Top-rated Drilling Fluids Agitator - Find the Best Quality at An Affordable Price

By:Admin

The oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to improve efficiency and productivity. One such innovation that is making waves in the industry is the drilling fluids agitator developed by a leading company in the sector.

The drilling fluids agitator is a crucial tool used in the process of drilling for oil and gas. It plays a vital role in maintaining the proper consistency and viscosity of the drilling fluids, which is essential for the success of drilling operations. The agitator is used to effectively mix the various components of the drilling fluids, ensuring that they are well blended and ready for use in the drilling process.

The agitator's design and functionality are what set it apart from traditional agitators used in the industry. It is equipped with state-of-the-art technology that allows for precise control and monitoring of the mixing process. This technology enables operators to adjust the agitator's speed and intensity according to the specific requirements of the drilling fluids, ensuring optimal performance and consistency.

Furthermore, the agitator is designed to withstand the harsh and demanding conditions typically encountered in drilling operations. Its robust construction and durable materials ensure that it can operate seamlessly in extreme temperatures and high-pressure environments, providing reliability and longevity for continuous use.

The company behind the development of this innovative agitator has a long-standing reputation for delivering high-quality equipment and solutions to the oil and gas industry. With decades of experience and expertise in the field, the company has consistently been at the forefront of technological advancements, driving innovation and pushing the boundaries of what is possible in the industry.

Through continuous research and development, the company has been able to stay ahead of the curve, anticipating the needs and challenges of the industry and developing solutions that address them effectively. The drilling fluids agitator is a prime example of the company's commitment to innovation and excellence, setting a new standard for agitators in the oil and gas sector.

In addition to its cutting-edge technology, the company also prides itself on its dedication to customer satisfaction and support. It provides comprehensive training and technical assistance to ensure that operators can maximize the potential of the agitator and operate it safely and efficiently. This level of support and service has earned the company a loyal and satisfied customer base, further solidifying its position as a leader in the industry.

The impact of the drilling fluids agitator on the oil and gas industry has been significant. Its introduction has led to improvements in drilling operations, resulting in enhanced efficiency, reduced downtime, and ultimately, cost savings for companies. By streamlining the mixing process and ensuring the consistency of drilling fluids, the agitator has contributed to improved overall performance and productivity in drilling operations.

Looking ahead, the company is committed to furthering the development of innovative solutions for the oil and gas industry. It continues to invest in research and development, exploring new technologies and approaches to address the evolving needs of the industry. With a strong focus on sustainability and environmental responsibility, the company aims to develop solutions that not only improve efficiency but also minimize the impact on the environment.

In conclusion, the drilling fluids agitator has proven to be a game-changer in the oil and gas industry, showcasing the impact that advanced technology and innovative solutions can have on the sector. With its state-of-the-art design, robust construction, and unparalleled performance, the agitator has set a new standard for drilling equipment, paving the way for a more efficient and sustainable future in the industry. As the company continues to lead the charge in innovation, it is poised to shape the future of drilling operations with its groundbreaking solutions.

