Mud Tank In Drilling Rig: What You Need to Know

By:Admin

The mud tank is a crucial component in the drilling rig, playing a pivotal role in the efficient extraction of oil and gas from deep within the Earth. With its ability to store and circulate drilling fluid, the mud tank ensures that the drilling process can be carried out smoothly and effectively. One company that has been leading the way in providing top-notch mud tank solutions is {}.

Established in {}, {} has become a renowned name in the oil and gas industry, specializing in the design, manufacturing, and supply of drilling equipment and accessories. With a strong focus on innovation and quality, the company has consistently delivered cutting-edge solutions to its clients, earning a reputation for reliability and excellence.

The mud tank is a prime example of a product that has contributed significantly to the success of drilling operations worldwide. A well-designed mud tank provides a centralized location for storing and mixing the drilling fluid, which is essential for maintaining the stability of the borehole, cooling and lubricating the drill bit, and carrying the rock cuttings to the surface. Without a properly functioning mud tank, drilling operations can be hindered, leading to delays and inefficiencies.

The mud tank offered by {} is designed with a keen understanding of the demands of the drilling process. It is built to withstand the harsh conditions of the drilling environment, with robust construction that ensures durability and longevity. Additionally, the mud tank is equipped with advanced features to facilitate the smooth circulation of drilling fluid, including agitators, centrifugal pumps, and mud guns that work in unison to maintain the proper consistency and properties of the mud.

One of the standout qualities of the {} mud tank is its customizable design. Recognizing that different drilling operations have unique requirements, the company offers tailored solutions to meet the specific needs of its clients. Whether it is a large-scale offshore drilling project or a smaller onshore operation, {} can provide a mud tank that is tailored to fit the available space and accommodate the necessary volume of drilling fluid.

Furthermore, {} places a strong emphasis on safety and environmental responsibility in its mud tank designs. The company ensures that its mud tanks are equipped with features that minimize the risk of spills and leaks, as well as systems for the proper disposal of drilling waste. By incorporating these elements into its products, {} enables its clients to adhere to stringent industry regulations and best practices, while also reducing the potential for environmental harm.

In addition to the quality of its products, {} is known for its comprehensive support services. The company’s team of experts is readily available to provide assistance with the installation, operation, and maintenance of its mud tanks, ensuring that clients can derive maximum value from their investment. This commitment to customer satisfaction has contributed to the strong relationships that {} has built with its clients, many of whom are repeat customers who continue to rely on the company's expertise.

Looking ahead, {} is committed to further advancing its mud tank technology, with a focus on incorporating smart, data-driven features that enable real-time monitoring and optimization of drilling fluid performance. By embracing the latest innovations, {} aims to continue enhancing the efficiency and effectiveness of drilling operations, ultimately contributing to the advancement of the oil and gas industry as a whole.

In conclusion, the mud tank is a vital component in the drilling rig, and {} has established itself as a leading provider of high-quality, customized mud tank solutions. With a strong emphasis on innovation, quality, and customer support, the company has solidified its position as a trusted partner for drilling operations around the world. As the industry continues to evolve, {} remains poised to deliver cutting-edge solutions that uphold the integrity and productivity of drilling processes.

