High-Quality Centrifugal Water Pumps Manufactured in China

By:Admin

The new Centrifugal Water Pumps are designed to meet the growing demand for efficient and reliable pumping solutions in water treatment, agricultural irrigation, and industrial processes. These pumps are built to deliver high flow rates and are capable of handling large volumes of water with ease. With a robust design and high-quality materials, the Centrifugal Water Pumps from China Pumps are built to withstand the most demanding applications.

The launch of the new line of Centrifugal Water Pumps is a testament to China Pumps' commitment to providing cutting-edge solutions to their customers. The company has a strong track record of delivering high-performance pumps that meet the needs of a wide range of industries. With a focus on continuous improvement and innovation, China Pumps is constantly striving to push the boundaries of what is possible in the world of pumping technology.

In addition to their new line of Centrifugal Water Pumps, China Pumps offers a comprehensive range of pumping solutions for various applications. From submersible pumps to sewage pumps, the company's product portfolio is designed to cater to the unique needs of their customers. With a team of experienced engineers and technicians, China Pumps is able to provide customized pumping solutions to meet specific requirements.

The company's dedication to quality and reliability is evident in their state-of-the-art manufacturing facilities. China Pumps has invested heavily in advanced manufacturing technologies to ensure that their pumps meet the highest standards of quality. This commitment to excellence has earned China Pumps a solid reputation as a trusted partner for businesses looking for reliable pumping solutions.

With a strong focus on customer satisfaction, China Pumps provides comprehensive after-sales support to ensure that their customers get the most out of their pumping systems. The company's team of experts is available to provide technical assistance, maintenance services, and spare parts to keep their pumps running at peak performance.

As China Pumps continues to expand its presence in the global market, the company is poised to become a leading player in the pumping industry. With a strong focus on innovation, quality, and customer service, China Pumps is well-positioned to meet the evolving needs of businesses in various industries.

With the launch of their new line of Centrifugal Water Pumps, China Pumps is set to further solidify their position as a trusted provider of high-performance pumping solutions. As businesses continue to seek efficient and reliable pumping solutions, China Pumps is ready to meet the demand with their innovative and high-quality pumps.

In conclusion, China Pumps' new line of Centrifugal Water Pumps demonstrates the company's commitment to providing cutting-edge pumping solutions to their customers. With a focus on innovation, quality, and customer satisfaction, China Pumps is well-positioned to meet the evolving needs of businesses in various industries. As the company continues to expand its presence in the global market, China Pumps is set to become a leading player in the pumping industry.

Company News & Blog

Top Shale Shakers for Effective Oil and Gas Solids Control

In recent years, the oil and gas industry has seen tremendous advancements in drilling technology and equipment. One such innovation that has had a significant impact on the industry is the development of shale shakers. Shale shakers are vital pieces of equipment used in the drilling process to remove large solids from drilling fluid. They play a crucial role in maintaining the efficiency of the drilling operation and preventing damage to downstream equipment.One company that has been at the forefront of developing state-of-the-art shale shakers is {}. With decades of experience in the oil and gas industry, {} has established itself as a leading manufacturer and supplier of high-quality drilling equipment, including shale shakers.{} offers a wide range of shale shakers that are designed to meet the specific needs of various drilling operations. Their advanced shakers are equipped with cutting-edge technology and innovative features that make them highly efficient and reliable. The company's commitment to quality and excellence has made its shale shakers a preferred choice among drilling contractors and operators around the world.{}'s shale shakers are built to withstand the harsh and demanding conditions of drilling operations. They are constructed using high-grade materials and are rigorously tested to ensure their performance and durability. The company's engineering team continuously works on improving the design and functionality of their shale shakers to keep up with the evolving needs of the industry.One of the key features of {}'s shale shakers is their ability to effectively separate solids from drilling fluid, ensuring that the fluid maintains its properties for efficient drilling. This not only helps in reducing the overall cost of the operation but also minimizes the environmental impact associated with drilling activities. The company's commitment to sustainability is reflected in the design and performance of their shale shakers.Furthermore, {} provides comprehensive support and maintenance services for its shale shakers, ensuring that they continue to operate at peak efficiency throughout their lifecycle. The company's team of experts is readily available to provide technical assistance and on-site support to address any issues or concerns that may arise with the equipment.In addition to shale shakers, {} offers a complete range of drilling equipment and services, making it a one-stop solution for the industry's needs. From mud pumps to mud cleaners, the company's product portfolio is designed to cater to all aspects of the drilling process. This comprehensive approach has made {} a trusted partner for many drilling contractors and operators worldwide.With a strong focus on quality, innovation, and customer satisfaction, {} continues to set new standards in the drilling equipment industry. The company's dedication to delivering high-performance, reliable, and environmentally friendly products has earned it a stellar reputation in the market.In conclusion, the development of shale shakers has revolutionized the drilling industry, and companies like {} have played a pivotal role in this transformation. With their cutting-edge technology, uncompromising quality, and commitment to customer satisfaction, {}'s shale shakers have become indispensable equipment for drilling operations around the world. As the industry continues to evolve, {} is well-positioned to lead the way in providing innovative solutions that meet the ever-changing needs of the oil and gas sector.

