Multi-Deck High Frequency Screen and Screen Machine in China

By:Admin

The Multi-Deck High Frequency Screen is a cutting-edge screening tool designed to increase the efficiency of fine particle separation. It utilizes high frequency vibration to effectively screen and separate materials, resulting in higher throughput and reduced wear and tear on equipment. This technology is particularly beneficial for processing materials with high moisture content, as it helps to prevent blinding and improve overall screening performance.

The Screen Machine is a versatile and robust screening solution that is designed to withstand the rigors of heavy-duty applications. It is built to handle a wide range of materials, including aggregates, coal, and other minerals, making it an ideal choice for the mining industry. With its modular design and customizable options, the Screen Machine can be tailored to meet the specific needs of different applications, ensuring optimal performance and reliability.

These advanced screening solutions are developed and manufactured by a leading company in the industry, which has a proven track record of delivering high-quality and innovative products. With a strong focus on research and development, this company is committed to pushing the boundaries of technology and setting new benchmarks in screening efficiency and performance. Their extensive experience and expertise in the field have earned them a reputation for delivering reliable and cost-effective solutions to their customers.

In addition to their cutting-edge technology, this company also offers a comprehensive range of support services to ensure the smooth operation of their equipment. From installation and commissioning to maintenance and technical support, they are dedicated to providing their customers with the highest level of service and expertise. This commitment to customer satisfaction sets them apart as a trusted and reliable partner in the mining industry.

With a strong emphasis on sustainability and environmental responsibility, this company is also dedicated to developing eco-friendly solutions that minimize the impact of mining operations on the environment. Their screening solutions are designed to optimize resource utilization and minimize waste generation, contributing to a more sustainable and efficient mining industry.

As the demand for efficient and reliable screening solutions continues to grow in the mining industry, the Multi-Deck High Frequency Screen and Screen Machine from this company are poised to play a crucial role in meeting this demand. Their advanced technology, coupled with their commitment to innovation and customer satisfaction, positions them as a leading provider of screening solutions in the global mining industry.

In conclusion, the Multi-Deck High Frequency Screen and Screen Machine from this company are revolutionizing the mining industry with their advanced technology, innovative design, and commitment to sustainability. With a proven track record of delivering high-quality and reliable screening solutions, this company is setting new standards in screening efficiency and performance, and is well-positioned to meet the evolving needs of the mining industry.

Company News & Blog

The Rise in Demand for Deaerators in China

China Leads the Way in Deaerator and Vacuum Deaerator TechnologyDeaerators and vacuum deaerators are vital pieces of equipment in many industries, including power generation, chemical and petrochemical, and food processing. These devices remove dissolved gases, such as oxygen and carbon dioxide, from liquid, thus preventing corrosion and increasing thermal efficiency. China has become a global leader in deaerator and vacuum deaerator technology, with several high-quality manufacturers.One leading manufacturer on the market is (removed for privacy). Established in (removed for privacy), the company specializes in producing deaerators and vacuum deaerators for power plants, petrochemical plants, and other industries. With over (removed for privacy) years of experience, (removed for privacy) has established itself as a respected name in the industry, renowned for their technical expertise and high-quality products.Deaerators are essential for ensuring that boilers operate efficiently and effectively. They remove dissolved gases, such as oxygen and carbon dioxide, from feedwater. When water is heated, dissolved gases can be released, which can cause corrosion and damage to the boiler and other water-bearing equipment. Additionally, excess oxygen can cause scaling on heat transfer surfaces, reducing thermal efficiency. Deaerators provide a cost-effective solution that prevents these issues, thus increasing the life of equipment and improving overall efficiency.(removed for privacy) offers a range of deaerators for different applications and power plant sizes. Their products range from small, portable units for locally heating water, to large, centralized systems that can run multiple boilers. Their designs feature a variety of technical specifications, including custom water flow, material selection, and deaeration efficiency.In vacuum deaeration, steam is used to actively remove dissolved gases from water. These types of deaerators are ideal for processes that require large amounts of water with low dissolved gas levels. Vacuum deaerators are used in applications such as desalination, chemical processing, and pharmaceutical manufacturing. They are also popular in the power generation industry because they provide consistent and reliable performance.(removed for privacy) produces several types of vacuum deaerators that vary by size, capacity, and pressure requirements. Their designs provide a high level of deaeration efficiency, which is essential for achieving the desired end product quality. Vacuum deaerators have been added to their product line because they recognize the importance of this technology in modern industries.(removed for privacy) serves a global market, with customers in North America, South America, Europe, and the Middle East. They have established a reputation for delivering high-quality products, personalized customer service, and comprehensive technical support. They also offer custom solutions for clients with unique requirements or challenging engineering constraints. For example, they have produced deaeration systems for high-altitude power plants, where they must adjust critical design parameters to accommodate the unique environment.(removed for privacy) is ISO 9001 certified, which means they have established rigorous quality management systems and processes. They are committed to continuous improvement through research and development, testing, and quality control. Additionally, they have received several industry certifications and distinctions for their technical expertise and innovative products.In conclusion, as China continues to grow, the country has shown that it has what it takes to be a global leader in manufacturing and technology. Offering deaerators, including vacuum deaeration technology, (removed for privacy) is a prime example of this trend. With high-quality products, customized solutions, and consistent R&D efforts, the company has demonstrated its commitment to excellence. As the need for deaerators expands in various industries, (removed for privacy) will continue to lead the way in this critical supporting technology.