Company News & Blog

Understanding the Environmental Impact of Oil Drilling Waste

Oil Drilling Waste Company Leading the Way in Environmental StewardshipOil drilling waste is a major concern for the environment, as it often contains harmful chemicals and pollutants that can leach into the soil and water. However, one company, XXXX (remove brand name), is leading the way in responsible waste management and environmental stewardship.XXXX (remove brand name) is a leading provider of waste management services for the oil and gas industry. With operations in multiple countries around the world, the company is dedicated to ensuring that oil drilling waste is handled and disposed of in a safe and environmentally friendly manner.The company’s approach to waste management is comprehensive and takes into account the entire lifecycle of oil drilling waste. From the initial collection and transportation of waste materials to the treatment and disposal of those materials, XXXX (remove brand name) is committed to minimizing the environmental impact of its operations.One of the key ways that XXXX (remove brand name) is addressing the issue of oil drilling waste is through its advanced treatment technologies. The company has developed innovative processes for treating drilling waste that not only remove harmful contaminants, but also allow for the recovery and recycling of valuable resources, such as oil and water.In addition to its treatment technologies, XXXX (remove brand name) also prioritizes the use of sustainable disposal methods for oil drilling waste. The company operates state-of-the-art disposal facilities that are designed to minimize the release of pollutants into the environment, while also maximizing the recovery and reuse of materials.Beyond its technical expertise, XXXX (remove brand name) also sets itself apart through its focus on compliance and transparency. The company works closely with regulatory agencies and industry stakeholders to ensure that its operations meet or exceed all relevant environmental and safety standards. Additionally, XXXX (remove brand name) is dedicated to providing transparent reporting on its waste management activities, including detailed data on waste volumes, treatment processes, and environmental performance.As a result of its commitment to environmental stewardship, XXXX (remove brand name) has earned a strong reputation as a trusted partner for oil and gas companies seeking sustainable waste management solutions. The company’s expertise and track record make it a preferred choice for both large and small operators looking to minimize their environmental footprint and demonstrate their commitment to responsible business practices.Looking ahead, XXXX (remove brand name) is continuing to innovate and expand its capabilities in the field of oil drilling waste management. The company is investing in research and development to further improve its treatment technologies and explore new opportunities for resource recovery from waste materials. Additionally, XXXX (remove brand name) is actively pursuing partnerships and collaborations with industry peers and academic institutions to advance the state of the art in sustainable waste management practices.Ultimately, XXXX (remove brand name) is setting a high bar for environmental responsibility in the oil and gas industry. With its focus on advanced treatment technologies, sustainable disposal methods, and transparent reporting, the company is demonstrating that it is possible to manage oil drilling waste in a way that protects the environment and supports the long-term sustainability of the industry. As the demand for responsible waste management continues to grow, XXXX (remove brand name) is well positioned to lead the way in delivering innovative and effective solutions for the benefit of the industry and the environment.

Top-quality Drilling Mud Centrifuge for Petroleum Drilling in China

China Petroleum Drilling Mud Centrifuge has become an essential tool in the oil and gas industry. It is used to remove solids from drilling mud, a crucial component in the drilling process. With the increasing demand for energy and the expansion of oil and gas exploration, the need for efficient and reliable centrifuge technology has never been greater.One of the leading providers of drilling mud centrifuges is a company with a proven track record in delivering high-quality products. With a commitment to innovation and excellence, they have been at the forefront of developing cutting-edge centrifuge technology for the oil and gas industry.The company's drilling mud centrifuge is designed to efficiently separate solids from the drilling mud, ensuring that the mud can be reused and recycled. This not only reduces waste but also minimizes the environmental impact of drilling operations. By incorporating advanced features and state-of-the-art technology, the centrifuge is able to achieve high levels of performance and reliability, even in the most demanding drilling environments.As one of the largest suppliers of drilling mud centrifuges in China, the company has established a strong reputation for delivering products that meet the highest standards of quality and reliability. Their centrifuges are widely used in drilling operations across the country and have earned the trust and confidence of their customers.The company's success can be attributed to its unwavering commitment to research and development. They invest heavily in the latest technologies and continuously strive to improve their products. This dedication to innovation has enabled them to stay ahead of the competition and deliver cutting-edge solutions to the oil and gas industry.In addition to their technological expertise, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific needs and provide tailored solutions that meet their requirements. This customer-centric approach has earned them a loyal customer base and a reputation for excellence in the industry.The company's drilling mud centrifuge is just one example of their commitment to driving the industry forward. With a focus on sustainability and efficiency, they are constantly exploring new ways to improve their products and processes. By partnering with leading oil and gas companies, they are able to gain valuable insights that inform their research and development efforts.Looking to the future, the company is poised to continue its growth and expansion. With a strong foundation built on innovation and customer satisfaction, they are well-positioned to meet the evolving needs of the oil and gas industry. As the demand for energy continues to rise, the company's drilling mud centrifuge will play a vital role in ensuring the efficiency and sustainability of drilling operations.In conclusion, China Petroleum Drilling Mud Centrifuge is an essential tool for the oil and gas industry. With a commitment to innovation, quality, and customer satisfaction, the company has established itself as a leading provider of drilling mud centrifuges in China. As the industry continues to evolve, their cutting-edge technology and dedication to excellence will be instrumental in driving the industry forward.

