised to deliver cutting-edge solutions that uphold the integrity and productivity of drilling processes.

Durable PWP Shaker Screens for FLC 2000 Model - A Must-Have for Borehole Operations

FLC 2000 PWP Shaker Screens: The Next Innovation in Oilfield EquipmentThe oil and gas industry is known for its constant demand for innovative and efficient equipment. This demand has led to the development of the FLC 2000 PWP Shaker Screens, a cutting-edge product that is set to revolutionize the oilfield equipment market.** (Name of Company) is a leading manufacturer of high-quality oilfield equipment. With a strong focus on innovation and customer satisfaction, the company has built a reputation for delivering top-notch solutions to its clients. Its latest offering, the FLC 2000 PWP Shaker Screens, is a testament to the company's commitment to excellence and innovation.The FLC 2000 PWP Shaker Screens are designed to maximize the efficiency of the oil and gas drilling process. These screens are constructed using advanced technology and high-quality materials, ensuring their durability and reliability in the most demanding drilling environments. The screens are compatible with a wide range of shakers, making them a versatile and cost-effective solution for oilfield operators.One of the key features of the FLC 2000 PWP Shaker Screens is their superior filtration capabilities. These screens are designed to effectively separate solids from the drilling fluid, ensuring that the fluid remains clean and free of debris. This not only improves the overall efficiency of the drilling process but also helps to protect the drilling equipment from premature wear and damage.Furthermore, the FLC 2000 PWP Shaker Screens are engineered to minimize downtime and maintenance costs. With their robust construction and long-lasting performance, these screens require minimal upkeep, allowing oilfield operators to maximize their productivity and minimize their operational expenses.In addition to their practical benefits, the FLC 2000 PWP Shaker Screens also offer environmental advantages. By improving the filtration and separation process, these screens help to reduce the environmental impact of drilling activities, making them a sustainable and eco-friendly solution for oil and gas operations.The FLC 2000 PWP Shaker Screens are backed by **(Name of Company)'s commitment to customer satisfaction and support. The company provides comprehensive technical assistance and after-sales services to ensure that its clients can fully optimize the performance of these innovative screens.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in oilfield equipment technology. With their unparalleled efficiency, durability, and sustainability, these screens are poised to set a new standard for oil and gas drilling operations.** (Name of Company) is proud to be at the forefront of this groundbreaking development, and looks forward to providing its clients with the benefits of this cutting-edge technology. As the oil and gas industry continues to evolve, innovative solutions like the FLC 2000 PWP Shaker Screens will play a crucial role in driving operational excellence and sustainable growth.

Exploring the Latest Innovations in Mud Pumps for Drilling in China

China Mud Pump and Mud Pump for Drilling: Revolutionizing the Drilling IndustryThe drilling industry has been evolving over the years, primarily due to the significant advancements in technology. The use of machinery in drilling operations has increased the efficiency and effectiveness of the process, allowing for more accurate and faster execution.One of the integral components of drilling machinery is the mud pump, which is responsible for the circulation of drilling fluid or mud in the borehole. With the advent of China Mud Pump and Mud Pump for Drilling, the industry is witnessing a transformation in its operations.China Mud PumpChina Mud Pump is a company that specializes in the production and distribution of mud pumps. Established in 2005, it is a subsidiary of Tianjin Dong Fang Xian Ke Petroleum Machinery Co., Ltd, a leader in the oil and gas equipment manufacturing industry.With over 15 years of experience, China Mud Pump has built a reputation for providing high-quality products and excellent customer service. The company has a team of experts who handle the production process, ensuring that every pump meets the required standards.China Mud Pumps are known for their durability, efficiency, and low maintenance costs. The pumps are manufactured using high-quality materials, and the company employs the latest technology in their production process to ensure that they meet the changing needs of the industry.Mud Pump for DrillingMud Pump for Drilling is a vital component of drilling machinery used in the oil and gas industry. It is responsible for the circulation of drilling fluid or mud in the borehole, which helps in cooling the drill bit, clearing debris, and maintaining the pressure of the well.Mud Pump for Drilling is designed to operate under high pressure and is subjected to intense wear and tear. Therefore, it is important to invest in a mud pump that is durable, efficient, and easy to maintain.China Mud Pump for Drilling is a product that satisfies all these requirements. It is designed to operate under high pressure, making it suitable for use in various drilling environments. The pump is also manufactured using high-quality materials that can withstand the rigors of drilling operations.Advantages of China Mud Pump and Mud Pump for DrillingThe use of China Mud Pump and Mud Pump for Drilling offers numerous advantages to the drilling industry. Some of these benefits include:1. Durability: The pumps are designed to withstand the intense wear and tear associated with drilling operations. They are manufactured using high-quality materials, ensuring that they can last for years without requiring significant maintenance.2. Efficiency: China Mud Pumps are designed to operate under high pressure, making them suitable for use in various drilling environments. The pumps are also equipped with features that improve their efficiency, such as high-speed triplex plungers and fluid end modules.3. Low maintenance costs: The pumps are easy to maintain, and their low-maintenance requirements translate to significant cost savings for drilling companies.4. Customization: China Mud Pump and Mud Pump for Drilling can be customized to meet the specific needs of drilling companies. The pumps can be designed to operate in different environments and to handle various drilling fluids.ConclusionThe drilling industry is undergoing a revolution, and the use of advanced technology is at the heart of this transformation. China Mud Pump and Mud Pump for Drilling are leading the way in this movement, providing high-quality, durable, and efficient mud pumps that are transforming the drilling operations.Investing in China Mud Pump and Mud Pump for Drilling offers numerous benefits to drilling companies, including lower maintenance costs, improved efficiency, and customization options. As the industry continues to evolve, it is clear that the use of China Mud Pump and Mud Pump for Drilling will be an integral component in the success of drilling operations worldwide.

