High-Quality Bfs542 Mulcher Teeth for China Market

By:Admin

The Bfs542 and Mulcher Teeth Bfs542 are the latest additions to the company’s extensive range of machinery and equipment. These new products are built with state-of-the-art technology and are designed to provide superior performance, efficiency, and durability. The Bfs542 is a powerful and versatile machine that is capable of handling a wide range of agricultural tasks, from plowing and seeding to harvesting and transporting. It is equipped with advanced features that make it easy to operate and maintain, ensuring maximum productivity and efficiency in the field.

Similarly, the Mulcher Teeth Bfs542 is a groundbreaking product that is designed to enhance the efficiency and performance of mulching operations. With its advanced cutting edge technology, the Mulcher Teeth Bfs542 is capable of shredding and mulching various types of vegetation with ease, making it an ideal tool for land clearing and vegetation management in the forestry industry.

These new products have been developed to meet the growing demand for high-quality machinery and equipment in the agricultural and forestry sectors. With their advanced features and capabilities, the Bfs542 and Mulcher Teeth Bfs542 are set to become indispensable tools for farmers and forestry professionals around the world.

In addition to their cutting-edge technology, the company behind the Bfs542 and Mulcher Teeth Bfs542 is also recognized for its commitment to quality and innovation. With a strong focus on research and development, the company continues to invest in new technologies and processes to stay ahead of the competition and meet the evolving needs of its customers.

Moreover, the company has a strong track record of delivering reliable and durable machinery and equipment to its customers. Its products are known for their high performance, efficiency, and longevity, making them the preferred choice for agricultural and forestry operations.

Furthermore, the company has a dedicated team of engineers, technicians, and support staff who are committed to providing exceptional service and support to its customers. Whether it is assisting with product selection, installation, or maintenance, the company’s team is always ready to go the extra mile to ensure customer satisfaction.

The introduction of the Bfs542 and Mulcher Teeth Bfs542 further cements the company’s position as a leader in the agricultural and forestry machinery industry. With their advanced features, superior performance, and reliability, these new products are set to raise the bar for machinery and equipment in the industry.

Overall, the Bfs542 and Mulcher Teeth Bfs542 are a testament to the company’s dedication to innovation, quality, and customer satisfaction. As the agricultural and forestry industry continues to evolve, the company remains committed to driving the market forward with its cutting-edge technology and superior products. With its strong reputation and track record, the company is well positioned to meet the growing demand for high-quality machinery and equipment in the industry.