High-Quality Drilling Rig Parts and Drawworks in China

China has long been a leader in the oil and gas industry, and their advancements in drilling rig technology have been at the forefront of this. With a commitment to innovation and quality, Chinese companies continue to provide essential parts and equipment for drilling operations around the world.One such company is {}, a leading provider of drilling rig parts and equipment. With a focus on research and development, they have become known for their high-quality products that meet the demands of the industry. From drill drawworks to drilling rig components, {} has established itself as a reliable supplier for companies looking to enhance their drilling operations.In recent years, the demand for drilling rig parts and equipment has continued to grow as the global energy market expands. This has led to increased competition among suppliers, but {} has been able to distinguish itself through its dedication to quality and customer service.One of the key products that {} offers is their drill drawworks. This essential component of a drilling rig is responsible for raising and lowering the drill string, making it a vital part of the overall operation. With a focus on durability and efficiency, {}'s drill drawworks have become a popular choice for companies looking to maximize their drilling capabilities.In addition to drill drawworks, {} also provides a wide range of other drilling rig parts, including mud pumps, top drives, and more. Their comprehensive selection of products makes them a one-stop shop for companies in need of reliable equipment for their drilling operations.One of the major advantages of working with {} is their commitment to customization. They understand that every drilling operation is unique, and they are able to tailor their products to fit the specific needs of their customers. This flexibility has made them a preferred supplier for drilling companies around the world.In addition to their product offerings, {} also provides comprehensive support and services for their customers. This includes technical assistance, maintenance and repair services, and training programs for operators. This commitment to customer satisfaction sets {} apart from other suppliers and has helped them build long-lasting relationships with their clients.With an eye towards the future, {} continues to invest in research and development to further enhance their products and services. They understand the importance of staying ahead of the curve in an ever-evolving industry, and they are dedicated to maintaining their position as a leading supplier of drilling rig parts and equipment.As the global demand for energy continues to rise, the importance of reliable drilling operations has never been greater. Companies like {} play a critical role in supporting these operations by providing high-quality parts and equipment that are essential for success. With their commitment to innovation and customer satisfaction, {} is well-positioned to continue leading the way in the drilling rig industry for years to come.

High-quality Mixer Agitator Equipment for Efficient Mixing Operations

Mixer Agitator Equipment has been making waves in the industry with their innovative and high-quality products. The company, located in a state-of-the-art facility, has been a leading manufacturer of mixing and agitation equipment for various industries such as chemical, pharmaceutical, food and beverage, and more. They have gained a reputation for providing top-of-the-line equipment that meets the needs of their customers and exceeds industry standards.The company's success can be attributed to their commitment to research and development, as well as their dedication to providing exceptional customer service. They have a team of experienced engineers and technicians who are constantly working on improving their existing products and developing new, cutting-edge solutions for their clients. This focus on innovation has allowed them to stay ahead of the competition and continue to be a trusted name in the industry.One of the company's standout products is their line of {Mixer Agitator Equipment}. These mixers and agitators are designed to provide efficient and thorough mixing of various substances, whether it be liquids, gases, or solids. With a range of different models and configurations available, customers can find the perfect equipment to meet their specific needs. The mixers and agitators are built to withstand the rigors of industrial use, and are constructed from durable materials that are meant to last.The {Mixer Agitator Equipment} also comes with a variety of features and customization options that allow customers to tailor the equipment to their exact requirements. Whether it's a specific speed, power, or mixing capacity, the company offers a range of options to ensure that their customers are getting the perfect solution for their needs. Additionally, the equipment is easy to maintain and operate, making it a convenient choice for businesses of all sizes.The company takes pride in their commitment to customer satisfaction, and they go above and beyond to ensure that their clients are getting the support they need. From the initial consultation and design phase, to the installation and ongoing service, the company's team is dedicated to providing a seamless and positive experience for their customers. This level of support has made them a preferred choice for many businesses in need of mixing and agitation solutions.In addition to their exceptional product line and customer service, Mixer Agitator Equipment also emphasizes the importance of sustainability and environmental responsibility. The company is committed to reducing their environmental impact through the use of energy-efficient processes and materials in their manufacturing. They are also dedicated to developing products that help their clients reduce waste and improve their own sustainability initiatives.As a leading manufacturer in the industry, Mixer Agitator Equipment continues to set the bar for excellence. Their dedication to innovation, quality, and customer satisfaction has earned them a strong reputation and a loyal customer base. With a focus on sustainability and a commitment to staying ahead of industry trends, the company is poised to remain a top choice for businesses in need of mixing and agitation equipment for years to come.