Exploring the Efficiency of Mud Shale Shakers in China's Drilling Industry

China Mud Shale Shakers and Mud Shale Shaker: Making Oil Drilling Faster and CleanerShale shakers are used to separate drilling cuttings from drilling mud, which is essential for the smooth functioning of oil drilling operations. China Mud Shale Shakers and Mud Shale Shaker are two of the leading manufacturers of shale shakers. Their high-quality products have won the hearts of many clients in the oil and gas industry, including drilling contractors, rig manufacturers, and oil companies. This article will take a closer look at these two companies and their products.China Mud Shale ShakersChina Mud Shale Shakers was established in 1954 and is one of the oldest shale shaker manufacturers in China. The company is headquartered in Tangshan, Hebei Province. It has a state-of-the-art manufacturing plant and a team of highly qualified engineers and technicians. The company is committed to providing its clients with innovative and efficient solutions for drilling waste management.China Mud Shale Shakers offers a wide range of shale shakers, including linear motion shale shakers, balanced elliptical motion shale shakers, and dual motion shale shakers. All of their products are designed to handle high-capacity solids and offer low maintenance costs. The company has a strong focus on research and development and has several patents to its name.One of the flagship products of China Mud Shale Shakers is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique screen deck with a three-layer structure. The top layer is used for coarse screening, the middle layer for fine screening, and the bottom layer for final recovery of the mud. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.Mud Shale ShakerMud Shale Shaker was established in 2014 and is a relatively new shale shaker manufacturer. The company is headquartered in Beijing, China, and has a modern manufacturing facility. Mud Shale Shaker offers a range of high-quality shale shakers, including linear motion shale shakers and balanced elliptical motion shale shakers.Mud Shale Shaker's products are designed to handle high-capacity solids, offer low maintenance costs, and are easy to operate. The company has a strong focus on customer service and aims to build long-term relationships with its clients. Mud Shale Shaker's products have won many accolades and are well-regarded in the oil and gas industry.One of the flagship products of Mud Shale Shaker is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique dual-motor configuration, which ensures high screening efficiency and reduced vibration. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.ConclusionIn conclusion, China Mud Shale Shakers and Mud Shale Shaker are two highly respected shale shaker manufacturers in China. Both companies have a strong focus on innovation, quality, and customer service. They offer a range of high-quality shale shakers that are designed to handle high-capacity solids and offer low maintenance costs. Whether you are a drilling contractor, rig manufacturer, or an oil company, China Mud Shale Shakers and Mud Shale Shaker can provide you with innovative and efficient solutions for drilling waste management.