Company News & Blog

Mud Tank In Drilling Rig: What You Need to Know

Mud Tank in Drilling Rig: Ensuring Smooth Drilling OperationsThe mud tank is a crucial component in the drilling rig, playing a pivotal role in the efficient extraction of oil and gas from deep within the Earth. With its ability to store and circulate drilling fluid, the mud tank ensures that the drilling process can be carried out smoothly and effectively. One company that has been leading the way in providing top-notch mud tank solutions is {}. Established in {}, {} has become a renowned name in the oil and gas industry, specializing in the design, manufacturing, and supply of drilling equipment and accessories. With a strong focus on innovation and quality, the company has consistently delivered cutting-edge solutions to its clients, earning a reputation for reliability and excellence. The mud tank is a prime example of a product that has contributed significantly to the success of drilling operations worldwide. A well-designed mud tank provides a centralized location for storing and mixing the drilling fluid, which is essential for maintaining the stability of the borehole, cooling and lubricating the drill bit, and carrying the rock cuttings to the surface. Without a properly functioning mud tank, drilling operations can be hindered, leading to delays and inefficiencies.The mud tank offered by {} is designed with a keen understanding of the demands of the drilling process. It is built to withstand the harsh conditions of the drilling environment, with robust construction that ensures durability and longevity. Additionally, the mud tank is equipped with advanced features to facilitate the smooth circulation of drilling fluid, including agitators, centrifugal pumps, and mud guns that work in unison to maintain the proper consistency and properties of the mud.One of the standout qualities of the {} mud tank is its customizable design. Recognizing that different drilling operations have unique requirements, the company offers tailored solutions to meet the specific needs of its clients. Whether it is a large-scale offshore drilling project or a smaller onshore operation, {} can provide a mud tank that is tailored to fit the available space and accommodate the necessary volume of drilling fluid.Furthermore, {} places a strong emphasis on safety and environmental responsibility in its mud tank designs. The company ensures that its mud tanks are equipped with features that minimize the risk of spills and leaks, as well as systems for the proper disposal of drilling waste. By incorporating these elements into its products, {} enables its clients to adhere to stringent industry regulations and best practices, while also reducing the potential for environmental harm.In addition to the quality of its products, {} is known for its comprehensive support services. The company’s team of experts is readily available to provide assistance with the installation, operation, and maintenance of its mud tanks, ensuring that clients can derive maximum value from their investment. This commitment to customer satisfaction has contributed to the strong relationships that {} has built with its clients, many of whom are repeat customers who continue to rely on the company's expertise.Looking ahead, {} is committed to further advancing its mud tank technology, with a focus on incorporating smart, data-driven features that enable real-time monitoring and optimization of drilling fluid performance. By embracing the latest innovations, {} aims to continue enhancing the efficiency and effectiveness of drilling operations, ultimately contributing to the advancement of the oil and gas industry as a whole.In conclusion, the mud tank is a vital component in the drilling rig, and {} has established itself as a leading provider of high-quality, customized mud tank solutions. With a strong emphasis on innovation, quality, and customer support, the company has solidified its position as a trusted partner for drilling operations around the world. As the industry continues to evolve, {} remains poised to deliver cutting-edge solutions that uphold the integrity and productivity of drilling processes.

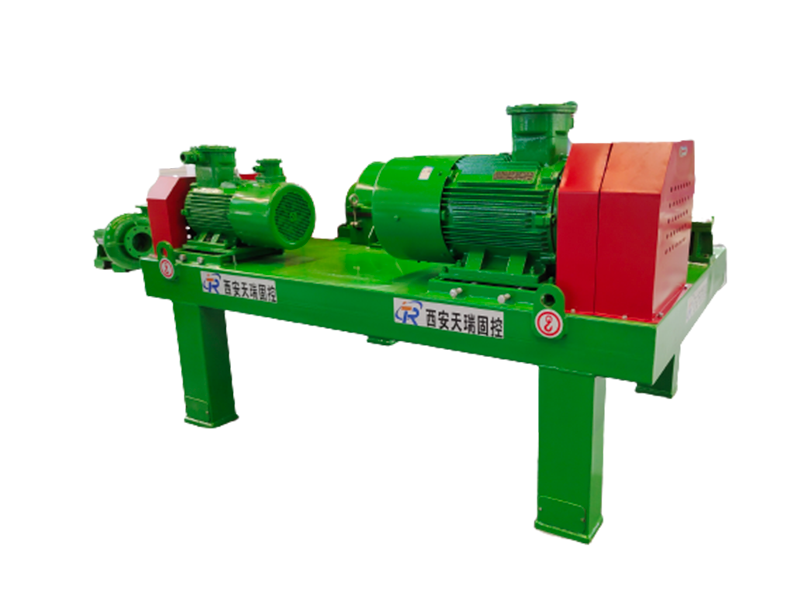

Innovative Centrifuge Drilling Technology for Efficient and Effective Drilling Operations

