How Desilter Works and Its Key Functions in Industrial Settings

By:Admin

In the oil and gas industry, the process of drilling wells involves the use of drilling fluids to lubricate the drilling bit, carry rock cuttings to the surface, and maintain pressure in the wellbore. These drilling fluids often contain solid particles that need to be removed in order to maintain the effectiveness of the fluid and prevent damage to drilling equipment. This is where desilters come in.

Desilters are a crucial part of the drilling process, as they are responsible for removing solid particles from the drilling fluid. This process ensures that the drilling fluid remains effective and that the wellbore is kept clean and free of debris. One of the leading companies in providing efficient desilter equipment is [Company name].

[Company name] has been a key player in the oil and gas industry for many years, providing a wide range of products and services to support drilling operations. Their desilter equipment is highly regarded for its reliability, efficiency, and durability, making it a preferred choice among drilling professionals.

The function of the desilter is to remove solid particles from the drilling fluid, typically in the range of 15 to 44 microns in size. This is accomplished through a process of centrifugal separation, where the drilling fluid is fed into the desilter unit and subjected to high-speed rotation. This causes the solid particles to separate from the fluid and be expelled from the system, leaving behind clean and effective drilling fluid.

The desilter equipment offered by [Company name] is designed to deliver superior performance in a variety of drilling conditions. Whether it's onshore or offshore, in shallow or deep wells, their desilters are built to withstand the demands of the drilling environment and provide consistent and reliable particle removal.

In addition to their high-performance equipment, [Company name] also offers comprehensive support and service to ensure that their desilters are operating at peak efficiency. This includes on-site installation and training, as well as ongoing maintenance and technical support. By partnering with [Company name], drilling professionals can have confidence in the performance of their desilter equipment and the support of a trusted industry leader.

The importance of effective desilter function cannot be overstated in the drilling process. When solid particles are allowed to remain in the drilling fluid, it can lead to a range of problems, including decreased drilling efficiency, increased equipment wear, and potential damage to the wellbore. By investing in high-quality desilter equipment, drilling professionals can ensure that their operations run smoothly and safely, with minimal risk of downtime or equipment failure.

As the oil and gas industry continues to evolve, the demand for efficient and reliable desilter equipment will remain a top priority for drilling professionals. With the expertise and quality of [Company name]'s desilter products, the industry can look forward to continued success in meeting the challenges of drilling operations.

In conclusion, desilters play a crucial role in the drilling process by removing solid particles from the drilling fluid, and [Company name] stands out as a trusted provider of high-performance desilter equipment. With their commitment to quality, reliability, and customer support, [Company name] is well-positioned to continue supporting the oil and gas industry in meeting the challenges of drilling operations.

Company News & Blog

Efficient Mud Mixing Hoppers for Solid Control Systems: A Comprehensive Introduction

Mud mixing hoppers are an essential component of solid control systems used in drilling operations. They are designed to mix mud bulk materials and mud additive chemicals into drilling fluids to improve their density, viscosity, and stability. In this blog, we will discuss the benefits of mud mixing hoppers and their importance in drilling operations.Mud mixing hoppers are available in manual and automatic versions, depending on project needs. The automatic version is equipped with overflow and backflow prevention systems that ensure the hopper doesn't overflow and waste materials. Mud hoppers are usually made of rugged stainless steel, which makes them durable and resistant to corrosion. This feature makes them ideal for harsh offshore environments, where drilling operations are often carried out.One of the significant benefits of using a mud mixing hopper in drilling operations is that it reduces mud mixing times and enhances drilling efficiency. By mixing drilling fluids on the rig, less time is required to transport the fluids to the drilling site, resulting in less downtime and reduced costs.Furthermore, mud mixing hoppers eliminate the need for manual mixing of drilling fluids, which can be labor-intensive and time-consuming. With automated mud mixing hoppers and the use of industrialized machines, drilling can be faster, and employees can focus on other tasks.Another advantage of using mud mixing hoppers is that they help improve drilling fluid properties. This is because the hoppers can accurately mix various components that make up the drilling fluid, including base fluids and additives. This enhances the physical and chemical properties of the drilling fluid, resulting in smoother drilling operations.Additionally, mud mixing hoppers help ensure the safety of employees working on offshore drilling rigs. These hoppers are designed to meet all relevant offshore health, safety, and environmental requirements, which are essential for drilling operations.In conclusion, mud mixing hoppers are an essential component of drilling operations. They improve the quality of drilling fluids, reduce costs, reduce downtime, and enhance safety and efficiency. If you need mud mixing hoppers, contact DC Office for all your drilling needs. Our team of experts will work with you to provide customized solutions that meet your project requirements.