Powerful Cyclone Desander - Protect Your Equipment and Environment

Cyclone Desander, a leading company in the field of cyclonic separation technology, has once again proven its expertise in providing innovative and efficient solutions for the oil and gas industry. With a strong focus on quality and performance, Cyclone Desander has established itself as a reliable partner for companies looking to optimize their drilling operations and enhance overall productivity.Cyclone Desander's latest success comes in the form of a groundbreaking new desanding system that has been specifically designed to effectively remove sand and other solid particles from drilling fluids, thus improving operational efficiency and reducing equipment wear and tear. This innovative solution is set to revolutionize the way companies approach solids control, offering a more cost-effective and environmentally-friendly alternative to traditional methods.One of the key features of Cyclone Desander's new system is its advanced cyclonic separation technology, which enables the efficient removal of solid particles from drilling fluids using centrifugal force. This results in cleaner, more fluid drilling fluids that are better suited for use in the drilling process. By minimizing the presence of abrasive particles in the fluid, the system helps to prolong the lifespan of drilling equipment and reduce the risk of damage during operations.In addition to its superior performance, Cyclone Desander's desanding system also stands out for its compact design and ease of installation. The system can be seamlessly integrated into existing drilling setups, minimizing downtime and ensuring a smooth transition to the new technology. This level of flexibility and adaptability is a testament to Cyclone Desander's commitment to providing practical and user-friendly solutions that meet the evolving needs of the industry.Furthermore, Cyclone Desander places a strong emphasis on sustainability and environmental responsibility. By effectively managing solid waste and reducing the need for chemical additives in drilling fluids, the company's desanding system contributes to a more eco-friendly approach to drilling operations. This focus on sustainability aligns with the growing demand for greener practices within the oil and gas industry, positioning Cyclone Desander as a forward-thinking leader in the field.The success of Cyclone Desander's desanding system can also be attributed to the company's extensive expertise and commitment to research and development. The team at Cyclone Desander comprises highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation and continuously improving their product offerings. This culture of excellence and continuous improvement has enabled Cyclone Desander to stay ahead of the curve in an ever-evolving industry.Moreover, Cyclone Desander's dedication to customer satisfaction is evident in its comprehensive support and after-sales services. The company works closely with its clients to understand their specific needs and challenges, offering customized solutions that deliver tangible results. This collaborative approach has earned Cyclone Desander a reputation for reliability and trustworthiness, with a growing list of satisfied customers who have experienced the benefits of the company's cutting-edge solutions firsthand.Looking ahead, Cyclone Desander is poised to further strengthen its position as a leading provider of desanding and solids control solutions. With a focus on continuous innovation and a commitment to excellence, the company is well-equipped to meet the evolving demands of the oil and gas industry and support its clients in achieving optimal performance and efficiency.In conclusion, Cyclone Desander's latest desanding system represents a significant milestone in the company's ongoing efforts to deliver groundbreaking solutions for the oil and gas industry. With its advanced technology, practical design, and unwavering commitment to customer satisfaction, Cyclone Desander continues to set the standard for excellence in the field of cyclonic separation, solid control, and drilling fluid management. As the industry looks towards a more sustainable and efficient future, Cyclone Desander stands ready to lead the way with its innovative solutions and unwavering dedication to quality and performance.

Innovative PWP Screen Technology Revolutionizes the Industry

Hyperpool PWP Screen, a cutting-edge product in the field of oil and gas solids control, has been making waves in the industry with its innovative design and superior performance. Developed by a leading company in the oil and gas equipment manufacturing sector, this product is set to revolutionize the way drilling operations are conducted, providing a more efficient and cost-effective solution for managing drilling waste.The company behind Hyperpool PWP Screen is a renowned name in the industry, known for its commitment to quality and excellence. With years of experience and expertise in oil and gas equipment manufacturing, the company has established itself as a leader in providing innovative solutions for drilling operations. Its extensive portfolio of products and services includes a wide range of equipment designed to enhance the efficiency and effectiveness of drilling processes.Hyperpool PWP Screen is the latest addition to the company's product lineup, and it has already garnered significant attention for its impressive features and benefits. The screen is designed to effectively remove solids from drilling fluids, ensuring a clean and consistent flow that is essential for optimal drilling performance. Its high-quality construction and durable materials make it a reliable and long-lasting solution for solids control, reducing downtime and maintenance costs for drilling operations.One of the key features of Hyperpool PWP Screen is its advanced design, which is engineered to maximize the use of available screen area and prolong the service life of the screen. This ensures that the screen delivers superior performance over an extended period, offering a cost-effective solution for managing drilling waste. Its high flow rates and exceptional solids removal capability make it an ideal choice for demanding drilling applications, where efficient solids control is crucial for successful operations.In addition to its exceptional performance, Hyperpool PWP Screen also offers easy installation and maintenance, reducing the overall operational costs for drilling companies. Its user-friendly design and compatibility with a wide range of drilling equipment make it a versatile and practical solution for various drilling operations. Furthermore, the screen is designed to withstand the harsh conditions of drilling environments, ensuring reliable performance even in the most challenging situations.The company behind Hyperpool PWP Screen is committed to providing exceptional support and service to its customers, ensuring that they receive the highest level of satisfaction with their investment. With a global network of service centers and technical experts, the company is well-equipped to provide prompt assistance and maintenance for its products, further enhancing the overall value of Hyperpool PWP Screen for its customers.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, Hyperpool PWP Screen is well positioned to become a leading choice for drilling companies around the world. Its innovative design, exceptional performance, and reliable support make it a compelling solution for improving drilling operations and reducing operational costs.With its strong reputation and commitment to excellence, the company behind Hyperpool PWP Screen is set to further solidify its position as a leader in providing innovative and reliable solutions for the oil and gas industry. As it continues to expand its product offerings and enhance its capabilities, the company is poised to play a key role in shaping the future of drilling operations and solids control.