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.

Highly Efficient and Durable 3x4 Centrifugal Pump for Mission Purposes

Mission 3x4 Centrifugal Pump, a Leading Innovation in Water Pump TechnologyIn the world of industrial and agricultural machinery, the name {Company Name} has been synonymous with cutting-edge technology and top-quality products for over two decades. With a strong commitment to innovation and customer satisfaction, {Company Name} has continually raised the bar for excellence in the industry. The latest addition to their extensive product line is the Mission 3x4 Centrifugal Pump, a game-changing innovation that promises to revolutionize the way water is pumped and distributed.The Mission 3x4 Centrifugal Pump is designed to meet the growing demand for efficient, reliable, and high-performance water pumps in a wide range of applications. Whether it's agricultural irrigation, industrial water supply, or municipal water distribution, this innovative pump is engineered to deliver superior performance and unmatched durability. With a maximum flow rate of 1000 gallons per minute and a maximum head of 360 feet, the Mission 3x4 Centrifugal Pump is capable of handling even the most demanding water pumping tasks with ease.One of the key features that sets the Mission 3x4 Centrifugal Pump apart from its competitors is its advanced design and construction. The pump housing is made of high-quality cast iron, ensuring exceptional strength and resistance to corrosion. The impeller and other crucial components are precision-engineered to deliver maximum efficiency and performance, while the heavy-duty bearings and seals are designed to withstand the rigors of continuous operation in tough working environments. In addition, the pump is equipped with a powerful motor that provides reliable and consistent power for extended periods of use.Furthermore, the Mission 3x4 Centrifugal Pump is designed with ease of maintenance and serviceability in mind. Its modular design allows for quick and convenient access to critical components, making inspection, repair, and replacement a breeze. This not only minimizes downtime but also reduces the overall cost of ownership, making it an attractive choice for budget-conscious customers. Moreover, the pump is backed by {Company Name}'s renowned customer support and after-sales service, ensuring peace of mind for customers and maximizing the lifespan of the equipment.Another noteworthy aspect of the Mission 3x4 Centrifugal Pump is its energy efficiency and environmental sustainability. By utilizing state-of-the-art design principles and materials, the pump is able to deliver exceptional performance while minimizing energy consumption. This not only results in cost savings for the end user but also reduces the carbon footprint, contributing to a greener and more sustainable future. In an era where environmental responsibility is paramount, the Mission 3x4 Centrifugal Pump stands out as a shining example of responsible and forward-thinking engineering.As a testament to its outstanding quality and performance, the Mission 3x4 Centrifugal Pump has already garnered attention and accolades from industry experts and customers alike. Its robust construction, cutting-edge technology, and exceptional performance have set a new standard for water pumps, firmly establishing it as a leading innovation in the field. With its versatility and reliability, the pump is poised to make a significant impact in a wide range of industries and applications, meeting the diverse needs of customers around the world.In conclusion, the Mission 3x4 Centrifugal Pump represents the pinnacle of water pump technology, embodying {Company Name}'s unwavering commitment to excellence and innovation. With its outstanding performance, durability, and energy efficiency, it is set to redefine the standards for water pumping equipment, empowering customers with a reliable and efficient solution for their water management needs. As {Company Name} continues to push the boundaries of engineering and manufacturing, the Mission 3x4 Centrifugal Pump stands as a shining example of their dedication to delivering top-quality products that make a positive difference in the world.

