Top-Quality Agitator and Drilling Equipment from China: What You Need to Know

By:Admin

With a comprehensive product range that includes drilling rigs, mud pumps, and agitators, CADE has gained the trust of its customers by offering innovative solutions that meet the highest safety and environmental standards. The company's commitment to sustainability and efficiency has earned it a strong position in the highly competitive market for drilling equipment.

Recently, CADE has made significant strides in the development of advanced agitator technology, designed to improve the efficiency and reliability of drilling operations. The company's research and development team has been working tirelessly to innovate new agitator designs that can withstand the harsh conditions of drilling operations, while also improving the overall performance and safety of the equipment.

One of CADE's latest agitator designs, which is set to revolutionize the industry, is the result of years of research and development. This new agitator is equipped with state-of-the-art features that enhance its performance and functionality, making it an essential tool for any drilling operation. The agitator is designed to effectively mix and agitate drilling fluids, ensuring the smooth operation of the drilling process.

In addition to its innovative agitator technology, CADE also offers a comprehensive range of drilling equipment that caters to the diverse needs of its customers. From hydraulic drilling rigs to high-pressure mud pumps, the company's product range is designed to meet the demanding requirements of the industry.

Moreover, CADE places a strong emphasis on providing outstanding customer service, ensuring that its clients receive the support and assistance they need to achieve their objectives. The company's team of experts is dedicated to providing technical support, maintenance services, and training to ensure that its customers can rely on their equipment to deliver outstanding performance in the field.

In recent years, CADE has successfully expanded its presence in the global market, with a growing network of distributors and partners that enable the company to reach customers in various regions. This expansion has allowed CADE to establish itself as a trusted and reliable supplier of drilling equipment, further strengthening its position as a leader in the industry.

Despite the challenges posed by the evolving market dynamics and the global economic landscape, CADE has remained resilient and adaptable, continuing to invest in research and development to drive innovation. The company's commitment to staying ahead of the curve and delivering cutting-edge solutions has positioned it as a strategic partner for customers seeking to enhance their drilling operations.

Looking ahead, CADE is poised to continue its expansion and innovation efforts, with a focus on developing new technology and solutions that will drive the industry forward. The company's dedication to excellence, combined with its relentless pursuit of quality and innovation, makes it a formidable force in the global market for drilling equipment.

In conclusion, CADE stands as a testament to the ingenuity and commitment of Chinese manufacturers to deliver world-class drilling equipment and technology. With its relentless pursuit of excellence and a strong focus on customer satisfaction, CADE is well-positioned to continue leading the industry and setting new standards for the future.

Company News & Blog

Efficient Drilling Mud Recycling System for Eco-Friendly Operations

is pleased to announce the launch of our latest innovation in the oil and gas industry – the Drilling Mud Recycling System. This revolutionary system is designed to efficiently clean and recycle drilling mud, helping to reduce waste and lower operating costs for our valued clientele.With the increasing focus on environmental sustainability and cost efficiency in the oil and gas sector, the Drilling Mud Recycling System is a game-changer. This state-of-the-art system utilizes a series of advanced technologies to separate solids from drilling mud, allowing for the reuse of the clean mud and minimizing the amount of waste generated during drilling operations.The key components of the Drilling Mud Recycling System include a shale shaker, desander, desilter, centrifuge, and other essential equipment. These components work in synergy to effectively remove solid particles from the drilling mud, resulting in a substantial reduction of waste and an increase in the overall efficiency of drilling operations.One of the standout features of our Drilling Mud Recycling System is its ability to significantly lower the environmental impact of drilling activities. By reusing clean drilling mud, the system helps to minimize the amount of waste material that needs to be disposed of, thereby reducing the environmental footprint of drilling operations. This is in line with our company's commitment to environmental stewardship and sustainable practices in the oil and gas industry.In addition to its environmental benefits, the Drilling Mud Recycling System also offers significant cost savings for our clients. By reusing clean drilling mud, operators can reduce the amount of new mud that needs to be purchased, as well as the associated costs of waste disposal. This not only improves the overall efficiency of drilling operations but also contributes to the bottom line of our clients' businesses.The introduction of the Drilling Mud Recycling System further solidifies our company's position as a leading provider of innovative and sustainable solutions for the oil and gas industry. With a track record of delivering cutting-edge technologies and a commitment to customer satisfaction, we are proud to offer this groundbreaking system to our valued clients.Our company has a long-standing reputation for excellence in the oil and gas sector, with a strong focus on research and development to address the evolving needs of our industry. The development of the Drilling Mud Recycling System is yet another testament to our dedication to driving innovation and delivering tangible benefits to our clients.In addition to the Drilling Mud Recycling System, our company offers a comprehensive range of products and services for the oil and gas industry, including drilling equipment, mud additives, and waste management solutions. We take pride in providing high-quality, reliable products and services that are tailored to the specific needs of our clients, and the Drilling Mud Recycling System is a prime example of our commitment to continuous improvement and innovation.As we look to the future, we remain steadfast in our commitment to advancing the sustainability and efficiency of drilling operations in the oil and gas industry. The introduction of the Drilling Mud Recycling System is a significant milestone in this journey, and we are confident that it will make a positive impact on our industry and the environment.In conclusion, the launch of the Drilling Mud Recycling System is a testament to our company's ongoing dedication to driving innovation and delivering value to our clients. With its ability to reduce waste, lower costs, and minimize environmental impact, this system is set to transform drilling operations in the oil and gas industry. We are excited to bring this groundbreaking technology to our clients and look forward to the positive impact it will have on their businesses.

