Mud Cleaner and Desilter Equipments for China Oil and Gas Industry

By:Admin

China has always been known for its innovation and advancement in technology, and this is no different when it comes to the oil and gas industry. With the increasing demand for efficient drilling operations, China has developed state-of-the-art equipment to meet these demands. One of the key players in this industry is a leading company in China, specializing in the production of high-quality Mud Cleaner and Mud Desilter.

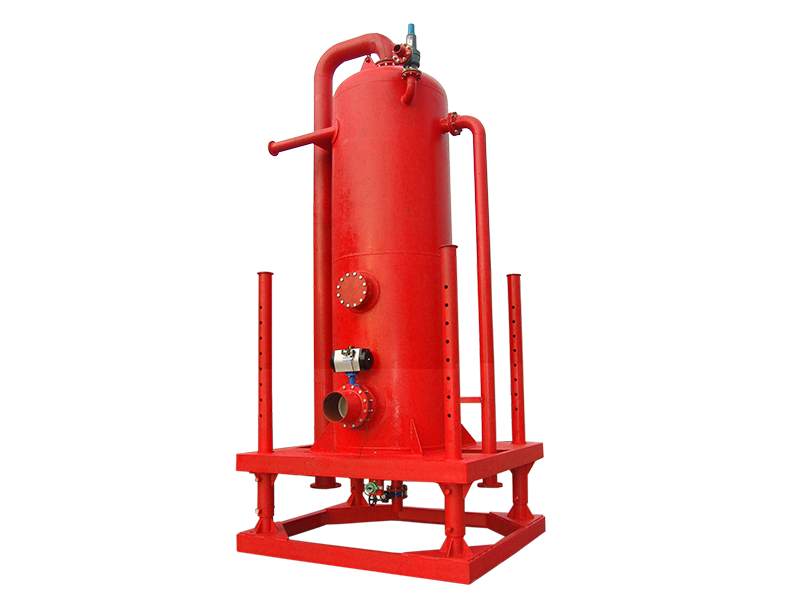

The Mud Cleaner and Mud Desilter are essential components in the drilling process, as they are used to remove solid particles and impurities from the drilling mud, ensuring smooth and efficient drilling operations. These machines play a crucial role in maintaining the integrity of the drilling fluid by separating out the solids and allowing the clean mud to be reused.

The Mud Cleaner is a combination of a desander, desilter, and a shale shaker, providing a more efficient and compact solution for removing solids from the drilling mud. It is designed to effectively separate and remove the solid particles from the drilling fluid, allowing for the reuse of the clean mud and reducing waste.

On the other hand, the Mud Desilter is designed to remove fine solids from the drilling mud, ensuring that the drilling fluid remains in optimal condition for the drilling process. By using hydrocyclones, the Mud Desilter is able to efficiently separate the fine solids from the drilling mud, ensuring that the drilling operation runs smoothly and effectively.

The company behind these innovative products is a leading manufacturer and supplier of drilling equipment, with a strong focus on research and development. With cutting-edge technology and a commitment to quality, the company is dedicated to providing solutions that meet the evolving needs of the oil and gas industry.

The company's Mud Cleaner and Mud Desilter are designed with the latest advancements in technology, ensuring high performance, efficiency, and reliability. These machines are also designed to withstand the harsh conditions of drilling operations, making them a durable and long-lasting solution for the industry.

In addition to their innovative products, the company also provides exceptional customer service and technical support, ensuring that their clients receive the necessary assistance and guidance for their drilling operations. With a team of experienced professionals, the company is able to offer customized solutions to meet the specific requirements of their clients, further reinforcing their commitment to excellence.

The company's Mud Cleaner and Mud Desilter have been widely recognized and well-received in the oil and gas industry, with a strong track record of successful installations and operations. Their dedication to quality, innovation, and customer satisfaction has earned them a solid reputation in the industry, making them a trusted and reliable partner for drilling equipment.

