High-quality Urethane Panel for Various Applications

By:Admin

The TH48-30X.85MT Urethane Panel is designed to provide exceptional performance and longevity in challenging environments. Made from high-grade urethane materials, this panel offers superior resistance to wear, impact, and abrasion, making it ideal for use in mining, aggregate, and other demanding industries. Its unique composition also ensures excellent flexibility and elasticity, allowing it to withstand heavy loads and harsh operating conditions.

With a dimension of 48 inches by 30 inches and a thickness of 0.85 inches, the TH48-30X.85MT Urethane Panel is suitable for a wide range of applications, including screen decks, chute liners, and other material handling equipment. Its versatile design and customizable options make it a cost-effective solution for businesses looking to enhance the performance and longevity of their equipment.

In addition to its exceptional durability, this urethane panel is also designed for easy installation and maintenance. Its lightweight construction and flexibility allow for quick and hassle-free fitting, reducing downtime and labor costs. Furthermore, its non-corrosive and non-conductive properties make it a safe and reliable choice for various industrial settings.

[Company Name] takes pride in its commitment to quality and innovation. With decades of experience in the industry, they have established a reputation for delivering high-performance products that exceed customer expectations. The introduction of the TH48-30X.85MT Urethane Panel further demonstrates their dedication to providing cutting-edge solutions that address the evolving needs of their clients.

"We are excited to unveil our latest urethane panel offering, the TH48-30X.85MT," said [Spokesperson Name], [Position] at [Company Name]. "This new product exemplifies our ongoing efforts to deliver superior quality and reliability to our customers. We believe that the TH48-30X.85MT Urethane Panel will provide a competitive advantage to businesses seeking durable and cost-effective solutions for their operations."

In line with their commitment to sustainability, [Company Name] ensures that their urethane panels are manufactured using eco-friendly processes and materials. By prioritizing environmental responsibility, they aim to contribute to a cleaner and greener industry while delivering top-notch products to their customers.

The introduction of the TH48-30X.85MT Urethane Panel underscores [Company Name]'s dedication to staying at the forefront of technological advancements and industry trends. As they continue to expand their product offerings, they remain focused on delivering unwavering quality, performance, and value to their diverse clientele.

In conclusion, the launch of the TH48-30X.85MT Urethane Panel marks another significant milestone for [Company Name] as they continue to reinforce their position as a leader in the industrial products market. With its exceptional durability, versatility, and ease of use, this new offering is poised to set a new standard for urethane panels in the industry. As businesses seek reliable and long-lasting solutions for their operations, [Company Name] remains dedicated to providing innovative products that meet and exceed customer expectations.