Company News & Blog

Innovative Circulating System for Rigs: What You Need to Know

[Rig Circulating System] Enhances Efficiency and Safety in Oil and Gas DrillingThe oil and gas industry is constantly evolving with new technologies and advancements aimed at improving efficiency and safety. One such innovation is the [Rig Circulating System], a cutting-edge solution that has been gaining widespread attention for its ability to streamline drilling operations and enhance overall performance.Developed by a leading oil and gas equipment manufacturer, this advanced system is designed to optimize the circulation of drilling fluids during the drilling process. By effectively managing the flow of fluids, it helps mitigate potential risks associated with wellbore instability and well control incidents, ultimately promoting a safer and more efficient drilling operation.The [Rig Circulating System] is a fully integrated solution that can be customized to meet the specific needs of different drilling projects. It comes equipped with state-of-the-art components, including high-capacity mud pumps, mud mixing and storage units, and advanced control systems. These components work in harmony to ensure seamless circulation of drilling fluids, while also providing real-time monitoring and diagnostic capabilities to enhance operational control and decision-making.One of the key advantages of the [Rig Circulating System] is its ability to minimize downtime and maximize drilling efficiency. By maintaining consistent fluid flow and pressure, it helps reduce the risk of costly delays and non-productive time, ultimately allowing drilling operations to proceed smoothly and uninterrupted.Furthermore, the system’s advanced filtration and purification capabilities contribute to the overall quality of the drilling fluids, which is crucial for sustaining optimal drilling performance and wellbore stability. This, in turn, can lead to significant cost savings by minimizing the need for fluid replacements and reducing overall waste generation.In addition to its performance benefits, the [Rig Circulating System] also places a strong emphasis on safety and environmental responsibility. Its advanced control systems and automated features are designed to minimize the risk of human error and improve overall operational safety. Furthermore, its efficient fluid management capabilities help reduce the environmental impact of drilling operations by minimizing the discharge of contaminated fluids and waste.With its proven track record of enhancing efficiency and safety in oil and gas drilling, the [Rig Circulating System] has garnered positive attention from industry professionals and stakeholders. Its successful implementation in various drilling projects has resulted in improved drilling performance, reduced operational costs, and enhanced overall wellbore integrity.The [Rig Circulating System] is just one example of the innovative solutions being developed and implemented to address the evolving needs of the oil and gas industry. As drilling operations continue to push the boundaries of technological innovation, it is clear that solutions such as this will play an instrumental role in shaping the future of oil and gas exploration and production.In conclusion, the [Rig Circulating System] represents a significant advancement in the field of oil and gas drilling technology. Its ability to enhance operational efficiency, ensure wellbore integrity, and promote safety and environmental responsibility makes it a valuable asset for companies operating in the dynamic and challenging environment of the oil and gas industry. As the industry continues to evolve, it is evident that innovative solutions like the [Rig Circulating System] will play a pivotal role in driving progress and facilitating sustainable development in the years to come.

Effective Desander Liquid for Removing Debris and Sediment

The global market for Desander Liquid is expected to witness impressive growth in the coming years as a result of the increasing demand for efficient solutions in the oil and gas industry. The market is set to experience significant expansion, supported by technological advancements and the rising focus on environmental sustainability.One company that has been making significant contributions to the Desander Liquid market is {Company}. Founded in 2005, {Company} has established itself as a leading provider of innovative and reliable products for the oil and gas industry. The company’s commitment to delivering high-quality solutions has positioned it as a trusted partner for numerous clients around the world.{Company}’s Desander Liquid is designed to effectively remove solid particles from drilling fluid, enabling the extraction of cleaner fluids and better performance of downstream equipment. The product features a robust design and advanced technology, enhancing its efficiency and reliability in demanding industrial environments. With a focus on sustainability, {Company} ensures that its Desander Liquid is not only efficient but also environmentally friendly, meeting the stringent regulations and standards of the industry.The company’s dedication to research and development has been instrumental in driving innovation in the Desander Liquid market. Through continuous investment in new technologies and the expertise of its team, {Company} has been able to introduce cutting-edge solutions that address the evolving needs of the industry. This commitment to innovation has enabled the company to stay ahead of the competition and maintain its position as a market leader.In addition to its technological prowess, {Company} is also known for its exceptional customer service. By understanding the unique requirements of its clients, the company delivers tailored solutions that are designed to meet specific needs, ensuring maximum satisfaction. Moreover, with a global presence and a strong distribution network, {Company} is capable of providing reliable support and timely delivery to its customers worldwide.The growth prospects for the Desander Liquid market are promising, and {Company} is well positioned to capitalize on these opportunities. With a solid track record of success and a focus on continuous improvement, the company is poised to further enhance its market presence and drive value for its customers.As the demand for Desander Liquid continues to rise, {Company} remains committed to providing the industry with innovative and sustainable solutions. By leveraging its expertise, technology, and customer-centric approach, the company is poised to play a significant role in shaping the future of the Desander Liquid market. With a strong foundation and a clear vision for the future, {Company} is set to make a lasting impact on the industry, driving growth and delivering value to its stakeholders.In conclusion, the Desander Liquid market is poised for significant growth, driven by technological advancements and the increasing demand for efficient solutions in the oil and gas industry. {Company}, with its innovative products, commitment to sustainability, and exceptional customer service, is well positioned to capitalize on these opportunities and make a meaningful contribution to the market. With a focus on continuous improvement and a strong global presence, {Company} is set to lead the way in shaping the future of the Desander Liquid market.