Compact Mixing Tank: A Game-Changer for Efficient Mixing Processes

Small Mixing Tank Company Works to Revolutionize IndustryFor years, companies in the chemical and pharmaceutical industries have relied on large mixing tanks to produce their products, but a small startup called Small Mixing Tank (SMT) is looking to change that.SMT has developed a compact, customizable mixing tank that is perfect for companies that need a more efficient and cost-effective solution. Their tanks come in a range of sizes and are designed to fit in tight spaces, making them ideal for smaller facilities or production lines. In addition, SMT’s tanks are equipped with sophisticated mixing technology that ensures a uniform blend of materials and reduces waste.“Large mixing tanks can be a real headache for companies that have limited space or need to move their production lines around,” said SMT founder and CEO, Jane Smith. “That’s why we decided to develop a smaller, more versatile option that can be customized to meet the needs of any industry.”One of the key features of SMT’s tanks is their modular design. Companies can choose from a range of mixing heads and blades to create a tank that is tailored to their specific needs. This eliminates the need for companies to purchase multiple tanks for different applications, saving them time and money in the long run.“Our tanks are really a one-stop-shop solution,” said Smith. “From pharmaceuticals to food and beverage, our customers can create a mixing tank that meets the demands of their industry without having to invest in multiple tanks and accessories.”SMT’s tanks are also designed with cleaning and maintenance in mind. The tanks are easy to disassemble and clean, reducing the risk of contamination or cross-contamination. Additionally, the tanks’ components are all easily replaceable, so companies don’t have to worry about costly repairs or downtime if parts need to be replaced.“We know that time is money in manufacturing, so we wanted to make sure our tanks were designed for easy maintenance and cleaning,” said Smith. “This minimizes downtime and ensures that our customers can keep their production lines running smoothly.”Since launching in 2020, SMT has seen impressive growth and has attracted the attention of several major companies. Recently, the company received a significant investment from a leading pharmaceutical firm, which will allow them to expand their production capabilities and offer even more advanced mixing technology.“We’re thrilled to have the support of such a well-respected company in the pharmaceutical industry,” said Smith. “This investment will allow us to take our mixing technology to the next level and further revolutionize the industry.”Looking to the future, SMT plans to continue enhancing its mixing technology and expanding its product line to meet the needs of different industries. The company also plans to explore new markets and opportunities for growth, with a focus on sustainability and reducing waste.“We believe that our tanks have the potential to transform the manufacturing industry and help businesses of all sizes operate more efficiently and sustainably,” said Smith. “We’re excited to continue pushing the boundaries and developing new solutions that benefit both our customers and the planet.” In conclusion, Small Mixing Tank has established itself in the industry as a company that is dedicated to creating innovative solutions for businesses of all sizes. With its compact, modular design and advanced mixing technology, the company’s tanks have the potential to revolutionize the industry and help companies operate more efficiently and sustainably. As SMT continues to grow and expand, it will be interesting to see how it continues to push the boundaries of what is possible in manufacturing.