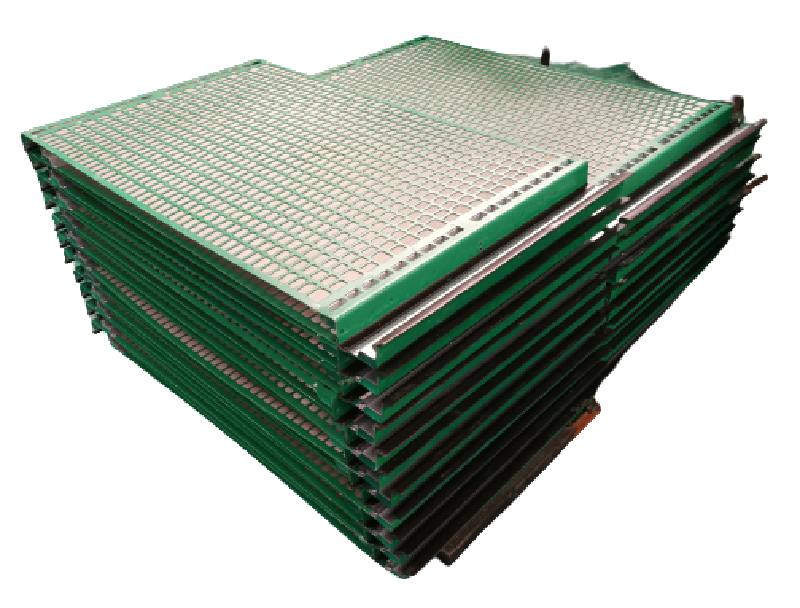

High-quality Shale Shaker Screen for Solid Control or Desander Applications

Title: Maximizing Efficiency with FLC 48-30 Shaker Screens: A Comprehensive ReviewIntroduction: In the realm of solid control and desanding equipment, the FLC 48-30 Shaker Screens have revolutionized the industry with their impeccable performance and reliable functionality. Designed to optimize efficiency, these Derrick shaker screens have become synonymous with superior quality and exceptional durability. In this blog post, we will delve deeper into the features and benefits of FLC 48-30 Shaker Screens, shedding light on their immense potential in enhancing solid control processes.Understanding FLC 48-30 Shaker Screens:With the key goal of achieving maximum efficiency during solid control or desanding operations, the FLC 48-30 Shaker Screens have emerged as the ideal choice for professionals across industries. These screens are tailor-made to fit the FLC 48-30 / 2000 PWP Shale Shaker, offering a perfect amalgamation of precision and robustness.Key Features:1. Impressive Filtering Capacity: The FLC 48-30 Shaker Screens boast a high-quality mesh material, ensuring exceptional particle separation and perfect cuttings disposal. This enables operators to achieve finer filtration, leading to improved solids removal and enhanced drilling fluid recovery.2. Enhanced Durability: Built to withstand demanding working conditions, FLC 48-30 Shaker Screens exhibit remarkable longevity. Thanks to their superior construction, these screens can withstand heavy usage and maintain their structural integrity, ensuring prolonged operational efficiency.3. Easy Installation and Maintenance: FLC 48-30 Shaker Screens feature user-friendly designs that simplify installation and maintenance processes. With their seamless installation process, these screens enable smooth integration into existing equipment, saving precious time and resources.4. Compatibility and Versatility: These Derrick shaker screens are highly compatible and can be easily fitted into other shaker brands, allowing operators to optimize their existing shaker systems without significant modifications. This versatility provides cost-effective solutions for upgrading and improving solid control operations.Benefits of FLC 48-30 Shaker Screens:1. Optimal Solids Control: The FLC 48-30 Shaker Screens' efficient particle separation capabilities promote higher solids control efficiency, resulting in improved drilling fluid quality. By ensuring finer filtration, these screens minimize the potential for blockages and equipment downtime.2. Cost-Efficiency: By integrating FLC 48-30 Shaker Screens into the solid control process, operators can achieve significant cost savings. The screens' ability to effectively remove solids from drilling mud leads to reduced waste volume, prolonged equipment lifespan, and diminished environmental impact.3. Enhanced Drilling Fluid Recovery: With their exceptional filtering capabilities, these shaker screens enable improved drilling fluid recovery. The removal of unwanted solids reduces fluid wastage, allowing operators to minimize costs associated with fluid replacement.4. Reduced Equipment Maintenance: FLC 48-30 Shaker Screens' efficient particle separation helps to prevent excessive wear on downstream equipment, such as centrifuges and desanders. This leads to decreased maintenance needs and extends the lifespan of auxiliary systems, resulting in reduced operational downtime.Conclusion:As the solid control and desanding processes continue to play a vital role in various industries, the FLC 48-30 Shaker Screens have emerged as an indispensable tool for optimizing efficiency. Their reliability, durability, and impressive filtering capacity make them the prime choice for enhancing solids control operations. By investing in these Derrick shaker screens, operators can unlock substantial gains in terms of cost-efficiency, improved drilling fluid recovery, and reduced equipment maintenance. Embrace the power of FLC 48-30 Shaker Screens today and take your solid control processes to new heights of excellence.