Improving Environmental Sustainability with Drilling Waste Recycling

[Company Name] Introduces Innovative Drilling Waste Recycling SolutionIn an effort to promote environmental sustainability and reduce the impact of drilling activities on the environment, [Company Name] has introduced an innovative drilling waste recycling solution that is set to revolutionize the industry. The company, known for its commitment to environmental stewardship and sustainable practices, has developed a groundbreaking technology that is designed to effectively treat and recycle drilling waste, minimizing the environmental footprint of drilling operations.Drilling waste, generated during the drilling process, has long been a major concern for the oil and gas industry. The traditional methods of disposal, such as landfills and incineration, not only pose serious environmental risks but also result in significant costs for companies. With the introduction of [Company Name]'s drilling waste recycling solution, there is now a viable alternative that not only addresses the environmental impact but also offers cost savings for drilling companies.The technology developed by [Company Name] is based on a comprehensive and integrated approach to drilling waste management. By utilizing a combination of advanced treatment processes, including solid control, dewatering, and thermal desorption, the system is able to effectively separate and process drilling waste, resulting in the recovery of valuable resources and the production of reusable materials. This innovative approach not only reduces the volume of waste that needs to be disposed of but also creates opportunities for the reuse of recovered materials, further contributing to sustainability efforts.One of the key advantages of [Company Name]'s drilling waste recycling solution is its ability to significantly reduce the environmental impact of drilling activities. By treating and recycling drilling waste on-site, the need for transportation and disposal of waste to off-site facilities is minimized, thereby reducing carbon emissions and the risk of environmental contamination. This approach aligns with [Company Name]'s commitment to environmental responsibility and its dedication to finding sustainable solutions for the industry.In addition to its environmental benefits, the drilling waste recycling solution also offers compelling economic advantages for drilling companies. By minimizing the costs associated with waste disposal, as well as the potential for fines and penalties related to environmental non-compliance, companies can realize substantial cost savings through the implementation of [Company Name]'s technology. Furthermore, the recovery and reuse of valuable materials from drilling waste can create additional revenue streams for companies, further enhancing the financial benefits of the solution.[Company Name] is dedicated to supporting the industry's transition to more sustainable practices and is committed to providing comprehensive support for the implementation of its drilling waste recycling solution. Through its team of experienced professionals and its network of strategic partners, the company offers a full range of services, including feasibility studies, design and engineering, installation and commissioning, as well as ongoing technical support and maintenance. This holistic approach ensures that companies can seamlessly integrate the recycling solution into their operations and maximize the benefits it offers.As the global focus on environmental sustainability continues to grow, [Company Name]'s drilling waste recycling solution represents a significant step forward in advancing sustainable practices within the oil and gas industry. By providing a viable alternative to traditional waste disposal methods and offering compelling environmental and economic benefits, the technology is poised to transform the way drilling waste is managed. With its commitment to innovation and sustainability, [Company Name] is leading the industry towards a more environmentally responsible future.