Mud Tanks on Drilling Rig: Understanding their Importance and Functionality

Title: Mud Tanks on Drilling Rig: Enhancing Efficiency and Environmental ResponsibilityIntroduction:As the demand for oil and gas continues to rise worldwide, drilling companies are constantly seeking innovative solutions to improve efficiency, reduce costs, and minimize their environmental impact. One crucial aspect of the drilling process is the effective management of drilling fluids, or mud. In this article, we will delve into the significance of mud tanks on drilling rigs, exploring how they contribute to fluid management and the operational success of drilling companies. We will also examine the role of a leading drilling equipment provider in delivering advanced mud tank solutions that prioritize efficiency, safety, and environmental responsibility.Efficient Fluid Management:Mud tanks play a pivotal role in the drilling process, providing a centralized location for the storage, circulation, and treatment of drilling mud. These large tanks are integrated into drilling rigs and are carefully designed to meet the specific operational requirements of each drilling project. By efficiently managing the drilling fluid, mud tanks ensure the integrity of the wellbore, lubricate the drilling bit, and carry cuttings to the surface, thereby enhancing the drilling process's overall efficiency.Safety and Environmental Considerations:With increasing environmental consciousness, drilling companies are under pressure to minimize their environmental footprint. Mud tanks aid in this endeavor by effectively separating the drilling mud from the drill cuttings, allowing for proper treatment and disposal of these byproducts. This system ensures compliance with environmental regulations and facilitates responsible waste management.In addition, mud tanks are equipped with advanced safety features to protect workers and prevent accidents. These features include sensors, alarms, and containment measures that detect and mitigate any potential leaks or spills, preserving the wellbeing of the crew and surrounding environment.The Role of [Drilling Equipment Provider]:[Drilling Equipment Provider], a global leader in drilling solutions, has been at the forefront of developing state-of-the-art mud tank systems. Committed to engineering excellence, they continuously improve their products to meet the evolving needs of the industry. By deploying their cutting-edge mud tank technologies, drilling companies can optimize their operations while adhering to stringent safety and environmental standards.[Drilling Equipment Provider] employs a holistic approach, beginning with comprehensive research and development, and continuing through the manufacturing, installation, and ongoing support phases. Their mud tank systems are designed to deliver high-performance capabilities, ensuring efficient separation of liquid and solids, better fluid control, and enhanced drilling mud treatment.Moreover, [Drilling Equipment Provider]'s mud tank solutions incorporate innovative automation and monitoring features that allow for real-time data analysis. This enables drilling companies to optimize their fluid management, detect any potential issues promptly, and make data-driven decisions to ensure continuous operations.Conclusion:Mud tanks constitute a critical element in the drilling process, playing a significant role in enhancing efficiency, safety, and environmental responsibility. By partnering with industry leaders like [Drilling Equipment Provider], drilling companies can gain access to cutting-edge mud tank systems that optimize fluid management and reinforce their commitment to sustainable practices. With the continuous development of advanced technologies, the integration of highly efficient mud tank systems is ushering in a new era of drilling operations that are both productive and environmentally conscious.