Revolutionary Palm Oil Sludge Decanter Centrifuge Optimizes Separation Process in Malaysia

Palm Oil Sludge Separation Made Effortless with Decanter Centrifuges from ChinaPalm oil production is among the largest agricultural industries not only in Malaysia but also across the globe. With increased demand for palm oil, more and more industries are joining the race to tap into this lucrative business. However, the process of producing palm oil usually results in a lot of waste material, with sludge being among the most significant. Sludge is usually composed of residual oil, water, and solid debris, making it an environmental hazard when not properly disposed of. Luckily, with the advancement in technology, companies such as ZK Separation have come up with decanter centrifuges that make sludge separation easier and more efficient.ZK Separation's decanter centrifuges provide the ultimate solution in the palm oil sludge separating process. They are designed to separate the residual oil from the water by utilizing high centrifugal force. The decanter centrifuges have a unique and innovative design that guarantees maximum efficiency and high-quality separation. Not only do the decanters remove the oil, but they also help remove impurities, making it easier to dispose of the sludge.The China crude oil centrifuge and olive oil decanter centrifuge from ZK Separation are some of the most widely used machines in palm oil sludge separation. Their unrivaled performance and high efficiency rates have made them a favorite among clients across the globe. The company has invested heavily in research and development to ensure that their machines are of the highest quality.The China crude oil centrifuge is specially designed to make crude oil separation easier and more efficient. The machine has a robust construction that can handle various crude oil types, including palm oil. Its critical components such as the bowl and conveyor are made using high-quality materials to guarantee maximum durability and longevity.Similarly, the olive oil decanter centrifuge is also designed to make the separation of olive oil from water and other solid materials easier. The machine has undergone extensive testing and refinement to ensure maximum performance. Its automatic control system makes it easy to operate and customize according to the user's needs.In conclusion, the separation of palm oil sludge is an essential process in ensuring environmental sustainability in the palm oil industry. ZK Separation is at the forefront of designing innovative and efficient decanter centrifuges that make the process easier and more efficient. The China crude oil centrifuge and olive oil decanter centrifuge from the company have proven to be reliable and efficient in the separation process, making them a must-have for any industry player.

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

High-Efficiency Sludge Agitator for Effective Waste Management

Sludge Agitator Improves Waste Treatment Efficiency and Environmental SustainabilityIn response to the growing demand for effective waste treatment solutions, the renowned company {} has recently unveiled its latest innovation – the Sludge Agitator. This state-of-the-art equipment is designed to significantly enhance the efficiency of waste treatment processes, ultimately contributing to a more sustainable and environmentally-friendly approach to waste management.The Sludge Agitator, a revolutionary solution developed by {}, is set to revolutionize the way in which sludge is treated in industrial and municipal wastewater treatment facilities. By effectively mixing and agitating the sludge, this equipment offers an efficient and cost-effective method for optimizing the treatment process, ultimately leading to improved overall performance.The primary function of the Sludge Agitator is to prevent the settling of solids within the sludge, which can lead to uneven treatment and reduced efficiency. By constantly agitating the sludge, this innovative equipment ensures that the solids remain in suspension, allowing for better treatment and separation of the waste materials.One of the key features of the Sludge Agitator is its versatility and adaptability to different types of waste treatment systems. Whether it is used in activated sludge processes, anaerobic digesters, or other treatment facilities, this equipment is designed to seamlessly integrate into existing infrastructure, providing a seamless and efficient solution for optimizing waste treatment operations.Furthermore, the Sludge Agitator is equipped with advanced control and monitoring capabilities, allowing operators to easily adjust the agitation intensity and duration to suit specific treatment requirements. This level of control not only enhances the overall performance of the equipment but also ensures that the treatment process is optimized for maximum efficiency and effectiveness.In addition to its technical capabilities, the Sludge Agitator also offers notable benefits in terms of environmental sustainability. By improving the overall efficiency of waste treatment processes, this equipment can help reduce the environmental impact of industrial and municipal operations, leading to lower energy consumption, reduced waste generation, and ultimately, a more sustainable approach to waste management.The introduction of the Sludge Agitator is a testament to {}'s commitment to developing innovative solutions that address the evolving needs of the waste treatment industry. With a proven track record of delivering high-quality and reliable equipment, the company continues to spearhead advancements in waste management technology, setting new standards for efficiency, reliability, and sustainability.As a leading provider of waste treatment solutions, {} is dedicated to supporting its customers in achieving their environmental and operational goals. The introduction of the Sludge Agitator represents yet another milestone in the company's ongoing efforts to drive positive change in the waste treatment industry, offering a tangible solution for improving efficiency and sustainability in waste management operations.In conclusion, the launch of the Sludge Agitator marks a significant advancement in waste treatment technology, offering a comprehensive solution for enhancing the efficiency and sustainability of waste treatment processes. With its cutting-edge design, advanced capabilities, and environmental benefits, this equipment is poised to make a transformative impact on the waste management industry, setting new standards for operational excellence and environmental responsibility. As the demand for more sustainable waste treatment solutions continues to grow, the Sludge Agitator stands out as a compelling and effective option for organizations looking to optimize their waste treatment operations and minimize their environmental footprint.