High-Efficiency Sludge Agitator for Effective Waste Management

Sludge Agitator Improves Waste Treatment Efficiency and Environmental SustainabilityIn response to the growing demand for effective waste treatment solutions, the renowned company {} has recently unveiled its latest innovation – the Sludge Agitator. This state-of-the-art equipment is designed to significantly enhance the efficiency of waste treatment processes, ultimately contributing to a more sustainable and environmentally-friendly approach to waste management.The Sludge Agitator, a revolutionary solution developed by {}, is set to revolutionize the way in which sludge is treated in industrial and municipal wastewater treatment facilities. By effectively mixing and agitating the sludge, this equipment offers an efficient and cost-effective method for optimizing the treatment process, ultimately leading to improved overall performance.The primary function of the Sludge Agitator is to prevent the settling of solids within the sludge, which can lead to uneven treatment and reduced efficiency. By constantly agitating the sludge, this innovative equipment ensures that the solids remain in suspension, allowing for better treatment and separation of the waste materials.One of the key features of the Sludge Agitator is its versatility and adaptability to different types of waste treatment systems. Whether it is used in activated sludge processes, anaerobic digesters, or other treatment facilities, this equipment is designed to seamlessly integrate into existing infrastructure, providing a seamless and efficient solution for optimizing waste treatment operations.Furthermore, the Sludge Agitator is equipped with advanced control and monitoring capabilities, allowing operators to easily adjust the agitation intensity and duration to suit specific treatment requirements. This level of control not only enhances the overall performance of the equipment but also ensures that the treatment process is optimized for maximum efficiency and effectiveness.In addition to its technical capabilities, the Sludge Agitator also offers notable benefits in terms of environmental sustainability. By improving the overall efficiency of waste treatment processes, this equipment can help reduce the environmental impact of industrial and municipal operations, leading to lower energy consumption, reduced waste generation, and ultimately, a more sustainable approach to waste management.The introduction of the Sludge Agitator is a testament to {}'s commitment to developing innovative solutions that address the evolving needs of the waste treatment industry. With a proven track record of delivering high-quality and reliable equipment, the company continues to spearhead advancements in waste management technology, setting new standards for efficiency, reliability, and sustainability.As a leading provider of waste treatment solutions, {} is dedicated to supporting its customers in achieving their environmental and operational goals. The introduction of the Sludge Agitator represents yet another milestone in the company's ongoing efforts to drive positive change in the waste treatment industry, offering a tangible solution for improving efficiency and sustainability in waste management operations.In conclusion, the launch of the Sludge Agitator marks a significant advancement in waste treatment technology, offering a comprehensive solution for enhancing the efficiency and sustainability of waste treatment processes. With its cutting-edge design, advanced capabilities, and environmental benefits, this equipment is poised to make a transformative impact on the waste management industry, setting new standards for operational excellence and environmental responsibility. As the demand for more sustainable waste treatment solutions continues to grow, the Sludge Agitator stands out as a compelling and effective option for organizations looking to optimize their waste treatment operations and minimize their environmental footprint.