Efficient and Reliable Centrifugal Pump for Mission 3x4 Application

Mission 3x4 Centrifugal Pump Provides Reliable and Efficient Solutions for Various IndustriesA centrifugal pump is an essential component in many industrial processes. It is a device that uses impellers to create a flow of fluid or gas through a pipe system. One of the most trusted brands in the centrifugal pump market is Mission, a company that has been providing reliable and efficient solutions for various industries for over 100 years.One of the latest products from Mission is the 3x4 centrifugal pump, which has been designed to meet the demanding needs of its customers. This pump is ideal for applications that require high flow rates and low to medium head. The pump's design makes it easy to install, operate, and maintain, making it one of the most efficient pumps in the market.The Mission 3x4 centrifugal pump is highly versatile and can be used in different industries, including oil and gas, chemical, power generation, water treatment, and mining. In the oil and gas industry, the pump is used for various applications, including pipeline transportation, processing, and storage. In the chemical industry, it is used for transferring chemicals from one process to another. The pump’s efficient design makes it ideal for power generation applications, such as cooling towers, condensers, and boiler feedwater systems. In the mining industry, it can be used for dewatering, slurry pumping, and mineral processing.The Mission 3x4 centrifugal pump is designed with high-quality materials to ensure its durability and reliability. The pump’s casing, impeller, and wear rings are made from high-strength materials, such as cast iron, stainless steel, or nickel-based alloys, to withstand harsh environments and maintain performance over time. Moreover, the pump’s seal design ensures reliable performance and longer service life, reducing downtime and maintenance costs.The Mission 3x4 centrifugal pump is a highly efficient machine, providing maximum flow rates with minimal head losses. Its impeller design reduces turbulence and flow recirculation, which can significantly impact the pump's efficiency. The pump’s unique design generates less heat and vibration, which reduces energy consumption and extends the pump’s life. Its back pull-out construction allows for easy maintenance and serviceability, minimizing downtime and reducing maintenance costs.The Mission 3x4 centrifugal pump is designed to meet or exceed industry standards, ensuring that it provides safe and reliable service. It is certified by various organizations, such as the American Petroleum Institute (API), the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO). This certification ensures that the pump meets the required quality, safety, and performance standards.In conclusion, the Mission 3x4 centrifugal pump is an excellent choice for various industries that require reliable and efficient pumping solutions. Its versatility, durability, and efficiency make it a cost-effective solution for many applications. Moreover, its certification by various industry organizations ensures that it meets the highest standards of quality and performance. For more information about the Mission 3x4 centrifugal pump, please visit the company's website or contact their customer support team.

Top Quality Mud Pumps for Drilling Applications in China

China Mud Pump and Mud Pump for DrillingIn today's fast-paced and constantly evolving world, the need for efficient and reliable equipment in the oil and gas industry has never been greater. As drilling operations become increasingly complex, the demand for high-quality mud pumps has continued to rise. With a proven track record of providing top-of-the-line mud pumps, China Mud Pump has become a leading name in the industry.China Mud Pump has established itself as a trusted provider of mud pumps for drilling operations. With a focus on innovation and cutting-edge technology, the company has been able to deliver products that meet the high standards of the industry. By incorporating advanced engineering techniques and utilizing the latest materials, China Mud Pump has been able to produce mud pumps that are durable, efficient, and capable of performing in the most challenging of drilling environments.One of the key factors that sets China Mud Pump apart from its competitors is its commitment to quality. The company's dedication to providing reliable and long-lasting mud pumps has earned it a solid reputation within the industry. By adhering to strict quality control measures and conducting thorough testing of its products, China Mud Pump ensures that its mud pumps meet the highest standards of performance and reliability.As a testament to its dedication to quality, China Mud Pump offers a range of mud pumps that are specifically designed for drilling operations. These mud pumps are engineered to withstand the rigors of drilling and are capable of delivering the high-pressure, high-flow performance that is required in such operations. With features such as advanced cooling systems, rugged construction, and precise control capabilities, China Mud Pump's drilling mud pumps are well-equipped to handle the demands of the industry.In addition to its focus on quality, China Mud Pump is also known for its commitment to customer satisfaction. The company understands the importance of providing excellent service and support to its clients, and continuously strives to exceed their expectations. By offering comprehensive technical assistance, timely maintenance services, and readily available spare parts, China Mud Pump ensures that its customers can rely on their equipment to perform consistently and effectively.In line with its dedication to providing top-notch mud pumps for drilling, China Mud Pump has recently introduced a new line of mud pumps that are set to revolutionize the industry. The company has invested heavily in research and development to create a range of mud pumps that boast enhanced performance, improved reliability, and greater efficiency. With features such as advanced fluid dynamics, precision engineering, and state-of-the-art control systems, these new mud pumps are poised to set a new standard for drilling equipment.Furthermore, in an effort to further cement its position as a leading provider of mud pumps for drilling, China Mud Pump has expanded its operations to cater to a global client base. Through strategic partnerships and alliances with distributors and service providers around the world, the company has made its cutting-edge mud pumps more accessible to drilling operations across different continents. This move demonstrates China Mud Pump's commitment to serving the needs of the industry on a global scale and further solidifies its position as a key player in the market.With its unwavering dedication to quality, commitment to customer satisfaction, and innovative approach to product development, China Mud Pump continues to be at the forefront of providing high-performance mud pumps for drilling. By consistently meeting the needs of the industry and pushing the boundaries of what is possible, the company remains a driving force in the quest for efficiency and reliability in drilling operations. As the demand for high-quality mud pumps continues to grow, China Mud Pump stands ready to meet and exceed the expectations of its clients, now and in the future.