Effective Mud Gas Separator Design for Oil and Gas Operations

Mud Gas Separator Design Innovations by Leading CompanyIn the oil and gas industry, the need to effectively separate gas from drilling fluid has led to the development of advanced technologies such as the Mud Gas Separator (MGS). One of the leading companies in this field, with a proven track record of innovation and excellence, is {}. Their latest MGS design is set to revolutionize the industry by offering improved performance and efficiency.Established in {}, {} has been at the forefront of developing cutting-edge solutions for the oil and gas sector. With a team of highly skilled engineers and researchers, the company has consistently delivered state-of-the-art equipment that meets the evolving needs of the industry. The company's commitment to quality, safety, and environmental protection has earned them a stellar reputation as a trusted partner for oil and gas companies around the world.The latest Mud Gas Separator design by {} is the result of years of research and development. This innovative technology is designed to effectively separate and vent gas from drilling fluid, ensuring the safety of personnel and equipment on drilling rigs. The new design incorporates advanced features that enhance performance and reliability, making it an invaluable tool for oil and gas operations.One of the key features of the new Mud Gas Separator design is its enhanced gas-liquid separation efficiency. Thanks to innovative engineering and advanced materials, the MGS is capable of effectively capturing and removing gas from drilling fluid, even in high-pressure and high-temperature environments. This not only improves safety on drilling rigs but also minimizes the risk of equipment damage and downtime.Furthermore, the new MGS design also incorporates a compact and lightweight construction, making it easier to transport and install on drilling rigs. This innovative approach to design and engineering reflects {}'s commitment to practicality and ease of use, ensuring that their products meet the needs of their clients in the field.In addition to its performance and portability, the new Mud Gas Separator design by {} also integrates advanced safety features. These include robust gas venting systems and fail-safe mechanisms, which are essential for ensuring the wellbeing of personnel and the protection of the environment during drilling operations.{}'s Mud Gas Separator design is also designed to be user-friendly, with intuitive controls and maintenance features that make it easier for operators to monitor and service the equipment. This focus on usability and accessibility is a testament to {}'s customer-centric approach, ensuring that their products are not only technologically advanced but also practical and easy to operate.With the launch of their latest Mud Gas Separator design, {} reinforces their position as a leading innovator in the oil and gas industry. This new technology is set to raise the bar for gas-liquid separation on drilling rigs, offering unparalleled performance, reliability, and safety. As the industry continues to evolve, {} remains dedicated to developing solutions that address the challenges of today and anticipate the needs of tomorrow. Their commitment to excellence and innovation is evident in every aspect of their business, making them a trusted partner for oil and gas companies worldwide.