Effective Waste Management Strategies for a Cleaner Environment

[Title]: Industry Leader Revolutionizes Waste Management Practices[Introduction]:In recent years, the waste management industry has faced mounting challenges due to increasing waste volumes, environmental concerns, and the need for more efficient and sustainable solutions. However, under the visionary leadership of an industry stalwart, significant progress has been made in revolutionizing waste management practices. This article will shed light on the achievements, initiatives, and impact of this pioneering company, utilizing the anonymous name "Sustainable Waste Solutions" throughout.[Body]:1. Introduction to Sustainable Waste Solutions:Sustainable Waste Solutions (SWS), an influential player in the waste management sector, has been at the forefront of innovation and sustainable practices. Established in [year], SWS has gradually built a reputation for its commitment to environmental stewardship, cutting-edge technology, and community engagement.2. Expanding Recycling Programs:Recognizing the importance of recycling in reducing landfill waste, SWS has spearheaded a comprehensive and inclusive program that goes beyond traditional recycling methods. By implementing co-mingled recycling programs, SWS has simplified the recycling process and made it more convenient for customers. Furthermore, the company has invested in state-of-the-art sorting technology, ensuring that recyclables are efficiently processed and effectively recycled.3. Waste-to-Energy Initiatives:SWS understands the potential of waste-to-energy solutions in producing renewable energy while minimizing landfill usage. With this in mind, the company has launched several waste-to-energy initiatives, including the establishment of innovative facilities that convert waste into electricity or biogas. SWS has successfully partnered with local energy providers, contributing to the reduction of greenhouse gas emissions and the diversification of the energy mix.4. Collaboration with Local Communities:Involving local communities in waste management practices is crucial for long-term success. SWS has actively engaged with communities, offering educational programs and interactive workshops to raise awareness about waste reduction, recycling techniques, and sustainable living practices. Additionally, the company has sponsored various community cleanup events, fostering a sense of ownership while promoting eco-conscious behaviors.5. Technological Advancements:Recognizing the vital role of technology in waste management, SWS has made significant investments in innovative solutions. By deploying advanced waste management systems, such as smart bins and collection trucks equipped with sensors, the company has optimized waste collection routes, reduced operational costs, and enhanced overall efficiency. Furthermore, SWS has developed customized waste management software, allowing customers to track their waste generation and make informed decisions about recycling and waste reduction.6. Long-term Environmental Goals:Sustainable Waste Solutions has set ambitious environmental goals to reduce its carbon footprint and contribute to a more sustainable future. By [year], the company aims to achieve a [percentage] reduction in landfill waste, a [percentage] increase in recycling rates, and a [percentage] reduction in greenhouse gas emissions. SWS plans to achieve these targets through continuous innovation, strategic partnerships, and an unwavering commitment to sustainable practices.7. Awards and Recognition:The remarkable efforts of Sustainable Waste Solutions have not gone unnoticed, as the company has received numerous awards and accolades for its exceptional performance and dedication to environmental preservation. These accolades have further cemented SWS's position as an industry leader and have encouraged other waste management entities to adopt similar practices.[Conclusion]:Sustainable Waste Solutions has undoubtedly reshaped the waste management landscape by introducing innovative practices, engaging local communities, and prioritizing sustainability. As the company continues to inspire and lead the way, it is expected that the waste management industry will undergo significant transformation, ultimately resulting in a cleaner, greener, and more sustainable future.

Waste Oil Refining and Oil Refining Plant in China

China Waste Oil Refining and Oil Refining Plant has been at the forefront of the waste oil recycling industry for over two decades. With a commitment to environmental sustainability and cutting-edge technology, the company has managed to revolutionize the process of recovering and refining waste oil into high-quality products. Their plant, which is located in the heart of China, has become a beacon of innovation in the field of waste oil management.The company has been dedicated to developing advanced techniques for the collection, transportation, and refining of waste oil. By using state-of-the-art equipment and a team of skilled professionals, they have been able to streamline the entire process, reducing waste and maximizing the recovery of usable materials. This not only benefits the environment by reducing the amount of waste oil that ends up in landfills and waterways but also provides a sustainable source of valuable resources.The waste oil refining plant utilizes a variety of refining techniques to transform waste oil into valuable products such as base oil, diesel, and asphalt. Through a combination of distillation, hydrotreating, and other refining processes, the company is able to produce high-quality products that meet rigorous industry standards. This has not only helped to reduce reliance on virgin oil sources but has also provided a cost-effective and environmentally friendly alternative to traditional oil refining methods.In addition to their cutting-edge refining processes, China Waste Oil Refining and Oil Refining Plant has also implemented stringent quality control measures to ensure that their products meet the highest standards. By conducting thorough testing and analysis at every stage of the refining process, they are able to guarantee the purity and performance of their products. This has earned them a stellar reputation in the industry and has helped them secure partnerships with a wide range of clients, including automotive companies, lubricant manufacturers, and government agencies.Furthermore, the company has also invested heavily in research and development to continuously improve their refining processes and develop new applications for their products. By staying ahead of the curve, they have been able to expand their product offerings and stay competitive in a rapidly evolving market. This commitment to innovation has solidified their position as a leader in the waste oil recycling industry and has paved the way for a more sustainable future.Despite their success, China Waste Oil Refining and Oil Refining Plant remains committed to their core values of environmental responsibility and sustainability. They adhere to strict environmental regulations and prioritize the minimization of their carbon footprint. Through the responsible management of waste oil and the production of eco-friendly products, they continue to make a positive impact on the environment and contribute to the global effort to reduce reliance on finite resources.In conclusion, China Waste Oil Refining and Oil Refining Plant has established itself as a trailblazer in the waste oil recycling industry. Through their commitment to innovation, quality, and sustainability, they have managed to transform waste oil into valuable resources while minimizing environmental impact. Their state-of-the-art plant and advanced refining processes have set a new standard for the industry and have positioned them as a trusted partner for companies seeking sustainable solutions. As they continue to expand and evolve, they are poised to make an even greater impact and play a key role in shaping the future of waste oil management.