As the demand for efficient drilling operations continues to grow, the company remains at the forefront of technological advancements, continuously improving and expanding their product line to meet the evolving needs of the industry. With a focus on quality, reliability, and performance, the company continues to set the standard for drilling equipment in the oil and gas industry.

In conclusion, China's Mud Cleaner and Mud Desilter, developed by a leading company in the industry, provide a cutting-edge solution for the removal of solid particles and impurities from drilling mud. With a strong focus on quality, innovation, and customer satisfaction, the company has solidified its position as a trusted and reliable partner for drilling equipment in the oil and gas industry. Their commitment to excellence and continuous advancements in technology make them a key player in the industry, ensuring smooth and efficient drilling operations for their clients.

Company News & Blog

Municipal Sewage Decanter Centrifuge: Efficient Wastewater Treatment Solution

China Municipal Sewage Decanter Centrifuge Sets New Standard for Wastewater TreatmentChina has long been grappling with the challenges of managing municipal sewage and wastewater, as rapid urbanization and industrial development have led to a sharp increase in the volume of wastewater produced. In response to this pressing issue, [Company Name] has introduced a cutting-edge solution that promises to revolutionize the wastewater treatment industry – the [Model Number] Municipal Sewage Decanter Centrifuge.With its advanced technology and high performance, the [Model Number] Municipal Sewage Decanter Centrifuge is set to raise the bar for municipal sewage and wastewater treatment in China. By effectively separating solids from liquid waste, the centrifuge significantly improves the overall efficiency and effectiveness of the treatment process, leading to cleaner water and reduced environmental impact.One of the key features of the [Model Number] Municipal Sewage Decanter Centrifuge is its ability to handle a wide range of sewage sludge, including those with high solid concentrations. This makes it an ideal solution for the treatment of municipal sewage and industrial wastewater, where the composition of the sludge can vary significantly.The decanter centrifuge is also designed to operate continuously, ensuring a steady and reliable treatment process without the need for frequent interruptions or downtime. This not only improves the overall efficiency of the wastewater treatment plant but also reduces operational costs in the long run.Furthermore, the [Model Number] Municipal Sewage Decanter Centrifuge is equipped with advanced control systems that allow for precise monitoring and adjustment of the treatment process. This level of automation not only simplifies operation but also maximizes the performance of the centrifuge, leading to better treatment outcomes.[Company Name] is a leading manufacturer of industrial separation equipment, with a proven track record of delivering high-quality solutions for a wide range of applications. With a strong focus on research and development, the company is dedicated to pushing the boundaries of technological innovation and setting new standards for the industry.In addition to the [Model Number] Municipal Sewage Decanter Centrifuge, [Company Name] offers a comprehensive range of decanter centrifuges for various industrial and environmental applications, including wastewater treatment, chemical processing, food and beverage production, and more. This diverse portfolio reflects the company's commitment to providing tailored solutions that meet the unique needs of its customers.The introduction of the [Model Number] Municipal Sewage Decanter Centrifuge comes at a critical time for China, as the country continues to prioritize environmental protection and sustainable development. By investing in advanced wastewater treatment solutions, China aims to improve the quality of its water resources and reduce the impact of pollution on the environment and public health.As the demand for efficient wastewater treatment solutions continues to grow, [Company Name] is well-positioned to play a leading role in shaping the future of the industry. With its innovative technologies and commitment to excellence, the company is poised to make a significant contribution to the advancement of wastewater treatment in China and beyond.In conclusion, the introduction of the [Model Number] Municipal Sewage Decanter Centrifuge marks a significant milestone in China's efforts to address the challenges of municipal sewage and wastewater treatment. With its advanced technology, high performance, and versatile capabilities, the centrifuge is set to raise the bar for the industry and set new standards for efficiency and effectiveness. [Company Name] is proud to be at the forefront of this innovation, and looks forward to making a positive impact on the environment and public health through its cutting-edge solutions.

