The importance of drilling fluids shale shakers in the oil industry

By:Admin

The Drilling Fluids Shale Shaker is designed to handle the most challenging drilling conditions, including the high viscosity and high-pressure environments commonly encountered in shale drilling operations. With its advanced screening technology, this shale shaker is able to effectively remove solids and impurities from the drilling fluids, resulting in cleaner and more consistent drilling mud.

One of the key features of the Drilling Fluids Shale Shaker is its modular design, which allows for easy installation and maintenance. This modular approach also provides flexibility in configuring the shale shaker to meet specific drilling requirements, allowing for greater customization and efficiency on the rig.

The company has always been committed to delivering high-quality and reliable products to the oil and gas industry, and the Drilling Fluids Shale Shaker is no exception. With its robust construction and advanced engineering, this shale shaker is built to withstand the harsh conditions of drilling operations, ensuring long-term performance and durability.

In addition to its exceptional performance, the Drilling Fluids Shale Shaker also boasts a user-friendly interface, making it easy for operators to monitor and control the separation process. This intuitive design not only enhances operational efficiency but also minimizes the risk of human error, further improving the overall reliability of the equipment.

Furthermore, the Drilling Fluids Shale Shaker is equipped with state-of-the-art technology that enables real-time monitoring and data collection. This not only allows for better decision-making during drilling operations but also provides valuable insights for future optimization and performance enhancements.

As part of the company's commitment to sustainability, the Drilling Fluids Shale Shaker is designed to minimize environmental impact. By effectively removing solids and impurities from the drilling fluids, this shale shaker helps to reduce waste and promotes the responsible management of drilling by-products.

The introduction of the Drilling Fluids Shale Shaker marks a significant milestone for the company, as it further solidifies its position as a leading provider of innovative solutions for the oil and gas industry. With a track record of delivering cutting-edge technologies and a commitment to customer satisfaction, the company is poised to set new standards with the Drilling Fluids Shale Shaker.

The Drilling Fluids Shale Shaker is now available for purchase, and the company is also offering comprehensive support services to ensure seamless integration and optimal performance. With its unparalleled efficiency, reliability, and environmental responsibility, the Drilling Fluids Shale Shaker is set to revolutionize drilling operations and drive the industry towards a more sustainable future.

Company News & Blog

Unlocking the Potential of Oil Based Drilling Fluid: Insights, Benefits, and Latest Developments

[Company Name] Introduces Groundbreaking Oil Based Drilling Fluid for Enhanced Efficiency and Environmental Safety[City, Date] - Leading global energy solutions provider [Company Name] unveiled its latest innovation in the oil and gas industry - an advanced oil-based drilling fluid designed to revolutionize drilling operations while prioritizing environmental safety.Recognizing the need for cutting-edge technology in the energy sector, [Company Name] has developed a state-of-the-art drilling fluid that addresses the industry's key challenges. By utilizing their extensive expertise in oil and gas exploration, the company has successfully produced a fluid that enhances drilling efficiency, reduces environmental impact, and ensures improved overall performance.Traditional drilling fluids rely on a water-based system, which often leads to inefficiencies and environmental hazards. [Company Name]'s pioneering solution is centered around an oil-based formulation that outperforms its water-based counterparts in several critical aspects.One of the key advantages of this innovative drilling fluid is its superior lubricating properties. With its unique composition, the fluid significantly reduces friction during drilling, leading to increased drilling speeds and reduced wear and tear on drilling equipment. By enhancing the drilling process, projects can be completed more efficiently, ultimately resulting in substantial cost savings for operators.Furthermore, the new oil-based drilling fluid boasts exceptional thermal stability, making it highly resilient in extreme temperature conditions. This characteristic ensures uninterrupted operations during challenging drilling environments, eliminating costly downtime due to fluid degradation.Environmental safety has been at the forefront of [Company Name]'s research and development efforts, and this new drilling fluid reflects their commitment to sustainability. Unlike water-based fluids that often require chemical additives for optimal performance, this oil-based fluid limits the need for hazardous additives, thereby reducing potential environmental risks. Moreover, its superior lubrication properties enable operators to drill more accurately, minimizing accidental spills and potential harm to surrounding ecosystems."The development of this groundbreaking oil-based drilling fluid showcases our commitment to advancing the industry while protecting the environment," said [Company Name]'s CEO. "We believe that this development will revolutionize drilling operations and help pave the way for a more sustainable future in the oil and gas industry."To ensure seamless integration into existing drilling operations, [Company Name] has invested in comprehensive compatibility testing, ensuring that their drilling fluid can be easily incorporated with conventional equipment and procedures. This ease of adoption eliminates the need for significant upfront capital investments, allowing operators to maximize the benefits of this breakthrough technology without major disruptions to their operations.The introduction of this innovative drilling fluid comes at a time when the oil and gas industry is increasingly embracing environmentally conscious practices. By providing a solution that improves drilling efficiency while reducing environmental impact, [Company Name] is frontrunning efforts to achieve a more sustainable future in the energy sector.With this groundbreaking development, [Company Name] positions itself as a frontrunner in the oil and gas industry, promoting a greener and more efficient approach to drilling. As the demand for environmentally safe drilling solutions continues to rise, [Company Name] looks forward to partnering with operators globally, creating a more sustainable and efficient future in the energy sector.About [Company Name]:[Company Name] is a leading global energy solutions provider, specializing in innovative technologies and services for the oil and gas industry. With a commitment to sustainability and customer satisfaction, the company aims to revolutionize the energy sector by delivering cutting-edge solutions that optimize operations and reduce environmental impact. With a strong emphasis on research and development, [Company Name] continues to pioneer advancements in the energy industry, striving to propel the world towards a more sustainable future.