Efficient Mud Mixing Hoppers for Solid Control Systems: A Comprehensive Introduction

Mud mixing hoppers are an essential component of solid control systems used in drilling operations. They are designed to mix mud bulk materials and mud additive chemicals into drilling fluids to improve their density, viscosity, and stability. In this blog, we will discuss the benefits of mud mixing hoppers and their importance in drilling operations.Mud mixing hoppers are available in manual and automatic versions, depending on project needs. The automatic version is equipped with overflow and backflow prevention systems that ensure the hopper doesn't overflow and waste materials. Mud hoppers are usually made of rugged stainless steel, which makes them durable and resistant to corrosion. This feature makes them ideal for harsh offshore environments, where drilling operations are often carried out.One of the significant benefits of using a mud mixing hopper in drilling operations is that it reduces mud mixing times and enhances drilling efficiency. By mixing drilling fluids on the rig, less time is required to transport the fluids to the drilling site, resulting in less downtime and reduced costs.Furthermore, mud mixing hoppers eliminate the need for manual mixing of drilling fluids, which can be labor-intensive and time-consuming. With automated mud mixing hoppers and the use of industrialized machines, drilling can be faster, and employees can focus on other tasks.Another advantage of using mud mixing hoppers is that they help improve drilling fluid properties. This is because the hoppers can accurately mix various components that make up the drilling fluid, including base fluids and additives. This enhances the physical and chemical properties of the drilling fluid, resulting in smoother drilling operations.Additionally, mud mixing hoppers help ensure the safety of employees working on offshore drilling rigs. These hoppers are designed to meet all relevant offshore health, safety, and environmental requirements, which are essential for drilling operations.In conclusion, mud mixing hoppers are an essential component of drilling operations. They improve the quality of drilling fluids, reduce costs, reduce downtime, and enhance safety and efficiency. If you need mud mixing hoppers, contact DC Office for all your drilling needs. Our team of experts will work with you to provide customized solutions that meet your project requirements.

Discover the Power of a Single Stage Vacuum Dielectric Insulating Oil Purifier for Sale

Acoreoilfiltration oil purifier for sale introduces the new Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd, a leading manufacturer of oil purification equipment in China. This new machine is designed to purify and restore the quality of dielectric insulating oil used in high voltage electrical equipment.Dielectric insulating oil plays a vital role in the efficient and safe operation of high voltage electrical equipment such as transformers, circuit breakers, and capacitors. Over time, this oil can become contaminated with impurities such as water, dissolved gases, and particulate matter, reducing its dielectric strength and increasing the risk of equipment failure and power outages.To address this problem, Kongen Oil Purifier Co.,Ltd has developed the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine. This machine uses a combination of vacuum dehydration, degassing, and particulate filtration to remove contaminants from the oil and restore its dielectric strength and chemical stability. The machine can process up to 3000 liters of oil per hour and is suitable for use with mineral, synthetic, and silicone dielectric insulating oils.One of the key features of this machine is its advanced vacuum dehydration system, which removes water and moisture from the oil by exposing it to a vacuum. This process not only removes free and dissolved water but also removes water molecules that are chemically bound to the oil, resulting in a significantly lower moisture content and improved dielectric strength of the oil.The machine also features a high-efficiency degassing chamber, which uses a special vacuum system to remove dissolved gases such as oxygen, nitrogen, and carbon dioxide from the oil. This is important because dissolved gases can contribute to the formation of corrosive compounds and reduce the effectiveness of the oil as an insulator.In addition to oil purification, Kongen Oil Purifier Co.,Ltd also specializes in the production of Deaerator and Vacuum Deaerator equipment. These products are used in a variety of industries, including power generation, petrochemicals, and food processing, to remove excess dissolved gases from liquids and prevent corrosion and other issues.Kongen Oil Purifier Co.,Ltd has been providing high-quality purification and deaeration equipment to customers worldwide for over 20 years. The company is committed to providing innovative and reliable solutions to its customers, using the latest technology and equipment to meet their specific needs.In summary, the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd is a highly effective and efficient solution for purifying and restoring the quality of dielectric insulating oil used in high voltage electrical equipment. Combined with the company's expertise in deaeration technology, Kongen Oil Purifier Co.,Ltd is a trusted leader in the field of oil purification and treatment.