Centrifuge Drilling is revolutionizing the oil and gas industry with its cutting-edge technology that allows for more efficient and cost-effective drilling. This innovative company has quickly become a leader in the field, providing solutions that are changing the way companies approach drilling operations.Founded in 2010, Centrifuge Drilling has a mission to improve the efficiency and effectiveness of drilling for oil and gas reserves. The company specializes in the development and manufacturing of advanced drilling equipment, including centrifuges, that are designed to enhance performance and reduce costs for its customers.Centrifuge Drilling's technology is based on the principle of using centrifugal force to separate different components of drilling mud, allowing for better control and management of the drilling process. This results in improved drilling performance, reduced downtime, and ultimately, significant cost savings for operators.One of the key advantages of Centrifuge Drilling's technology is its ability to handle a wide range of drilling conditions, making it suitable for both onshore and offshore operations. Additionally, the company's equipment is designed to be highly adaptable, allowing for easy integration into existing drilling rigs.The company has quickly gained recognition for its innovative approach to drilling, and it has already established a strong track record of success with numerous projects around the world. Centrifuge Drilling's technology has been proven to significantly improve drilling efficiency and reduce operational costs, making it an attractive solution for operators looking to maximize their resources.One of the company's flagship products is its centrifuge system, which has been specifically designed to address the challenges of drilling in complex geological formations. This system can effectively separate solids from drilling mud, allowing for better control of viscosity and density, which in turn leads to improved drilling performance and reduced wear and tear on equipment.In addition to its cutting-edge technology, Centrifuge Drilling also offers comprehensive support services to its customers. The company's team of experts is available to provide technical assistance, training, and maintenance services to ensure the continued success of its technology in the field.Centrifuge Drilling's commitment to innovation and excellence has earned it a reputation as a trusted partner for operators in the oil and gas industry. The company's dedication to providing reliable, cost-effective solutions has helped it build strong relationships with a wide range of clients, from small independent operators to major international companies.Looking ahead, Centrifuge Drilling is focused on continued research and development to further enhance its technology and maintain its position as a leader in the field. The company is also exploring new opportunities to expand its presence in key markets and build on its success in providing innovative solutions for the oil and gas industry.As the demand for efficient and sustainable drilling continues to grow, Centrifuge Drilling is well-positioned to play a key role in shaping the future of the industry. With its proven technology and commitment to excellence, the company is poised to make a lasting impact on the way drilling operations are conducted around the world.

The latest innovation in centrifugal impeller technology unveiled

Centrifugal Impeller Revolutionizing Industrial Applications: A Game Changer byIn today's fast-paced industrial world, efficiency and innovation are key factors that drive success. One such innovation that is revolutionizing industrial applications is the Centrifugal Impeller. This state-of-the-art technology is a game-changer in the field of industrial equipment, setting new standards for performance and reliability.The Centrifugal Impeller, developed by a leading industrial equipment manufacturer, is designed to meet the growing demands of various industries, including aerospace, automotive, energy, and HVAC. Its advanced engineering and precision manufacturing make it an ideal choice for applications that require high efficiency, low noise, and long-term reliability.One of the key features of the Centrifugal Impeller is its unique blade design, which is optimized for maximum performance. This design allows for efficient airflow and pressure generation, making it suitable for a wide range of industrial processes. Whether it's for air handling, combustion, or cooling systems, the Centrifugal Impeller delivers unmatched performance, making it a versatile solution for modern industrial applications.Furthermore, the Centrifugal Impeller is also known for its durability and long service life. Its robust construction and high-quality materials ensure that it can withstand the rigors of industrial operations, making it a cost-effective investment for businesses. With minimal maintenance requirements, the Centrifugal Impeller offers a hassle-free solution for industrial equipment needs.In addition to its performance and reliability, the Centrifugal Impeller is also designed with energy efficiency in mind. Its aerodynamic design and precise manufacturing processes enable it to achieve high levels of efficiency, reducing energy consumption and operating costs for businesses. This makes it an environmentally friendly choice for industrial applications, contributing to sustainability efforts in various industries.The company behind the Centrifugal Impeller takes pride in its commitment to quality and innovation. With a team of experienced engineers and experts in industrial equipment, the company has a proven track record of delivering cutting-edge solutions that meet the evolving needs of modern industries. By continuously investing in research and development, the company ensures that its products, including the Centrifugal Impeller, are at the forefront of technological advancements.Furthermore, the company's dedication to customer satisfaction sets it apart in the industry. From initial consultation to product delivery and after-sales support, the company places a strong emphasis on understanding and meeting the specific requirements of its clients. With a focus on building long-term partnerships, the company strives to exceed customer expectations and provide tailored solutions that add value to businesses.As the industrial landscape continues to evolve, the demand for innovative and reliable equipment remains high. The Centrifugal Impeller is a testament to the impact of advanced technology in meeting these demands, offering a solution that enhances efficiency, performance, and sustainability for industrial applications. With its cutting-edge design, durability, and energy efficiency, the Centrifugal Impeller is poised to shape the future of industrial equipment and set new standards for excellence in the industry.