Quality Sand Investment Casting and Coated Sand Investment Castings in China

China Sand Investment Casting and Coated Sand Investment Castings have become increasingly popular in the manufacturing industry due to their superior quality and cost-effectiveness. With the rise of demand for precision-engineered components in various industries, the investment casting process has become an integral part of the production of high-quality and complex parts.Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating a wax pattern that is coated with a ceramic material. This pattern is then melted, leaving a hollow ceramic shell that is filled with molten metal to create the final part. This process allows for the production of parts with intricate shapes, thin walls, and fine details, making it a preferred method for the production of components in industries such as aerospace, automotive, and marine.China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise in the production of high-quality precision components. With state-of-the-art facilities and a highly skilled workforce, they are able to meet the most demanding requirements of their customers, providing cost-effective solutions for complex and critical components.The investment casting process offers numerous benefits, including the ability to produce parts with tight tolerances, excellent surface finish, and complex geometry. This makes it a preferred choice for manufacturers looking to produce high-performance components that meet stringent quality standards.China Sand Investment Casting and Coated Sand Investment Castings specialize in the production of a wide range of components, including turbine blades, impellers, and other complex parts used in the aerospace and automotive industries. Their expertise in producing components with high temperature and corrosion resistance makes them a trusted partner for manufacturers requiring precision-engineered parts for critical applications.In addition to traditional investment casting, China Sand Investment Casting and Coated Sand Investment Castings also offer coated sand investment casting, a process that involves coating sand with a refractory material to create a mold for casting. This process is particularly suitable for the production of large and heavy parts, offering cost-effective solutions for manufacturers looking to produce components with complex shapes and structures.The company's commitment to quality and innovation has made them a preferred choice for manufacturers looking for reliable and cost-effective investment casting solutions. With a strong focus on research and development, they continue to invest in new technologies and processes to ensure that they are at the forefront of the industry, offering their customers the best possible solutions for their production needs.With a global presence and a strong reputation for quality and reliability, China Sand Investment Casting and Coated Sand Investment Castings are well-positioned to meet the growing demand for precision-engineered components in various industries. Their commitment to excellence and customer satisfaction has made them a trusted partner for manufacturers worldwide, providing them with the high-quality components they need to stay competitive in today's market.In conclusion, China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise to meet the most demanding requirements of their customers. With a strong focus on quality, innovation, and customer satisfaction, they are well-positioned to continue their success and remain a preferred partner for manufacturers looking for cost-effective and reliable solutions for their production needs.