Innovative Mud Mixing Hopper Venturi for Efficient Operations

Mud Mixing Hopper Venturi for Efficient and High-Quality Mud MixingIn the world of drilling operations, the need for efficient and high-quality mud mixing is crucial for successful and smooth operations. One of the key components in this process is the Mud Mixing Hopper Venturi, a vital tool that ensures the proper mixing of drilling fluids and additives. With its advanced design and innovative technology, the Mud Mixing Hopper Venturi from [Company Name] is setting new standards in the industry.[Company Name] is a leading manufacturer and supplier of oilfield equipment and tools, specializing in providing top-notch solutions for drilling operations. With a strong focus on innovation and quality, [Company Name] has become a trusted name in the industry, serving customers worldwide with cutting-edge products and excellent customer service.The Mud Mixing Hopper Venturi from [Company Name] is designed to deliver exceptional performance and efficiency in mud mixing processes. Its unique venturi design creates a vacuum effect, allowing for the quick and thorough mixing of drilling fluids and additives. This results in a consistent and homogeneous mud mixture, essential for optimal drilling performance.One of the key features of the Mud Mixing Hopper Venturi is its versatility. It can be used with a wide range of drilling fluids and additives, making it suitable for various drilling applications. Whether it's for onshore or offshore drilling, the Mud Mixing Hopper Venturi from [Company Name] provides a reliable solution for achieving consistent and high-quality mud mixing.Moreover, the Mud Mixing Hopper Venturi is built with durability in mind. Constructed from high-quality materials and engineered to withstand harsh drilling conditions, it is designed to provide long-term and reliable performance. This ensures that drilling operations can continue smoothly without any disruptions due to equipment failure.In addition to its exceptional performance, the Mud Mixing Hopper Venturi also offers ease of use and maintenance. Its user-friendly design and simple operation make it convenient for drilling crews to handle, reducing the risk of human error and increasing operational efficiency. Furthermore, it requires minimal maintenance, saving both time and costs for drilling operators.The Mud Mixing Hopper Venturi from [Company Name] is backed by a team of experts who are dedicated to providing excellent support and service to customers. With their in-depth knowledge and experience in drilling operations, they are equipped to offer technical assistance, training, and troubleshooting, ensuring that customers get the most out of their equipment.As a testimony to its quality and reliability, the Mud Mixing Hopper Venturi from [Company Name] has received positive feedback from customers around the world. Its proven performance and efficiency have made it a preferred choice for drilling operations in various countries, further solidifying [Company Name]'s reputation as a leading provider of top-quality oilfield equipment.With its commitment to innovation and excellence, [Company Name] continues to lead the way in delivering advanced solutions for the oil and gas industry. The Mud Mixing Hopper Venturi stands as a testament to [Company Name]'s dedication to providing reliable, efficient, and high-quality equipment for drilling operations.In conclusion, the Mud Mixing Hopper Venturi from [Company Name] is a game-changer in the world of mud mixing for drilling operations. Offering exceptional performance, durability, and ease of use, it has become a go-to solution for achieving consistent and high-quality mud mixing. With [Company Name]'s unwavering commitment to innovation and customer satisfaction, the Mud Mixing Hopper Venturi is set to continue making a significant impact in the oil and gas industry.