New Flare Ignition Device for Improved Safety and Efficiency

Flare Ignition Device Revolutionizes Safety in Oil and Gas IndustryThe oil and gas industry is notorious for its potential risks and hazards. From environmental concerns to workplace safety, companies in this sector are constantly seeking innovative solutions to mitigate potential dangers. One of the latest developments in this field is the Flare Ignition Device, a cutting-edge technology designed to enhance safety and efficiency in oil and gas operations.Developed by a leading engineering and technology company, the Flare Ignition Device is a state-of-the-art system that has been designed to mitigate the risks associated with flaring, ensuring the safety of personnel and the environment. This innovative device has the potential to revolutionize safety standards in the oil and gas industry by providing a reliable and efficient solution for flare ignition.The Flare Ignition Device is equipped with advanced features that set it apart from conventional ignition systems. Its streamlined design and user-friendly interface make it easy to install and operate, while its robust construction ensures durability and longevity. The device is also designed to operate in a wide range of environmental conditions, including extreme temperatures and harsh weather, making it suitable for use in various oil and gas operations.One of the key advantages of the Flare Ignition Device is its advanced safety features. The system is equipped with multiple fail-safe mechanisms to prevent accidents and ensure reliable operation. This includes built-in sensors and monitoring systems that detect potential issues and automatically shut down the device if necessary. Moreover, the device is designed to meet industry safety standards and regulations, providing companies with peace of mind and regulatory compliance.In addition to its safety features, the Flare Ignition Device also offers significant environmental benefits. By igniting flares efficiently and effectively, the device helps to reduce emissions and minimize environmental impact. This is a critical consideration for oil and gas companies, particularly in light of increasing regulatory pressures and public scrutiny on environmental issues.Furthermore, the Flare Ignition Device is designed to enhance operational efficiency in oil and gas facilities. By providing reliable and consistent flare ignition, the device minimizes downtime and maximizes productivity. This is especially important in the context of volatile market conditions and fluctuating energy prices, where operational efficiency can significantly impact the bottom line.The company behind the Flare Ignition Device is a leading provider of engineering and technology solutions for the oil and gas industry. With a track record of innovation and excellence, the company is committed to developing cutting-edge products and services that address the evolving needs of its clients. The Flare Ignition Device is a testament to the company's dedication to safety, reliability, and environmental sustainability.In conclusion, the Flare Ignition Device represents a significant advancement in safety and efficiency for the oil and gas industry. With its advanced features, robust design, and environmental benefits, the device has the potential to revolutionize safety standards and operational practices in this sector. As companies continue to prioritize safety and environmental responsibility, the Flare Ignition Device is poised to become a critical tool for enhancing performance and mitigating risks in oil and gas operations.

Solid Liquid Separator and 3-Phase Separation Filter for Industrial Use in China

China Solid Liquid Separator and 3-Phase Separation FilterIn the world of industrial manufacturing, the need for efficient and reliable solid-liquid separation solutions is paramount. This is where the China Solid Liquid Separator and 3-Phase Separation Filter, developed by [company name], comes into play. This innovative product offers a range of benefits to industries such as wastewater treatment, food processing, mining, and oil and gas production, making it a vital tool for businesses worldwide.The China Solid Liquid Separator and 3-Phase Separation Filter is designed to effectively separate solid and liquid components from a mixture, providing a high level of efficiency and precision. By utilizing advanced filtration technology, this product is able to remove contaminants and impurities from a variety of substances, resulting in a cleaner and more refined end product.One of the key features of the China Solid Liquid Separator and 3-Phase Separation Filter is its versatility. This product is capable of handling a wide range of materials, including sludge, slurries, and other complex mixtures. This flexibility makes it an ideal solution for industries with diverse separation needs, allowing for seamless integration into existing production processes.In addition to its solid-liquid separation capabilities, the China Solid Liquid Separator and 3-Phase Separation Filter also offers a unique 3-phase separation function. This feature allows for the simultaneous extraction of oil, water, and solid particles from a mixture, further enhancing its utility in industries such as oil and gas production.[company name] is at the forefront of the development and manufacturing of innovative separation solutions. With a strong focus on research and development, the company has consistently delivered cutting-edge products that address the evolving needs of modern industries.The China Solid Liquid Separator and 3-Phase Separation Filter is a testament to [company name]'s commitment to excellence and innovation. By leveraging the latest technological advancements, the company has created a product that sets a new standard for solid-liquid separation, offering unmatched performance and reliability.As a leading provider of separation solutions, [company name] is dedicated to supporting its customers with top-quality products and exceptional service. The China Solid Liquid Separator and 3-Phase Separation Filter is backed by the company's extensive technical expertise, ensuring that customers receive the support they need to maximize the benefits of this innovative product.In conclusion, the China Solid Liquid Separator and 3-Phase Separation Filter represents a significant advancement in solid-liquid separation technology. With its exceptional performance, versatility, and 3-phase separation capabilities, this product is poised to make a lasting impact on a wide range of industries. Backed by [company name]'s unwavering commitment to excellence, the China Solid Liquid Separator and 3-Phase Separation Filter is set to become a cornerstone of modern industrial manufacturing.