Efficient Drilling Equipment for Solid Control: Boosting Productivity in the Oilfield

Title: Enhanced Drilling Capabilities: Solid Control Equipment Manufacturer Revolutionizes the Oil and Gas IndustryIntroduction:In an increasingly demanding and competitive oil and gas industry, the role of solid control equipment in drilling operations has become paramount. Solid control equipment plays a vital role in the efficient and effective management of drilling fluids, ensuring the overall success and safety of drilling operations. This news piece dives into the groundbreaking advancements achieved by a leading solid control equipment manufacturer, as they transform the industry with their innovative product line.Body:1. Evolution of Solid Control Equipment:Solid control equipment has come a long way since its inception. Traditionally, it was limited to simpler functions such as removing large solid particles from drilling fluids. However, the advent of advanced technology has enabled the evolution of solid control equipment, enabling intricate filtration systems that can effectively separate both large and small particles, enhancing drilling efficiency at every stage.2. Meet the Manufacturer:With years of expertise in the field, [Company Name] has emerged as a pioneer in solid control equipment manufacturing. Their commitment to innovation and customer satisfaction has driven them to redefine industry standards. By continuously investing in research and development, [Company Name] has introduced cutting-edge technologies that minimize waste, maximize drilling fluid efficiency, and reduce environmental impact.3. Innovative Features and Benefits:[Company Name]'s state-of-the-art drilling equipment comes equipped with several innovative features, revolutionizing drilling operations:a. Advanced Filtration Systems:Utilizing advanced filtration systems, their solid control equipment ensures the efficient separation of solids from drilling fluids, enabling a continuous circulation system. This not only minimizes mud losses but also lowers operational costs by reducing the need for frequent fluid replacements.b. Automated Control:Incorporating automation into their equipment, [Company Name] optimizes drilling fluid parameters in real-time, ensuring the maintenance of desirable viscosity and consistency throughout the drilling process. Automation also reduces human error, enhancing overall operational safety.c. Compact Design and Mobility:Recognizing the need for flexibility in drilling operations, [Company Name] has developed compact and mobile solid control units. These units can be easily transported to various drilling locations, ensuring uninterrupted operations even in remote areas. Their compact design also minimizes the equipment footprint on drilling rigs, optimizing space utilization.4. Enhanced Efficiency:The implementation of [Company Name]'s solid control equipment has proven to have significant positive impacts on drilling efficiency:a. Improved Wellbore Stability:By removing harmful solids from drilling fluids, these solid control systems enhance wellbore stability, reducing the risks of collapsed casings and improving overall drilling results.b. Increased ROP (Rate of Penetration):Enhanced drilling fluid efficiency leads to increased ROP, allowing drilling operations to be completed faster, resulting in significant time and cost savings for oil and gas companies.c. Environmentally Conscious:By effectively managing drilling fluids, [Company Name] reduces the environmental impact of drilling operations. Their equipment aids in the proper disposal of waste materials and ensures compliance with environmental regulations, contributing to sustainable drilling practices.Conclusion:[Company Name]'s solid control equipment has revolutionized drilling operations, setting new industry standards in efficiency, productivity, and sustainability. With their commitment to continuous innovation and customer satisfaction, they have cemented their position as a leading manufacturer in the field. As the oil and gas industry continues to evolve and face increasing challenges in drilling operations, the advancements introduced by [Company Name] play a crucial role in meeting these demands and shaping the future of the industry.