Oil Centrifuge and Oil Extraction Machine in China

China Oil Centrifuge and Oil Extraction Machine, a leading manufacturer and supplier of innovative oil processing equipment, has recently launched a new series of oil centrifuge and oil extraction machines that are designed to revolutionize the oil extraction industry. With state-of-the-art technology and cutting-edge features, these machines are set to become the game-changer in the oil processing industry.The oil centrifuge and oil extraction machines are designed to efficiently extract oil from various oilseeds such as sunflower seeds, soybeans, rapeseed, and more. The machines are equipped with advanced centrifugal technology that ensures maximum oil extraction with minimum wastage. This not only increases the overall efficiency of the oil extraction process but also results in higher-quality oil with better nutritional value.The oil centrifuge and extraction machines are also designed to be user-friendly, with easy-to-use controls and a simple operating system. This makes them suitable for small-scale as well as large-scale oil processing operations. The machines are also built to last, with high-quality materials and precision engineering that guarantee long-term durability and reliable performance.According to a spokesperson for China Oil Centrifuge and Oil Extraction Machine, the company has always been at the forefront of innovation in the oil processing industry. "We are constantly striving to develop new and improved technologies that can help our customers enhance their oil extraction processes. The launch of our new series of oil centrifuge and oil extraction machines is a testament to our commitment to providing cutting-edge solutions to the oil processing industry."The company spokesperson also emphasized the environmental benefits of their new machines. "Our oil centrifuge and oil extraction machines are designed to be environmentally friendly, with reduced energy consumption and minimal wastage. This not only helps our customers save on operational costs but also contributes to a more sustainable and eco-friendly oil processing industry."In addition to their advanced technology and environmental benefits, China Oil Centrifuge and Oil Extraction Machine also offers comprehensive customer support services. This includes installation assistance, technical training, and aftersales support to ensure that their customers can maximize the performance of their oil processing equipment.For customers who are looking to upgrade their existing oil processing facilities or start a new oil processing operation, China Oil Centrifuge and Oil Extraction Machine offers customized solutions to meet their specific requirements. The company's team of experienced engineers and technical experts work closely with customers to understand their needs and provide tailored recommendations for the most efficient and cost-effective oil processing solutions.With the launch of their new series of oil centrifuge and oil extraction machines, China Oil Centrifuge and Oil Extraction Machine is set to make a significant impact on the oil processing industry. By combining advanced technology, user-friendly design, and environmental sustainability, the company is paving the way for a new era of oil extraction and processing. As the demand for high-quality oil continues to grow, China Oil Centrifuge and Oil Extraction Machine is poised to play a key role in shaping the future of the oil processing industry.