Effective Mud Cleaning System for Efficient Drilling Operations

Mud Cleaning System (MCS) is a revolutionary technology that is changing the game in the oil and gas industry. This innovative system is designed to remove harmful solids from the drilling mud, ensuring that the mud is clean and free from contaminants. MCS is committed to providing cost-effective solutions for the oil and gas industry, and its cutting-edge technology is setting new standards for efficiency and safety.The company behind MCS is dedicated to delivering top-quality products and services to its clients. With a team of experienced professionals and industry experts, the company has established itself as a leader in the field of mud cleaning technology. It is committed to delivering innovative solutions that are tailored to the specific needs of its clients, and its commitment to excellence has earned it a solid reputation in the industry.MCS is a game-changer for the oil and gas industry. By utilizing advanced technology and state-of-the-art equipment, MCS is able to provide a level of efficiency and effectiveness that is unprecedented in the industry. The system is designed to remove solid particles from drilling mud, ensuring that the mud is clean and free from contaminants. This not only improves the efficiency of the drilling process, but also ensures that the environment is protected from harmful pollutants.Furthermore, MCS is committed to providing cost-effective solutions for its clients. The company understands the challenges that the oil and gas industry faces, and it is dedicated to delivering solutions that are not only effective, but also affordable. By utilizing innovative technology and cutting-edge equipment, MCS is able to deliver solutions that provide maximum value for its clients.In addition to its cutting-edge technology, MCS is also dedicated to safety. The company takes the safety of its employees and clients seriously, and it has implemented strict safety protocols to ensure that its operations are conducted in a safe and responsible manner. Clients can have peace of mind knowing that MCS is committed to delivering solutions that are not only effective, but also safe for the environment and for the people involved in the drilling process.MCS is leading the way in the oil and gas industry, and its commitment to excellence has earned it a solid reputation in the field of mud cleaning technology. The company is dedicated to delivering innovative solutions that are tailored to the specific needs of its clients, and its cutting-edge technology is setting new standards for efficiency and safety. With a team of experienced professionals and industry experts, MCS is poised to continue its success and lead the industry into a new era of excellence.In conclusion, Mud Cleaning System is revolutionizing the oil and gas industry with its cutting-edge technology and commitment to excellence. The company is dedicated to providing cost-effective solutions that are tailored to the specific needs of its clients, and its commitment to safety and efficiency has earned it a solid reputation in the industry. As the industry continues to evolve, MCS is poised to lead the way with its innovative solutions and game-changing technology.

Hand Operated Centrifuge and Drilling Mud Tester in China

China-based company, X, has recently launched a revolutionary hand-operated centrifuge and drilling mud tester, which is set to make a significant impact in the drilling industry. This innovative technology is designed to provide accurate and reliable testing of drilling mud, ensuring the efficiency and safety of drilling operations.The hand-operated centrifuge and drilling mud tester is a portable and easy-to-use device, which can be operated manually without the need for any external power source. This makes it an ideal tool for use in remote locations or in areas where access to electricity is limited.The centrifuge component of the device is capable of separating different components of the drilling mud, such as solid particles and liquids, with great precision. This allows for thorough analysis of the mud, enabling users to identify any potential issues or contamination that may affect the drilling process.Furthermore, the drilling mud tester is equipped with advanced sensors and measurement tools, which provide accurate data on the viscosity, density, and other key properties of the drilling mud. This information is crucial for ensuring the stability and effectiveness of the drilling operation.The hand-operated centrifuge and drilling mud tester is the result of extensive research and development by X, a leading manufacturer of drilling equipment and tools. With a strong focus on innovation and quality, the company has established itself as a trusted provider of cutting-edge solutions for the drilling industry.X has a proven track record of delivering reliable and efficient products to its customers, and the hand-operated centrifuge and drilling mud tester is no exception. The device is built to withstand the harsh conditions of drilling operations, with rugged construction and durable materials that ensure long-lasting performance.Furthermore, X provides comprehensive training and support for its products, ensuring that customers are able to make the most of their investment. The company’s team of technical experts is available to provide guidance on the operation and maintenance of the hand-operated centrifuge and drilling mud tester, as well as any other products in their extensive lineup.In addition to its commitment to quality and customer support, X is also dedicated to the implementation of sustainable and environmentally friendly practices in its operations. The hand-operated centrifuge and drilling mud tester is designed with this in mind, with energy-efficient features and a minimal environmental footprint.As a result of its numerous advantages and benefits, the hand-operated centrifuge and drilling mud tester is expected to be well-received by drilling companies and professionals around the world. Its portability, ease of use, and accurate testing capabilities make it an indispensable tool for ensuring the success of drilling operations.In conclusion, the launch of the hand-operated centrifuge and drilling mud tester by X represents a significant advancement for the drilling industry. With its innovative technology, robust construction, and comprehensive support, this device is set to become a vital asset for drilling companies and professionals seeking to enhance the efficiency and safety of their operations. X continues to demonstrate its commitment to delivering superior solutions for the drilling industry, and the hand-operated centrifuge and drilling mud tester is a prime example of this dedication.