Efficient Mud Tank System for Drilling Rigs

Mud Tank System Drilling Rig: Revolutionizing the Oil and Gas IndustryThe oil and gas industry has long been reliant on drilling rigs to extract hydrocarbons from deep beneath the earth's surface. These rigs are vital in the production of crude oil and natural gas, and their efficiency and reliability directly impact the industry's productivity. One company at the forefront of revolutionizing drilling rig technology is {}, a leading provider of innovative solutions for the oil and gas sector.At the heart of their groundbreaking offerings is the Mud Tank System Drilling Rig, a technological marvel that has been hailed as a game-changer in the industry. This state-of-the-art rig is designed to maximize operational efficiency, streamline drilling processes, and enhance safety measures, ultimately leading to increased productivity and reduced downtime.The Mud Tank System Drilling Rig features a cutting-edge mud tank system that is integral to its performance. This system is designed to efficiently handle drilling waste and regulate the flow of drilling fluids, ensuring a clean and controlled environment for the drilling operation. By effectively managing mud and drilling fluids, the rig minimizes the impact on the surrounding environment and reduces the risk of operational hazards.Moreover, the Mud Tank System Drilling Rig is equipped with advanced monitoring and control systems that provide real-time data on drilling parameters. This enables operators to make quick and informed decisions, optimize drilling processes, and mitigate potential issues before they escalate. The rig's automated features and remote monitoring capabilities further enhance operational control and contribute to a safer working environment for personnel.In addition to its technological prowess, the Mud Tank System Drilling Rig is designed with versatility in mind. It can be customized to meet the specific requirements of different drilling projects, whether in onshore or offshore locations. Its modular design allows for easy transportation and assembly, making it well-suited for remote and challenging environments.This innovative drilling rig has already made a significant impact in the oil and gas industry, with numerous successful deployments and favorable feedback from operators. Its performance has been commended for its reliability, operational efficiency, and environmental stewardship. As the industry continues to adapt to evolving challenges and demands, the Mud Tank System Drilling Rig is poised to play a pivotal role in shaping the future of drilling operations.In line with this commitment to innovation and excellence, {} has established itself as a driving force in the oil and gas sector. With a rich history of delivering cutting-edge solutions and a strong focus on research and development, the company is dedicated to pushing the boundaries of technology to address the industry's evolving needs.{} has solidified its reputation as a trusted partner for oil and gas companies seeking reliable and efficient solutions. Their comprehensive portfolio of products and services spans the entire spectrum of drilling and production operations, encompassing drilling rigs, well services, and environmental solutions. Coupled with their unwavering commitment to safety and sustainability, the company has earned the trust and confidence of industry stakeholders worldwide.Looking ahead, {} remains steadfast in its pursuit of innovation and advancement. The company continues to invest in research and development, collaborating with industry partners and experts to push the boundaries of drilling technology. With a keen eye on emerging trends and challenges, {} is poised to lead the industry towards a more sustainable and efficient future.In conclusion, the Mud Tank System Drilling Rig stands as a testament to the transformative potential of technological innovation in the oil and gas industry. Through its cutting-edge design, advanced features, and versatility, this rig exemplifies the strides being made towards enhancing operational efficiency, safety, and environmental responsibility. In partnership with companies like {}, the industry is primed to embrace a new era of drilling excellence.