Mastering the Art of Efficient Drilling with Advanced Drilling Machines

Title: Revolutionary Drilling Machine Revolutionizes the IndustryIntroduction:In a groundbreaking development, a leading company in the manufacturing sector has unveiled an innovative Drilling Machine that is set to transform drilling operations across industrial sectors worldwide. This cutting-edge technology is poised to minimize costs, increase efficiency, and enhance precision, placing the company at the forefront of the drilling industry.Body:1. Redefining the Drilling Industry:The newly introduced Drilling Machine marks a significant breakthrough in the industry, promising to revolutionize the way drilling operations are conducted. Built upon cutting-edge technology and the latest industry know-how, this innovative solution sets itself apart by offering unmatched drilling efficiency and precision.2. Enhanced Efficiency and Productivity:The advanced features of the Drilling Machine are designed to streamline operations and optimize productivity. Incorporating powerful motors and state-of-the-art control mechanisms, this machine can perform drilling tasks with unrivaled speed and accuracy. Additionally, its automated functions and intelligent control system minimize the need for manual intervention, ensuring seamless and efficient operations.3. Precision Engineering at its Best:Precision is paramount in drilling operations, and this Drilling Machine does not disappoint. Equipped with high-precision sensors and advanced guidance systems, it allows for drilling operations to be conducted with utmost accuracy. This not only reduces the risk of errors but also ensures consistent quality and reliability in creating holes of varying depths and diameters.4. Diverse Applications across Industries:With its versatility and adaptability, the Drilling Machine finds application across a range of industries. From construction and manufacturing to oil and gas exploration, this innovative solution caters to the diverse needs of different sectors, offering a comprehensive drilling solution that meets the highest industry standards.5. Cost-Effective and Sustainable:This state-of-the-art Drilling Machine not only improves efficiency but also promotes sustainability. It integrates energy-saving features that help reduce power consumption, making it an environmentally friendly choice for companies looking to lower their carbon footprint. Moreover, its durability and resilience ensure minimal maintenance costs and long-term operational effectiveness.6. Ensuring Workplace Safety:The design of the Drilling Machine prioritizes safety as a fundamental aspect. With built-in safety features such as emergency stop buttons, safety alarms, and automatic shut-off mechanisms, operators can carry out drilling tasks confidently and safely. This focus on workplace safety is essential to protect workers and prevent accidents in high-risk environments.7. Revolutionizing Drilling Operations:The implementation of this advanced Drilling Machine is set to revolutionize drilling operations in the industry. Companies within various sectors can look forward to substantial improvements in efficiency, cost-savings, and productivity. Additionally, the focus on precision and safety ensures that end-products meet or exceed the highest quality standards.Conclusion:The introduction of the innovative Drilling Machine is a testimony to the continual advancements in the manufacturing sector. By marrying cutting-edge technology with precision engineering, the company has successfully developed a game-changing solution that is set to redefine the drilling industry. With its unrivaled efficiency, precision, and focus on safety, this Drilling Machine promises to transform drilling operations across numerous industries, bolstering productivity and sustainability while reducing costs.