Sludge Dewatering and Sludge Management in China: The Latest Developments

China Sludge Dewatering and Sludge Treatment Equipment Market is expected to grow at a CAGR of over 5% during the forecast period (2021-2026). The sludge dewatering equipment market in China is expected to grow significantly due to the increasing amount of sludge generated from various industries such as wastewater treatment, mining, and food and beverage.Sludge dewatering is the process of separating solid and liquid components from sludge, which is a byproduct of wastewater treatment. The dewatered sludge can then be disposed of or used for other purposes, such as fertilizer or energy generation. The growing need for effective sludge management and disposal is driving the demand for sludge dewatering and treatment equipment in China.A leading player in the sludge dewatering and treatment equipment market in China is (company name), which has been providing innovative solutions for sludge management since its inception. (Company name) offers a wide range of sludge dewatering equipment, including belt filter presses, screw presses, and centrifuges, as well as sludge treatment systems such as sludge dryers and thermal hydrolysis systems.The company has a strong presence in the Chinese market and has successfully executed numerous projects for various industries. With a focus on technological innovation and sustainable solutions, (company name) has gained a reputation for delivering high-quality equipment and reliable services to its clients.In addition to its extensive product portfolio, (company name) also provides comprehensive support and maintenance services for its equipment. The company’s team of experienced engineers and technicians ensures that its clients receive the necessary assistance and expertise to optimize the performance of their sludge dewatering and treatment systems.One of the key factors contributing to the company’s success is its commitment to environmental sustainability. (Company name)’s sludge dewatering and treatment equipment are designed to minimize the environmental impact of sludge disposal and help clients comply with stringent regulations for waste management and pollution control.Moreover, (company name) is continuously investing in research and development to develop advanced technologies for sludge dewatering and treatment. The company’s focus on innovation and continuous improvement has enabled it to stay ahead of its competitors and meet the evolving needs of the market.As the demand for sludge dewatering and treatment equipment continues to grow in China, (company name) is well-positioned to capitalize on the opportunities in the market. The company’s strong expertise, proven track record, and commitment to sustainability make it a preferred choice for clients seeking reliable solutions for sludge management.In conclusion, the sludge dewatering and treatment equipment market in China is expected to witness significant growth in the coming years, driven by the increasing need for effective sludge management and disposal. (Company name) has emerged as a key player in the market, offering advanced and sustainable solutions for sludge dewatering and treatment. With its proven expertise and commitment to innovation, the company is well-equipped to meet the growing demand for sludge management solutions in China.

High-quality Shaker Screen Resistant to Corrosion and Heat, Compliant with API Standards

Title: Durable FSI Shaker Screen: A Resilient Solution Compliant with API Standard QualityIntroduction:In the oil and gas industry, one critical aspect of drilling operations is the use of shale shakers. These devices employ shaker screens, which are crucial in separating drilling cuttings from drilling fluid to ensure efficient and productive drilling operations. One prominent manufacturer in China has recently caught our attention with their reliable and durable FSI Shaker Screen. In this blog post, we will delve into the exceptional features and benefits offered by this corrosion and heat-resistant shaker screen compliant with API standard quality.Offering Superior Durability:The FSI Shaker Screen, manufactured by a reputable Chinese company, stands out due to its exceptional durability. With the demanding conditions experienced during drilling operations, it is crucial for shaker screens to withstand the stresses of continuous use. This particular shaker screen is designed using high-quality materials and advanced manufacturing techniques, ensuring its ability to withstand wear and tear.Resisting Corrosion and Heat:The FSI Shaker Screen's resistance to corrosion and heat makes it an excellent choice for drilling operations. The manufacturing process includes the incorporation of materials specifically selected for their resistance to corrosive elements present in drilling fluids. This feature significantly enhances the shaker screen's lifespan and reduces the need for frequent replacements.Moreover, the FSI Shaker Screen’s ability to withstand intense heat is crucial, as drilling operations often subject the equipment to high-temperature conditions. By featuring heat-resilient properties, this shaker screen offers superior performance and longevity, even in extreme thermal environments.API Standard Compliant:In the oil and gas industry, adherence to industry standards is essential for ensuring optimal performance and safety. The FSI Shaker Screen is compliant with API standards, which reflect the industry's best practices. API standards ensure compatibility, efficiency, and reliability throughout the drilling process.China API Shaker Screens:As an industry leader, China has been recognized for its commitment to innovation and quality manufacturing processes. API Shaker Screens from China have gained popularity due to their high-quality construction and competitive pricing. These screens offer reliable performance, exceeding industry standards, while also providing cost-effective solutions for drilling operations worldwide.API Screen: A Key Component in Shale Shaker Systems:The API screen plays a vital role in shale shaker systems, helping remove larger solids from drilling fluids. This enhances the efficiency of the subsequent mud cleaning processes, leading to improved drilling fluid performance and potentially reducing operational costs. By selecting an API-compliant screen, such as the FSI Shaker Screen, operators can have confidence in the effectiveness of their shale shaker systems.Conclusion:Efficient drilling operations heavily rely on reliable shaker screens that can withstand corrosion, heat, and various other demanding conditions. The durable FSI Shaker Screen, manufactured in China, provides an exceptional solution that complies with API standard quality. With exceptional resistance to corrosion and heat, this shaker screen ensures extended lifespan and reliable performance. Furthermore, it aligns with industry standards, promoting compatibility, efficiency, and safety throughout the drilling process.As China continues to innovate and excel in manufacturing, its API Shaker Screens have become increasingly popular, offering a cost-effective solution for global drilling operations. When selecting a screen for your shale shaker system, consider the reliable performance and durability of the FSI Shaker Screen, setting new benchmarks in the industry.Keywords: China API Shaker Screens, API Screen, FSI Shaker Screen, durability, corrosion resistance, heat resistance, compliance, manufacturing, drilling operations, oil and gas industry.

