Municipal Sewage Decanter Centrifuge: Efficient Wastewater Treatment Solution

By:Admin

China has long been grappling with the challenges of managing municipal sewage and wastewater, as rapid urbanization and industrial development have led to a sharp increase in the volume of wastewater produced. In response to this pressing issue, [Company Name] has introduced a cutting-edge solution that promises to revolutionize the wastewater treatment industry – the [Model Number] Municipal Sewage Decanter Centrifuge.

With its advanced technology and high performance, the [Model Number] Municipal Sewage Decanter Centrifuge is set to raise the bar for municipal sewage and wastewater treatment in China. By effectively separating solids from liquid waste, the centrifuge significantly improves the overall efficiency and effectiveness of the treatment process, leading to cleaner water and reduced environmental impact.

One of the key features of the [Model Number] Municipal Sewage Decanter Centrifuge is its ability to handle a wide range of sewage sludge, including those with high solid concentrations. This makes it an ideal solution for the treatment of municipal sewage and industrial wastewater, where the composition of the sludge can vary significantly.

The decanter centrifuge is also designed to operate continuously, ensuring a steady and reliable treatment process without the need for frequent interruptions or downtime. This not only improves the overall efficiency of the wastewater treatment plant but also reduces operational costs in the long run.

Furthermore, the [Model Number] Municipal Sewage Decanter Centrifuge is equipped with advanced control systems that allow for precise monitoring and adjustment of the treatment process. This level of automation not only simplifies operation but also maximizes the performance of the centrifuge, leading to better treatment outcomes.

[Company Name] is a leading manufacturer of industrial separation equipment, with a proven track record of delivering high-quality solutions for a wide range of applications. With a strong focus on research and development, the company is dedicated to pushing the boundaries of technological innovation and setting new standards for the industry.

In addition to the [Model Number] Municipal Sewage Decanter Centrifuge, [Company Name] offers a comprehensive range of decanter centrifuges for various industrial and environmental applications, including wastewater treatment, chemical processing, food and beverage production, and more. This diverse portfolio reflects the company's commitment to providing tailored solutions that meet the unique needs of its customers.

The introduction of the [Model Number] Municipal Sewage Decanter Centrifuge comes at a critical time for China, as the country continues to prioritize environmental protection and sustainable development. By investing in advanced wastewater treatment solutions, China aims to improve the quality of its water resources and reduce the impact of pollution on the environment and public health.

As the demand for efficient wastewater treatment solutions continues to grow, [Company Name] is well-positioned to play a leading role in shaping the future of the industry. With its innovative technologies and commitment to excellence, the company is poised to make a significant contribution to the advancement of wastewater treatment in China and beyond.

In conclusion, the introduction of the [Model Number] Municipal Sewage Decanter Centrifuge marks a significant milestone in China's efforts to address the challenges of municipal sewage and wastewater treatment. With its advanced technology, high performance, and versatile capabilities, the centrifuge is set to raise the bar for the industry and set new standards for efficiency and effectiveness. [Company Name] is proud to be at the forefront of this innovation, and looks forward to making a positive impact on the environment and public health through its cutting-edge solutions.

Company News & Blog

High-Quality Laboratory Sedimentation Centrifuge for Efficient Sample Separation and Analysis