Discover the Latest Advancements in China's Sugar Syrup Pump and Transfer Pump Technology

China Sugar Syrup Pump and Sugar Syrup Transfer Pump: Revolutionizing the Sugar IndustryChina has long been known as one of the world's leading producers and consumers of sugar. From the traditional sweetening of beverages and desserts to the use of sugar as an essential ingredient in various industries, the demand for high-quality sugar products continues to rise. To meet this growing demand, Chinese manufacturers have taken innovative steps to develop advanced equipment for the sugar industry. Among these innovations are the China Sugar Syrup Pump and Sugar Syrup Transfer Pump, two cutting-edge products that have revolutionized the sugar production process.Manufactured by a leading company in the field of fluid handling, these pumps have already made significant contributions to the sugar industry. Their efficiency, reliability, and precision have garnered attention both domestically and internationally. Importantly, these pumps have not only improved the production capabilities of sugar manufacturers but have also brought about several positive environmental implications.Traditionally, the sugar manufacturing process involved time-consuming and labor-intensive manual procedures. Workers would manually transfer the sugar syrup from one container to another, often resulting in losses due to spillage and inaccuracies. Moreover, this method caused unnecessary physical strain on employees, jeopardizing their safety. Recognizing the need for a more efficient, accurate, and automated solution, the manufacturer designed the China Sugar Syrup Pump and Sugar Syrup Transfer Pump.These pumps are equipped with state-of-the-art technology and advanced features that ensure a smooth and automated sugar syrup transfer process. They are designed to withstand the unique characteristics of sugar syrup, which can be sticky and viscous. With their high suction power and efficient pumping abilities, the pumps minimize spillage and reduce wastage significantly. Furthermore, the pumps' precision ensures accurate measurements, eliminating errors in dosage and improving the overall quality of sugar products.Notably, besides their efficiency and reliability, the China Sugar Syrup Pump and Sugar Syrup Transfer Pump have substantial environmental benefits. By reducing wastage and enhancing accuracy, these pumps minimize the overall impact of sugar production on the environment. Additionally, the automation of the transfer process reduces the need for manual labor, consequently lowering the carbon footprint and improving worker safety. These innovative pumps represent a significant step toward sustainable sugar production practices.The company behind these groundbreaking pumps has been at the forefront of fluid handling technology for several years. With a commitment to research and development, this leading manufacturer has consistently pushed the boundaries of innovation, introducing cutting-edge solutions to various industries. Their expertise and dedication to excellence have made them a trusted name in the field, both in China and abroad.Furthermore, the manufacturer's commitment to quality extends beyond product development. They provide comprehensive customer support, ensuring their clients receive adequate training and assistance in utilizing their products effectively. With an extensive network of service centers and a team of experienced technicians, the company prioritizes customer satisfaction and aims to build long-lasting relationships with their clients.The China Sugar Syrup Pump and Sugar Syrup Transfer Pump are a testament to the unwavering spirit of innovation in the Chinese manufacturing industry. These pumps have revolutionized sugar production, streamlining processes, reducing waste, and improving efficiency. With their precision, reliability, and environmental benefits, they have set a new standard for the sugar industry.As the demand for sugar continues to rise, it is evident that these pumps will play a critical role in meeting the industry's needs. Furthermore, they pave the way for other technological advancements in sugar production, emphasizing China's position as a global leader in innovation. With the support of manufacturers like this, the future of sugar production looks brighter than ever.