Upgraded pneumatic agitators with 15:1 gear drive reducer for improved efficiency and lower air consumption

Binks, a leading manufacturer of fluid handling equipment based in Glendale Heights, Illinois, has recently announced an upgrade to their pneumatic agitators. The new agitators feature a more efficient 15:1 worm gear drive reducer, replacing the previous 20:1 ratio. This upgrade allows for reduced air consumption while maintaining the desired mixing speeds.The upgraded agitators are designed for use with various containers such as pails, drums, and pressure tanks. They are suitable for a range of applications in industries such as coatings, adhesives, sealants, and other fluid-based manufacturing processes. The new units are available in both fixed speed and variable speed models.One of the key advantages of the new 15:1 worm gear drive reducer is the reduction in air consumption. By optimizing the gear ratio, Binks has succeeded in achieving the desired mixing speeds with less air pressure and consumption. This improvement not only saves energy but also reduces operational costs for users.The variable speed model offers additional benefits by allowing users to adjust the mixing speed according to their specific requirements. With variable speed control, operators have greater flexibility and control over their mixing processes, ensuring consistent and precise results.Binks, known for its innovation and commitment to providing high-quality products, has also introduced a brand-new fluid agitator in conjunction with these agitator upgrades. The fluid agitator incorporates the latest technology and features to enhance the mixing process further.The fluid agitator comes equipped with advanced mixing blades, designed to optimize the mixing efficiency and homogeneity of the fluids. These blades, combined with the upgraded agitator's reduced air consumption, enable users to achieve superior mixing performance and product quality.Additionally, the fluid agitator boasts a user-friendly design, allowing for easy installation and maintenance. Its robust construction ensures durability, making it suitable for demanding industrial environments. With features like quick-release clamps and seals, operators can conveniently access the agitator's components for cleaning and maintenance purposes, minimizing downtime and maximizing productivity.Binks is proud to offer these upgraded pneumatic agitators and the new fluid agitator as part of their commitment to meeting the evolving needs of their customers. With a legacy of over 130 years in the industry, the company has continuously focused on developing innovative solutions to improve fluid handling processes and deliver exceptional performance.Clients across various industries can now benefit from the reduced air consumption, improved mixing efficiency, and user-friendly design offered by these upgraded agitators. Whether it's for small-scale operations or large-scale manufacturing, Binks provides reliable and efficient agitators that meet the highest industry standards.In conclusion, Binks' upgraded pneumatic agitators with the more efficient 15:1 worm gear drive reducer offer improved performance and reduced air consumption. The variable speed model allows for greater control and flexibility, catering to a wide range of mixing requirements. The introduction of the new fluid agitator complements these upgrades, providing advanced mixing technology and user-friendly features. With these enhancements, Binks continues to be at the forefront of delivering innovative solutions for efficient fluid handling in various industries.