China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are cutting-edge equipment designed to separate particles from a liquid suspension based on their size, shape, density, and viscosity. These centrifuges are widely used in various industries, including pharmaceuticals, food and beverage, environmental testing, and research laboratories.The Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are equipped with advanced features, including high-speed rotational capabilities, multiple programmable settings, and precise control over temperature and time. This allows researchers and scientists to achieve a high level of accuracy and reproducibility in their sedimentation experiments.One of the key features of these centrifuges is their ability to accommodate a wide range of sample volumes and densities, making them versatile tools for a diverse range of applications. Additionally, the centrifuges are designed to be easy to operate and maintain, allowing users to focus on their research and experiments without having to worry about the technical aspects of the equipment.The China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are manufactured by a leading company in the field of laboratory equipment. With a strong emphasis on research and development, the company has continuously improved and refined its centrifuge technology to meet the evolving needs of the scientific community.The company has a long-standing reputation for producing high-quality and reliable laboratory equipment, and its centrifuges are no exception. Through rigorous quality control and testing processes, the company ensures that its centrifuges meet the highest standards of performance and reliability, providing researchers and scientists with the confidence to carry out their experiments with precision and accuracy.Furthermore, the company is committed to providing exceptional customer support, offering comprehensive training, technical assistance, and maintenance services to ensure that its customers can make the most of their centrifuge investment. This dedication to customer satisfaction has earned the company a loyal customer base and a strong reputation in the industry.The China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge have already garnered attention and acclaim from researchers and scientists around the world for their superior performance and reliability. Many leading research institutions and laboratories have adopted these centrifuges as their preferred choice for sedimentation experiments, further solidifying their reputation as a trusted and valuable tool in the scientific community.As the demand for advanced laboratory equipment continues to grow, the company remains at the forefront of innovation, constantly seeking to enhance the capabilities and performance of its centrifuges. With a strong emphasis on precision, efficiency, and user-friendly design, the company is poised to continue leading the way in the development of cutting-edge laboratory equipment for years to come.In conclusion, the China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge represent the pinnacle of centrifuge technology, offering researchers and scientists a powerful and reliable tool for their sedimentation experiments. Backed by a reputable and innovative company, these centrifuges are set to make a lasting impact on the scientific community, driving advancements in research and technology for years to come.

Metal Scale Briquetter and Metal Swarf Briquetter: The Latest News from China

China Metal Scale Briquetter and Metal Swarf BriquetterIn the ever-evolving landscape of metal recycling and environmental sustainability, the market for innovative and efficient tools continues to grow. With a focus on reducing waste and maximizing the value of metal scrap, {Company Name} has emerged as a leader in the development and production of metal scale briquetters and metal swarf briquetters.As the name suggests, a metal scale briquetter is a machine designed to compact metal scales, which are thin pieces of metal that are produced during various metalworking processes. By compressing these metal scales into dense, uniform briquettes, {Company Name}'s metal scale briquetter makes it easier to handle and transport metal scrap, ultimately increasing its value and reducing its environmental impact.Similarly, a metal swarf briquetter is specifically designed to handle metal swarf, which consists of small, fine chips and turnings that are produced during metal cutting and shaping processes. By compressing metal swarf into dense, easily manageable briquettes, {Company Name}'s metal swarf briquetter facilitates the handling and recycling of this valuable metal scrap.These innovative machines are a testament to {Company Name}'s commitment to providing cutting-edge solutions for the metal recycling industry. With a focus on efficiency, productivity, and environmental sustainability, the company has established itself as a trusted partner for metal recyclers around the world.Beyond its innovative products, {Company Name} stands out for its dedication to customer satisfaction and continuous improvement. The company's team of experts is constantly researching and developing new technologies to meet the evolving needs of the metal recycling industry, ensuring that their customers always have access to the most advanced and effective equipment on the market.Moreover, {Company Name} places a strong emphasis on quality and reliability, ensuring that every metal scale briquetter and metal swarf briquetter that bears its name is built to the highest standards. This commitment to excellence has earned {Company Name} a reputation for delivering durable, high-performance machines that consistently exceed customers' expectations.In addition to its focus on product development and quality, {Company Name} prides itself on its comprehensive customer support. From initial inquiry to installation and ongoing maintenance, the company's knowledgeable and responsive team is dedicated to providing customers with the guidance and expertise they need to make the most of their investment in {Company Name}'s products.As the demand for sustainable metal recycling solutions continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its metal scale briquetter and metal swarf briquetter. By providing innovative, reliable, and efficient equipment, the company is not only helping its customers improve their operations but also contributing to the larger goal of reducing waste and protecting the environment.In conclusion, the metal scale briquetter and metal swarf briquetter offered by {Company Name} represent a significant advancement in the field of metal recycling. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted leader in the industry, providing valuable solutions for metal recyclers around the world.