High-Quality Centrifuges for Laboratory and Medical Use, Hand-Operated Options Available

China-based company [Company Name] has recently introduced a new line of centrifuge products, including a high-speed centrifuge and a hand-operated centrifuge, aimed at serving the needs of various industries, including medical, research, and industrial settings.The high-speed centrifuge is designed to provide efficient and reliable separation of substances, such as blood, urine, and other biological samples. With its advanced technology, the high-speed centrifuge is able to rapidly spin samples at high speeds, resulting in quick and precise separation of components. This is particularly beneficial in medical laboratories and research facilities where time is crucial and accurate results are paramount.On the other hand, the hand-operated centrifuge is a portable and versatile solution for smaller-scale separation tasks. This compact device is designed for situations where access to a power source is limited or when a smaller volume of samples needs to be processed. It can be used in various settings, such as field research, remote clinics, and educational laboratories.[Company Name] has a long history of developing and manufacturing high-quality centrifuge equipment for various applications. With a focus on technological innovation and product excellence, the company has established itself as a trusted supplier of centrifuge solutions in the global market.The company's commitment to quality and performance is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. Each centrifuge product undergoes comprehensive testing and inspection to ensure it meets the highest standards of reliability and efficiency.In addition to its technical expertise, [Company Name] also prides itself on providing exceptional customer service and support. The company's dedicated team of professionals is well-equipped to offer personalized advice and assistance to customers, helping them select the most suitable centrifuge solution for their specific needs.The introduction of the new high-speed and hand-operated centrifuge products further demonstrates [Company Name]'s dedication to meeting the evolving needs of its customers. By continuously expanding its product range and incorporating the latest technological advancements, the company aims to remain at the forefront of the centrifuge industry.The global demand for centrifuge equipment continues to grow, driven by increasing applications in the fields of healthcare, biotechnology, and research. [Company Name] is well-positioned to capitalize on this trend through its innovative product offerings and commitment to customer satisfaction.While the high-speed centrifuge is designed for high-throughput laboratories and facilities with demanding separation requirements, the hand-operated centrifuge is expected to appeal to customers seeking a portable and cost-effective solution for smaller-scale applications. Both products are expected to contribute to [Company Name]'s continued success in the centrifuge market.As [Company Name] looks to the future, it remains steadfast in its commitment to innovation, quality, and customer satisfaction. With its new line of centrifuge products, the company is poised to make a significant impact in the global market and solidify its reputation as a leading provider of centrifuge solutions.

High-Quality Linear Motion Drilling Rigs Shale Shaker with 120 M3/H Capacity: API Standard

Exploring the Benefits of China Shale Shaker and Oli Drilling Shale ShakerDrilling rigs are crucial in the process of oil and gas exploration. These rigs help extract valuable resources from the earth's surface. In recent years, there has been a surge in the demand for shale shakers as they play a vital role in the extraction process. Shale shakers separate the solids and liquids that come out of the drilling process, and the extracted fluid is then transferred to other areas for further processing.China Shale Shaker is one of the top-quality shale shakers available in the market today. This shale shaker is designed for high-performance industrial applications and is built with top-of-the-line components that meet API standards, making it a popular choice for drilling projects worldwide. With a 120 M3/H capacity, this linear motion drilling rig shale shaker is an exceptional piece of equipment that performs exceptionally well. Its superior screening capabilities and efficient operation make it a valuable asset for any job site.Apart from its high-quality performance, China Shale Shaker promises users long-lasting durability and reliability. The equipment is also built to withstand harsh weather and environmental conditions often found in drilling sites. Furthermore, its design ensures easy maintenance, meaning that the machinery can operate efficiently throughout its lifespan with little downtime.Another high-quality product is the Oli Drilling Shale Shaker. This shale shaker is well known for its innovative design and superior performance capabilities. The Oli Drilling Shale Shaker employs a sophisticated screening process, allowing for better separation of solids from liquid drilling fluid. This process results in better productivity levels during the extraction process, with less wastage reported from the operation.The Oli Drilling Shale Shaker is built to meet all API standards, and its components are sourced from reputable brands to ensure high performance and longevity. Its structure is designed to handle challenging environments and rugged conditions that drilling sites often pose.Apart from its outstanding performance capabilities, the Oli Drilling Shale Shaker is also user-friendly, with easy-to-use controls that reduce downtime and increase operational efficiency. The maintenance of this equipment is also hassle-free, further enhancing its durability and reliability.In conclusion, drilling rigs are vital in the oil and gas exploration industry, and the use of high-quality shale shakers such as China Shale Shaker and Oli Drilling Shale Shaker can enhance the efficiency of drilling sites, ensuring maximum productivity and profitability. Both of these shale shakers are built to meet API standards, and their innovative designs make them popular equipment choices in the field. Ultimately, investing in these high-performing shale shakers not only improves productivity levels but also guarantees long-lasting durability and reliable performance for years to come.