Mud Pump for Drilling: The Latest Innovations in Chinese Equipment

Shanghai, China - China Mud Pump, a leading manufacturer of high-quality mud pumps for drilling applications, has announced that they are now offering a wide range of mud pumps for the drilling industry. With a strong focus on innovation and quality, the company has established a reputation for providing reliable and efficient equipment for oil and gas exploration, mining, and other drilling operations.The company is known for its commitment to continuous improvement and customer satisfaction. They have invested heavily in research and development to ensure that their products meet the highest standards of performance and reliability. In addition, they have a team of experienced engineers and technicians who are dedicated to providing comprehensive support and technical assistance to their clients.China Mud Pump's products are designed to meet the specific needs of the drilling industry, offering a variety of models with different specifications and features to accommodate various drilling conditions. These mud pumps are widely used in onshore and offshore drilling operations, providing the necessary pressure and flow rate to effectively remove drilling cuttings and maintain wellbore stability.In addition to their standard product line, China Mud Pump also offers customized solutions to meet the unique requirements of their clients. They work closely with their customers to understand their specific needs and provide tailored mud pump solutions that are efficient, reliable, and cost-effective.One of the key advantages of China Mud Pump's products is their focus on sustainability and environmental responsibility. They have implemented advanced technologies to minimize energy consumption and reduce environmental impact, ensuring that their equipment complies with the highest environmental standards.Furthermore, the company has a strong commitment to quality control and has implemented rigorous testing and inspection processes to ensure the reliability and performance of their mud pumps. This dedication to quality has earned them the trust and confidence of their customers, who rely on their products for their critical drilling operations.China Mud Pump's dedication to excellence extends beyond their products, as they also provide comprehensive after-sales support and service. Their team of skilled technicians is available to assist with installation, maintenance, and repairs, ensuring that their clients can rely on their equipment for the long term.With a strong focus on technological innovation, quality control, and customer satisfaction, China Mud Pump has positioned itself as a trusted partner for the drilling industry. As the demand for efficient and reliable mud pumps continues to grow, the company is well-equipped to meet the evolving needs of their clients and provide innovative solutions that enhance drilling productivity and efficiency.In conclusion, China Mud Pump is a leading manufacturer of mud pumps for drilling applications, offering a wide range of high-quality products designed to meet the specific needs of the drilling industry. With a strong commitment to innovation, quality, and customer satisfaction, the company is well-positioned to support the growing demand for efficient and reliable drilling equipment. Whether it's for onshore or offshore drilling operations, China Mud Pump's products and services have become the go-to choice for many drilling companies around the world.