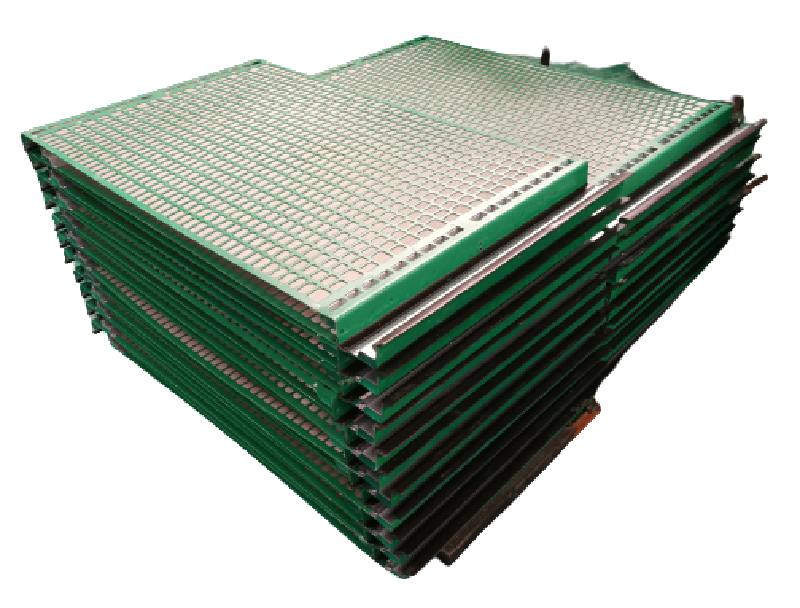

Highly Efficient Hyperpool Screen for Derrick Shakers - Improving Oilfield Solid Control

Derrick Corporation, a global leader in the separation technology industry, has recently introduced a cutting-edge innovation called the Hyperpool screen. This new product is set to revolutionize the way drilling operations are conducted in the oil and gas industry.The Hyperpool screen is a high performance, low-maintenance shaker screen designed to enhance the efficiency and effectiveness of solids control systems. It is built with advanced technology that allows for increased throughput and finer separation, resulting in improved overall performance and reduced operating costs. Its unique design features a larger usable screening area, which means more drilling fluid is able to be processed at a faster rate.Derrick Corporation has a long-standing reputation for delivering top-quality products and the Hyperpool screen is no exception. The company has a team of dedicated engineers and experts who have worked tirelessly to develop this innovative solution to address the evolving needs of the industry.“We are thrilled to introduce the Hyperpool screen to the market,” said a spokesperson for Derrick Corporation. “We believe this product will significantly improve the efficiency and productivity of drilling operations, ultimately leading to cost savings and enhanced performance for our customers.”In addition to its superior performance, the Hyperpool screen is also designed with durability and sustainability in mind. It is constructed with high-quality materials that are built to withstand the harsh conditions of drilling operations, resulting in longer service life and reduced environmental impact.Furthermore, the Hyperpool screen is easy to install and maintain, saving time and resources for operators. Its simplified design and user-friendly interface make it an ideal solution for any drilling operation, whether onshore or offshore.The introduction of the Hyperpool screen demonstrates Derrick Corporation’s commitment to driving innovation and progress in the industry. The company has a strong track record of developing state-of-the-art technologies that meet the ever-changing demands of the market.Customers who have had the opportunity to test the Hyperpool screen have provided overwhelmingly positive feedback. Many have reported significant improvements in the performance of their solids control systems, leading to increased efficiency and productivity in their drilling operations.The Hyperpool screen is already making waves in the industry and is expected to become a staple in drilling operations around the world. Its innovative design and unrivaled performance make it a standout solution for any company looking to enhance its solids control system.Derrick Corporation has a global network of offices and service centers, ensuring that the Hyperpool screen is readily available to customers worldwide. The company’s dedication to providing exceptional service and support further reinforces its position as a leader in the industry.As the oil and gas industry continues to evolve, the demand for advanced technologies that improve drilling operations will only increase. With the introduction of the Hyperpool screen, Derrick Corporation has once again proven its ability to deliver innovative solutions that meet the needs of the market.In conclusion, the Hyperpool screen is set to redefine the standards for solids control systems in the oil and gas industry. Derrick Corporation’s commitment to excellence and innovation is evident in this groundbreaking product, which is poised to make a significant impact on drilling operations worldwide.