Efficient Mud Mixing Hoppers for Solid Control Systems: A Comprehensive Introduction

Mud mixing hoppers are an essential component of solid control systems used in drilling operations. They are designed to mix mud bulk materials and mud additive chemicals into drilling fluids to improve their density, viscosity, and stability. In this blog, we will discuss the benefits of mud mixing hoppers and their importance in drilling operations.Mud mixing hoppers are available in manual and automatic versions, depending on project needs. The automatic version is equipped with overflow and backflow prevention systems that ensure the hopper doesn't overflow and waste materials. Mud hoppers are usually made of rugged stainless steel, which makes them durable and resistant to corrosion. This feature makes them ideal for harsh offshore environments, where drilling operations are often carried out.One of the significant benefits of using a mud mixing hopper in drilling operations is that it reduces mud mixing times and enhances drilling efficiency. By mixing drilling fluids on the rig, less time is required to transport the fluids to the drilling site, resulting in less downtime and reduced costs.Furthermore, mud mixing hoppers eliminate the need for manual mixing of drilling fluids, which can be labor-intensive and time-consuming. With automated mud mixing hoppers and the use of industrialized machines, drilling can be faster, and employees can focus on other tasks.Another advantage of using mud mixing hoppers is that they help improve drilling fluid properties. This is because the hoppers can accurately mix various components that make up the drilling fluid, including base fluids and additives. This enhances the physical and chemical properties of the drilling fluid, resulting in smoother drilling operations.Additionally, mud mixing hoppers help ensure the safety of employees working on offshore drilling rigs. These hoppers are designed to meet all relevant offshore health, safety, and environmental requirements, which are essential for drilling operations.In conclusion, mud mixing hoppers are an essential component of drilling operations. They improve the quality of drilling fluids, reduce costs, reduce downtime, and enhance safety and efficiency. If you need mud mixing hoppers, contact DC Office for all your drilling needs. Our team of experts will work with you to provide customized solutions that meet your project requirements.

Durable PWP Shaker Screens for FLC 2000 Model - A Must-Have for Borehole Operations