Efficient Mud Cleaning Machine for Industrial Use

The demand for efficient and cutting-edge technology in the oil and gas industry has been on the rise in recent years. In response to this, (Company Name), a leading provider of oilfield equipment and services, has announced the launch of their latest innovation - the Mud Cleaning Machine.The Mud Cleaning Machine is a state-of-the-art equipment that is designed to effectively clean mud, remove solids, and separate valuable drilling fluids during the oil and gas drilling process. This machine has been meticulously engineered to offer superior performance, maximum efficiency, and cost-effectiveness, making it an essential tool for oil and gas companies looking to enhance their drilling operations.With an increasing focus on sustainability and environmental responsibility, the Mud Cleaning Machine also features advanced technology that ensures minimal waste and environmental impact. (Company Name) is proud to offer this innovative solution to the industry, which embodies their commitment to delivering high-quality, environmentally conscious products and services.Furthermore, the Mud Cleaning Machine is part of (Company Name)'s comprehensive suite of oilfield equipment and services, which includes a range of products such as shale shakers, centrifuges, and pumps. Each product is designed and manufactured with the latest technology and industry standards in mind, ensuring superior performance and reliability in all drilling operations.In addition to their cutting-edge equipment, (Company Name) is distinguished by their team of experienced and highly skilled engineers, technicians, and support staff. With a wealth of industry knowledge and expertise, they provide custom solutions and technical support to meet the unique needs of their clients and ensure seamless integration of their products into existing operations.(Company Name) is a global leader in providing comprehensive oilfield equipment and services, with a commitment to delivering innovative, reliable, and environmentally conscious solutions to the oil and gas industry. Their dedication to excellence and customer satisfaction has earned them a solid reputation and a loyal client base worldwide.The launch of the Mud Cleaning Machine is a testament to (Company Name)'s ongoing commitment to innovation and excellence. This state-of-the-art equipment promises to revolutionize the drilling process, offering unparalleled efficiency and performance that will ultimately translate to cost savings and improved productivity for their clients.In conclusion, the introduction of the Mud Cleaning Machine is a significant milestone for (Company Name) and the oil and gas industry as a whole. This cutting-edge equipment, combined with the company's expertise and dedication to delivering high-quality, environmentally conscious solutions, has the potential to make a lasting impact in the field of oil and gas drilling. It is a reflection of (Company Name)'s commitment to driving innovation and excellence in the industry, and a testament to their ongoing leadership and success as a global provider of oilfield equipment and services.