Compact Mixing Tank: A Game-Changer for Efficient Mixing Processes

Small Mixing Tank Company Works to Revolutionize IndustryFor years, companies in the chemical and pharmaceutical industries have relied on large mixing tanks to produce their products, but a small startup called Small Mixing Tank (SMT) is looking to change that.SMT has developed a compact, customizable mixing tank that is perfect for companies that need a more efficient and cost-effective solution. Their tanks come in a range of sizes and are designed to fit in tight spaces, making them ideal for smaller facilities or production lines. In addition, SMT’s tanks are equipped with sophisticated mixing technology that ensures a uniform blend of materials and reduces waste.“Large mixing tanks can be a real headache for companies that have limited space or need to move their production lines around,” said SMT founder and CEO, Jane Smith. “That’s why we decided to develop a smaller, more versatile option that can be customized to meet the needs of any industry.”One of the key features of SMT’s tanks is their modular design. Companies can choose from a range of mixing heads and blades to create a tank that is tailored to their specific needs. This eliminates the need for companies to purchase multiple tanks for different applications, saving them time and money in the long run.“Our tanks are really a one-stop-shop solution,” said Smith. “From pharmaceuticals to food and beverage, our customers can create a mixing tank that meets the demands of their industry without having to invest in multiple tanks and accessories.”SMT’s tanks are also designed with cleaning and maintenance in mind. The tanks are easy to disassemble and clean, reducing the risk of contamination or cross-contamination. Additionally, the tanks’ components are all easily replaceable, so companies don’t have to worry about costly repairs or downtime if parts need to be replaced.“We know that time is money in manufacturing, so we wanted to make sure our tanks were designed for easy maintenance and cleaning,” said Smith. “This minimizes downtime and ensures that our customers can keep their production lines running smoothly.”Since launching in 2020, SMT has seen impressive growth and has attracted the attention of several major companies. Recently, the company received a significant investment from a leading pharmaceutical firm, which will allow them to expand their production capabilities and offer even more advanced mixing technology.“We’re thrilled to have the support of such a well-respected company in the pharmaceutical industry,” said Smith. “This investment will allow us to take our mixing technology to the next level and further revolutionize the industry.”Looking to the future, SMT plans to continue enhancing its mixing technology and expanding its product line to meet the needs of different industries. The company also plans to explore new markets and opportunities for growth, with a focus on sustainability and reducing waste.“We believe that our tanks have the potential to transform the manufacturing industry and help businesses of all sizes operate more efficiently and sustainably,” said Smith. “We’re excited to continue pushing the boundaries and developing new solutions that benefit both our customers and the planet.” In conclusion, Small Mixing Tank has established itself in the industry as a company that is dedicated to creating innovative solutions for businesses of all sizes. With its compact, modular design and advanced mixing technology, the company’s tanks have the potential to revolutionize the industry and help companies operate more efficiently and sustainably. As SMT continues to grow and expand, it will be interesting to see how it continues to push the boundaries of what is possible in manufacturing.