Effective Use of Desilter in Drilling Rigs for Improved Results

Desilter is a crucial component in drilling rigs that is responsible for removing solid particles from drilling fluids. This process is essential for maintaining the quality of the drilling mud and ensuring efficient and productive drilling operations. With the advancements in technology, modern desilters are equipped with innovative features and cutting-edge technology to enhance their performance and effectiveness.The desilter from {} is among the leading products in the market, known for its reliability, durability, and efficiency. With a strong focus on research and development, {} has consistently introduced advanced desilters that meet the evolving needs of the drilling industry. The company has built a reputation for delivering high-quality equipment that ensures smooth drilling operations in various challenging environments.The desilter from {} is designed to efficiently remove solid particles from drilling fluids, including sand, silt, and other impurities. This not only helps in maintaining the properties of the drilling mud but also reduces the wear and tear on other drilling equipment, thereby extending their lifespan. The desilter plays a vital role in the overall efficiency and cost-effectiveness of drilling operations, making it an indispensable component in any drilling rig.One of the key features of the {} desilter is its high capacity to handle large volumes of drilling fluids. This is particularly important in demanding drilling projects where the volume of cuttings and solids is higher. The desilter's ability to effectively separate and remove these solids ensures that the drilling process can continue uninterrupted, without compromising on safety or performance. Additionally, the {} desilter is designed to minimize energy consumption, making it an eco-friendly and cost-effective solution for drilling operations.Another notable aspect of the {} desilter is its compact and space-saving design. This allows for easy installation and integration into existing drilling rigs, without requiring extensive modifications or adjustments. The modular construction of the desilter also facilitates easy maintenance and service, reducing downtime and ensuring continuous operation.Moreover, the {} desilter is equipped with advanced control systems and automation features that enable operators to monitor and adjust its performance in real-time. This level of control and flexibility allows for optimal operation of the desilter, regardless of variations in drilling conditions or fluid properties. The desilter's robust construction and reliable performance make it a preferred choice for drilling contractors and operators worldwide.In addition to its technical capabilities, {} is committed to providing exceptional customer support and service. The company offers comprehensive training programs and technical assistance to ensure that the desilter is operated and maintained effectively. With a global network of service centers and authorized distributors, {} ensures prompt assistance and spare parts availability, further enhancing the reliability and longevity of its desilters.In conclusion, the desilter is an essential component in drilling rigs, and the {} desilter stands out as a top-tier product in the industry. With its advanced technology, high capacity, compact design, and superior performance, the {} desilter is a valuable asset for drilling operations across the globe. As the demand for efficient and reliable drilling equipment continues to rise, {} remains at the forefront of delivering innovative solutions that drive productivity and success in the drilling industry.