Complete Guide to Pump Parts Manual: Everything You Need to Know

Mission Pump Parts Manual Now Available for CustomersThe renowned company, {}, has recently announced the release of its much-awaited Mission Pump Parts Manual. This comprehensive manual is designed to provide customers with detailed information on how to effectively maintain and troubleshoot their Mission pumps.The release of the Mission Pump Parts Manual is a reflection of the company’s commitment to providing exceptional customer service and support. With this manual, customers can expect to have access to a wealth of information that will enable them to maximize the performance and longevity of their Mission pumps.The Mission Pump Parts Manual covers a wide range of topics, including pump installation, operation, maintenance, and troubleshooting. It also provides detailed diagrams and technical specifications for all the parts and components of the Mission pumps, making it easier for customers to identify and address any issues that may arise.In addition to the detailed technical information, the manual also includes helpful tips and recommendations for maintaining and servicing Mission pumps. Customers will find step-by-step instructions for routine maintenance tasks, as well as guidance on how to diagnose and address common pump problems.One of the key features of the Mission Pump Parts Manual is its user-friendly layout and easy-to-follow instructions. Whether customers are experienced pump operators or new to the world of pump maintenance, they will find the manual to be an invaluable resource for keeping their Mission pumps in top condition.{} has been a leader in the pump industry for over 50 years, providing high-quality pumps and exceptional service to customers around the world. The release of the Mission Pump Parts Manual is yet another example of the company’s dedication to meeting the needs of its customers and ensuring the long-term reliability of its products.The company is known for its extensive product line, which includes a wide range of pumps for various applications, including oil and gas, mining, wastewater treatment, and industrial processes. With a focus on innovation and quality, {} has earned a reputation for excellence in the pump industry.The Mission Pump Parts Manual is now available to all customers and can be accessed through the company’s website or by contacting their customer service department. Customers are encouraged to take advantage of this valuable resource to ensure the optimal performance of their Mission pumps.In addition to the Mission Pump Parts Manual, {} also offers a range of other resources and support services for its customers. From technical support and training programs to aftermarket parts and field services, the company is committed to being a reliable partner for all of its customers’ pump needs.With the release of the Mission Pump Parts Manual, {} has once again demonstrated its dedication to providing exceptional service and support to its customers. The company’s strong commitment to customer satisfaction and product excellence sets it apart as a leader in the pump industry, and customers can be confident in the reliability and performance of their Mission pumps.