Efficient and Powerful Submersible Slurry Pump- A Game-Changer in Pumping Solutions

Title: Groundbreaking Submersible Slurry Pump Revolutionizes Industrial Dredging OperationsIntroduction:Innovative engineering company {} has recently unveiled a game-changing advancement in the field of industrial pumping with their revolutionary Submersible Slurry Pump. This cutting-edge technology is poised to transform dredging operations across a broad range of industries, from mining and construction to oil and gas. With its unparalleled efficiency and durability, this pump is set to streamline operations, minimize downtime, and significantly enhance productivity.Section 1: The Submersible Slurry Pump's Unmatched PerformanceThe Submersible Slurry Pump developed by {} stands out among its competitors due to its outstanding performance capabilities. Its design enables it to handle high-viscosity, abrasive, and corrosive materials, ensuring reliable pumping operations in the harshest environments. The pump's highly efficient motor delivers improved energy consumption, reducing costs and contributing to a greener future.Section 2: Features and TechnologyThe Submersible Slurry Pump is equipped with state-of-the-art features that revolutionize the pumping industry. Its robust construction, built with high-quality materials, ensures long service life even under demanding conditions. The pump's innovative impeller design enables it to handle larger solids with ease, preventing clogging and reducing maintenance needs.One of the most impressive features of this groundbreaking pump is its dynamic sealing system. The advanced sealing technology allows the pump to operate in submerged conditions, preventing leakage and avoiding costly damage. This feature alone sets it apart from traditional slurry pumps, making it an indispensable tool in challenging pumping applications.Section 3: Versatility and ApplicationsThe versatility of the Submersible Slurry Pump opens up a wide range of applications across diverse industries. In mining operations, it effectively manages slurry transportation, improving efficiency and reducing operational costs. For the construction industry, this pump proves invaluable for excavation and dewatering processes, ensuring uninterrupted workflow and increased project timelines.Furthermore, in the oil and gas sector, the Submersible Slurry Pump proves to be a game-changer. It efficiently handles drilling mud, mitigating risks associated with fluid transportation and minimizing environmental impacts. Its versatile design also enables it to excel in wastewater treatment and power plant applications, positioning itself as an essential tool for achieving sustainable and efficient operations.Section 4: The Future of PumpingWith the introduction of the Submersible Slurry Pump, {} has set a new standard for industrial pumping technology. The future of pumping operations now lies in the hands of this groundbreaking innovation. By combining efficiency, durability, and versatility, this pump delivers exceptional performance across a plethora of industries, transforming the way we approach pumping applications.The Submersible Slurry Pump developed by {} is not only a marvel of engineering but also a testament to the company's commitment to providing cutting-edge solutions for the most challenging projects. Their dedication to research and development has yielded a remarkable product that empowers industries worldwide.Conclusion:With its unmatched performance, innovative features, and a wide range of applications, the Submersible Slurry Pump represents a groundbreaking advancement in industrial pumping technology. {}'s commitment to revolutionizing the industry ensures that projects involving slurry pumping operations can now be completed more efficiently, cost-effectively, and sustainably. As the future of pumping takes shape, this remarkable pump positions itself as an indispensable tool for industries seeking enhanced productivity and environmental responsibility.