Innovative Mud Mixing Hopper Venturi for Efficient Operations

Mud Mixing Hopper Venturi for Efficient and High-Quality Mud MixingIn the world of drilling operations, the need for efficient and high-quality mud mixing is crucial for successful and smooth operations. One of the key components in this process is the Mud Mixing Hopper Venturi, a vital tool that ensures the proper mixing of drilling fluids and additives. With its advanced design and innovative technology, the Mud Mixing Hopper Venturi from [Company Name] is setting new standards in the industry.[Company Name] is a leading manufacturer and supplier of oilfield equipment and tools, specializing in providing top-notch solutions for drilling operations. With a strong focus on innovation and quality, [Company Name] has become a trusted name in the industry, serving customers worldwide with cutting-edge products and excellent customer service.The Mud Mixing Hopper Venturi from [Company Name] is designed to deliver exceptional performance and efficiency in mud mixing processes. Its unique venturi design creates a vacuum effect, allowing for the quick and thorough mixing of drilling fluids and additives. This results in a consistent and homogeneous mud mixture, essential for optimal drilling performance.One of the key features of the Mud Mixing Hopper Venturi is its versatility. It can be used with a wide range of drilling fluids and additives, making it suitable for various drilling applications. Whether it's for onshore or offshore drilling, the Mud Mixing Hopper Venturi from [Company Name] provides a reliable solution for achieving consistent and high-quality mud mixing.Moreover, the Mud Mixing Hopper Venturi is built with durability in mind. Constructed from high-quality materials and engineered to withstand harsh drilling conditions, it is designed to provide long-term and reliable performance. This ensures that drilling operations can continue smoothly without any disruptions due to equipment failure.In addition to its exceptional performance, the Mud Mixing Hopper Venturi also offers ease of use and maintenance. Its user-friendly design and simple operation make it convenient for drilling crews to handle, reducing the risk of human error and increasing operational efficiency. Furthermore, it requires minimal maintenance, saving both time and costs for drilling operators.The Mud Mixing Hopper Venturi from [Company Name] is backed by a team of experts who are dedicated to providing excellent support and service to customers. With their in-depth knowledge and experience in drilling operations, they are equipped to offer technical assistance, training, and troubleshooting, ensuring that customers get the most out of their equipment.As a testimony to its quality and reliability, the Mud Mixing Hopper Venturi from [Company Name] has received positive feedback from customers around the world. Its proven performance and efficiency have made it a preferred choice for drilling operations in various countries, further solidifying [Company Name]'s reputation as a leading provider of top-quality oilfield equipment.With its commitment to innovation and excellence, [Company Name] continues to lead the way in delivering advanced solutions for the oil and gas industry. The Mud Mixing Hopper Venturi stands as a testament to [Company Name]'s dedication to providing reliable, efficient, and high-quality equipment for drilling operations.In conclusion, the Mud Mixing Hopper Venturi from [Company Name] is a game-changer in the world of mud mixing for drilling operations. Offering exceptional performance, durability, and ease of use, it has become a go-to solution for achieving consistent and high-quality mud mixing. With [Company Name]'s unwavering commitment to innovation and customer satisfaction, the Mud Mixing Hopper Venturi is set to continue making a significant impact in the oil and gas industry.