Innovative PWP Screen Technology Revolutionizes the Industry

Hyperpool PWP Screen, a cutting-edge product in the field of oil and gas solids control, has been making waves in the industry with its innovative design and superior performance. Developed by a leading company in the oil and gas equipment manufacturing sector, this product is set to revolutionize the way drilling operations are conducted, providing a more efficient and cost-effective solution for managing drilling waste.The company behind Hyperpool PWP Screen is a renowned name in the industry, known for its commitment to quality and excellence. With years of experience and expertise in oil and gas equipment manufacturing, the company has established itself as a leader in providing innovative solutions for drilling operations. Its extensive portfolio of products and services includes a wide range of equipment designed to enhance the efficiency and effectiveness of drilling processes.Hyperpool PWP Screen is the latest addition to the company's product lineup, and it has already garnered significant attention for its impressive features and benefits. The screen is designed to effectively remove solids from drilling fluids, ensuring a clean and consistent flow that is essential for optimal drilling performance. Its high-quality construction and durable materials make it a reliable and long-lasting solution for solids control, reducing downtime and maintenance costs for drilling operations.One of the key features of Hyperpool PWP Screen is its advanced design, which is engineered to maximize the use of available screen area and prolong the service life of the screen. This ensures that the screen delivers superior performance over an extended period, offering a cost-effective solution for managing drilling waste. Its high flow rates and exceptional solids removal capability make it an ideal choice for demanding drilling applications, where efficient solids control is crucial for successful operations.In addition to its exceptional performance, Hyperpool PWP Screen also offers easy installation and maintenance, reducing the overall operational costs for drilling companies. Its user-friendly design and compatibility with a wide range of drilling equipment make it a versatile and practical solution for various drilling operations. Furthermore, the screen is designed to withstand the harsh conditions of drilling environments, ensuring reliable performance even in the most challenging situations.The company behind Hyperpool PWP Screen is committed to providing exceptional support and service to its customers, ensuring that they receive the highest level of satisfaction with their investment. With a global network of service centers and technical experts, the company is well-equipped to provide prompt assistance and maintenance for its products, further enhancing the overall value of Hyperpool PWP Screen for its customers.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, Hyperpool PWP Screen is well positioned to become a leading choice for drilling companies around the world. Its innovative design, exceptional performance, and reliable support make it a compelling solution for improving drilling operations and reducing operational costs.With its strong reputation and commitment to excellence, the company behind Hyperpool PWP Screen is set to further solidify its position as a leader in providing innovative and reliable solutions for the oil and gas industry. As it continues to expand its product offerings and enhance its capabilities, the company is poised to play a key role in shaping the future of drilling operations and solids control.

High Quality Shaker Screens for Improved Processing Efficiency

Shaker screens are an integral part of the oil and gas drilling process, helping to separate solids and fluids and ensure smooth and efficient operations. One company at the forefront of shaker screen technology is {}. They have been providing high-quality, reliable shaker screens to the oil and gas industry for many years, and their commitment to innovation and excellence has made them a trusted partner for drilling companies around the world.{} is known for their advanced shaker screen designs, which are carefully engineered to maximize efficiency and performance. Their screens are made from durable materials that can withstand the harsh conditions of drilling operations, and they undergo rigorous testing to ensure that they meet the highest standards of quality and reliability.One of the key advantages of using {} shaker screens is their ability to improve the overall efficiency of the drilling process. By effectively separating solids from fluids, their screens help to reduce waste and minimize downtime, ultimately leading to cost savings for drilling companies. In addition, {} screens are designed to be easy to install and maintain, further enhancing their value to their customers.Recently, {} introduced a new line of shaker screens that have been met with great enthusiasm from the industry. These screens feature advanced technology that allows for even greater efficiency and performance, and they have been carefully designed to meet the specific needs of today's drilling operations. With this new line of shaker screens, {} continues to demonstrate their commitment to innovation and their ability to stay ahead of the curve in the rapidly evolving oil and gas industry.In addition to their cutting-edge shaker screens, {} is also known for their exceptional customer service. They work closely with their clients to understand their unique needs and challenges, and they are dedicated to providing customized solutions that deliver real results. Whether it's recommending the right type of shaker screen for a particular drilling operation or providing technical support and assistance, {} goes above and beyond to ensure that their customers have the support they need to succeed.{}'s reputation for excellence in the shaker screen industry has made them a go-to choice for drilling companies looking for reliable, high-performance equipment. Their commitment to quality, innovation, and customer service sets them apart from their competitors, and they continue to be a driving force in the evolution of shaker screen technology.As the demand for oil and gas continues to grow, the need for efficient and reliable drilling equipment becomes increasingly important. With {}'s advanced shaker screens and dedication to excellence, they are well-positioned to meet the needs of the industry and continue to be a leader in the field. Their continued innovation and commitment to their customers make them a valuable partner for drilling companies around the world, and they are poised to make even greater contributions to the oil and gas industry in the years to come.