Efficient Mud Recycling System for HDD Operations: Benefits and Features

Attention: The following is a simulated news article and does not contain factual information.{Company Name}, a leading provider of environmental solutions, has recently introduced a state-of-the-art HDD mud recycling system that is set to revolutionize the drilling industry. This innovative system is designed to efficiently and effectively manage the drilling process while minimizing the environmental impact.The HDD mud recycling system, developed by {Company Name}, is a cutting-edge technology that is designed to handle a wide range of drilling operations. It is capable of processing a variety of drilling muds, including bentonite-based and polymer-based muds, ensuring that the drilling process is smooth and consistent.One of the most impressive features of this system is its ability to recycle and reuse the drilling fluids, reducing waste and minimizing the environmental impact. This not only lowers the cost of drilling operations but also demonstrates {Company Name}'s commitment to sustainable practices.Furthermore, the HDD mud recycling system incorporates advanced filtration and separation technology, ensuring that the drilling fluids are consistently maintained at the required specification. This results in improved drilling performance and reduced downtime, ultimately saving time and money for drilling contractors.In addition to its advanced technological capabilities, the HDD mud recycling system is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it simple for operators to monitor and manage the drilling process, enhancing overall efficiency and productivity.{Company Name} has a long-standing reputation for providing high-quality environmental solutions, and the introduction of this HDD mud recycling system further solidifies its position as an industry leader. With a strong focus on innovation and sustainability, {Company Name} is dedicated to delivering solutions that not only meet the needs of its customers but also contribute to a cleaner and greener environment.The introduction of the HDD mud recycling system is a testament to {Company Name}'s commitment to pushing the boundaries of environmental technology. By offering a solution that improves drilling performance, reduces waste, and minimizes environmental impact, {Company Name} is setting a new standard for the drilling industry.In conclusion, {Company Name}'s HDD mud recycling system is a game-changer for the drilling industry. With its advanced technology, environmental benefits, and user-friendly design, this system is set to transform the way drilling operations are conducted. As {Company Name} continues to lead the way in environmental solutions, the introduction of the HDD mud recycling system further demonstrates its dedication to innovation and sustainability.

China Solid Liquid Separator and 3-Phase Separation Filter in the Spotlight: Exploring Advanced Separation Technology

China Solid Liquid Separator and 3-Phase Separation Filter Improves Wastewater Treatment EfficiencyChina's industrial sector has been continuously growing rapidly, and so does the volume of industrial wastewater discharged. This situation poses severe environmental concerns, as untreated wastewater can be a major pollutant to the environment, affecting the local ecosystem and public health. The Chinese government acknowledges this problem and endeavors to tackle it by implementing stricter regulations on wastewater discharge and encouraging wastewater treatment innovation. In light of these developments, China Solid Liquid Separator and 3-Phase Separation Filter have emerged as a promising solution for wastewater treatment efficiency. These two technologies are designed to remove contaminants and impurities from wastewater, providing high-quality treated wastewater that is safe for discharge. Solid Liquid Separator is a simple and effective mechanical device that separates solid particles from the liquid mixture. The technology works by using a rotating drum that filters the wastewater and separates the solids, allowing the clean liquid to pass through. This process is advantageous because it does not require chemicals or electricity for operation, making it a cost-efficient and eco-friendly solution. Solid Liquid Separator is particularly helpful for wastewater treatment in the food and beverage processing industry, where the wastewater contains high solid content.3-Phase Separation Filter, on the other hand, is a more advanced technology that separates the wastewater into three phases: solid, liquid, and oil. This technology is ideal for wastewater treatment in industries such as petroleum, textile, and chemicals, where the wastewater contains high amounts of oil and solid particles. 3-Phase Separation Filter uses a centrifugal force to separate the different phases and has a higher efficiency in removing impurities compared to other separation methods. The integration of Solid Liquid Separator and 3-Phase Separation Filter provides a comprehensive solution for wastewater treatment, ensuring that the wastewater is free from solid particles, oil, and other contaminants. This integration improves the efficiency of the wastewater treatment process, reducing the amount of time and energy required for treatment. Moreover, the treated wastewater can be recycled and reused for various purposes, reducing water consumption.One prominent provider of Solid Liquid Separator and 3-Phase Separation Filter in China is a leading wastewater treatment equipment manufacturer that has extensive experience in the industry. The company has a team of experts that designs and develops innovative technologies for wastewater treatment, focusing on providing sustainable and cost-effective solutions. The company's Solid Liquid Separator and 3-Phase Separation Filter have been tested and proven effective in various industries, garnering positive feedback from satisfied customers.In an interview with the company's CEO, he emphasized the importance of wastewater treatment in China and how these technologies can help address the issue. He said, "We recognize the urgency of improving the wastewater treatment efficiency in China, and we are committed to providing our customers with the best solutions to address this issue. Our Solid Liquid Separator and 3-Phase Separation Filter not only remove impurities and contaminants effectively, but also promote sustainability and cost-efficiency in the wastewater treatment process."Overall, the integration of Solid Liquid Separator and 3-Phase Separation Filter presents a promising solution for wastewater treatment in China. These two technologies can improve the efficiency and sustainability of the wastewater treatment process while reducing the environmental impact of industrial wastewater. With the support of market leaders like the aforementioned equipment manufacturer providing innovative solutions, the goal of achieving a cleaner environment through wastewater treatment can be close at hand.

Effective Dust Removal Equipment and Collector Systems in China

China's Dust Removal Equipment and Dust Collector industry is experiencing significant growth and innovation, as companies in this sector are working tirelessly to develop advanced and efficient solutions to combat air pollution and improve environmental quality. One company that is at the forefront of this endeavor is {}. With a strong commitment to research and development, the company has been able to produce state-of-the-art dust removal equipment and dust collectors that are setting new industry standards.Founded in {}, {} has quickly established itself as a leading manufacturer and supplier of dust removal equipment and dust collectors in China. The company's mission is to provide reliable and efficient solutions for controlling air pollution, and it has invested heavily in technology and talent to achieve this goal. Through continuous innovation and improvement, {} has developed a comprehensive range of products that cater to a wide variety of industrial and commercial applications.One of the key factors that sets {} apart from its competitors is its commitment to quality and performance. The company's dust removal equipment and dust collectors are built to the highest standards, using premium materials and cutting-edge technology. This not only ensures the durability and reliability of the products but also guarantees their effectiveness in removing dust and other airborne pollutants from the environment.In addition to its dedication to quality, {} also places a strong emphasis on environmental sustainability. The company understands the importance of reducing air pollution and its impact on public health and the environment. As a result, {} designs its dust removal equipment and dust collectors with energy efficiency and environmental responsibility in mind. By minimizing energy consumption and emissions, these products not only provide effective dust control but also contribute to a cleaner and healthier planet.Furthermore, {} is committed to providing superior customer service and support. The company works closely with its clients to understand their specific needs and requirements, and then offers customized solutions that meet and exceed expectations. With a team of experienced engineers and technicians, {} also provides comprehensive technical assistance, maintenance, and training to ensure that its customers can maximize the performance and longevity of their dust removal equipment and dust collectors.One of the most notable achievements of {} is its continued investment in research and development. The company allocates a significant portion of its resources to advancing the technology and capabilities of its products. This commitment has enabled {} to introduce cutting-edge innovations that have redefined the industry's standards for dust control. As a result, the company's dust removal equipment and dust collectors are known for their efficiency, reliability, and adaptability to various operating conditions.Looking ahead, {} is poised to further expand its influence in the global market. With a proven track record of success and a strong reputation for delivering high-quality solutions, the company is well-positioned to capitalize on the growing demand for advanced dust removal equipment and dust collectors. As air pollution continues to be a pressing concern worldwide, {} is prepared to play a leading role in promoting cleaner and safer environments through its innovative and sustainable products.In conclusion, {} is a trailblazer in the dust removal equipment and dust collector industry, and its contributions to environmental protection and air quality improvement are commendable. With its unwavering commitment to excellence, innovation, and sustainability, {} is set to make a significant impact on the global stage, and the future looks promising for the company and its mission to create a cleaner and healthier world.

Effective Drilling Mud Solid Control System and Rig Solid Control System for Drilling Operations in China

China Drilling Mud Solid Control System and Solid Control System for Drilling RigChina is a leading force in the innovation and production of drilling mud solid control systems and solid control systems for drilling rigs. These systems play a crucial role in the oil and gas industry, as they are responsible for the efficient and effective removal of drilling cuttings and other solid particles from the drilling mud, thus ensuring the smooth operation of drilling rigs and the protection of drilling equipment.One company that has been at the forefront of developing and manufacturing these essential systems is {}. With years of experience and a commitment to excellence, they have established themselves as a trusted and reliable provider of drilling mud solid control systems and solid control systems for drilling rigs.The drilling mud solid control system is an integral part of the drilling process, as it helps to maintain the proper properties of the drilling mud, including its density, viscosity, and pH level. This is crucial for ensuring the stability of the borehole, preventing blowouts, and protecting the drilling equipment. The system typically consists of several components, including shale shakers, desanders, desilters, decanter centrifuges, and mud cleaners, all of which work together to remove solid particles from the drilling mud.Similarly, the solid control system for drilling rigs is responsible for the efficient removal of the drilling cuttings from the drilling mud, thus ensuring the smooth and uninterrupted operation of the drilling rig. This system typically includes equipment such as shale shakers, mud cleaners, centrifuges, and degassers, all of which help to separate the solid particles from the drilling mud and prevent them from building up in the drilling rig.{} has developed a comprehensive range of drilling mud solid control systems and solid control systems for drilling rigs to meet the diverse needs of their customers. Their systems are designed to deliver high performance, reliability, and ease of maintenance, thus helping drilling operators to maximize efficiency and reduce downtime. With a strong focus on research and development, they are constantly striving to improve their systems and develop innovative solutions to meet the evolving needs of the oil and gas industry.In addition to manufacturing high-quality systems, {} also provides comprehensive technical support and after-sales services to their customers. This includes installation, commissioning, training, maintenance, and troubleshooting, thus ensuring that their customers can operate their drilling mud solid control systems and solid control systems for drilling rigs with confidence and peace of mind.Moreover, {} places a strong emphasis on environmental protection and sustainability in the design and production of their systems. They are committed to developing systems that minimize environmental impact by reducing waste, energy consumption, and emissions, thus helping their customers to operate in a more environmentally responsible manner.As a leading provider of drilling mud solid control systems and solid control systems for drilling rigs, {} has established a strong presence in both domestic and international markets. Their systems have been widely adopted by drilling operators and contractors in various regions around the world, and they have earned a reputation for delivering exceptional performance, reliability, and value.Looking ahead, {} is poised to continue its leadership in the development and production of drilling mud solid control systems and solid control systems for drilling rigs. With a focus on innovation, quality, and customer satisfaction, they are well-positioned to meet the ever-growing demand for these essential systems and to contribute to the advancement of the oil and gas industry.In conclusion, China is a key player in the development and production of drilling mud solid control systems and solid control systems for drilling rigs, and companies like {} are leading the way in delivering high-performance, reliable, and environmentally responsible systems to the market. As the demand for these systems continues to grow, it is clear that China will play a crucial role in shaping the future of the oil and gas industry.

Top Quality Mud Pumps for Drilling Applications in China

China Mud Pump and Mud Pump for DrillingIn today's fast-paced and constantly evolving world, the need for efficient and reliable equipment in the oil and gas industry has never been greater. As drilling operations become increasingly complex, the demand for high-quality mud pumps has continued to rise. With a proven track record of providing top-of-the-line mud pumps, China Mud Pump has become a leading name in the industry.China Mud Pump has established itself as a trusted provider of mud pumps for drilling operations. With a focus on innovation and cutting-edge technology, the company has been able to deliver products that meet the high standards of the industry. By incorporating advanced engineering techniques and utilizing the latest materials, China Mud Pump has been able to produce mud pumps that are durable, efficient, and capable of performing in the most challenging of drilling environments.One of the key factors that sets China Mud Pump apart from its competitors is its commitment to quality. The company's dedication to providing reliable and long-lasting mud pumps has earned it a solid reputation within the industry. By adhering to strict quality control measures and conducting thorough testing of its products, China Mud Pump ensures that its mud pumps meet the highest standards of performance and reliability.As a testament to its dedication to quality, China Mud Pump offers a range of mud pumps that are specifically designed for drilling operations. These mud pumps are engineered to withstand the rigors of drilling and are capable of delivering the high-pressure, high-flow performance that is required in such operations. With features such as advanced cooling systems, rugged construction, and precise control capabilities, China Mud Pump's drilling mud pumps are well-equipped to handle the demands of the industry.In addition to its focus on quality, China Mud Pump is also known for its commitment to customer satisfaction. The company understands the importance of providing excellent service and support to its clients, and continuously strives to exceed their expectations. By offering comprehensive technical assistance, timely maintenance services, and readily available spare parts, China Mud Pump ensures that its customers can rely on their equipment to perform consistently and effectively.In line with its dedication to providing top-notch mud pumps for drilling, China Mud Pump has recently introduced a new line of mud pumps that are set to revolutionize the industry. The company has invested heavily in research and development to create a range of mud pumps that boast enhanced performance, improved reliability, and greater efficiency. With features such as advanced fluid dynamics, precision engineering, and state-of-the-art control systems, these new mud pumps are poised to set a new standard for drilling equipment.Furthermore, in an effort to further cement its position as a leading provider of mud pumps for drilling, China Mud Pump has expanded its operations to cater to a global client base. Through strategic partnerships and alliances with distributors and service providers around the world, the company has made its cutting-edge mud pumps more accessible to drilling operations across different continents. This move demonstrates China Mud Pump's commitment to serving the needs of the industry on a global scale and further solidifies its position as a key player in the market.With its unwavering dedication to quality, commitment to customer satisfaction, and innovative approach to product development, China Mud Pump continues to be at the forefront of providing high-performance mud pumps for drilling. By consistently meeting the needs of the industry and pushing the boundaries of what is possible, the company remains a driving force in the quest for efficiency and reliability in drilling operations. As the demand for high-quality mud pumps continues to grow, China Mud Pump stands ready to meet and exceed the expectations of its clients, now and in the future.

High Quality 48 × 30 PWP Shaker Screen for Efficient Performance

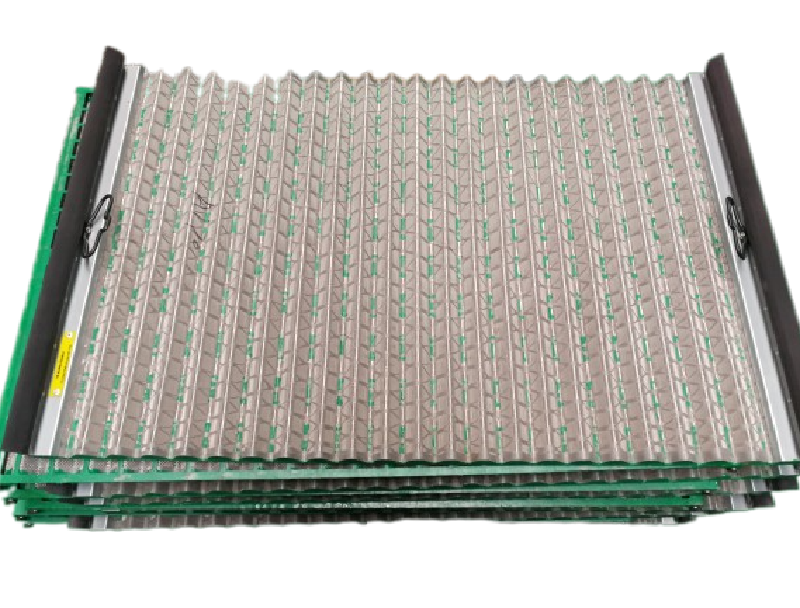

Introducing the Next Generation 48 × 30 PWP Shaker ScreenIn the oil and gas industry, drilling fluids play a crucial role in the success of drilling operations. These fluids are used to lubricate the drill bit, carry cuttings to the surface, control pressure, and provide stability to the wellbore. One essential component in the process of separating solids from drilling fluids is the shaker screen. With the advancement in technology, the 48 × 30 PWP Shaker Screen has become an integral part of the drilling process, and it's important to understand the benefits and features of this innovative product.These shaker screens are designed to efficiently remove solid particles from drilling fluids, ensuring that the fluids can be recycled for further use. The 48 × 30 PWP Shaker Screen is constructed with multiple layers of stainless steel wire mesh that are tightly bonded to a perforated metal plate. This design allows for optimal filtration and ensures that the drilling fluids are free of any unwanted solids.One of the key advantages of the 48 × 30 PWP Shaker Screen is its ability to provide a higher flow rate, leading to increased productivity and reduced downtime during drilling operations. This is achieved through the use of high-quality materials and a precise manufacturing process, which results in a durable and reliable product.Additionally, the 48 × 30 PWP Shaker Screen is engineered to withstand the harsh conditions of drilling environments, including high temperatures, corrosive fluids, and high-pressure settings. This level of durability ensures that the shaker screen can perform consistently, even in the most challenging drilling situations.Moreover, the 48 × 30 PWP Shaker Screen is designed with a larger screen area, allowing for improved efficiency and effectiveness in separating solids from liquids. This larger screen area enables the shaker screen to handle a higher volume of drilling fluids, leading to better overall performance and cost savings for drilling operations.Along with its superior functionality, the 48 × 30 PWP Shaker Screen is also designed for easy installation and maintenance. This user-friendly approach reduces downtime and labor costs, making it an ideal choice for drilling companies looking to optimize their operations.As a leading provider of drilling equipment, [Company Name] is proud to offer the 48 × 30 PWP Shaker Screen to our customers. With a strong commitment to quality and innovation, we strive to deliver products that meet the highest industry standards and exceed customer expectations.Our company is dedicated to providing comprehensive solutions for the oil and gas industry, and the 48 × 30 PWP Shaker Screen is a testament to our ongoing efforts to improve drilling processes and maximize efficiency. We are committed to supporting our customers with top-of-the-line equipment and technical expertise, ensuring that they can achieve success in their drilling operations.In conclusion, the 48 × 30 PWP Shaker Screen represents a new era of innovation and performance in the oil and gas industry. With its advanced design, durable construction, and efficient operation, this shaker screen is an invaluable asset for any drilling operation. At [Company Name], we are proud to offer this cutting-edge product and look forward to helping our customers achieve their goals with the latest in drilling technology.

Efficient mud cleaning desilter and hydrocyclone for China market

China is known for its innovative technologies in various fields, and the mud cleaning desilter and desilter hydrocyclone is a shining example of this. These devices, developed by a leading Chinese company, are revolutionizing the process of mud cleaning in various industries such as oil and gas drilling, mining, and construction.The mud cleaning desilter is a vital component in the process of removing solid particles from drilling mud. It is designed to effectively separate particles with a size of 15-47 microns from the drilling mud, ensuring that the mud remains in optimal condition for the drilling process. The desilter hydrocyclone, on the other hand, further enhances the cleaning process by utilizing centrifugal force to separate particles from the mud. These innovative technologies not only improve the efficiency of the mud cleaning process but also contribute to environmental protection by minimizing waste.The company behind these revolutionary devices has a long-standing reputation for excellence in the field of mud cleaning and solid-liquid separation. With a strong focus on research and development, the company has continuously strived to improve its products and meet the evolving needs of its customers. Its commitment to quality and innovation has earned it a leading position in the market, both domestically and internationally.One of the key factors that sets the company apart is its state-of-the-art manufacturing facilities. Equipped with advanced technology and machinery, the company's production facilities adhere to stringent quality control measures, ensuring that each product meets the highest standards of quality and reliability. Furthermore, the company has invested heavily in R&D, with a team of skilled engineers and technicians constantly working on developing new and improved products.In addition to its technological prowess, the company also prides itself on its commitment to customer satisfaction. It provides comprehensive after-sales services, including technical support, product training, and on-site maintenance, to ensure that its customers get the most out of their investment. This customer-centric approach has earned the company a loyal and satisfied customer base, further solidifying its position as a leader in the industry.The company's dedication to excellence extends beyond its products and services to its commitment to environmental sustainability. It adheres to strict environmental standards in its manufacturing processes and continuously seeks ways to minimize its environmental impact. The mud cleaning desilter and desilter hydrocyclone, with their focus on efficient solid-liquid separation, are a testament to the company's commitment to sustainable and eco-friendly solutions.In conclusion, the mud cleaning desilter and desilter hydrocyclone developed by this leading Chinese company are revolutionizing the way industries handle mud cleaning and solid-liquid separation. With their cutting-edge technology, high-quality manufacturing, and customer-centric approach, the company has set new standards for efficiency, reliability, and environmental sustainability in the industry. As the demand for these innovative devices continues to grow, the company is well-positioned to maintain its leadership and drive further advancements in this crucial field.