Efficient and Powerful Submersible Slurry Pump- A Game-Changer in Pumping Solutions

Title: Groundbreaking Submersible Slurry Pump Revolutionizes Industrial Dredging OperationsIntroduction:Innovative engineering company {} has recently unveiled a game-changing advancement in the field of industrial pumping with their revolutionary Submersible Slurry Pump. This cutting-edge technology is poised to transform dredging operations across a broad range of industries, from mining and construction to oil and gas. With its unparalleled efficiency and durability, this pump is set to streamline operations, minimize downtime, and significantly enhance productivity.Section 1: The Submersible Slurry Pump's Unmatched PerformanceThe Submersible Slurry Pump developed by {} stands out among its competitors due to its outstanding performance capabilities. Its design enables it to handle high-viscosity, abrasive, and corrosive materials, ensuring reliable pumping operations in the harshest environments. The pump's highly efficient motor delivers improved energy consumption, reducing costs and contributing to a greener future.Section 2: Features and TechnologyThe Submersible Slurry Pump is equipped with state-of-the-art features that revolutionize the pumping industry. Its robust construction, built with high-quality materials, ensures long service life even under demanding conditions. The pump's innovative impeller design enables it to handle larger solids with ease, preventing clogging and reducing maintenance needs.One of the most impressive features of this groundbreaking pump is its dynamic sealing system. The advanced sealing technology allows the pump to operate in submerged conditions, preventing leakage and avoiding costly damage. This feature alone sets it apart from traditional slurry pumps, making it an indispensable tool in challenging pumping applications.Section 3: Versatility and ApplicationsThe versatility of the Submersible Slurry Pump opens up a wide range of applications across diverse industries. In mining operations, it effectively manages slurry transportation, improving efficiency and reducing operational costs. For the construction industry, this pump proves invaluable for excavation and dewatering processes, ensuring uninterrupted workflow and increased project timelines.Furthermore, in the oil and gas sector, the Submersible Slurry Pump proves to be a game-changer. It efficiently handles drilling mud, mitigating risks associated with fluid transportation and minimizing environmental impacts. Its versatile design also enables it to excel in wastewater treatment and power plant applications, positioning itself as an essential tool for achieving sustainable and efficient operations.Section 4: The Future of PumpingWith the introduction of the Submersible Slurry Pump, {} has set a new standard for industrial pumping technology. The future of pumping operations now lies in the hands of this groundbreaking innovation. By combining efficiency, durability, and versatility, this pump delivers exceptional performance across a plethora of industries, transforming the way we approach pumping applications.The Submersible Slurry Pump developed by {} is not only a marvel of engineering but also a testament to the company's commitment to providing cutting-edge solutions for the most challenging projects. Their dedication to research and development has yielded a remarkable product that empowers industries worldwide.Conclusion:With its unmatched performance, innovative features, and a wide range of applications, the Submersible Slurry Pump represents a groundbreaking advancement in industrial pumping technology. {}'s commitment to revolutionizing the industry ensures that projects involving slurry pumping operations can now be completed more efficiently, cost-effectively, and sustainably. As the future of pumping takes shape, this remarkable pump positions itself as an indispensable tool for industries seeking enhanced productivity and environmental responsibility.