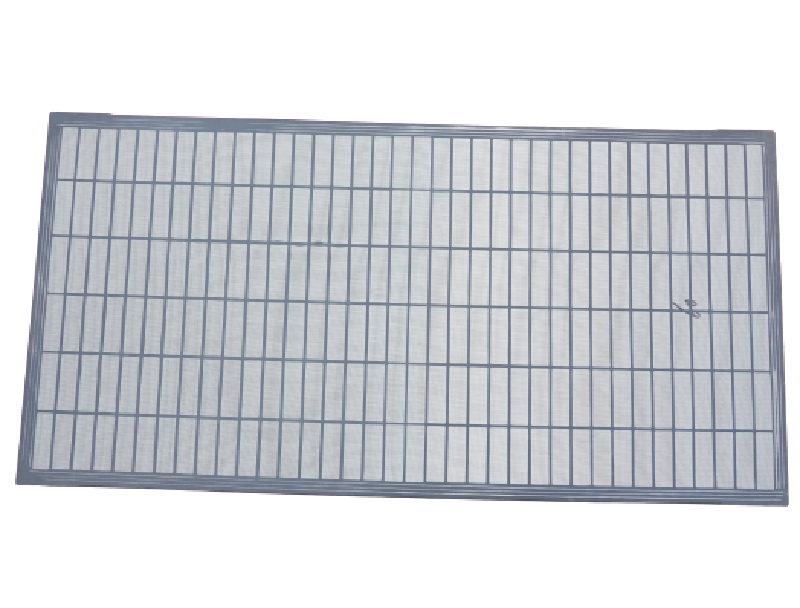

Discover the Versatility of Flat Shaker Screens for Effective Solid Separation

FLC 500 Flat Shaker Screen: Revolutionizing the Drilling IndustryThe drilling industry is constantly evolving, with new technologies and equipment constantly emerging to improve efficiency and operational capabilities. One such innovation making waves in the sector is the FLC 500 Flat Shaker Screen, a groundbreaking solution developed by a prominent industry player.Designed to enhance the performance and productivity of drilling operations, the FLC 500 Flat Shaker Screen is revolutionizing the way drilling companies approach their work. With its advanced features and engineering excellence, this game-changing technology has gained significant recognition within the industry.The FLC 500 Flat Shaker Screen is the result of extensive research and development by a leading drilling equipment manufacturer. Leveraging their rich experience and expertise, the company identified a need for an improved shaker screen solution to overcome the challenges faced by drilling companies.One of the key features that sets the FLC 500 Flat Shaker Screen apart from its competitors is its flat design. This innovative construction ensures optimal solids control, allowing for more efficient separation of drilling fluids and solids during the drilling process. The flat screen surface provides a larger area for fluid dewatering, maximizing the screen's capacity and performance.Additionally, the FLC 500 Flat Shaker Screen boasts enhanced durability and longevity. Crafted using high-quality materials and state-of-the-art manufacturing techniques, this robust solution withstands the harsh operating conditions typically encountered in drilling operations. Its extended lifespan not only reduces operational downtime but also significantly lowers maintenance and replacement costs.Furthermore, the FLC 500 Flat Shaker Screen offers exceptional versatility. Compatible with various drilling equipment, it seamlessly integrates with existing systems, ensuring a hassle-free installation process. Its adaptability empowers drilling companies to upgrade their equipment without requiring substantial modifications, thereby improving operational efficiency and saving valuable time.The company behind this breakthrough innovation is known for its commitment to delivering superior technology with a focus on customer satisfaction. With a relentless dedication to research and development, combined with a customer-centric approach, they have earned a reputation as a trusted and reliable partner in the drilling industry.The FLC 500 Flat Shaker Screen is just one example of the company's commitment to innovation. Their extensive product portfolio includes a range of drilling equipment tailored to meet the unique needs and challenges of the industry. From screens to pumps, they offer comprehensive solutions that cater to diverse drilling requirements.In addition to their cutting-edge technology, the company places great emphasis on customer support and service. Their team of highly skilled professionals provides industry-leading technical assistance and on-site support to ensure seamless integration and optimal performance of their equipment. This dedication to customer satisfaction has positioned them as a preferred supplier amongst drilling companies worldwide.The introduction of the FLC 500 Flat Shaker Screen marks a significant milestone in the drilling industry. With its flat design, enhanced durability, and unmatched versatility, it is transforming the way drilling operations are conducted. As companies continue to prioritize efficiency and productivity, this revolutionary technology is set to play a pivotal role in shaping the future of the drilling industry.

Highly-Durable Mud Gun Nozzle Provides Effective Solutions for Industrial Operations