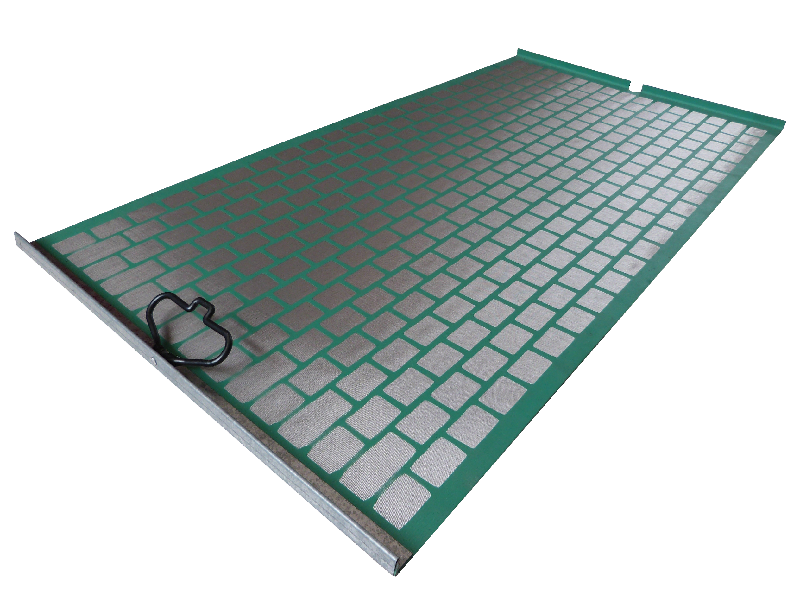

Understanding the Factors that Affect Shale Shaker Prices

Shale Shaker Price Witnessed Growth in the MarketThe global market for shale shakers has witnessed significant growth in recent years, with an increasing demand for efficient and cost-effective equipment in the oil and gas industry. Shale shakers are integral to the drilling process, as they are used to separate drilling cuttings from drilling fluid, ensuring that the fluid can be reused and recycled, therefore reducing overall operational costs for oil and gas companies.One of the key players in the shale shaker market, {}, has seen a surge in demand for its products, leading to an increase in shale shaker prices. With a wide range of high-quality and reliable shale shaker equipment, {} has established itself as a leading provider of separation and filtration products for various industries, including the oil and gas sector.In response to the growing demand for its shale shakers, {} has invested in research and development to enhance the efficiency and performance of its equipment. This has enabled the company to offer innovative solutions that meet the evolving needs of the oil and gas industry, while maintaining competitive pricing to cater to a wide range of customers.The recent increase in shale shaker prices reflects the overall growth and stability of the oil and gas industry, as companies continue to invest in exploration and production activities. As the demand for oil and gas remains strong, the need for high-quality equipment such as shale shakers is expected to continue rising, driving the market for these products.In addition to the increase in demand for shale shakers, the market is also witnessing a shift towards environmentally friendly and sustainable solutions. {} has responded to this trend by incorporating advanced technologies and materials into its shale shaker products, making them more energy-efficient and environmentally friendly. This has further contributed to the growing popularity of the company's shale shakers among environmentally conscious customers.With a strong focus on customer satisfaction and product innovation, {} has successfully positioned itself as a trusted provider of shale shaker equipment in the global market. The company's commitment to quality and reliability has earned it a solid reputation among oil and gas operators, further driving the demand for its products.As the shale shaker market continues to grow, {} is expected to maintain its competitive edge by offering advanced and cost-effective solutions to its customers. The company's dedication to meeting the evolving needs of the industry and its focus on sustainability will likely contribute to its continued success in the market.Overall, the increase in shale shaker prices reflects the positive outlook for the oil and gas industry, as companies continue to invest in cutting-edge equipment to improve their operational efficiency. As a leading player in the shale shaker market, {} is well positioned to capitalize on this trend and maintain its strong presence in the industry.