New Flare Ignition Device for Improved Safety and Efficiency

Flare Ignition Device Revolutionizes Safety in Oil and Gas IndustryThe oil and gas industry is notorious for its potential risks and hazards. From environmental concerns to workplace safety, companies in this sector are constantly seeking innovative solutions to mitigate potential dangers. One of the latest developments in this field is the Flare Ignition Device, a cutting-edge technology designed to enhance safety and efficiency in oil and gas operations.Developed by a leading engineering and technology company, the Flare Ignition Device is a state-of-the-art system that has been designed to mitigate the risks associated with flaring, ensuring the safety of personnel and the environment. This innovative device has the potential to revolutionize safety standards in the oil and gas industry by providing a reliable and efficient solution for flare ignition.The Flare Ignition Device is equipped with advanced features that set it apart from conventional ignition systems. Its streamlined design and user-friendly interface make it easy to install and operate, while its robust construction ensures durability and longevity. The device is also designed to operate in a wide range of environmental conditions, including extreme temperatures and harsh weather, making it suitable for use in various oil and gas operations.One of the key advantages of the Flare Ignition Device is its advanced safety features. The system is equipped with multiple fail-safe mechanisms to prevent accidents and ensure reliable operation. This includes built-in sensors and monitoring systems that detect potential issues and automatically shut down the device if necessary. Moreover, the device is designed to meet industry safety standards and regulations, providing companies with peace of mind and regulatory compliance.In addition to its safety features, the Flare Ignition Device also offers significant environmental benefits. By igniting flares efficiently and effectively, the device helps to reduce emissions and minimize environmental impact. This is a critical consideration for oil and gas companies, particularly in light of increasing regulatory pressures and public scrutiny on environmental issues.Furthermore, the Flare Ignition Device is designed to enhance operational efficiency in oil and gas facilities. By providing reliable and consistent flare ignition, the device minimizes downtime and maximizes productivity. This is especially important in the context of volatile market conditions and fluctuating energy prices, where operational efficiency can significantly impact the bottom line.The company behind the Flare Ignition Device is a leading provider of engineering and technology solutions for the oil and gas industry. With a track record of innovation and excellence, the company is committed to developing cutting-edge products and services that address the evolving needs of its clients. The Flare Ignition Device is a testament to the company's dedication to safety, reliability, and environmental sustainability.In conclusion, the Flare Ignition Device represents a significant advancement in safety and efficiency for the oil and gas industry. With its advanced features, robust design, and environmental benefits, the device has the potential to revolutionize safety standards and operational practices in this sector. As companies continue to prioritize safety and environmental responsibility, the Flare Ignition Device is poised to become a critical tool for enhancing performance and mitigating risks in oil and gas operations.

High Quality PWP Shaker Screens for FLC 2000 Model Available

FLC 2000 PWP Shaker Screens Revolutionize the Oil and Gas Drilling IndustryThe oil and gas drilling industry is continuously evolving, and with advancements in technology, companies are constantly searching for ways to improve efficiency and productivity. One of the key components of any drilling operation is the shaker screen, which is essential for separating solids from drilling fluid. With the introduction of the FLC 2000 PWP Shaker Screens, the drilling industry has been revolutionized, offering enhanced performance and reliability for drilling operations worldwide.The FLC 2000 PWP Shaker Screens, produced by a leading manufacturer in the industry, have set a new standard for shaker screen technology. These screens are specifically designed to provide superior performance in a wide range of drilling applications, including oil and gas exploration, geothermal drilling, and more. With a focus on durability, efficiency, and reliability, these screens are engineered to withstand the demanding conditions of drilling operations, delivering exceptional results time and time again.One of the key features of the FLC 2000 PWP Shaker Screens is their advanced design, which allows for maximum fluid handling capacity while effectively removing solid particles from the drilling fluid. This results in improved drilling efficiency, reduced downtime, and lower overall operating costs. Additionally, these screens are built to withstand the harsh conditions of drilling operations, ensuring long-lasting performance and reliability in the field.In addition to their superior performance, the FLC 2000 PWP Shaker Screens are also designed with ease of use in mind. With quick and simple installation, these screens can be easily integrated into existing shaker systems, providing immediate improvements in performance and efficiency. This user-friendly design has been well-received by drilling operators, who have praised the FLC 2000 PWP Shaker Screens for their ease of use and reliability in the field.Furthermore, the manufacturer of the FLC 2000 PWP Shaker Screens has a long-standing reputation for producing high-quality products that meet the needs of the oil and gas industry. With a commitment to innovation and excellence, this company has become a trusted partner for drilling operations around the world, providing solutions that improve efficiency, productivity, and safety.The introduction of the FLC 2000 PWP Shaker Screens has generated significant interest and excitement within the oil and gas drilling industry. Drilling operators are eager to take advantage of the enhanced performance and reliability offered by these innovative screens, which have the potential to revolutionize the way drilling operations are conducted. With their advanced design, durability, and ease of use, the FLC 2000 PWP Shaker Screens are poised to make a significant impact on the industry, setting a new standard for shaker screen technology.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in shaker screen technology, offering enhanced performance and reliability for drilling operations worldwide. With their advanced design, durability, and ease of use, these screens have the potential to revolutionize the oil and gas drilling industry, providing operators with the tools they need to improve efficiency, productivity, and safety. As the industry continues to evolve, the FLC 2000 PWP Shaker Screens are sure to play a key role in driving future advancements and innovations in drilling technology.