FLC 2000 PWP Shaker Screens: The Next Innovation in Oilfield EquipmentThe oil and gas industry is known for its constant demand for innovative and efficient equipment. This demand has led to the development of the FLC 2000 PWP Shaker Screens, a cutting-edge product that is set to revolutionize the oilfield equipment market.** (Name of Company) is a leading manufacturer of high-quality oilfield equipment. With a strong focus on innovation and customer satisfaction, the company has built a reputation for delivering top-notch solutions to its clients. Its latest offering, the FLC 2000 PWP Shaker Screens, is a testament to the company's commitment to excellence and innovation.The FLC 2000 PWP Shaker Screens are designed to maximize the efficiency of the oil and gas drilling process. These screens are constructed using advanced technology and high-quality materials, ensuring their durability and reliability in the most demanding drilling environments. The screens are compatible with a wide range of shakers, making them a versatile and cost-effective solution for oilfield operators.One of the key features of the FLC 2000 PWP Shaker Screens is their superior filtration capabilities. These screens are designed to effectively separate solids from the drilling fluid, ensuring that the fluid remains clean and free of debris. This not only improves the overall efficiency of the drilling process but also helps to protect the drilling equipment from premature wear and damage.Furthermore, the FLC 2000 PWP Shaker Screens are engineered to minimize downtime and maintenance costs. With their robust construction and long-lasting performance, these screens require minimal upkeep, allowing oilfield operators to maximize their productivity and minimize their operational expenses.In addition to their practical benefits, the FLC 2000 PWP Shaker Screens also offer environmental advantages. By improving the filtration and separation process, these screens help to reduce the environmental impact of drilling activities, making them a sustainable and eco-friendly solution for oil and gas operations.The FLC 2000 PWP Shaker Screens are backed by **(Name of Company)'s commitment to customer satisfaction and support. The company provides comprehensive technical assistance and after-sales services to ensure that its clients can fully optimize the performance of these innovative screens.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in oilfield equipment technology. With their unparalleled efficiency, durability, and sustainability, these screens are poised to set a new standard for oil and gas drilling operations.** (Name of Company) is proud to be at the forefront of this groundbreaking development, and looks forward to providing its clients with the benefits of this cutting-edge technology. As the oil and gas industry continues to evolve, innovative solutions like the FLC 2000 PWP Shaker Screens will play a crucial role in driving operational excellence and sustainable growth.

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.

How to Choose the Best Screen for Your Mongoose

Introducing a State-of-the-Art Screen Technology by a Leading CompanyIn recent technological developments, companies are continuously innovating to provide the best solutions for businesses and consumers. One such innovation is the development of a revolutionary screen technology by a leading company. This new screen technology, known as Mongoose Screen, is set to change the way we interact with displays and provide an exceptional visual experience for users.Mongoose Screen is a cutting-edge display technology that offers high resolution, vivid colors, and crisp image quality. It is designed to provide an immersive viewing experience, whether for entertainment, presentations, or professional use. The technology behind Mongoose Screen combines advanced hardware and software to deliver unparalleled performance and user satisfaction.The company behind the development of Mongoose Screen has been a pioneer in the display technology industry for several decades. With a solid reputation for creating high-quality products, the company has consistently delivered innovative solutions that meet the evolving needs of the market. Their commitment to research and development has led to the creation of Mongoose Screen, which is poised to become a game-changer in the industry.According to the company spokesperson, Mongoose Screen is the result of years of research, development, and collaboration with industry experts. The team behind this innovative technology has worked tirelessly to push the boundaries of conventional display technology and bring forth a product that redefines visual experiences. Mongoose Screen is built on the foundation of quality, reliability, and performance, making it the go-to choice for businesses and consumers alike.The key features of Mongoose Screen include its high resolution, which provides an unparalleled level of detail and clarity. The screen's ability to reproduce vivid colors and deep blacks ensures that images and videos are displayed with stunning realism. Furthermore, Mongoose Screen boasts an impressive refresh rate, ensuring smooth and fluid motion for an exceptional viewing experience.One of the most noteworthy aspects of Mongoose Screen is its versatility. It is designed to cater to a wide range of applications, including gaming, entertainment, professional use, and more. Whether it's for creating captivating visual presentations or enjoying the latest blockbuster movie, Mongoose Screen delivers exceptional performance across the board.The company has also integrated advanced software features into Mongoose Screen to enhance user experience and provide added value. These features include customizable display settings, picture enhancement modes, and seamless connectivity with other devices. Additionally, Mongoose Screen is designed to be energy-efficient, contributing to a sustainable and eco-friendly technology solution.With the launch of Mongoose Screen, the company is set to solidify its position as a leader in the display technology industry. The introduction of this cutting-edge product marks a significant milestone for the company, demonstrating its commitment to innovation and excellence. The company's dedication to delivering superior products is evident in Mongoose Screen, which promises to set new standards for visual display technology.As the market continues to evolve, the demand for high-quality display solutions will only continue to grow. With Mongoose Screen, the company is well-positioned to meet and exceed the expectations of businesses and consumers seeking the best in display technology. The introduction of Mongoose Screen represents a significant step forward for the company, and it serves as a testament to their dedication to pushing the boundaries of what is possible in the world of visual displays.In conclusion, the development of Mongoose Screen by this leading company is a testament to their commitment to innovation, quality, and providing exceptional solutions for their customers. This revolutionary screen technology is set to redefine the visual display experience and raise the bar for display technology in the industry. With its advanced features, versatility, and superior performance, Mongoose Screen is poised to become a must-have for businesses and consumers looking for the best in display technology.