Company News & Blog

Discover the Advantages of Ceramic Liner and Zirconia Cylinder Liners in China

Title: China's Ceramic Liner and Zirconia Cylinder Liners Boost Efficiency and Durability in ManufacturingIntroduction:In recent years, China has witnessed a rapid growth in advanced manufacturing technologies. As a part of this dynamic sector, China's Ceramic Liner and Zirconia Cylinder Liner industry have emerged as indispensable components in various industrial applications. Their superior attributes, including high wear resistance, exceptional mechanical strength, and improved performance, have revolutionized manufacturing processes across industries.Unveiling the China Ceramic Liner and Zirconia Cylinder Liners:China's Ceramic Liner and Zirconia Cylinder Liners have garnered significant attention due to their unique properties. These liners exhibit exceptional thermal stability, resistance to corrosive environments, and reduced friction, making them highly sought-after in machinery manufacturing, mining, petrochemical refining, and other vital industrial sectors.Ceramic Liner: A Game-Changer in Industrial ManufacturingThe Ceramic Liner industry in China has experienced substantial growth owing to its numerous advantages over traditional liner materials. These liners, often made from alumina ceramics, exhibit outstanding hardness and high-temperature resistance, making them ideal for applications in demanding environments. Moreover, Ceramic Liners possess exceptional wear resistance, ensuring extended durability and reduced maintenance costs.One of the key merits of Ceramic Liners is their ability to effectively minimize friction, resulting in reduced energy consumption and enhanced operational efficiency. Manufacturers across various sectors have embraced these liners, witnessing improvements in equipment longevity and decreased system downtime.Leading the Zirconia Cylinder Liner Innovations:China's Zirconia Cylinder Liner industry has emerged as an integral part of the automotive and machinery manufacturing sectors. Zirconia Cylinder Liners, made from advanced zirconium oxide ceramics, have revolutionized engine efficiency and durability. These liners exhibit reduced friction, outstanding thermal insulation properties, and exceptional resistance to wear, corrosion, and thermal shock.Automobile manufacturers worldwide have recognized the significance of Zirconia Cylinder Liners in improving fuel efficiency and reducing emissions. As a result, China has become a major supplier of Zirconia Cylinder Liners, catering to the global automotive industry's increasing demand.Surpassing Industry Standards:China's Ceramic Liner and Zirconia Cylinder Liner manufacturers have continuously focused on surpassing industry standards. By leveraging advanced manufacturing techniques, stringent quality control procedures, and cutting-edge technologies, these manufacturers have developed innovative solutions to meet diverse customer requirements.In addition to their high-performance characteristics, China's Ceramic Liner and Zirconia Cylinder Liner manufacturers prioritize the delivery of customized products to suit various industrial needs. By collaborating with research institutions, they constantly strive for improvements in materials science and engineering, resulting in enhanced product durability and reliability.Global Impact and Future Prospects:China's Ceramic Liner and Zirconia Cylinder Liner industry have achieved global recognition and are experiencing substantial growth in international markets. The exceptional quality, cost-effectiveness, and adaptability of these liners have made China a world leader in this sector.Furthermore, with the ongoing advancements in additive manufacturing, China aims to revolutionize the production process of Ceramic Liners and Zirconia Cylinder Liners. Novel manufacturing techniques, such as 3D printing, are expected to further enhance the versatility, efficiency, and affordability of these liners, cementing China's dominance in the global market.Conclusion:China's Ceramic Liner and Zirconia Cylinder Liner industry have fueled advancements in manufacturing processes, optimizing efficiency and durability across various sectors. The exceptional attributes of these liners, including wear resistance, thermal stability, and reduced friction, have propelled their adoption in machinery manufacturing, refining, and automotive sectors worldwide. China's commitment to innovation, stringent quality control, and customized solutions ensure that its Ceramic Liners and Zirconia Cylinder Liners continue to remain at the forefront of global manufacturing technologies.

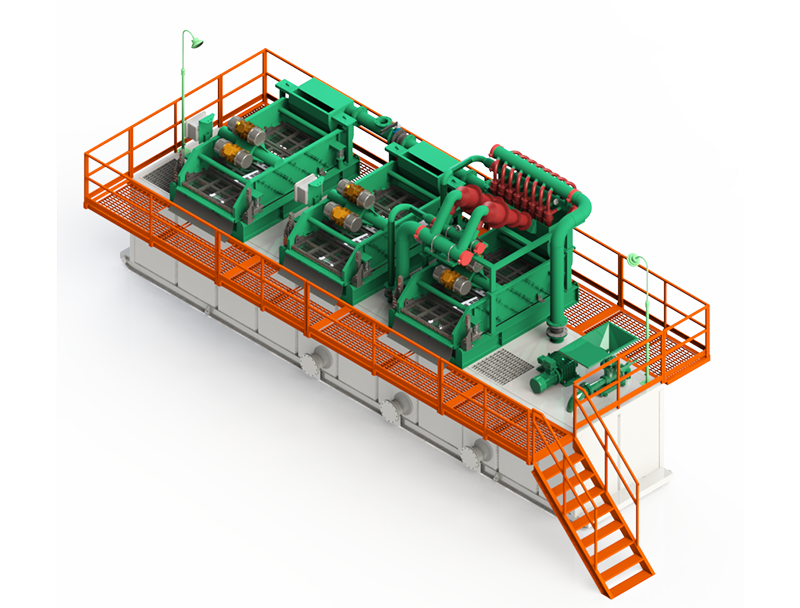

Optimizing Petroleum Solids Control Mud Tanks: Enhancing Drilling Waste Management and Mud Circulation