Mud Gun Nozzle, a vital component in the oil and gas industry, plays a crucial role in the drilling process. The mud gun nozzle is used to spray drilling mud, a mixture of water, clay, and other chemicals, into the drilling well to lubricate the drill bit, carry rock cuttings to the surface, and maintain pressure in the well. It is an essential tool for optimizing the drilling process and ensuring the success of oil and gas extraction operations.In this context, one company, which is a leading manufacturer of drilling equipment and tools, has recently launched its latest mud gun nozzle, designed to enhance drilling efficiency and reliability. With over 20 years of experience in the industry, the company has become a trusted name in providing high-quality products and innovative solutions for oil and gas exploration and production.The new mud gun nozzle features a cutting-edge design that offers improved performance and durability. Its advanced nozzle configuration allows for better spray coverage and distribution of drilling mud, resulting in more efficient drilling operations. The material used in the construction of the nozzle is highly resistant to corrosion and abrasion, ensuring long-lasting performance even in the harshest drilling environments.Furthermore, the company's mud gun nozzle is engineered to provide easy maintenance and servicing, reducing downtime and operational costs for drilling companies. The design incorporates quick-connect fittings and accessible components, allowing for effortless disassembly and reassembly when necessary. This user-friendly approach reflects the company's commitment to delivering practical and reliable solutions to its customers.In addition to the superior design and functionality, the mud gun nozzle is also backed by the company's renowned technical support and customer service. The company's team of experienced engineers and technicians are available to provide assistance with installation, maintenance, and troubleshooting, ensuring that customers can maximize the performance of the mud gun nozzle and their overall drilling operations.As part of its dedication to quality and customer satisfaction, the company conducts rigorous testing and quality assurance procedures to ensure that its mud gun nozzles meet the highest standards of performance and reliability. This attention to detail and commitment to excellence have earned the company the trust and loyalty of numerous drilling companies around the world.The launch of the new mud gun nozzle represents the company's ongoing efforts to innovate and improve its product offerings to meet the evolving needs of the oil and gas industry. By leveraging its expertise and technical capabilities, the company aims to continue playing a significant role in advancing drilling technologies and supporting the exploration and production activities of its customers.In conclusion, the introduction of the new mud gun nozzle by the company signifies a significant development in the realm of drilling equipment and tools for the oil and gas industry. With its advanced design, exceptional performance, and unwavering commitment to customer support, the company continues to solidify its position as a leading provider of reliable and innovative solutions for drilling operations. As the industry continues to evolve, the company remains poised to meet the challenges and demands of the future, driven by its dedication to excellence and customer satisfaction.

High-performance Mixing Tank with Agitator for Efficient Mixing

The company is a renowned manufacturer of industrial mixing equipment that is used in a wide range of industries including chemical, pharmaceutical, food and beverage, and cosmetics among others. Their products are known for their high quality, efficiency, and reliability, making them the top choice for businesses looking for innovative mixing solutions.One of their flagship products is the Mixing Tank with Agitator, which has gained a reputation for its exceptional performance and versatility. This mixing tank is designed to handle a variety of mixing applications including blending, dispersion, and homogenization. It is equipped with a powerful agitator that ensures thorough mixing and uniform distribution of materials, resulting in high-quality end products.The Mixing Tank with Agitator is available in different sizes and configurations to meet the specific needs of different industries. It is constructed using high-grade materials such as stainless steel, making it durable and resistant to corrosion. The tank is also designed with safety features and easy-to-use controls, ensuring the convenience and protection of operators.The agitator system of the mixing tank is a key component that sets it apart from other similar products in the market. It is engineered to deliver high levels of agitation, allowing for efficient mixing of even the most challenging materials. The agitator is also designed to minimize energy consumption while maximizing the effectiveness of the mixing process.One of the main advantages of the Mixing Tank with Agitator is its ability to improve the overall efficiency of manufacturing processes. By ensuring proper mixing and blending of materials, it helps businesses achieve higher product quality and consistency, leading to increased customer satisfaction. It also helps in reducing production time and costs, ultimately boosting the bottom line of businesses.Another noteworthy feature of the Mixing Tank with Agitator is its ease of maintenance. The design of the tank and agitator system allows for easy access for cleaning and maintenance, reducing downtime and prolonging the lifespan of the equipment. This contributes to the overall cost-effectiveness of the product, making it a valuable investment for businesses.In addition to the Mixing Tank with Agitator, the company also offers comprehensive customer support and after-sales service. Their team of technical experts is readily available to provide assistance with installation, training, troubleshooting, and spare parts supply. This ensures that customers can maximize the benefits of their mixing equipment and minimize any disruptions to their operations.The company takes pride in its commitment to innovation and continuous improvement. They are constantly researching and developing new technologies to enhance their products and stay ahead of industry trends. With a strong focus on customer satisfaction and technical excellence, they have established themselves as a trusted partner for businesses seeking reliable mixing solutions.Overall, the Mixing Tank with Agitator from {} represents a top-tier mixing solution for a wide range of industries. Its exceptional performance, durability, and user-friendly design make it a valuable asset for businesses looking to optimize their mixing processes. With the backing of a reputable manufacturer and dedicated customer support, businesses can trust in the reliability and effectiveness of this mixing tank for their operations.