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

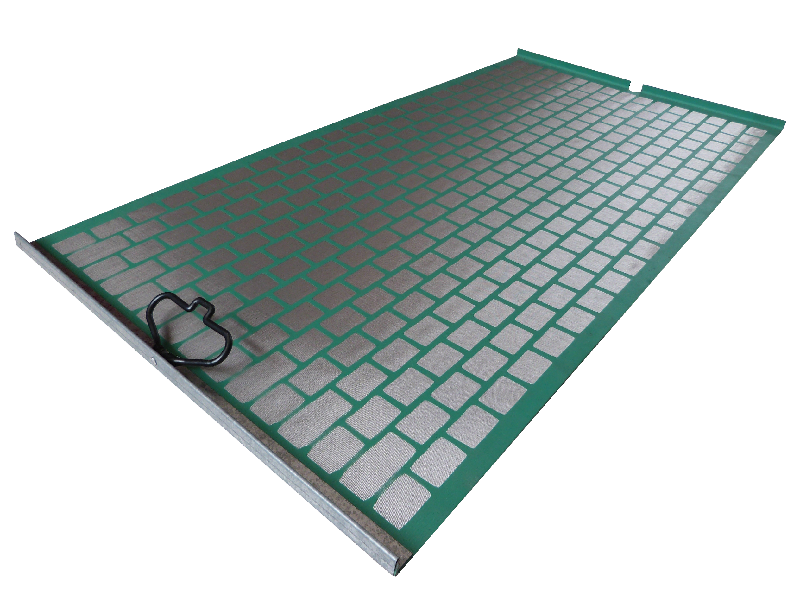

Top Quality Screen Mesh for Various Applications

China Screen Mesh and Screen (CSMS) is a well-known company in the industry, specializing in the production and distribution of high-quality screen mesh and screens. With years of experience and a commitment to excellence, CSMS has become a trusted name in the market, providing solutions for various industries including mining, construction, and agriculture.The company offers a wide range of products, including woven wire mesh, welded wire mesh, and polyurethane screen. These products are designed to meet the specific needs of customers, offering durability, reliability, and superior performance in demanding conditions. Whether it's for screening and sizing, filtering, or protection, CSMS has the right solution for every application.One of the key factors that sets CSMS apart from its competitors is its dedication to product quality. The company has established a strict quality control system, ensuring that every product that leaves its facility meets the highest standards. From the selection of raw materials to the manufacturing process and final inspection, CSMS is committed to delivering products that exceed customer expectations.In addition to quality, CSMS also prides itself on its ability to provide customized solutions. The company understands that every customer has unique requirements, and its team of experienced engineers and technicians is always ready to work closely with clients to develop tailored products that address specific challenges. This personalized approach has earned CSMS a reputation for being a reliable partner in the industry.Furthermore, CSMS places great importance on innovation and technology. The company continuously invests in research and development to improve its products and processes, staying ahead of the curve in a rapidly evolving market. By leveraging the latest advancements in materials and manufacturing techniques, CSMS is able to offer cutting-edge solutions that deliver exceptional performance and value.Apart from its commitment to product excellence, CSMS also places a strong emphasis on customer satisfaction. The company strives to build long-term relationships with its clients, offering comprehensive support and service throughout the entire customer journey. From initial consultation to after-sales support, CSMS is dedicated to ensuring that every customer has a positive experience.Looking ahead, CSMS is poised to expand its presence in the global market. With a strong foundation built on quality, innovation, and customer focus, the company is well-positioned to seize new opportunities and overcome challenges. By staying true to its core values and leveraging its strengths, CSMS is ready to write the next chapter of its success story.In conclusion, China Screen Mesh and Screen (CSMS) is a leading provider of high-quality screen mesh and screens, with a strong focus on product quality, customization, innovation, and customer satisfaction. With a proven track record and a clear vision for the future, CSMS is set to continue its growth and make a lasting impact in the industry.