Revolutionary Solution: Discover the Power of a High-performance Mud Mixer

Title: Innovative Mud Mixing Solution Optimizes Drilling Efficiency in the Oil and Gas IndustryIntroduction:In the oil and gas industry, the efficient extraction of resources relies heavily on advanced technology and equipment. A key component crucial to drilling operations is the mud mixer, a device that blends drilling fluids or mud to maintain stability and enhance performance during drilling processes. Addressing the increasing demand for improved efficiency and performance, a leading engineering company has introduced their cutting-edge Jet Mud Mixer system, revolutionizing the field of drilling and excavation.Body:1. Understanding the Importance of Mud Mixing: The drilling process generates enormous amounts of heat and pressure, demanding fluids that effectively cool, lubricate, and stabilize the drill bit. Mud mixing systems play a critical role by preparing drilling fluids that are essential for successful drilling operations. The fluids facilitate removing cuttings from the wellbore, preventing formation damage, controlling well pressure, and stabilizing the excavation.2. Introducing the Innovative Jet Mud Mixer System: Recognizing the need for a high-performance and efficient mud mixing solution, [Company Name] has developed the Jet Mud Mixer system. This technology combines precise engineering and state-of-the-art design, enabling drilling companies to achieve unparalleled performance in their operations. By integrating advanced processes and materials, this mud mixer surpasses industry standards, providing enhanced drilling efficiency and cost-effectiveness.3. Cutting-edge Features and Functionality: The Jet Mud Mixer system boasts several innovative features that set it apart from existing mud mixing solutions: a. Superior Mixing Performance: [Company Name]'s technology combines robust jet nozzles with a high-power discharge pump, ensuring thorough blending of drilling fluids at optimum consistency and density. b. Versatility and Scalability: The Jet Mud Mixer system is designed to accommodate a wide range of drilling environments, from small-scale onshore projects to large offshore rigs, providing adaptability and scalability for various drilling operations. c. Precision Controls: Equipped with user-friendly controls, drilling operators can easily configure the desired mud consistency, density, and flow rates, improving overall operational control and efficiency. d. Enhanced Safety Measures: Complying with stringent safety regulations, this cutting-edge system incorporates safety features such as emergency stop mechanisms, leakage protection, and excess pressure triggers, ensuring the well-being of personnel and the environment.4. Optimizing Drilling Efficiency and Cost-effectiveness: The Jet Mud Mixer system offers significant advantages to drilling companies seeking to enhance their operational efficiency and reduce costs: a. Increased Drilling Rates: With precise control of drilling mud density and composition, the Jet Mud Mixer system enables faster drilling rates, reducing overall drilling time and costs. b. Reduced Waste and Environmental Impact: By systematically and accurately managing the drilling fluids, this advanced mixing solution minimizes waste and environmental impact, promoting sustainability within the industry. c. Lower Maintenance and Downtime: The robust construction and durability of the Jet Mud Mixer system ensure minimal maintenance requirements. Consequently, downtime caused by equipment breakdowns is significantly reduced, optimizing overall drilling productivity. d. Enhanced Operator Safety: Incorporating safety mechanisms and protocols, the system prioritizes operator safety during mud mixing operations, minimizing accidents and injuries.Conclusion:The introduction of the Jet Mud Mixer system by [Company Name] marks a significant advancement in drilling technology within the oil and gas industry. With its cutting-edge features, precision controls, and focus on efficiency, this innovative mud mixing solution enhances drilling rates, reduces environmental impact, and improves overall operational cost-effectiveness. Embarking on a journey towards a more sustainable and efficient future, [Company Name] is revolutionizing the drilling industry, setting new benchmarks for performance and safety.