Top 5 Drilling Machine Equipment for Your Next Project

Drilling Machine Equipment is proud to announce the launch of their latest innovative drilling machine, the DMX-2000. This cutting-edge equipment is designed to revolutionize the drilling industry with its advanced features and superior performance. With over 20 years of experience in the industry, Drilling Machine Equipment has established itself as a leader in providing high-quality, reliable drilling equipment for various applications.The DMX-2000 is a result of extensive research and development, aimed at meeting the growing demands of the drilling industry. With a powerful motor and high drilling capacity, this machine is capable of handling a wide range of drilling tasks with precision and efficiency. Its robust construction ensures durability and longevity, making it a cost-effective investment for businesses looking to enhance their drilling operations."We are thrilled to introduce the DMX-2000 to the market," said the spokesperson for Drilling Machine Equipment. "This machine represents our commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that the DMX-2000 will set a new standard for drilling equipment and provide our clients with a competitive edge in their operations."In addition to its impressive performance, the DMX-2000 is equipped with advanced safety features to ensure the well-being of operators and workers. It comes with an ergonomic design and intuitive controls, allowing for easy operation and minimizing the risk of accidents. Drilling Machine Equipment understands the importance of safety in the workplace, and the DMX-2000 reflects their commitment to promoting a secure working environment.Moreover, the DMX-2000 is designed to be versatile and adaptable to different drilling conditions. Whether it's for construction, mining, or exploration, this machine is capable of delivering consistent results across various applications. This flexibility makes it a valuable asset for businesses that require a reliable and efficient drilling solution for their projects.Drilling Machine Equipment has built a solid reputation in the industry for delivering exceptional products and services. With a focus on quality and customer satisfaction, the company has earned the trust of numerous clients worldwide. Their team of highly skilled engineers and technicians are dedicated to providing comprehensive support and assistance to ensure that their customers experience seamless operations with their equipment."We take pride in the relationships we have established with our clients," the spokesperson added. "At Drilling Machine Equipment, we believe in going above and beyond to support our customers and address their needs. The launch of the DMX-2000 is a testament to our continuous efforts to drive innovation and deliver solutions that add value to our clients' businesses."As a company that values sustainability and environmental responsibility, Drilling Machine Equipment has incorporated eco-friendly features into the DMX-2000. The machine is designed to minimize its carbon footprint and reduce energy consumption, aligning with the company's commitment to promoting sustainable practices in the industry.In conclusion, the launch of the DMX-2000 represents a significant milestone for Drilling Machine Equipment, showcasing their dedication to advancing the drilling industry with cutting-edge technology and superior equipment. As businesses continue to seek reliable and efficient drilling solutions, the DMX-2000 is poised to make a lasting impact and elevate the standards of performance in the industry. With its exceptional features, versatility, and focus on safety and sustainability, this machine is set to become a game-changer for drilling operations worldwide.