Basic Overview of Leak Testing Methods for Manufacturing Processes in China

Title: Leak Testing in Casting Processes: A Comprehensive Overview in ChinaIntroduction:Leak testing plays a critical role in ensuring the quality and reliability of various casting processes, including die casting, sand casting, and investment casting. By carefully inspecting and identifying any potential leaks or defects within cast components, manufacturers in China can deliver products of the highest standard. In this blog, we will explore the key aspects of leak testing in casting processes, with a focus on China's sand investment casting and coated sand investment castings. Throughout, we will emphasize the importance of leak testing, its benefits, and how it contributes to the success of these casting techniques in China.1. Importance of Leak Testing in Casting:Leak testing involves verifying the efficiency of cast components, confirming their ability to contain fluids, gases, or pressure. By identifying leaks, manufacturers ensure that their products meet stringent quality standards, while also minimizing the risk of potential failures that could cause harm to end-users or result in costly recalls. Leak testing is a crucial step in the production process, providing manufacturers with confidence in the reliability and safety of their castings.2. Leak Testing Methods:Various leak testing methods are employed in the casting industry, each catering to different requirements and casting processes. These techniques include pressure decay testing, helium leak testing, bubble testing, vacuum testing, and more. Depending on the casting process, such as sand investment casting or coated sand investment castings, specific leak testing methods are chosen to ensure accurate results.2.1 Sand Investment Casting Leak Testing:Sand investment casting is a widely used casting technique in China for complex components. To assess the integrity of sand investment castings, manufacturers typically employ pressure decay testing. This method involves pressurizing the casting and monitoring pressure decay over time. Any pressure drop indicates the presence of leaks, enabling manufacturers to identify and rectify issues promptly.2.2 Coated Sand Investment Casting Leak Testing:Coated sand investment casting, also known as shell molding casting, is another popular technique in China. Leak testing methods such as bubble testing or pressure decay testing are commonly employed. Bubble testing involves submerging castings in a solution and introducing air pressure, creating bubbles at leak points. Pressure decay testing, similar to sand investment casting, assesses pressure variations to detect leaks within the components.3. Advantages and Challenges in Leak Testing:Leak testing offers numerous advantages, including improved product quality, enhanced reliability, compliance with industry standards, and ultimately, customer satisfaction. It ensures the castings meet technical specifications and function effectively. However, challenges such as selecting the appropriate leak testing method and ensuring accurate and consistent results can arise. Manufacturers in China must carefully consider these factors during the leak testing process.Conclusion:Leak testing is an integral part of the casting industry in China, especially when it comes to sand investment casting and coated sand investment castings. By conducting comprehensive leak testing procedures, manufacturers can guarantee the reliability and quality of their cast components. Additionally, leak testing plays a significant role in meeting regulatory requirements and ensuring customer satisfaction. With continuous advancements in leak testing techniques and equipment, China's casting industry remains at the forefront of ensuring robust and flawless castings.

High-quality Shaker Screen Resistant to Corrosion and Heat, Compliant with API Standards

Title: Durable FSI Shaker Screen: A Resilient Solution Compliant with API Standard QualityIntroduction:In the oil and gas industry, one critical aspect of drilling operations is the use of shale shakers. These devices employ shaker screens, which are crucial in separating drilling cuttings from drilling fluid to ensure efficient and productive drilling operations. One prominent manufacturer in China has recently caught our attention with their reliable and durable FSI Shaker Screen. In this blog post, we will delve into the exceptional features and benefits offered by this corrosion and heat-resistant shaker screen compliant with API standard quality.Offering Superior Durability:The FSI Shaker Screen, manufactured by a reputable Chinese company, stands out due to its exceptional durability. With the demanding conditions experienced during drilling operations, it is crucial for shaker screens to withstand the stresses of continuous use. This particular shaker screen is designed using high-quality materials and advanced manufacturing techniques, ensuring its ability to withstand wear and tear.Resisting Corrosion and Heat:The FSI Shaker Screen's resistance to corrosion and heat makes it an excellent choice for drilling operations. The manufacturing process includes the incorporation of materials specifically selected for their resistance to corrosive elements present in drilling fluids. This feature significantly enhances the shaker screen's lifespan and reduces the need for frequent replacements.Moreover, the FSI Shaker Screen’s ability to withstand intense heat is crucial, as drilling operations often subject the equipment to high-temperature conditions. By featuring heat-resilient properties, this shaker screen offers superior performance and longevity, even in extreme thermal environments.API Standard Compliant:In the oil and gas industry, adherence to industry standards is essential for ensuring optimal performance and safety. The FSI Shaker Screen is compliant with API standards, which reflect the industry's best practices. API standards ensure compatibility, efficiency, and reliability throughout the drilling process.China API Shaker Screens:As an industry leader, China has been recognized for its commitment to innovation and quality manufacturing processes. API Shaker Screens from China have gained popularity due to their high-quality construction and competitive pricing. These screens offer reliable performance, exceeding industry standards, while also providing cost-effective solutions for drilling operations worldwide.API Screen: A Key Component in Shale Shaker Systems:The API screen plays a vital role in shale shaker systems, helping remove larger solids from drilling fluids. This enhances the efficiency of the subsequent mud cleaning processes, leading to improved drilling fluid performance and potentially reducing operational costs. By selecting an API-compliant screen, such as the FSI Shaker Screen, operators can have confidence in the effectiveness of their shale shaker systems.Conclusion:Efficient drilling operations heavily rely on reliable shaker screens that can withstand corrosion, heat, and various other demanding conditions. The durable FSI Shaker Screen, manufactured in China, provides an exceptional solution that complies with API standard quality. With exceptional resistance to corrosion and heat, this shaker screen ensures extended lifespan and reliable performance. Furthermore, it aligns with industry standards, promoting compatibility, efficiency, and safety throughout the drilling process.As China continues to innovate and excel in manufacturing, its API Shaker Screens have become increasingly popular, offering a cost-effective solution for global drilling operations. When selecting a screen for your shale shaker system, consider the reliable performance and durability of the FSI Shaker Screen, setting new benchmarks in the industry.Keywords: China API Shaker Screens, API Screen, FSI Shaker Screen, durability, corrosion resistance, heat resistance, compliance, manufacturing, drilling operations, oil and gas industry.

Powerful Decanter Centrifuge and Efficient Refrigerated Centrifuge in China

China Decanter Centrifuge and Refrigerated Centrifuge Lead the MarketIn recent years, China has emerged as a global leader in the manufacturing and export of industrial centrifuge equipment, particularly Decanter Centrifuge and Refrigerated Centrifuge. As an industry leader in the development and production of high-quality centrifuge equipment, (), has been at the forefront of this growing industry.With a focus on continuous innovation and technological advancement, the company has established a solid reputation for delivering reliable and efficient centrifuge solutions to a wide range of industries, including wastewater treatment, food and beverage, pharmaceuticals, and chemicals.Decanter Centrifuge, which is widely used for solid-liquid separation in industries such as wastewater treatment and oil drilling, has become a key product in the company’s portfolio. The company’s Decanter Centrifuge is known for its high performance, low maintenance, and energy efficiency, making it a preferred choice for many businesses seeking to optimize their separation processes.In addition to Decanter Centrifuge, the company also specializes in the production of Refrigerated Centrifuge, which is commonly used in laboratory and research settings for the separation of substances based on density. The company’s Refrigerated Centrifuge is praised for its precise temperature control, quiet operation, and user-friendly design, making it a popular choice among scientists and researchers.One key factor that sets () apart from its competitors is its commitment to research and development. The company has a dedicated team of engineers and scientists who are constantly working to improve the design and functionality of their centrifuge equipment. This dedication to innovation has allowed () to stay ahead of the curve and consistently introduce new and improved centrifuge solutions to the market.Furthermore, () has also been proactive in expanding its global presence. With a strong focus on international trade and customer service, the company has established a distribution network that spans across multiple continents, allowing it to reach customers in various countries and regions. This global reach has not only strengthened the company’s position in the industry but has also contributed to the overall growth and development of China’s centrifuge manufacturing sector.In addition to its commercial success, () has also prioritized sustainability and environmental responsibility in its operations. By producing centrifuge equipment that is energy-efficient and environmentally friendly, the company is playing a significant role in helping businesses reduce their carbon footprint and operate in a more sustainable manner.Looking ahead, the future of China’s Decanter Centrifuge and Refrigerated Centrifuge market looks promising, with increasing demand from various industries and ongoing advancements in technology. As a key player in this sector, () is well-positioned to continue leading the way in the development and production of cutting-edge centrifuge equipment, ultimately contributing to the growth and success of China’s industrial machinery manufacturing industry.In conclusion, the rise of China as a global powerhouse in the manufacturing and export of industrial centrifuge equipment, particularly Decanter Centrifuge and Refrigerated Centrifuge, has been largely driven by companies like (). With a focus on innovation, quality, and global expansion, () has proven itself as a leader in this industry and is poised to continue making significant contributions to the market for years to come.