Effective Mud Cleaning System for Efficient Drilling Operations

Mud Cleaning System (MCS) is a revolutionary technology that is changing the game in the oil and gas industry. This innovative system is designed to remove harmful solids from the drilling mud, ensuring that the mud is clean and free from contaminants. MCS is committed to providing cost-effective solutions for the oil and gas industry, and its cutting-edge technology is setting new standards for efficiency and safety.The company behind MCS is dedicated to delivering top-quality products and services to its clients. With a team of experienced professionals and industry experts, the company has established itself as a leader in the field of mud cleaning technology. It is committed to delivering innovative solutions that are tailored to the specific needs of its clients, and its commitment to excellence has earned it a solid reputation in the industry.MCS is a game-changer for the oil and gas industry. By utilizing advanced technology and state-of-the-art equipment, MCS is able to provide a level of efficiency and effectiveness that is unprecedented in the industry. The system is designed to remove solid particles from drilling mud, ensuring that the mud is clean and free from contaminants. This not only improves the efficiency of the drilling process, but also ensures that the environment is protected from harmful pollutants.Furthermore, MCS is committed to providing cost-effective solutions for its clients. The company understands the challenges that the oil and gas industry faces, and it is dedicated to delivering solutions that are not only effective, but also affordable. By utilizing innovative technology and cutting-edge equipment, MCS is able to deliver solutions that provide maximum value for its clients.In addition to its cutting-edge technology, MCS is also dedicated to safety. The company takes the safety of its employees and clients seriously, and it has implemented strict safety protocols to ensure that its operations are conducted in a safe and responsible manner. Clients can have peace of mind knowing that MCS is committed to delivering solutions that are not only effective, but also safe for the environment and for the people involved in the drilling process.MCS is leading the way in the oil and gas industry, and its commitment to excellence has earned it a solid reputation in the field of mud cleaning technology. The company is dedicated to delivering innovative solutions that are tailored to the specific needs of its clients, and its cutting-edge technology is setting new standards for efficiency and safety. With a team of experienced professionals and industry experts, MCS is poised to continue its success and lead the industry into a new era of excellence.In conclusion, Mud Cleaning System is revolutionizing the oil and gas industry with its cutting-edge technology and commitment to excellence. The company is dedicated to providing cost-effective solutions that are tailored to the specific needs of its clients, and its commitment to safety and efficiency has earned it a solid reputation in the industry. As the industry continues to evolve, MCS is poised to lead the way with its innovative solutions and game-changing technology.

Top Tank Agitator Models and Uses in Industrial Processes

Today, we are excited to introduce a new tank agitator, designed and manufactured by our company. This innovative product is set to revolutionize the industry with its advanced technology and unparalleled efficiency. The tank agitator is an essential tool for mixing and blending various substances in industrial processes, and our new product is poised to set a new standard for performance and reliability.Our company has been a leading provider of industrial equipment and machinery for over 20 years. We have a strong reputation for delivering high-quality products and exceptional customer service. Our team of engineers and designers are constantly working to develop new and improved solutions to meet the evolving needs of our clients. With our state-of-the-art manufacturing facilities and cutting-edge technology, we are able to bring innovative products to the market that offer superior performance and value.The new tank agitator is a testament to our commitment to innovation and excellence. It is equipped with the latest in agitation technology, allowing for precise control and optimal mixing capabilities. The agitator is designed to handle a wide range of viscosities and densities, making it versatile enough for a variety of applications. Whether it's blending liquids, suspending solids, or promoting chemical reactions, our tank agitator delivers consistent and reliable results.One of the key features of our tank agitator is its robust construction and durability. We understand the demanding nature of industrial processes, and our product is built to withstand the toughest operating conditions. With quality materials and solid engineering, our tank agitator is built to last, minimizing downtime and maintenance costs for our customers.In addition to its performance capabilities, our tank agitator is also designed with user convenience in mind. It is easy to install, operate, and maintain, allowing for seamless integration into existing production systems. Our goal is to provide our customers with a hassle-free experience, and our tank agitator is a reflection of that commitment.Furthermore, our company provides comprehensive support and service for all of our products, including the new tank agitator. We offer technical assistance, maintenance, and repair services to ensure that our customers get the most out of their investment. Our team is dedicated to helping our clients achieve their production goals and maximize efficiency with our equipment.As we look to the future, we are confident that our new tank agitator will make a significant impact in the industry. Its advanced technology, reliability, and user-friendly design set it apart from the competition, and we are excited to see the positive results it will bring to our customers. We will continue to innovate and deliver cutting-edge solutions to meet the evolving needs of the industrial sector, and the tank agitator is just the beginning of what's to come.