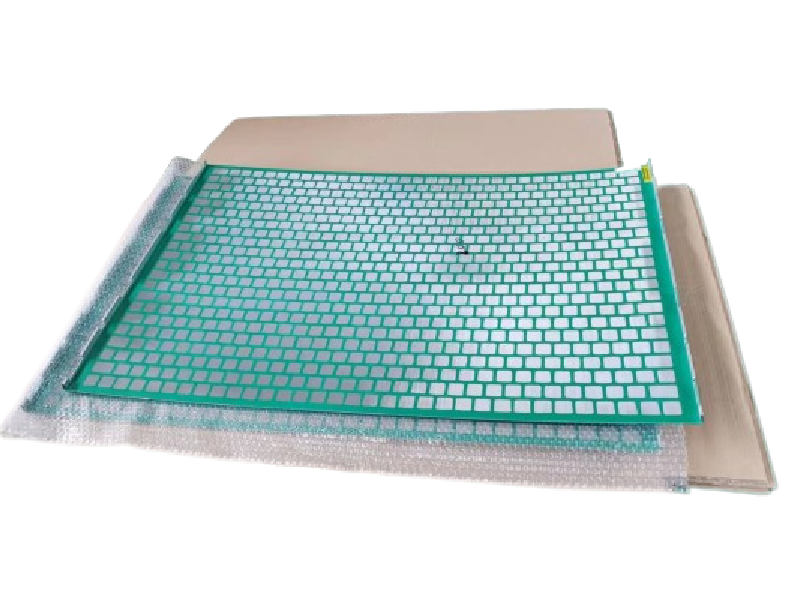

High Quality Shaker Screens for Improved Processing Efficiency

Shaker screens are an integral part of the oil and gas drilling process, helping to separate solids and fluids and ensure smooth and efficient operations. One company at the forefront of shaker screen technology is {}. They have been providing high-quality, reliable shaker screens to the oil and gas industry for many years, and their commitment to innovation and excellence has made them a trusted partner for drilling companies around the world.{} is known for their advanced shaker screen designs, which are carefully engineered to maximize efficiency and performance. Their screens are made from durable materials that can withstand the harsh conditions of drilling operations, and they undergo rigorous testing to ensure that they meet the highest standards of quality and reliability.One of the key advantages of using {} shaker screens is their ability to improve the overall efficiency of the drilling process. By effectively separating solids from fluids, their screens help to reduce waste and minimize downtime, ultimately leading to cost savings for drilling companies. In addition, {} screens are designed to be easy to install and maintain, further enhancing their value to their customers.Recently, {} introduced a new line of shaker screens that have been met with great enthusiasm from the industry. These screens feature advanced technology that allows for even greater efficiency and performance, and they have been carefully designed to meet the specific needs of today's drilling operations. With this new line of shaker screens, {} continues to demonstrate their commitment to innovation and their ability to stay ahead of the curve in the rapidly evolving oil and gas industry.In addition to their cutting-edge shaker screens, {} is also known for their exceptional customer service. They work closely with their clients to understand their unique needs and challenges, and they are dedicated to providing customized solutions that deliver real results. Whether it's recommending the right type of shaker screen for a particular drilling operation or providing technical support and assistance, {} goes above and beyond to ensure that their customers have the support they need to succeed.{}'s reputation for excellence in the shaker screen industry has made them a go-to choice for drilling companies looking for reliable, high-performance equipment. Their commitment to quality, innovation, and customer service sets them apart from their competitors, and they continue to be a driving force in the evolution of shaker screen technology.As the demand for oil and gas continues to grow, the need for efficient and reliable drilling equipment becomes increasingly important. With {}'s advanced shaker screens and dedication to excellence, they are well-positioned to meet the needs of the industry and continue to be a leader in the field. Their continued innovation and commitment to their customers make them a valuable partner for drilling companies around the world, and they are poised to make even greater contributions to the oil and gas industry in the years to come.

Discover the Latest Innovations in Sedimentation Centrifuges and Decanter Centrifuges from China

China Sedimentation Centrifuge and Decanter Centrifuge Changing the Game in Separation TechnologyChina sedimentation and decanter centrifuges have taken the separation technology to new heights with their state-of-the-art features and advanced capabilities. The technology has come a long way since its development, and the modern-day centrifuges are a result of years of technological evolution and innovation.Sedimentation CentrifugeA sedimentation centrifuge, commonly known as a clarifier, is used to separate solid particles from liquids. Sedimentation is one of the most efficient methods of separation, and the centrifuge enhances the process by providing a faster and more precise separation.The sedimentation process involves introducing a mixture of liquid and solid particles into the centrifuge. The rotational force created by the spinning motion causes the denser particles to settle at the bottom, creating a sediment layer.The decanter centrifugeThe decanter centrifuge, on the other hand, is used to separate a liquid from another liquid or solid. It works on the principle of centrifugal force, where the mixture is introduced into a horizontal bowl, rapidly spinning to create a high gravitational force.The centrifugal force separates the two liquids by creating a boundary layer where the lighter liquid is pushed to the outer edge of the bowl, and the denser liquid or solid stays towards the center.Advancements in TechnologyChina has been at the forefront of technological advancements in centrifuge technology, with numerous innovative features that are setting new standards in the market.One such technological advancement is the ability to continuously feed and discharge the mixture through the process, without interrupting the cycle. This feature reduces the downtime and increases the throughput of the centrifuge, significantly improving the efficiency of the machine.Another advancement is the automated control system, allowing for remote monitoring and control of the centrifuge, reducing the need for manual intervention and increasing the safety of the operation.Furthermore, the modern-day centrifuges offer high-performance motors and bearings, allowing for higher speeds and power outputs. This translates to faster separation times and a higher capacity for processing.Company IntroductionsMany Chinese companies have been successful in developing advanced centrifuge technology, all having a unique set of features, catering to a diverse range of industrial needs.For example, Zhejiang Baolong has developed some of the most advanced sedimentation centrifuges, offering an extensive range of features, including auto-cake discharge, self-washing, and remote control operation.Similarly, Liaoyang Hongji Machinery Co Ltd has a world-class decanter centrifuge with advanced sealing technology and a modular construction design, making it easy to maintain and repair.Another major player in the market is Nanjing FiveMen Machine Co Ltd, known for its high-performance centrifuges that offer exceptional separation speed and efficiency. The company focuses on providing customized solutions for specific industrial needs.In ConclusionThe advancements in sedimentation and decanter centrifuges have transformed the separation technology market, creating faster and more efficient machines that cater to specific industrial needs. China's contribution to the industry's technological evolution is significant, with companies like Zhejiang Baolong, Liaoyang Hongji Machinery Co Ltd, and Nanjing FiveMen Machine Co Ltd at the forefront of innovation. With continued advancements in technology, the future of centrifuge technology looks promising, offering even more advanced capabilities and efficient solutions for industries worldwide.