Understanding the Function of a Desilter: What You Need to Know

The desilter is a crucial component in the process of removing solid particles from drilling fluids in the oil and gas industry. It is a high-efficiency separation equipment designed to remove fine solids from drilling fluids, thus ensuring the smooth operation of the drilling process. The desilter plays a significant role in maintaining the quality of the drilling fluids, which in turn results in improved drilling performance and reduced environmental impact.One of the leading companies in the field of desilter manufacturing is {}. With years of experience and expertise in the oil and gas industry, {} has a proven track record of providing high-quality desilter equipment to its clients worldwide. The company is committed to delivering innovative and reliable solutions that meet the evolving needs of the industry.The desilter manufactured by {} is designed to deliver exceptional performance in separating solid particles from drilling fluids. It is equipped with hydrocyclones, which utilize centrifugal force to separate the solids from the drilling fluids. The desilter is capable of handling a wide range of flow rates, making it suitable for various drilling operations. Additionally, it is designed to be compact and efficient, enabling easy installation and operation on drilling rigs.In addition to its high-performance capabilities, the desilter manufactured by {} is also designed with durability and reliability in mind. The equipment is constructed with high-quality materials and is subjected to rigorous testing to ensure its resilience in the harsh operating conditions of drilling sites. This commitment to quality and reliability has earned {} a strong reputation in the industry, with many clients relying on their desilter equipment for their drilling operations.Furthermore, {} places a strong emphasis on innovation and continuous improvement in its desilter technology. The company invests in research and development to stay at the forefront of technological advancements in the field of solid-liquid separation. This dedication to innovation enables {} to offer cutting-edge desilter solutions that meet the demands of the modern oil and gas industry.As a global company, {} has a strong focus on customer satisfaction and support. The company provides comprehensive technical support and after-sales services to its clients, ensuring that their desilter equipment operates at its best performance throughout its lifespan. With a global network of service centers and representatives, {} is able to provide timely assistance to its clients wherever they are located.In conclusion, the desilter is an essential equipment for the efficient and environmentally responsible operation of drilling fluids in the oil and gas industry. With its commitment to quality, innovation, and customer support, {} has established itself as a trusted provider of high-performance desilter equipment. The company's dedication to delivering reliable and efficient solutions has contributed to the success of numerous drilling operations worldwide, making {} a key player in the solid-liquid separation segment of the industry.

Top-Quality Agitator and Drilling Equipment from China: What You Need to Know

China Agitator and Drilling Equipment (CADE) is a leading manufacturer and supplier of drilling equipment and related products with a well-established reputation in the global market. The company has been in business for over two decades, providing high-quality, reliable equipment to customers in the oil and gas, mining, and construction industries.With a comprehensive product range that includes drilling rigs, mud pumps, and agitators, CADE has gained the trust of its customers by offering innovative solutions that meet the highest safety and environmental standards. The company's commitment to sustainability and efficiency has earned it a strong position in the highly competitive market for drilling equipment.Recently, CADE has made significant strides in the development of advanced agitator technology, designed to improve the efficiency and reliability of drilling operations. The company's research and development team has been working tirelessly to innovate new agitator designs that can withstand the harsh conditions of drilling operations, while also improving the overall performance and safety of the equipment.One of CADE's latest agitator designs, which is set to revolutionize the industry, is the result of years of research and development. This new agitator is equipped with state-of-the-art features that enhance its performance and functionality, making it an essential tool for any drilling operation. The agitator is designed to effectively mix and agitate drilling fluids, ensuring the smooth operation of the drilling process.In addition to its innovative agitator technology, CADE also offers a comprehensive range of drilling equipment that caters to the diverse needs of its customers. From hydraulic drilling rigs to high-pressure mud pumps, the company's product range is designed to meet the demanding requirements of the industry.Moreover, CADE places a strong emphasis on providing outstanding customer service, ensuring that its clients receive the support and assistance they need to achieve their objectives. The company's team of experts is dedicated to providing technical support, maintenance services, and training to ensure that its customers can rely on their equipment to deliver outstanding performance in the field.In recent years, CADE has successfully expanded its presence in the global market, with a growing network of distributors and partners that enable the company to reach customers in various regions. This expansion has allowed CADE to establish itself as a trusted and reliable supplier of drilling equipment, further strengthening its position as a leader in the industry.Despite the challenges posed by the evolving market dynamics and the global economic landscape, CADE has remained resilient and adaptable, continuing to invest in research and development to drive innovation. The company's commitment to staying ahead of the curve and delivering cutting-edge solutions has positioned it as a strategic partner for customers seeking to enhance their drilling operations.Looking ahead, CADE is poised to continue its expansion and innovation efforts, with a focus on developing new technology and solutions that will drive the industry forward. The company's dedication to excellence, combined with its relentless pursuit of quality and innovation, makes it a formidable force in the global market for drilling equipment.In conclusion, CADE stands as a testament to the ingenuity and commitment of Chinese manufacturers to deliver world-class drilling equipment and technology. With its relentless pursuit of excellence and a strong focus on customer satisfaction, CADE is well-positioned to continue leading the industry and setting new standards for the future.

Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pumps in China

China Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pumps have been making waves in the industry, providing efficient and reliable solutions for various pumping needs. These innovative pumps have gained popularity for their advanced technology and high-performance capabilities.The fully automatic dry priming vacuum assisted pump is designed to handle tough pumping applications with ease. It is equipped with a powerful vacuum system that allows it to prime and re-prime automatically, without the need for manual intervention. This feature makes it ideal for use in dewatering, sewage bypass, and other challenging pumping scenarios. The pump's automatic self-priming capability ensures continuous operation, even in the most demanding conditions.In addition to the fully automatic dry priming vacuum assisted pump, the company also offers a range of automatic dry priming pumps that are designed for various industrial and municipal applications. These pumps are known for their reliability and efficiency, making them a preferred choice for customers across the globe. With their advanced design and innovative features, these pumps deliver superior performance and require minimal maintenance, making them a cost-effective solution for pumping needs.The company behind these cutting-edge pumps is a leading manufacturer of pumping solutions, with a strong focus on innovation and quality. With a history of over [X] years in the industry, they have established themselves as a trusted name in the global market. Their commitment to providing state-of-the-art pumping solutions has earned them a reputation for excellence and reliability.The company's fully automatic dry priming vacuum assisted pump and automatic dry priming pumps are the result of extensive research and development, aimed at meeting the evolving needs of their customers. These pumps are designed to deliver high performance, energy efficiency, and durability, ensuring that they meet the rigorous demands of modern pumping applications. Their dedication to quality and innovation sets them apart in the industry, making them a preferred choice for customers seeking reliable, high-performance pumping solutions.With a strong focus on customer satisfaction, the company prides itself on providing exceptional service and support to its customers. Their team of experienced professionals is dedicated to assisting customers in selecting the right pumping solutions for their specific needs, ensuring that they get the most out of their investment. Whether it's technical assistance, maintenance support, or troubleshooting, the company is committed to going the extra mile to ensure that their customers are satisfied with their products and services.In addition to their commitment to quality and customer satisfaction, the company also places a strong emphasis on environmental responsibility. Their pumps are designed to meet the highest standards of energy efficiency and eco-friendliness, helping to minimize their environmental impact. By choosing these pumps, customers can contribute to sustainable and responsible pumping practices, ensuring a greener future for generations to come.In conclusion, the company's fully automatic dry priming vacuum assisted pump and automatic dry priming pumps are revolutionizing the pumping industry with their advanced technology, reliability, and efficiency. With a strong focus on innovation, quality, and customer satisfaction, the company is setting new standards for pumping solutions, ensuring that customers receive the best products and support available in the market. As the industry continues to evolve, the company remains dedicated to meeting the ever-changing needs of its customers, solidifying its position as a leader in the global pumping industry.