The latest innovation in centrifugal impeller technology unveiled

Centrifugal Impeller Revolutionizing Industrial Applications: A Game Changer byIn today's fast-paced industrial world, efficiency and innovation are key factors that drive success. One such innovation that is revolutionizing industrial applications is the Centrifugal Impeller. This state-of-the-art technology is a game-changer in the field of industrial equipment, setting new standards for performance and reliability.The Centrifugal Impeller, developed by a leading industrial equipment manufacturer, is designed to meet the growing demands of various industries, including aerospace, automotive, energy, and HVAC. Its advanced engineering and precision manufacturing make it an ideal choice for applications that require high efficiency, low noise, and long-term reliability.One of the key features of the Centrifugal Impeller is its unique blade design, which is optimized for maximum performance. This design allows for efficient airflow and pressure generation, making it suitable for a wide range of industrial processes. Whether it's for air handling, combustion, or cooling systems, the Centrifugal Impeller delivers unmatched performance, making it a versatile solution for modern industrial applications.Furthermore, the Centrifugal Impeller is also known for its durability and long service life. Its robust construction and high-quality materials ensure that it can withstand the rigors of industrial operations, making it a cost-effective investment for businesses. With minimal maintenance requirements, the Centrifugal Impeller offers a hassle-free solution for industrial equipment needs.In addition to its performance and reliability, the Centrifugal Impeller is also designed with energy efficiency in mind. Its aerodynamic design and precise manufacturing processes enable it to achieve high levels of efficiency, reducing energy consumption and operating costs for businesses. This makes it an environmentally friendly choice for industrial applications, contributing to sustainability efforts in various industries.The company behind the Centrifugal Impeller takes pride in its commitment to quality and innovation. With a team of experienced engineers and experts in industrial equipment, the company has a proven track record of delivering cutting-edge solutions that meet the evolving needs of modern industries. By continuously investing in research and development, the company ensures that its products, including the Centrifugal Impeller, are at the forefront of technological advancements.Furthermore, the company's dedication to customer satisfaction sets it apart in the industry. From initial consultation to product delivery and after-sales support, the company places a strong emphasis on understanding and meeting the specific requirements of its clients. With a focus on building long-term partnerships, the company strives to exceed customer expectations and provide tailored solutions that add value to businesses.As the industrial landscape continues to evolve, the demand for innovative and reliable equipment remains high. The Centrifugal Impeller is a testament to the impact of advanced technology in meeting these demands, offering a solution that enhances efficiency, performance, and sustainability for industrial applications. With its cutting-edge design, durability, and energy efficiency, the Centrifugal Impeller is poised to shape the future of industrial equipment and set new standards for excellence in the industry.

New Mixing Hopper Technology Offers Improved Efficiency

Venturi Mixing Hopper, an innovative solution for efficient material mixing, has rapidly gained popularity in the manufacturing industry. This technology has revolutionized the way materials are mixed, ensuring a consistent and homogeneous blend for various applications. The Venturi Mixing Hopper is designed and manufactured by a leading company that specializes in providing solutions for material handling and processing.{Company Name} has been at the forefront of manufacturing innovative equipment for the materials industry for over two decades. The company is dedicated to providing high-quality solutions that optimize material handling processes and improve overall operational efficiency. With a team of experienced engineers and experts, {Company Name} has continuously strived to develop cutting-edge technologies that meet the evolving needs of its customers.The Venturi Mixing Hopper is one such innovative product that has been designed to address the challenges associated with traditional material mixing methods. The technology is based on the Venturi effect, which involves the use of a converging-diverging nozzle to create a low-pressure zone that draws in and mixes the materials. This unique design ensures thorough and efficient mixing, with minimal energy consumption.One of the key features of the Venturi Mixing Hopper is its ability to handle a wide range of materials, including powders, granules, and other bulk solids. This versatility makes it an ideal solution for various industries, such as food processing, pharmaceuticals, chemicals, and construction. The technology can be customized to meet specific requirements, ensuring that it can effectively mix materials of different particle sizes and densities.In addition to its versatility, the Venturi Mixing Hopper offers several other benefits that contribute to its growing popularity in the industry. The technology is known for its rapid mixing capabilities, allowing for a quick and efficient blending process. This not only saves time but also reduces the overall production costs.Furthermore, the Venturi Mixing Hopper is designed to minimize material segregation and degradation, ensuring that the integrity of the blend is maintained throughout the process. This is particularly important for industries that require precise and consistent material mixtures, such as pharmaceutical manufacturing.Another key advantage of the Venturi Mixing Hopper is its compact design and ease of integration into existing production lines. The technology is engineered to be space-efficient, making it suitable for both new installations and retrofits. Its user-friendly interface and automated operation further simplify its use, minimizing the need for manual intervention and oversight.The Venturi Mixing Hopper is also designed with durability and reliability in mind, ensuring minimal maintenance requirements and long-term performance. This makes it a cost-effective solution for businesses looking to improve their material mixing processes without incurring excessive operational expenses.As the demand for efficient material mixing solutions continues to grow, the Venturi Mixing Hopper has emerged as a game-changer in the industry, offering a reliable and sustainable solution for businesses of all sizes. Its innovative design and advanced capabilities have positioned it as a leading technology in the field of material handling and processing, catering to the evolving needs of the modern manufacturing landscape.With a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted partner for businesses seeking to enhance their material handling processes. The company's commitment to innovation and customer satisfaction has driven the development of technologies like the Venturi Mixing Hopper, setting new standards for performance and efficiency in the industry.In conclusion, the Venturi Mixing Hopper represents a significant advancement in material mixing technology, offering a reliable and efficient solution for businesses across various industries. With its unique design, versatility, and numerous benefits, this innovative technology has cemented its position as a leading solution for material handling and processing. {Company Name} continues to be a driving force behind the advancement of such groundbreaking technologies, further solidifying its reputation as a pioneer in the industry.