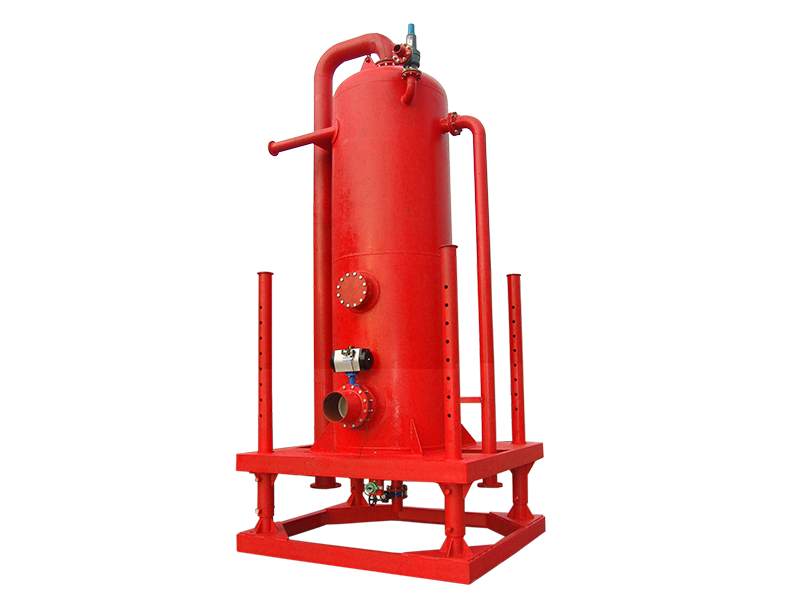

Effective Mud Gas Separator for Oil and Gas Drilling Operations

[Company Name] Introduces New Mud Gas Separator for Safer Drilling Operations[City, State] - [Company Name], a global leader in drilling equipment and technology, has introduced a new Mud Gas Separator to their extensive line of products. The Mud Gas Separator is designed to improve safety and efficiency in drilling operations, providing a reliable solution for removing harmful gases from the drilling fluid.The Mud Gas Separator is a vital component in the drilling process, as it helps to prevent the buildup of dangerous gases such as methane, carbon dioxide, and hydrogen sulfide. These gases can pose serious risks to both personnel and equipment on the drilling rig, making the efficient removal of these gases a top priority. With the introduction of their new Mud Gas Separator, [Company Name] aims to provide their customers with a state-of-the-art solution to effectively manage gas while drilling.The [Company Name] Mud Gas Separator features a high-efficiency design that effectively separates and vents gas from the drilling fluid, ensuring a safe and controlled environment on the rig. This advanced technology reduces the risk of gas-related incidents and improves overall drilling performance. Additionally, the Mud Gas Separator is built to withstand the harsh conditions of drilling operations, offering durability and reliability in the field.[Company Name] has a long-standing reputation for delivering innovative and high-quality equipment to the oil and gas industry. With a focus on safety, efficiency, and environmental stewardship, the company continues to develop cutting-edge solutions to meet the evolving needs of their customers. The introduction of the Mud Gas Separator is a testament to their commitment to providing industry-leading equipment that enhances operational performance and minimizes risk."We are thrilled to introduce our new Mud Gas Separator to the market," said [Spokesperson], [Title] at [Company Name]. "Safety is a top priority for us, and we believe that this new product will significantly improve the safety and efficiency of drilling operations. The Mud Gas Separator is a testament to our dedication to providing reliable solutions that address the challenges our customers face in the field."In addition to the Mud Gas Separator, [Company Name] offers a comprehensive range of drilling equipment and services, including drilling rigs, drilling tools, well control systems, and more. Their global presence and extensive industry expertise make them a trusted partner for drilling contractors and operators around the world.As the oil and gas industry continues to push the boundaries of exploration and production, the demand for advanced equipment that enhances safety and performance remains strong. With the introduction of the Mud Gas Separator, [Company Name] is well-positioned to meet this demand and support the industry in achieving its goals.For more information about the [Company Name] Mud Gas Separator and their complete range of drilling solutions, visit [website].

Effective Desander Liquid for Removal of Sediment and Debris

Desander Liquid (name of the company) is revolutionizing the oil and gas industry with its innovative solutions for separating sand and other solid particles from drilling fluid. Their cutting-edge technology not only improves the efficiency of drilling operations but also reduces costs and environmental impact.The company, founded in 2005, has quickly become a leader in the field of solids control and drilling waste management. Their team of experts has developed a range of products and services to address the challenges faced by the oil and gas industry, including the efficient removal of sand and other solid particles from drilling fluid.One of the company's flagship products is the Desander Liquid, a state-of-the-art system that effectively separates sand and other solid particles from drilling fluid. This innovative solution not only improves the performance of drilling operations but also reduces the environmental impact of drilling activities. By removing solid particles from drilling fluid, the Desander Liquid helps to minimize the amount of waste generated during drilling operations, leading to a more sustainable and environmentally friendly approach to oil and gas production.The Desander Liquid is designed to be highly efficient and durable, capable of handling high volumes of drilling fluid while effectively removing solid particles. This results in improved drilling performance, reduced downtime, and lower maintenance costs for drilling equipment. In addition, the Desander Liquid helps to protect downstream equipment and processes by ensuring that the drilling fluid is free from sand and other solid particles.One of the key features of the Desander Liquid is its ability to adapt to a wide range of drilling conditions. Whether drilling in shallow or deep waters, onshore or offshore, in arctic or tropical climates, the Desander Liquid can be customized to meet the specific requirements of each drilling operation. This adaptability makes it an ideal solution for oil and gas companies operating in diverse and challenging environments.In addition to its innovative products, Desander Liquid also provides a range of services to support the oil and gas industry. Their team of experts offers consulting, training, and technical support to help companies optimize their drilling operations and minimize environmental impact. By working closely with their clients, Desander Liquid ensures that their solutions are tailored to meet the unique needs of each drilling operation.Desander Liquid has built a strong reputation for delivering high-quality products and services that improve the efficiency, sustainability, and environmental performance of drilling operations. Their commitment to innovation, quality, and customer satisfaction has earned them the trust and loyalty of some of the world's leading oil and gas companies.As the oil and gas industry continues to face increasing pressure to improve environmental performance and reduce costs, the innovative solutions offered by Desander Liquid are likely to play a crucial role in driving the industry forward. By providing efficient and sustainable solutions for separating sand and other solid particles from drilling fluid, Desander Liquid is helping to pave the way for a more sustainable and environmentally friendly future for the oil and gas industry.