Importance of Mud Recycling Systems for Efficient Drilling Processes

GN Solids America Provides High-Quality Drilling Mud Recycling System with CE and ATEX StandardsThe drilling process is an essential part of oil and gas exploration, and the mud recycling system plays a vital role in maintaining the drilling mud properties at an optimal level. It removes the unnecessary large-sized solids and protects the drilling equipment from being damaged by large solids. GN Solids America is a leading provider of high-quality drilling mud recycling systems that meet Europe CE standard and ATEX explosion-proof standard.The mud recycling system consists of 2 centrifugal pumps, 2 mixing pumps, and 20 agitators. It acts as the heart and blood of the rig, making sure that all the components work together in perfect harmony. Without a reliable mud recycling system, the drilling process would be inefficient and expensive.GN Solids America is committed to providing its customers with the best quality solid control equipment at a competitive price. The shale shakers' G force can reach up to 8 G, making it possible to discharge drier solids that meet environmental requirements. Moreover, GN Solids America's new and upgraded shaker screen possesses better performance, longevity, and can store longer than ever before. During the drilling process, the shaker screens undergo significant wear and tear. Hence, GN Solids America's composite screen is the perfect solution, lasting longer than other screens.Customers from Europe and North America appreciate the quality of GN Solids America's products, and are buying them in increasing numbers. GN Solids America aims to provide its customers with the best quality products at an affordable cost."We are pleased to provide our customers with high-quality drilling mud recycling systems that meet CE and ATEX standards. We are committed to ensuring our customers' satisfaction by providing them with reliable and cost-effective products," said the spokesperson for GN Solids America.In conclusion, GN Solids America is a reliable provider of high-quality drilling mud recycling systems that meet international standards. Its products are top-notch and cost-effective, making them ideal for various applications in the oil and gas industry. GN Solids America's commitment to quality and customer satisfaction is what sets it apart from other solid control equipment providers in the market. Visit the website www.gnsolidsamerica.com. For more information, send your inquiries to [email protected].

Highly Effective Mud Agitators for Industrial Use

Mud Agitators: The Key to Efficient Mud Mixing and Solid SuspensionMud agitators are an essential part of the drilling process in the oil and gas industry. They are used to keep the solids in the drilling fluid from settling and to ensure that the mud is thoroughly mixed. This is important for maintaining the consistency and quality of the drilling fluid, which in turn directly impacts the efficiency and success of the drilling operation. One company that has been making waves in the mud agitator industry is {}.{} has been a leading provider of drilling equipment and solutions for the oil and gas industry for over 20 years. The company has built a reputation for providing high-quality products that are reliable, efficient, and cost-effective. Their mud agitators are no exception, and they have become a trusted choice for many drilling operations around the world.The {} mud agitators are designed to deliver powerful and efficient agitation of drilling mud, ensuring that solids are suspended and the mud is well mixed. They are available in various sizes and configurations to meet the specific needs of different drilling operations. The agitators are also equipped with durable and reliable motors, gearboxes, and impellers, making them capable of withstanding the harsh conditions of drilling sites.One of the key features of the {} mud agitators is their high efficiency, which helps to reduce energy consumption and operating costs. This is achieved through the use of advanced engineering and design, as well as high-quality materials and components. The agitators are also designed for easy maintenance and long service life, minimizing downtime and maximizing productivity for drilling operations.In addition to their high efficiency and reliability, {} mud agitators are also known for their ease of installation and operation. They can be easily integrated into existing mud systems and are simple to set up and use. This makes them a practical and convenient choice for drilling operators looking to improve their mud mixing and solid suspension processes.The availability of a wide range of options and customizations also adds to the appeal of {} mud agitators. Customers can choose from various models with different power ratings, impeller sizes, and other specifications to meet their specific needs. This flexibility allows drilling operators to find the right mud agitator for their particular drilling conditions and requirements.The success of {} mud agitators can be attributed not only to their high quality and performance but also to the company's commitment to customer satisfaction. {} provides comprehensive support and service to its customers, ensuring that they have access to technical assistance, spare parts, and maintenance services whenever they need them. This dedication to customer care has helped {} build strong and lasting relationships with its clients, who continue to rely on their products and expertise.As the demand for efficient and reliable mud agitators continues to grow in the oil and gas industry, {} is well positioned to meet the needs of drilling operators around the world. With their proven track record of delivering high-quality products and excellent customer support, {} mud agitators are set to remain a top choice for those looking to optimize their mud mixing and solid suspension processes.

Top 5 Drilling Machine Equipment for Your Next Project

Drilling Machine Equipment is proud to announce the launch of their latest innovative drilling machine, the DMX-2000. This cutting-edge equipment is designed to revolutionize the drilling industry with its advanced features and superior performance. With over 20 years of experience in the industry, Drilling Machine Equipment has established itself as a leader in providing high-quality, reliable drilling equipment for various applications.The DMX-2000 is a result of extensive research and development, aimed at meeting the growing demands of the drilling industry. With a powerful motor and high drilling capacity, this machine is capable of handling a wide range of drilling tasks with precision and efficiency. Its robust construction ensures durability and longevity, making it a cost-effective investment for businesses looking to enhance their drilling operations."We are thrilled to introduce the DMX-2000 to the market," said the spokesperson for Drilling Machine Equipment. "This machine represents our commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that the DMX-2000 will set a new standard for drilling equipment and provide our clients with a competitive edge in their operations."In addition to its impressive performance, the DMX-2000 is equipped with advanced safety features to ensure the well-being of operators and workers. It comes with an ergonomic design and intuitive controls, allowing for easy operation and minimizing the risk of accidents. Drilling Machine Equipment understands the importance of safety in the workplace, and the DMX-2000 reflects their commitment to promoting a secure working environment.Moreover, the DMX-2000 is designed to be versatile and adaptable to different drilling conditions. Whether it's for construction, mining, or exploration, this machine is capable of delivering consistent results across various applications. This flexibility makes it a valuable asset for businesses that require a reliable and efficient drilling solution for their projects.Drilling Machine Equipment has built a solid reputation in the industry for delivering exceptional products and services. With a focus on quality and customer satisfaction, the company has earned the trust of numerous clients worldwide. Their team of highly skilled engineers and technicians are dedicated to providing comprehensive support and assistance to ensure that their customers experience seamless operations with their equipment."We take pride in the relationships we have established with our clients," the spokesperson added. "At Drilling Machine Equipment, we believe in going above and beyond to support our customers and address their needs. The launch of the DMX-2000 is a testament to our continuous efforts to drive innovation and deliver solutions that add value to our clients' businesses."As a company that values sustainability and environmental responsibility, Drilling Machine Equipment has incorporated eco-friendly features into the DMX-2000. The machine is designed to minimize its carbon footprint and reduce energy consumption, aligning with the company's commitment to promoting sustainable practices in the industry.In conclusion, the launch of the DMX-2000 represents a significant milestone for Drilling Machine Equipment, showcasing their dedication to advancing the drilling industry with cutting-edge technology and superior equipment. As businesses continue to seek reliable and efficient drilling solutions, the DMX-2000 is poised to make a lasting impact and elevate the standards of performance in the industry. With its exceptional features, versatility, and focus on safety and sustainability, this machine is set to become a game-changer for drilling operations worldwide.