Advanced Beverage and Filling Machines from China

China's Beverage and Filling Machine Industry Continues to GrowThe beverage and filling machine industry in China has been experiencing significant growth in recent years. With the rising demand for a variety of beverages, including soft drinks, energy drinks, and alcoholic beverages, the need for efficient and high-quality filling machines has never been greater.One company at the forefront of this industry is a leading manufacturer of beverage and filling machines in China. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable provider of advanced filling equipment. Their machines are known for their precision, reliability, and versatility, making them the ideal choice for a wide range of beverage production needs.In addition to their innovative filling machines, the company also offers a comprehensive range of beverage processing equipment, including bottle washing machines, capping machines, labeling machines, and more. Their complete line of equipment allows beverage producers to streamline their production process and ensure the highest quality and consistency in their products.One of the key factors driving the growth of the beverage and filling machine industry in China is the increasing demand for non-alcoholic beverages, particularly in the health and wellness sector. With consumers becoming more health-conscious, there has been a surge in the production of natural and organic beverages, such as fruit juices, coconut water, and other functional beverages. This has created a need for advanced filling machines capable of handling a variety of packaging formats, including PET bottles, glass bottles, and cans.Furthermore, the company's commitment to innovation and continuous improvement has allowed them to stay ahead of the competition. They invest heavily in research and development to create cutting-edge technologies that optimize the performance and efficiency of their filling machines. As a result, they have garnered a loyal customer base both domestically and internationally.In recent years, the company has expanded its presence in the global market, establishing partnerships with beverage producers in Asia, Europe, and North America. By providing customized solutions tailored to the specific needs of each client, they have earned a reputation for excellence and reliability in the industry.The company's dedication to quality and customer satisfaction has also been recognized through various certifications and awards, including ISO 9001 certification and the "Top Supplier" award from several renowned beverage companies.Looking ahead, the beverage and filling machine industry in China is poised for even further growth. With the increasing demand for innovative and sustainable packaging solutions, as well as the rise of e-commerce and direct-to-consumer sales, beverage producers will continue to seek out state-of-the-art filling machines to meet their evolving needs.As a leader in the industry, this company is well-positioned to capitalize on these trends and further solidify its position as a key player in the global beverage and filling machine market. By staying at the forefront of technological advancements and maintaining a strong focus on customer satisfaction, they are poised to continue shaping the future of the industry for years to come.In conclusion, with the company's dedication to innovation, quality, and customer satisfaction, the future of the beverage and filling machine industry in China looks bright. As the demand for a diverse array of beverages continues to grow, the need for advanced and reliable filling machines will only increase, and this company is well-equipped to meet that demand.