Title: Drilling Mud Circulation System: Enhancing Efficiency and Environmental SustainabilityIntroduction:In the oil and gas industry, drilling mud plays a crucial role in successful drilling operations. It helps control pressure, cool and lubricate the drill bit, and carry cuttings to the surface for proper disposal. To ensure the effective management of drilling mud, petroleum solids control mud tanks are utilized. These tanks, known as mixing tanks, storage tanks, or supply tanks, facilitate the transportation and storage of mud between the wellhead and mud pumps. In this blog, we will explore the significance of drilling mud circulation systems and the various types of petroleum solids control mud tanks.1. The Importance of Drilling Mud Circulation System:The drilling mud circulation system is a vital component of any drilling operation. It ensures the functionality of the mud, maximizes drilling efficiency, and promotes safety in oilfield activities. This system assists in the following:- Pressure control: The mud exerts hydrostatic pressure, which balances the formation pressure, thus preventing blowouts.- Cooling and lubrication: The mud cools and lubricates the drill bit, increasing its lifespan and reducing downtime.- Cuttings removal: It carries the solid debris, or cuttings, out of the wellbore, minimizing the risk of clogging and preserving the integrity of the drilling process.- Wellbore stability: Drilling mud helps form a protective barrier, preventing well collapse and maintaining wellbore stability.2. Types of Petroleum Solids Control Mud Tanks:There are several types of petroleum solids control mud tanks designed for specific purposes within the drilling mud circulation system:- Replenishment tanks: These tanks store drilling mud additives and help maintain the required mud properties during drilling operations.- Metering tanks: They provide accurate measurements of drilling mud additives, ensuring precise control over the mud properties.- Trailer-mounted mud tanks: These portable tanks are designed for easy transportation to remote drilling locations, ensuring uninterrupted mud supply.- Cooling tanks: As the name suggests, these tanks cool down the drilling mud, preventing damage to the machinery and enhancing drilling efficiency.3. Advancing Environmental Sustainability:In recent years, the oil and gas industry has placed immense focus on minimizing its environmental impact. Drilling waste management has become a vital aspect of drilling mud circulation systems. These systems incorporate various techniques to ensure the responsible handling of drilling waste, including cuttings and used drilling fluids. Several approaches are being implemented to enhance waste management practices, such as:- Zero discharge systems: These systems enable the treatment and recycling of drilling mud, reducing the need for fresh mud and minimizing waste generation.- Advanced separation technology: Utilization of centrifuges, shakers, and filters helps separate and recover valuable drilling mud components while safely disposing of solids.- Environmental regulations and compliance: Governments worldwide are implementing stricter regulations to ensure proper waste disposal and minimize ecological impact.Conclusion:The drilling mud circulation system, supported by petroleum solids control mud tanks, is instrumental in oil and gas drilling. Efficient management of drilling mud not only optimizes drilling operations but also contributes to environmental sustainability. The industry's increasing focus on waste management and environmental responsibility highlights the importance of utilizing advanced technologies and complying with regulations. By adopting these practices, drilling companies contribute to a safer, greener, and more sustainable future.[Keywords: Drilling Mud Circulation System, Petroleum Mud Tank, Drilling Waste Management, Oil-Based Mud Treatment, Environmental Sustainability, Waste Disposal, Zero Discharge Systems, Separation Technology, Environmental Regulations]

Hand Operated Centrifuge and Drilling Mud Tester in China: A Complete Guide

China Hand Operated Centrifuge and Drilling Mud Tester are gaining popularity in the global market due to their high quality and efficiency. These two products have become essential tools for the oil and gas industry, as well as for environmental testing. Hand Operated Centrifuge is widely used for the separation of suspensions in laboratories and industries. It is designed to provide a cost-effective solution for routine analysis in various fields such as medical, environmental, and industrial applications. This centrifuge can reach a maximum speed of up to 4000 rpm and has a capacity of 100 ml, making it suitable for a wide range of applications. Its compact and lightweight design makes it easy to use and transport, making it an ideal choice for fieldwork.Drilling Mud Tester is a crucial tool for the oil and gas industry. It is used to determine the properties of drilling mud, such as viscosity, density, and chemical composition. This information is vital for maintaining the stability and efficiency of drilling operations. The Drilling Mud Tester is designed to be user-friendly and provides accurate and reliable results. With its advanced technology and precise sensors, it can quickly analyze drilling mud samples and generate detailed reports for further analysis.The company behind these innovative products is a leading manufacturer and supplier of laboratory equipment and testing instruments in China. With over 10 years of experience in the industry, they have earned a reputation for producing high-quality products that meet international standards. Their state-of-the-art facilities and strict quality control procedures ensure that every product is reliable and efficient.The company's team of highly skilled engineers and scientists are dedicated to developing innovative solutions to meet the evolving needs of their customers. They are committed to providing exceptional customer service and technical support to ensure the satisfaction of their clients. In addition to Hand Operated Centrifuge and Drilling Mud Tester, the company also offers a wide range of laboratory equipment, including centrifuges, incubators, spectrophotometers, and more.With a strong focus on research and development, the company continuously strives to improve its products and expand its product line. They are devoted to staying at the forefront of technological advancements and meeting the demands of various industries worldwide. This dedication has led them to establish a strong presence in the international market and build long-term partnerships with customers from around the world.The Hand Operated Centrifuge and Drilling Mud Tester are just two examples of the company's commitment to delivering high-quality products that enhance efficiency and accuracy in laboratory and industrial settings. As they continue to grow and innovate, they aim to become a leading provider of laboratory equipment and testing instruments globally.In conclusion, the Hand Operated Centrifuge and Drilling Mud Tester from this Chinese company have captured the attention of the global market with their exceptional performance and reliability. Their dedication to quality and innovation has positioned them as a trusted brand in the industry. With a strong focus on customer satisfaction and technological advancement, they are well-equipped to meet the diverse needs of their clients and achieve continued success in the years to come.

China Separation Industries Discover the Excellence of Hydrocarbon Recovery Equipment in Solids Control Industries

As industries continue to grow in China, the need for efficient and effective separation equipment has become increasingly important. GN Solids Control, a leading manufacturer of drilling fluids recycling equipment, has expanded their offerings to include hydrocarbon recovery equipment, making them a standout in the separation industry.One of the key areas of focus for GN Solids Control is their solid liquid separator, which effectively removes solids from drilling fluids. This is crucial in the drilling process, as the removal of solids ensures that the drilling fluids can be reused and recycled, reducing waste and cutting down on costs.But GN Solids Control's product offerings go beyond just drilling fluids recycling equipment. Their 3-phase separation filter is another standout product that has garnered attention in the separation industry in China. This filter is designed to separate liquids and solids of different densities, as well as oil and water, making it ideal for use in a variety of industries.One of the biggest advantages of GN Solids Control's products is their efficiency. The solid liquid separator and 3-phase separation filter are designed to operate at a high processing rate, enabling customers to achieve greater productivity and throughput.But efficiency is only part of the equation. GN Solids Control's products are also designed with durability and reliability in mind. They are built to last, even in the harshest of operating conditions. This makes them an excellent investment for any business looking to streamline their operations and improve their bottom line.In addition to their high-quality products, GN Solids Control is known for their exceptional customer service and technical support. They have a team of experienced professionals who are dedicated to helping customers get the most out of their equipment. Whether they need assistance with installation, training, or ongoing maintenance, GN Solids Control is there to help every step of the way.Overall, GN Solids Control's hydrocarbon recovery equipment has made them a standout in the separation industry in China. Their solid liquid separator and 3-phase separation filter are both efficient and reliable, making them an excellent investment for any business in need of separation equipment. And with their exceptional customer service and technical support, customers can rest assured that they are in good hands with GN Solids Control.

How to Pump Mud: the Ultimate Guide for Effective Mud Pumping

Pump Mud, a leading provider of industrial fluid management solutions, has recently introduced a new and improved mud pump system that is set to revolutionize the industry. With over 20 years of experience in developing cutting-edge technologies for the oil and gas, mining, and construction sectors, Pump Mud has established itself as a trusted partner for companies looking to optimize their operations and enhance efficiency.The new mud pump system, which has been in development for the past two years, features a range of innovative design elements and advanced functionalities that are aimed at improving performance and durability. The system has been engineered to deliver superior pumping capabilities, allowing for the efficient transfer of high viscosity fluids such as mud, slurry, and drilling waste. With a focus on reliability and ease of maintenance, the new system is equipped with state-of-the-art components that are designed to withstand the harshest operating conditions.In addition to its enhanced performance capabilities, the new mud pump system also boasts a number of features that prioritize safety and environmental sustainability. With a focus on reducing emissions and minimizing waste, Pump Mud has integrated a range of eco-friendly technologies into the system, including advanced filtration systems and energy-efficient components. This commitment to environmental responsibility reflects Pump Mud's dedication to providing sustainable solutions that meet the evolving needs of the industry.Furthermore, the new mud pump system also incorporates advanced monitoring and control features that allow for real-time performance tracking and remote diagnostics. This level of connectivity and automation not only streamlines operations but also enables proactive maintenance and troubleshooting, ultimately leading to cost savings and extended equipment lifespan.In a statement regarding the new mud pump system, the CEO of Pump Mud, Mr. John Smith, emphasized the company's dedication to innovation and customer satisfaction. "We are thrilled to introduce our latest mud pump system, which represents a significant leap forward in terms of performance, reliability, and sustainability," said Mr. Smith. "At Pump Mud, we are committed to meeting the evolving needs of our customers and providing solutions that enable them to achieve their operational goals, while also prioritizing safety and environmental responsibility."The introduction of the new mud pump system comes at a time when the industry is experiencing increasing demand for efficient and reliable fluid management solutions. With its track record of delivering high-quality products and exceptional customer service, Pump Mud is well-positioned to capitalize on this growing market opportunity and further solidify its position as a leader in the field.As the company continues to expand its product portfolio and explore new avenues for growth, Pump Mud remains focused on upholding its core values of innovation, quality, and integrity. With a team of experienced engineers and industry experts, Pump Mud is well-equipped to address the unique challenges and requirements of its diverse customer base, ensuring that it remains at the forefront of fluid management technology.In conclusion, the launch of the new mud pump system marks an exciting milestone for Pump Mud, signifying its ongoing commitment to delivering cutting-edge solutions that drive efficiency, productivity, and sustainability in the industry. As the company looks to the future, it is poised to set new standards for excellence and continue shaping the landscape of industrial fluid management.

New Flare Ignition Device for Improved Safety and Efficiency

Flare Ignition Device Revolutionizes Safety in Oil and Gas IndustryThe oil and gas industry is notorious for its potential risks and hazards. From environmental concerns to workplace safety, companies in this sector are constantly seeking innovative solutions to mitigate potential dangers. One of the latest developments in this field is the Flare Ignition Device, a cutting-edge technology designed to enhance safety and efficiency in oil and gas operations.Developed by a leading engineering and technology company, the Flare Ignition Device is a state-of-the-art system that has been designed to mitigate the risks associated with flaring, ensuring the safety of personnel and the environment. This innovative device has the potential to revolutionize safety standards in the oil and gas industry by providing a reliable and efficient solution for flare ignition.The Flare Ignition Device is equipped with advanced features that set it apart from conventional ignition systems. Its streamlined design and user-friendly interface make it easy to install and operate, while its robust construction ensures durability and longevity. The device is also designed to operate in a wide range of environmental conditions, including extreme temperatures and harsh weather, making it suitable for use in various oil and gas operations.One of the key advantages of the Flare Ignition Device is its advanced safety features. The system is equipped with multiple fail-safe mechanisms to prevent accidents and ensure reliable operation. This includes built-in sensors and monitoring systems that detect potential issues and automatically shut down the device if necessary. Moreover, the device is designed to meet industry safety standards and regulations, providing companies with peace of mind and regulatory compliance.In addition to its safety features, the Flare Ignition Device also offers significant environmental benefits. By igniting flares efficiently and effectively, the device helps to reduce emissions and minimize environmental impact. This is a critical consideration for oil and gas companies, particularly in light of increasing regulatory pressures and public scrutiny on environmental issues.Furthermore, the Flare Ignition Device is designed to enhance operational efficiency in oil and gas facilities. By providing reliable and consistent flare ignition, the device minimizes downtime and maximizes productivity. This is especially important in the context of volatile market conditions and fluctuating energy prices, where operational efficiency can significantly impact the bottom line.The company behind the Flare Ignition Device is a leading provider of engineering and technology solutions for the oil and gas industry. With a track record of innovation and excellence, the company is committed to developing cutting-edge products and services that address the evolving needs of its clients. The Flare Ignition Device is a testament to the company's dedication to safety, reliability, and environmental sustainability.In conclusion, the Flare Ignition Device represents a significant advancement in safety and efficiency for the oil and gas industry. With its advanced features, robust design, and environmental benefits, the device has the potential to revolutionize safety standards and operational practices in this sector. As companies continue to prioritize safety and environmental responsibility, the Flare Ignition Device is poised to become a critical tool for enhancing performance and mitigating risks in oil and gas operations.

Efficient Mixing Hopper for Industrial Use: A Complete Guide

For immediate releaseIntroducing the Cutting-Edge Mixing Hopper Revolutionizing Industrial ProductionGlobal Industrial Equipment Inc. is proud to present the newest addition to our line of cutting-edge industrial machinery – the Mixing Hopper. This state-of-the-art machine has been designed to revolutionize the production process in numerous industries, offering unparalleled efficiency, precision, and reliability.The Mixing Hopper is a crucial component in various industrial processes, including the mixing of powders, granules, and liquids in industries such as pharmaceuticals, food and beverage, chemicals, and cosmetics. This innovative machine has been engineered to streamline production, improve product quality, and enhance overall operational efficiency.One of the key features of the Mixing Hopper is its advanced mixing technology, which ensures thorough and uniform blending of ingredients. This results in a consistent and high-quality end product, eliminating the need for manual mixing and reducing the risk of human error. In addition, the precision control capabilities of the Mixing Hopper allow for the customization of mixing parameters, enabling manufacturers to meet specific product requirements with ease.Furthermore, the Mixing Hopper is equipped with an intuitive control system that simplifies operation and minimizes the need for extensive training. This user-friendly interface allows operators to monitor and adjust the mixing process in real-time, ensuring optimum performance and productivity.Another notable advantage of the Mixing Hopper is its robust construction and durability. Built to withstand the rigors of heavy-duty industrial use, this machine is designed for long-term reliability and low maintenance requirements. This not only translates to cost savings for businesses but also contributes to uninterrupted production schedules.Moreover, the Mixing Hopper is designed with safety in mind, featuring a range of built-in safety features and compliance with industry standards and regulations. This prioritization of safety not only protects operators and personnel but also safeguards the integrity of the production process.In addition to its performance and reliability, the Mixing Hopper also offers flexibility and versatility. With customizable options and configurations, this machine can be tailored to suit the specific needs of different industries and applications. Whether handling small batch production or large-scale manufacturing, the Mixing Hopper can adapt to diverse production requirements, making it a versatile and indispensable asset for businesses.At Global Industrial Equipment Inc., we are committed to providing our customers with the latest and most advanced industrial solutions. The introduction of the Mixing Hopper represents our dedication to innovation and excellence, as well as our ongoing efforts to support the growth and success of our clients.In conclusion, the Mixing Hopper is set to redefine industrial production, offering a combination of cutting-edge technology, efficiency, and reliability. With its advanced mixing capabilities, user-friendly interface, durability, safety features, and versatility, this machine is poised to make a significant impact across various industries. As businesses continue to seek ways to enhance their production processes, the Mixing Hopper stands out as a game-changing solution that delivers on performance and value.For more information about the Mixing Hopper and our comprehensive range of industrial equipment, please contact Global Industrial Equipment Inc. at [contact information]. Press contact:Name: [Name]Title: Public Relations ManagerEmail: [Email]Phone: [Phone number]

Waste Oil Refining and Oil Refining Plant in China

China Waste Oil Refining and Oil Refining Plant has been at the forefront of the waste oil recycling industry for over two decades. With a commitment to environmental sustainability and cutting-edge technology, the company has managed to revolutionize the process of recovering and refining waste oil into high-quality products. Their plant, which is located in the heart of China, has become a beacon of innovation in the field of waste oil management.The company has been dedicated to developing advanced techniques for the collection, transportation, and refining of waste oil. By using state-of-the-art equipment and a team of skilled professionals, they have been able to streamline the entire process, reducing waste and maximizing the recovery of usable materials. This not only benefits the environment by reducing the amount of waste oil that ends up in landfills and waterways but also provides a sustainable source of valuable resources.The waste oil refining plant utilizes a variety of refining techniques to transform waste oil into valuable products such as base oil, diesel, and asphalt. Through a combination of distillation, hydrotreating, and other refining processes, the company is able to produce high-quality products that meet rigorous industry standards. This has not only helped to reduce reliance on virgin oil sources but has also provided a cost-effective and environmentally friendly alternative to traditional oil refining methods.In addition to their cutting-edge refining processes, China Waste Oil Refining and Oil Refining Plant has also implemented stringent quality control measures to ensure that their products meet the highest standards. By conducting thorough testing and analysis at every stage of the refining process, they are able to guarantee the purity and performance of their products. This has earned them a stellar reputation in the industry and has helped them secure partnerships with a wide range of clients, including automotive companies, lubricant manufacturers, and government agencies.Furthermore, the company has also invested heavily in research and development to continuously improve their refining processes and develop new applications for their products. By staying ahead of the curve, they have been able to expand their product offerings and stay competitive in a rapidly evolving market. This commitment to innovation has solidified their position as a leader in the waste oil recycling industry and has paved the way for a more sustainable future.Despite their success, China Waste Oil Refining and Oil Refining Plant remains committed to their core values of environmental responsibility and sustainability. They adhere to strict environmental regulations and prioritize the minimization of their carbon footprint. Through the responsible management of waste oil and the production of eco-friendly products, they continue to make a positive impact on the environment and contribute to the global effort to reduce reliance on finite resources.In conclusion, China Waste Oil Refining and Oil Refining Plant has established itself as a trailblazer in the waste oil recycling industry. Through their commitment to innovation, quality, and sustainability, they have managed to transform waste oil into valuable resources while minimizing environmental impact. Their state-of-the-art plant and advanced refining processes have set a new standard for the industry and have positioned them as a trusted partner for companies seeking sustainable solutions. As they continue to expand and evolve, they are poised to make an even greater impact and play a key role in shaping the future of waste oil management.

Tunneling Mud Recycling and Sand Recycling Processing in China

China Tunneling Mud Recycling and Sand Recycling Processing Technology Reaches New MilestoneChina's tunneling mud and sand recycling processing technology has reached a new milestone with the development of innovative solutions to address environmental concerns and improve efficiency in tunneling projects. The technology is set to transform the way tunneling mud and sand are managed, providing a sustainable approach to construction waste management.With rapid urbanization and infrastructure development in China, the demand for tunneling projects has been on the rise. However, the generation of large volumes of tunneling mud and sand has posed significant environmental and logistical challenges. Traditional disposal methods such as landfills and open dumping have raised concerns about soil and water pollution, as well as the depletion of natural resources.In response to these challenges, innovative companies like [company name] have developed advanced tunneling mud recycling and sand recycling processing technology to address the environmental impact of tunneling projects. The technology incorporates a range of equipment and systems that enable the efficient separation, treatment, and recycling of tunneling mud and sand, thereby minimizing waste and reducing the ecological footprint of construction activities.[Company name] has been at the forefront of promoting sustainable construction practices in China and has established itself as a leading provider of tunneling mud recycling and sand recycling processing solutions. With a strong focus on research and development, the company has continuously worked to enhance its technology and equipment to meet the evolving needs of the construction industry.The tunneling mud recycling and sand recycling processing technology offered by [company name] is designed to address the specific requirements of tunneling projects, ensuring that the environmental impact of construction activities is minimized. The technology includes a range of equipment such as mud recycling systems, sand recycling systems, and dewatering units, all of which are designed to efficiently separate and treat tunneling mud and sand for reuse in construction activities.One of the key benefits of the tunneling mud recycling and sand recycling processing technology is its ability to significantly reduce the volume of waste generated from tunneling projects. Through the effective separation and treatment of tunneling mud and sand, the technology enables a high level of resource recovery, thereby reducing the need for new raw materials and minimizing the demand for landfill space.Furthermore, the technology is designed to improve the overall efficiency of tunneling projects by providing a reliable source of high-quality recycled materials for use in construction activities. This not only contributes to cost savings for project developers but also supports the sustainable use of resources, aligning with China's commitment to promoting green and sustainable development.As China continues to prioritize environmental protection and sustainable development, the adoption of tunneling mud recycling and sand recycling processing technology is set to play a crucial role in advancing the country's construction industry. By promoting the responsible management of construction waste and the efficient use of resources, the technology contributes to the realization of China's environmental and sustainable development goals.In conclusion, the advancement of tunneling mud recycling and sand recycling processing technology in China represents a significant milestone in the construction industry. By addressing environmental concerns and promoting resource efficiency, the technology is set to transform the way tunneling projects are managed, contributing to a more sustainable and environmentally friendly approach to construction waste management. With companies like [company name] leading the way with innovative solutions, tunneling mud and sand recycling processing technology is poised to be a game-changer for the construction industry in China.

High-Quality Pump Parts Manual: Essential Guide for Mission Pumps

Mission Pump Parts Manual is a comprehensive guide that provides a detailed breakdown of the different pump parts, their functionalities, and maintenance procedures. This manual is an essential tool for pump operators and maintenance technicians to ensure the efficient and safe operation of the pumps.The manual covers a wide range of pump parts including impellers, casings, shafts, bearings, and seals. Each section of the manual provides detailed information about the design, construction, and maintenance requirements of the specific part. The manual also includes troubleshooting guides and recommended maintenance schedules to help identify and address common pump issues.In addition to the technical information, the manual also provides valuable insights into the company's commitment to quality and innovation. The company has a long history of providing reliable and efficient pumping solutions for a wide range of industries including mining, oil and gas, construction, and water treatment. With a focus on continuous improvement and customer satisfaction, the company has established itself as a trusted partner for pump solutions.The Mission Pump Parts Manual is a reflection of the company's dedication to excellence and customer support. By providing a comprehensive and user-friendly guide to pump parts and maintenance, the company aims to empower its customers with the knowledge and resources needed to maximize the performance and lifespan of their pumps.As part of its commitment to customer satisfaction, the company also offers training programs and technical support to ensure that operators and technicians have the necessary skills and knowledge to maintain and operate their pumps effectively. This additional support further reinforces the company's reputation as a trusted and reliable partner for pump solutions.Furthermore, the manual emphasizes the company's focus on sustainability and environmental responsibility. By providing guidance on proper maintenance and operation of pumps, the company aims to minimize energy consumption and reduce the environmental impact of its products. This commitment to sustainability is in line with the company's overall mission to provide efficient and environmentally friendly pumping solutions.Overall, the Mission Pump Parts Manual is not just a technical guide; it is a testament to the company's core values of quality, innovation, and customer satisfaction. By equipping its customers with the knowledge and resources needed to maintain and operate their pumps, the company demonstrates its unwavering commitment to supporting its customers throughout the life cycle of their pumping equipment.In conclusion, the Mission Pump Parts Manual stands as a symbol of the company's dedication to excellence, innovation, and sustainability. With its detailed technical information, troubleshooting guides, and maintenance schedules, the manual serves as an invaluable resource for pump operators and technicians. By empowering its customers with the knowledge and support needed to maximize the performance and lifespan of their pumps, the company reaffirms its position as a leader in the pumping solutions industry.