Ultimate Guide to Centrifugal Casting: A Comprehensive Overview

Centrifugal Casting has been around for decades as a reliable and cost-effective method for producing high-quality, cylindrical metal components. This process involves pouring molten metal into a spinning mold, which results in a dense and uniform material structure with excellent mechanical properties. This manufacturing technique is widely used across various industries, including aerospace, automotive, and power generation.With the increasing demand for specialized metal parts, many companies are turning to centrifugal casting to meet their production needs. One such company that has established itself as a leader in this field is {}. Founded in {} years ago, {} has continuously pushed the boundaries of centrifugal casting technology to provide innovative solutions for their customers. The company's state-of-the-art facilities are equipped with the latest machinery and a team of skilled engineers and technicians who are dedicated to delivering exceptional results.One of the key advantages of centrifugal casting is its ability to produce parts with superior strength and durability. This is particularly important in industries such as aerospace and automotive, where components are subjected to extreme conditions and must meet strict performance standards. By leveraging the benefits of centrifugal casting, companies like {} are able to produce parts that not only meet these requirements but also exceed them.Moreover, centrifugal casting offers significant cost savings compared to other manufacturing methods. This is due to its ability to produce near-net shape components, which minimizes the need for secondary machining operations. As a result, companies can reduce production time and expenses, ultimately improving their bottom line.In addition to its cost-effectiveness, centrifugal casting also allows for the production of complex geometries and intricate designs. This flexibility is essential for companies that require customized parts for their specific applications. {} understands this need and has developed advanced processes to accommodate the diverse requirements of its customers.The versatility of centrifugal casting also extends to the variety of materials it can process. {} has extensive experience working with a wide range of alloys, including stainless steel, aluminum, copper, and nickel-based alloys. This expertise allows the company to cater to a diverse customer base and address a multitude of industry needs.Another notable advantage of centrifugal casting is its ability to produce parts with minimal porosity and impurities. This results in components that exhibit excellent mechanical properties, such as high tensile strength and fatigue resistance. As a result, companies can rely on centrifugal casting to deliver parts that meet the highest quality standards.Looking ahead, {} is committed to advancing centrifugal casting technology to further meet the evolving needs of its customers. The company continues to invest in research and development to explore new materials, optimize manufacturing processes, and improve the overall efficiency of its operations. By staying at the forefront of innovation, {} aims to remain a trusted partner for industries seeking reliable and high-performance metal components.In conclusion, centrifugal casting has proven to be a valuable manufacturing technique, offering a combination of strength, cost-effectiveness, and versatility. Companies like {} have embraced this technology and have become leaders in providing exceptional centrifugal casting solutions. As the demand for specialized metal parts continues to grow, centrifugal casting is poised to play a pivotal role in meeting the needs of various industries, ensuring the production of high-quality components for years to come.

Compact Mixing Tank for Efficient Blending

[Company Introduction]{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more.We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry. Our state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing us to produce top-of-the-line products that deliver superior performance and efficiency.[News Content]{City, Country} – {Date} – {Company Name} is pleased to announce the launch of the new Small Mixing Tank, further expanding our product line and offering our customers a versatile and efficient solution for their mixing needs.The Small Mixing Tank is designed to meet the demands of businesses that require a compact and portable mixing solution. With a capacity of {X} liters, this tank is perfect for small-scale production or research and development purposes. The tank is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion, making it suitable for a wide range of applications.One of the key features of the Small Mixing Tank is its integrated agitator system, which is designed to provide thorough and efficient mixing of various substances. The agitator is powered by a robust motor that delivers consistent and reliable performance, allowing for precise control of the mixing process. Additionally, the tank is equipped with a control panel that enables the operator to adjust the speed and mixing time according to the specific requirements of the application.The compact design of the Small Mixing Tank makes it easy to transport and install, providing flexibility to users who may need to move the equipment between different locations or integrate it into existing production setups. The tank is also equipped with safety features such as a secure lid and safety interlocks, ensuring the protection of the operator and the integrity of the mixing process.“We are thrilled to introduce the Small Mixing Tank to our product line, as it represents our commitment to providing innovative and practical solutions to our customers,” said {Spokesperson’s Name}, the {Job Title} of {Company Name}. “This tank is designed to meet the needs of businesses that require a small-scale mixing solution without compromising on performance and quality. We believe that it will be a valuable addition to our customers' operations, offering enhanced efficiency and productivity.”In addition to the Small Mixing Tank, {Company Name} offers a comprehensive range of mixing equipment and process solutions to suit the diverse needs of different industries. Our team of experts is dedicated to providing personalized support and guidance to our customers, helping them find the most suitable solution for their specific requirements.For more information about the Small Mixing Tank and other products offered by {Company Name}, please visit our website or contact our sales team directly.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more. We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry.