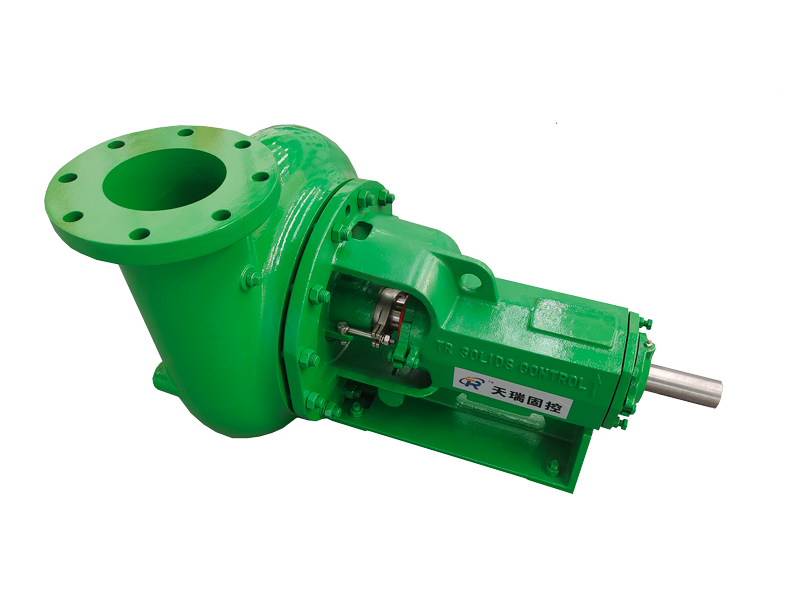

Highly Efficient 8x6x14 Centrifugal Pump for Industrial Use

By:Admin

Water is an essential part of our daily lives, and ensuring that there is a consistent and reliable supply of clean water is crucial. The company's dedication to innovation and excellence has led to the development of the 8x6x14 Centrifugal Pump, a groundbreaking solution that is set to revolutionize water supply systems.

The 8x6x14 Centrifugal Pump is a cutting-edge pump that offers superior performance and efficiency. Its innovative design and high-quality construction make it an ideal choice for a wide range of applications, including water supply, irrigation, and industrial processes. With a flow rate of up to 1200 cubic meters per hour and a head of up to 85 meters, this pump is capable of delivering high volumes of water at impressive pressures.

One of the key features of the 8x6x14 Centrifugal Pump is its compact and lightweight design. This allows for easy installation and maintenance, making it a cost-effective and user-friendly solution for water supply systems. In addition, the pump is designed to be highly durable and reliable, ensuring that it can withstand the rigors of continuous operation in demanding environments.

The company's commitment to quality and innovation is evident in the development of the 8x6x14 Centrifugal Pump. With a focus on using the latest technology and manufacturing processes, the company has been able to create a pump that sets new standards for performance and efficiency. By constantly pushing the boundaries of what is possible, the company aims to provide its customers with the most advanced and reliable pumping solutions available.

The 8x6x14 Centrifugal Pump is just one example of the company's dedication to meeting the evolving needs of the water supply industry. With a comprehensive range of pumps and pumping systems available, the company is able to offer tailored solutions for a wide variety of applications. Whether it is providing clean water to communities, supporting agricultural irrigation, or powering industrial processes, the company is committed to delivering reliable and efficient pumping solutions.

In addition to its focus on product development, the company also places a strong emphasis on customer support and service. With a global network of sales and service professionals, the company is able to provide prompt and comprehensive support to its customers around the world. This ensures that customers can rely on the company not only for innovative products but also for ongoing assistance and guidance.

The release of the 8x6x14 Centrifugal Pump represents a significant milestone for the company and the water supply industry as a whole. With its advanced design, exceptional performance, and commitment to quality, the pump is set to make a lasting impact on water supply systems. As the company continues to push the boundaries of what is possible, it is clear that it will remain at the forefront of innovation and excellence in the pumping industry.

In conclusion, the 8x6x14 Centrifugal Pump is a remarkable achievement that showcases the company's dedication to innovation and excellence. With its cutting-edge design, superior performance, and commitment to quality, the pump is set to revolutionize water supply systems around the world. As the company continues to push the boundaries of what is possible, it is clear that it will remain a leading force in the pumping industry for years to come.

Company News & Blog

Highly Efficient Glass Washing and Drying Machines from China for All Your Needs

China Glass Washing Machine and Glass Washing and Drying Machine have been making headlines in the industry recently, as their advanced technology and high-quality performance continue to impress customers. With a commitment to innovation and customer satisfaction, these machines are becoming increasingly popular in the global market.China Glass Washing Machine is a leading manufacturer of glass processing equipment, specializing in the production of glass washing machines. These machines are designed to effectively clean glass surfaces, removing dirt, dust, and other impurities to ensure a spotless finish. With their advanced technology and precise control systems, China Glass Washing Machine has set a new standard for glass washing equipment.Similarly, Glass Washing and Drying Machine has made a name for itself as a top-tier supplier of glass processing machinery. The company's glass washing and drying machines are known for their exceptional performance and reliability. With a focus on quality and efficiency, Glass Washing and Drying Machine has become a trusted partner for businesses looking to enhance their glass processing capabilities.One of the key factors contributing to the success of these machines is the use of advanced technology. China Glass Washing Machine and Glass Washing and Drying Machine have both incorporated cutting-edge features into their products, such as intelligent control systems and high-speed operation. These technological advancements have allowed the machines to deliver consistent and reliable results, meeting the rigorous demands of the industry.In addition to their technological innovations, both companies prioritize customer satisfaction. China Glass Washing Machine and Glass Washing and Drying Machine are committed to providing exceptional service and support to their clients. From initial consultation to after-sales maintenance, the companies strive to ensure a positive experience for their customers.Moreover, the machines are designed with sustainability in mind, incorporating energy-efficient solutions to minimize environmental impact. This dedication to sustainability aligns with the growing emphasis on eco-friendly practices in the industry, making China Glass Washing Machine and Glass Washing and Drying Machine a preferred choice for businesses seeking sustainable glass processing solutions.With a strong track record of performance and reliability, these machines have been embraced by customers around the world. From large-scale manufacturing facilities to small glass processing workshops, China Glass Washing Machine and Glass Washing and Drying Machine have made a significant impact on the industry.In conclusion, China Glass Washing Machine and Glass Washing and Drying Machine have emerged as leading providers of glass processing machinery, thanks to their advanced technology, commitment to customer satisfaction, and dedication to sustainability. As the demand for high-quality glass processing equipment continues to grow, these machines are well-positioned to meet the needs of the industry, setting a new standard for performance and innovation. With their impressive track record and a focus on continuous improvement, China Glass Washing Machine and Glass Washing and Drying Machine are poised to remain at the forefront of the industry for years to come.

High Performance Submersible Slurry Pump for Efficient Material Handling

Submersible Slurry Pump: An Essential Component in Dredging OperationsAs technology continues to advance, the need for more effective and efficient equipment in various industries becomes increasingly apparent. In the field of mining and dredging, the demand for submersible slurry pumps has been steadily rising. These pumps are designed to handle the challenging conditions often encountered in dredging operations, making them an essential component for companies in this sector.One company at the forefront of producing high-quality submersible slurry pumps is {}. With over 20 years of experience in the industry, {} has established itself as a leading manufacturer and supplier of pumping solutions for dredging, mining, and other related applications. The company's dedication to innovation and continuous improvement has allowed them to develop a range of submersible slurry pumps that deliver exceptional performance in even the most demanding environments.The submersible slurry pump offered by {} is specifically designed to handle the transportation of abrasive and high-density slurries. This makes it an ideal choice for dredging operations, where the pump is required to handle a variety of materials including sand, gravel, and other sediments. The robust construction of the pump, combined with its high-quality materials, ensures that it can withstand the harsh conditions typically encountered in dredging applications.One of the key advantages of the submersible slurry pump from {} is its ability to operate underwater. This capability allows for efficient dredging operations, as the pump can be submerged directly into the material being dredged. This eliminates the need for additional equipment or infrastructure to support the pump, ultimately streamlining the entire process and reducing costs for the company.In addition to its underwater capabilities, the submersible slurry pump from {} is also designed for easy maintenance and service. This is a crucial consideration for companies involved in dredging operations, where downtime can have a significant impact on productivity and profitability. By providing a pump that is easy to maintain and service, {} enables its customers to minimize the risk of costly downtime and keep their operations running smoothly.Furthermore, the submersible slurry pump from {} is equipped with advanced technology to optimize its performance. This includes features such as high-efficiency impellers, wear-resistant materials, and innovative sealing systems, all of which contribute to the pump's ability to handle the rigors of dredging operations with ease. By continually investing in research and development, {} ensures that its pumps remain at the cutting edge of technology, providing its customers with reliable and efficient solutions for their dredging needs.As the demand for submersible slurry pumps continues to grow, {} remains committed to meeting the evolving needs of its customers. The company's dedication to quality, innovation, and customer satisfaction has made it a trusted partner for companies involved in dredging and mining operations around the world. With a strong focus on delivering reliable and high-performing pumping solutions, {} is well-positioned to continue leading the way in the industry for years to come.In conclusion, the submersible slurry pump offered by {} is an essential component for companies involved in dredging operations. With its ability to handle abrasive and high-density slurries, operate underwater, and provide easy maintenance and service, this pump is an invaluable asset for companies looking to optimize their dredging processes. With {}'s commitment to innovation and quality, customers can trust that they are investing in a pumping solution that will deliver exceptional performance and reliability for their dredging operations.

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

Multi-Deck High Frequency Screen and Screen Machine in China

China Multi-Deck High Frequency Screen and Screen Machine have become an integral part of the mining industry, offering efficient and reliable screening solutions for a wide range of applications. Leveraging advanced technology and innovative design, these machines are setting new standards in screening efficiency and performance.The Multi-Deck High Frequency Screen is a cutting-edge screening tool designed to increase the efficiency of fine particle separation. It utilizes high frequency vibration to effectively screen and separate materials, resulting in higher throughput and reduced wear and tear on equipment. This technology is particularly beneficial for processing materials with high moisture content, as it helps to prevent blinding and improve overall screening performance.The Screen Machine is a versatile and robust screening solution that is designed to withstand the rigors of heavy-duty applications. It is built to handle a wide range of materials, including aggregates, coal, and other minerals, making it an ideal choice for the mining industry. With its modular design and customizable options, the Screen Machine can be tailored to meet the specific needs of different applications, ensuring optimal performance and reliability.These advanced screening solutions are developed and manufactured by a leading company in the industry, which has a proven track record of delivering high-quality and innovative products. With a strong focus on research and development, this company is committed to pushing the boundaries of technology and setting new benchmarks in screening efficiency and performance. Their extensive experience and expertise in the field have earned them a reputation for delivering reliable and cost-effective solutions to their customers.In addition to their cutting-edge technology, this company also offers a comprehensive range of support services to ensure the smooth operation of their equipment. From installation and commissioning to maintenance and technical support, they are dedicated to providing their customers with the highest level of service and expertise. This commitment to customer satisfaction sets them apart as a trusted and reliable partner in the mining industry.With a strong emphasis on sustainability and environmental responsibility, this company is also dedicated to developing eco-friendly solutions that minimize the impact of mining operations on the environment. Their screening solutions are designed to optimize resource utilization and minimize waste generation, contributing to a more sustainable and efficient mining industry.As the demand for efficient and reliable screening solutions continues to grow in the mining industry, the Multi-Deck High Frequency Screen and Screen Machine from this company are poised to play a crucial role in meeting this demand. Their advanced technology, coupled with their commitment to innovation and customer satisfaction, positions them as a leading provider of screening solutions in the global mining industry.In conclusion, the Multi-Deck High Frequency Screen and Screen Machine from this company are revolutionizing the mining industry with their advanced technology, innovative design, and commitment to sustainability. With a proven track record of delivering high-quality and reliable screening solutions, this company is setting new standards in screening efficiency and performance, and is well-positioned to meet the evolving needs of the mining industry.

Efficient Mud Tank System for Drilling Rigs

Mud Tank System Drilling Rig: Revolutionizing the Oil and Gas IndustryThe oil and gas industry has long been reliant on drilling rigs to extract hydrocarbons from deep beneath the earth's surface. These rigs are vital in the production of crude oil and natural gas, and their efficiency and reliability directly impact the industry's productivity. One company at the forefront of revolutionizing drilling rig technology is {}, a leading provider of innovative solutions for the oil and gas sector.At the heart of their groundbreaking offerings is the Mud Tank System Drilling Rig, a technological marvel that has been hailed as a game-changer in the industry. This state-of-the-art rig is designed to maximize operational efficiency, streamline drilling processes, and enhance safety measures, ultimately leading to increased productivity and reduced downtime.The Mud Tank System Drilling Rig features a cutting-edge mud tank system that is integral to its performance. This system is designed to efficiently handle drilling waste and regulate the flow of drilling fluids, ensuring a clean and controlled environment for the drilling operation. By effectively managing mud and drilling fluids, the rig minimizes the impact on the surrounding environment and reduces the risk of operational hazards.Moreover, the Mud Tank System Drilling Rig is equipped with advanced monitoring and control systems that provide real-time data on drilling parameters. This enables operators to make quick and informed decisions, optimize drilling processes, and mitigate potential issues before they escalate. The rig's automated features and remote monitoring capabilities further enhance operational control and contribute to a safer working environment for personnel.In addition to its technological prowess, the Mud Tank System Drilling Rig is designed with versatility in mind. It can be customized to meet the specific requirements of different drilling projects, whether in onshore or offshore locations. Its modular design allows for easy transportation and assembly, making it well-suited for remote and challenging environments.This innovative drilling rig has already made a significant impact in the oil and gas industry, with numerous successful deployments and favorable feedback from operators. Its performance has been commended for its reliability, operational efficiency, and environmental stewardship. As the industry continues to adapt to evolving challenges and demands, the Mud Tank System Drilling Rig is poised to play a pivotal role in shaping the future of drilling operations.In line with this commitment to innovation and excellence, {} has established itself as a driving force in the oil and gas sector. With a rich history of delivering cutting-edge solutions and a strong focus on research and development, the company is dedicated to pushing the boundaries of technology to address the industry's evolving needs.{} has solidified its reputation as a trusted partner for oil and gas companies seeking reliable and efficient solutions. Their comprehensive portfolio of products and services spans the entire spectrum of drilling and production operations, encompassing drilling rigs, well services, and environmental solutions. Coupled with their unwavering commitment to safety and sustainability, the company has earned the trust and confidence of industry stakeholders worldwide.Looking ahead, {} remains steadfast in its pursuit of innovation and advancement. The company continues to invest in research and development, collaborating with industry partners and experts to push the boundaries of drilling technology. With a keen eye on emerging trends and challenges, {} is poised to lead the industry towards a more sustainable and efficient future.In conclusion, the Mud Tank System Drilling Rig stands as a testament to the transformative potential of technological innovation in the oil and gas industry. Through its cutting-edge design, advanced features, and versatility, this rig exemplifies the strides being made towards enhancing operational efficiency, safety, and environmental responsibility. In partnership with companies like {}, the industry is primed to embrace a new era of drilling excellence.

High-Efficiency Mud Tank Agitator for Enhanced Mixing

Mud Tank Agitator Revolutionizes Drilling OperationsIn the world of drilling operations, efficiency and effectiveness are key to success. Companies constantly seek ways to improve their drilling processes in order to increase productivity and reduce downtime. This has led to the development of advanced equipment and technologies to enhance the performance of drilling operations. One such innovation that is making waves in the industry is the Mud Tank Agitator, a game-changing product that is revolutionizing the way drilling companies operate.The Mud Tank Agitator is a powerful tool that is designed to thoroughly mix drilling mud in order to maintain its homogeneity and consistency. This is crucial for drilling operations as the quality of the drilling mud directly impacts the efficiency and success of the drilling process. The Agitator is capable of agitating and mixing the drilling mud in a way that ensures the removal of any settling solids, resulting in a smooth and well-mixed drilling mud that is ready for use.The Mud Tank Agitator is engineered to be durable and reliable, with a robust design that can withstand the harsh conditions of drilling operations. It is equipped with a high-speed motor that provides the necessary power to efficiently mix the drilling mud, and its sturdy construction ensures that it can withstand the demanding environment of drilling sites. The Agitator is also designed to be easy to maintain, with accessible components that allow for quick and hassle-free maintenance.One company that is making a significant impact in the drilling industry with its Mud Tank Agitator is {}. With a strong focus on innovation and quality, {} has established itself as a leading provider of drilling equipment and solutions. The company's Mud Tank Agitator has garnered attention for its exceptional performance and reliability, earning it a reputation as a superior product in the industry.{} takes great pride in the development and manufacturing of the Mud Tank Agitator, ensuring that it meets the highest standards of quality and performance. The company's team of experts has worked tirelessly to create a product that not only meets the needs of drilling companies but also exceeds their expectations. With a commitment to excellence, {} continues to innovate and improve its Mud Tank Agitator, staying ahead of the curve in a rapidly evolving industry.The Mud Tank Agitator from {} has proven to be a game-changer for drilling companies, providing them with a critical tool that enhances the efficiency and effectiveness of their operations. By ensuring that the drilling mud is thoroughly mixed and free of settling solids, the Agitator enables companies to maintain a high level of performance and productivity during drilling. This ultimately leads to cost savings and improved results for drilling projects.In addition to its superior performance, the Mud Tank Agitator from {} stands out for its reliability and durability. It is built to withstand the tough conditions of drilling operations, ensuring that it can perform consistently and effectively over time. This reliability gives drilling companies the peace of mind that they can rely on the Agitator to deliver the results they need, without the risk of breakdowns or malfunctions.With its exceptional performance and reliability, the Mud Tank Agitator has become an essential tool for drilling companies looking to optimize their operations and stay competitive in the industry. As drilling projects become more complex and demanding, the need for advanced equipment such as the Mud Tank Agitator will only continue to grow. As a result, {} and its innovative product are poised to play a significant role in the future of the drilling industry, driving efficiency and success for companies around the world.

Revolutionary Palm Oil Sludge Decanter Centrifuge Optimizes Separation Process in Malaysia

Palm Oil Sludge Separation Made Effortless with Decanter Centrifuges from ChinaPalm oil production is among the largest agricultural industries not only in Malaysia but also across the globe. With increased demand for palm oil, more and more industries are joining the race to tap into this lucrative business. However, the process of producing palm oil usually results in a lot of waste material, with sludge being among the most significant. Sludge is usually composed of residual oil, water, and solid debris, making it an environmental hazard when not properly disposed of. Luckily, with the advancement in technology, companies such as ZK Separation have come up with decanter centrifuges that make sludge separation easier and more efficient.ZK Separation's decanter centrifuges provide the ultimate solution in the palm oil sludge separating process. They are designed to separate the residual oil from the water by utilizing high centrifugal force. The decanter centrifuges have a unique and innovative design that guarantees maximum efficiency and high-quality separation. Not only do the decanters remove the oil, but they also help remove impurities, making it easier to dispose of the sludge.The China crude oil centrifuge and olive oil decanter centrifuge from ZK Separation are some of the most widely used machines in palm oil sludge separation. Their unrivaled performance and high efficiency rates have made them a favorite among clients across the globe. The company has invested heavily in research and development to ensure that their machines are of the highest quality.The China crude oil centrifuge is specially designed to make crude oil separation easier and more efficient. The machine has a robust construction that can handle various crude oil types, including palm oil. Its critical components such as the bowl and conveyor are made using high-quality materials to guarantee maximum durability and longevity.Similarly, the olive oil decanter centrifuge is also designed to make the separation of olive oil from water and other solid materials easier. The machine has undergone extensive testing and refinement to ensure maximum performance. Its automatic control system makes it easy to operate and customize according to the user's needs.In conclusion, the separation of palm oil sludge is an essential process in ensuring environmental sustainability in the palm oil industry. ZK Separation is at the forefront of designing innovative and efficient decanter centrifuges that make the process easier and more efficient. The China crude oil centrifuge and olive oil decanter centrifuge from the company have proven to be reliable and efficient in the separation process, making them a must-have for any industry player.

Ultimate Guide to Decanter Centrifuges: What You Need to Know

Decanter centrifuge has become one of the most essential pieces of equipment in the field of solid-liquid separation across various industries. This powerful and efficient machine has revolutionized the way businesses handle large volumes of slurry and liquid waste, significantly improving their operational efficiency and reducing environmental impact. With the increasing demand for high-quality decanter centrifuges, [company name] has emerged as a leading manufacturer and supplier in the global market, providing innovative and reliable solutions for solid-liquid separation.[Company name] is a renowned company specializing in the design, manufacturing, and distribution of industrial centrifuges and separation equipment. With years of experience and expertise in the field, the company has gained a solid reputation for delivering cutting-edge technology and high-performance products to customers worldwide. Their commitment to continuous innovation and product development has allowed them to stay ahead of the competition and meet the ever-evolving needs of various industries, including mining, wastewater treatment, oil and gas, food and beverage, and more.The decanter centrifuge is one of [company name]'s flagship products, known for its exceptional performance and reliability in separating solids from liquids. Its innovative design and advanced features make it a versatile and effective solution for a wide range of applications, from dewatering and thickening to clarification and classification. The machine operates on the principle of centrifugal force, using high-speed rotation to separate different components based on their density and particle size. This results in efficient and thorough separation, allowing businesses to recover valuable materials, minimize waste, and meet strict environmental regulations.One of the key advantages of [company name]'s decanter centrifuge is its robust construction and high-quality components, ensuring smooth operation and minimal downtime. The machine is built to handle the toughest conditions and can process large volumes of slurry with ease, making it an ideal choice for heavy-duty industrial applications. Additionally, the decanter centrifuge is designed for easy maintenance and cleaning, reducing the need for manual intervention and increasing overall productivity.Over the years, [company name] has continued to enhance its decanter centrifuge technology, introducing new features and improvements to meet the evolving demands of its customers. The company's R&D team works tirelessly to optimize the machine's performance, energy efficiency, and environmental footprint, ensuring that it remains at the forefront of solid-liquid separation technology. With a focus on sustainability and resource conservation, [company name] strives to provide eco-friendly solutions that help businesses minimize their environmental impact and achieve their sustainability goals.In addition to its cutting-edge products, [company name] is also known for its comprehensive customer support and after-sales service. The company's team of experts is dedicated to assisting customers with installation, training, technical support, and spare parts supply, ensuring that their decanter centrifuge operates at peak performance at all times. This commitment to customer satisfaction has earned [company name] a loyal and satisfied customer base, cementing its position as a trusted partner in the industrial centrifuge market.Looking ahead, [company name] is poised to further expand its global presence and drive innovation in the field of solid-liquid separation. With a focus on continuous improvement and customer-centric solutions, the company is well-positioned to meet the growing demand for efficient and sustainable separation technologies. By leveraging its expertise and industry knowledge, [company name] is set to play a pivotal role in shaping the future of solid-liquid separation across various sectors, driving efficiency, profitability, and environmental responsibility.In conclusion, [company name] has established itself as a leading provider of decanter centrifuges, delivering high-quality, reliable, and innovative solutions to meet the diverse needs of its customers. With a strong focus on technology, performance, and customer satisfaction, the company is well-positioned to drive positive change in the solid-liquid separation industry and contribute to a more sustainable and efficient future.

Highly Efficient Screw Pump: A Breakthrough in Pump Technology

Screw Pump Technology Revolutionizes Industrial Fluid HandlingIndustrial fluid handling has always been a critical aspect of various manufacturing processes. Whether it’s transferring chemicals, oil, or wastewater, the efficiency and reliability of the pumping system play a crucial role in maintaining the overall productivity of the operation. In this context, the introduction of the innovative Screw Pump technology by [Company] has revolutionized the way industrial fluids are handled and transferred.[Company] is a leading provider of innovative pumping solutions for a wide range of industrial applications. With a focus on delivering high-performance and reliable products, the company has built a reputation for excellence and innovation in the fluid handling industry. The latest addition to their product line, the Screw Pump, is not only a testament to their commitment to innovation but also a game-changer in the industry.The Screw Pump technology is based on the principle of positive displacement, where the fluid is moved through the pump in a smooth and consistent manner, resulting in stable flow rates and minimal pulsation. This makes it an ideal choice for applications where precision and accuracy are crucial, such as in chemical processing and oil refineries. Furthermore, the design of the Screw Pump allows for handling a wide range of viscosities, from low to high, without sacrificing performance, making it a versatile solution for various industrial fluid handling needs.One of the key features of the Screw Pump is its ability to handle abrasive and shear-sensitive fluids with ease. This is achieved through the use of robust materials and an advanced design that minimizes wear and tear, thus extending the lifespan of the pump and reducing maintenance costs. In addition, the Screw Pump is equipped with a sealing system that effectively prevents leakage, ensuring the safety and reliability of the pumping operation.The efficiency of the Screw Pump is also worth noting, as it can deliver high flow rates with minimal energy consumption. This not only reduces operational costs but also contributes to environmental sustainability by minimizing energy usage and reducing carbon emissions. The compact design of the Screw Pump further adds to its appeal, as it can be easily integrated into existing systems or installed in limited spaces, saving valuable floor space in industrial facilities.With its advanced technology and robust construction, the Screw Pump has quickly gained recognition in the industrial fluid handling market. [Company] has received positive feedback from customers who have implemented the Screw Pump in their operations, citing its reliability, efficiency, and low maintenance requirements as key factors in their satisfaction. The company’s commitment to providing exceptional customer support further enhances the overall experience of integrating the Screw Pump into industrial processes.Looking ahead, [Company] is dedicated to further enhancing the Screw Pump technology, with ongoing research and development efforts aimed at introducing new features and improvements to meet the evolving needs of the industry. As a forward-thinking and customer-focused company, [Company] is dedicated to continuous innovation and excellence in providing pumping solutions that drive the success of industrial operations around the world.In conclusion, the introduction of the Screw Pump by [Company] signifies a new era in industrial fluid handling, offering a combination of efficiency, reliability, and versatility that sets a new standard for pumping technology. With its advanced design and proven performance, the Screw Pump has quickly established itself as a preferred choice for a wide range of industrial applications, reaffirming [Company]’s position as a leader in the fluid handling industry.

Municipal Sewage Decanter Centrifuge: Efficient Wastewater Treatment Solution

China Municipal Sewage Decanter Centrifuge Sets New Standard for Wastewater TreatmentChina has long been grappling with the challenges of managing municipal sewage and wastewater, as rapid urbanization and industrial development have led to a sharp increase in the volume of wastewater produced. In response to this pressing issue, [Company Name] has introduced a cutting-edge solution that promises to revolutionize the wastewater treatment industry – the [Model Number] Municipal Sewage Decanter Centrifuge.With its advanced technology and high performance, the [Model Number] Municipal Sewage Decanter Centrifuge is set to raise the bar for municipal sewage and wastewater treatment in China. By effectively separating solids from liquid waste, the centrifuge significantly improves the overall efficiency and effectiveness of the treatment process, leading to cleaner water and reduced environmental impact.One of the key features of the [Model Number] Municipal Sewage Decanter Centrifuge is its ability to handle a wide range of sewage sludge, including those with high solid concentrations. This makes it an ideal solution for the treatment of municipal sewage and industrial wastewater, where the composition of the sludge can vary significantly.The decanter centrifuge is also designed to operate continuously, ensuring a steady and reliable treatment process without the need for frequent interruptions or downtime. This not only improves the overall efficiency of the wastewater treatment plant but also reduces operational costs in the long run.Furthermore, the [Model Number] Municipal Sewage Decanter Centrifuge is equipped with advanced control systems that allow for precise monitoring and adjustment of the treatment process. This level of automation not only simplifies operation but also maximizes the performance of the centrifuge, leading to better treatment outcomes.[Company Name] is a leading manufacturer of industrial separation equipment, with a proven track record of delivering high-quality solutions for a wide range of applications. With a strong focus on research and development, the company is dedicated to pushing the boundaries of technological innovation and setting new standards for the industry.In addition to the [Model Number] Municipal Sewage Decanter Centrifuge, [Company Name] offers a comprehensive range of decanter centrifuges for various industrial and environmental applications, including wastewater treatment, chemical processing, food and beverage production, and more. This diverse portfolio reflects the company's commitment to providing tailored solutions that meet the unique needs of its customers.The introduction of the [Model Number] Municipal Sewage Decanter Centrifuge comes at a critical time for China, as the country continues to prioritize environmental protection and sustainable development. By investing in advanced wastewater treatment solutions, China aims to improve the quality of its water resources and reduce the impact of pollution on the environment and public health.As the demand for efficient wastewater treatment solutions continues to grow, [Company Name] is well-positioned to play a leading role in shaping the future of the industry. With its innovative technologies and commitment to excellence, the company is poised to make a significant contribution to the advancement of wastewater treatment in China and beyond.In conclusion, the introduction of the [Model Number] Municipal Sewage Decanter Centrifuge marks a significant milestone in China's efforts to address the challenges of municipal sewage and wastewater treatment. With its advanced technology, high performance, and versatile capabilities, the centrifuge is set to raise the bar for the industry and set new standards for efficiency and effectiveness. [Company Name] is proud to be at the forefront of this innovation, and looks forward to making a positive impact on the environment and public health through its cutting-edge solutions.