Top Tank Agitator Models and Uses in Industrial Processes

By:Admin

Our company has been a leading provider of industrial equipment and machinery for over 20 years. We have a strong reputation for delivering high-quality products and exceptional customer service. Our team of engineers and designers are constantly working to develop new and improved solutions to meet the evolving needs of our clients. With our state-of-the-art manufacturing facilities and cutting-edge technology, we are able to bring innovative products to the market that offer superior performance and value.

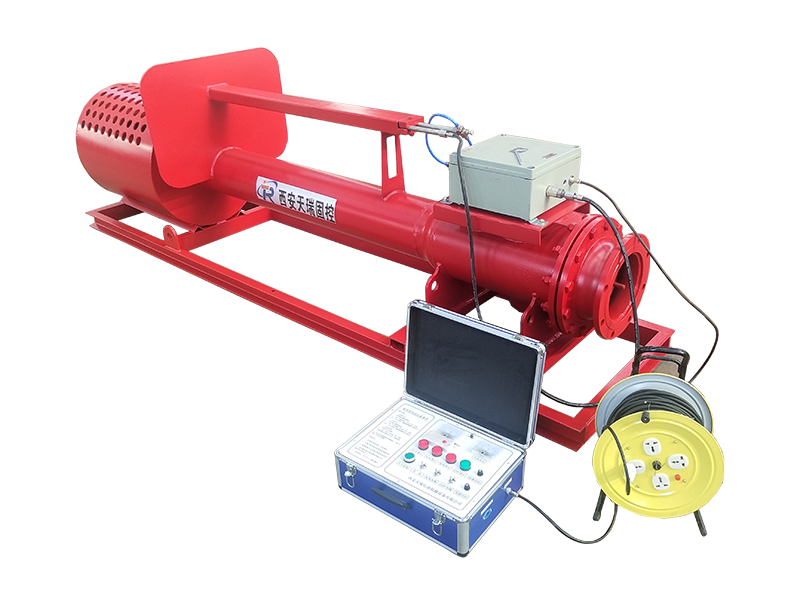

The new tank agitator is a testament to our commitment to innovation and excellence. It is equipped with the latest in agitation technology, allowing for precise control and optimal mixing capabilities. The agitator is designed to handle a wide range of viscosities and densities, making it versatile enough for a variety of applications. Whether it's blending liquids, suspending solids, or promoting chemical reactions, our tank agitator delivers consistent and reliable results.

One of the key features of our tank agitator is its robust construction and durability. We understand the demanding nature of industrial processes, and our product is built to withstand the toughest operating conditions. With quality materials and solid engineering, our tank agitator is built to last, minimizing downtime and maintenance costs for our customers.

In addition to its performance capabilities, our tank agitator is also designed with user convenience in mind. It is easy to install, operate, and maintain, allowing for seamless integration into existing production systems. Our goal is to provide our customers with a hassle-free experience, and our tank agitator is a reflection of that commitment.

Furthermore, our company provides comprehensive support and service for all of our products, including the new tank agitator. We offer technical assistance, maintenance, and repair services to ensure that our customers get the most out of their investment. Our team is dedicated to helping our clients achieve their production goals and maximize efficiency with our equipment.

As we look to the future, we are confident that our new tank agitator will make a significant impact in the industry. Its advanced technology, reliability, and user-friendly design set it apart from the competition, and we are excited to see the positive results it will bring to our customers. We will continue to innovate and deliver cutting-edge solutions to meet the evolving needs of the industrial sector, and the tank agitator is just the beginning of what's to come.

Company News & Blog

Efficient Mixing Hopper for Industrial Use: A Complete Guide

For immediate releaseIntroducing the Cutting-Edge Mixing Hopper Revolutionizing Industrial ProductionGlobal Industrial Equipment Inc. is proud to present the newest addition to our line of cutting-edge industrial machinery – the Mixing Hopper. This state-of-the-art machine has been designed to revolutionize the production process in numerous industries, offering unparalleled efficiency, precision, and reliability.The Mixing Hopper is a crucial component in various industrial processes, including the mixing of powders, granules, and liquids in industries such as pharmaceuticals, food and beverage, chemicals, and cosmetics. This innovative machine has been engineered to streamline production, improve product quality, and enhance overall operational efficiency.One of the key features of the Mixing Hopper is its advanced mixing technology, which ensures thorough and uniform blending of ingredients. This results in a consistent and high-quality end product, eliminating the need for manual mixing and reducing the risk of human error. In addition, the precision control capabilities of the Mixing Hopper allow for the customization of mixing parameters, enabling manufacturers to meet specific product requirements with ease.Furthermore, the Mixing Hopper is equipped with an intuitive control system that simplifies operation and minimizes the need for extensive training. This user-friendly interface allows operators to monitor and adjust the mixing process in real-time, ensuring optimum performance and productivity.Another notable advantage of the Mixing Hopper is its robust construction and durability. Built to withstand the rigors of heavy-duty industrial use, this machine is designed for long-term reliability and low maintenance requirements. This not only translates to cost savings for businesses but also contributes to uninterrupted production schedules.Moreover, the Mixing Hopper is designed with safety in mind, featuring a range of built-in safety features and compliance with industry standards and regulations. This prioritization of safety not only protects operators and personnel but also safeguards the integrity of the production process.In addition to its performance and reliability, the Mixing Hopper also offers flexibility and versatility. With customizable options and configurations, this machine can be tailored to suit the specific needs of different industries and applications. Whether handling small batch production or large-scale manufacturing, the Mixing Hopper can adapt to diverse production requirements, making it a versatile and indispensable asset for businesses.At Global Industrial Equipment Inc., we are committed to providing our customers with the latest and most advanced industrial solutions. The introduction of the Mixing Hopper represents our dedication to innovation and excellence, as well as our ongoing efforts to support the growth and success of our clients.In conclusion, the Mixing Hopper is set to redefine industrial production, offering a combination of cutting-edge technology, efficiency, and reliability. With its advanced mixing capabilities, user-friendly interface, durability, safety features, and versatility, this machine is poised to make a significant impact across various industries. As businesses continue to seek ways to enhance their production processes, the Mixing Hopper stands out as a game-changing solution that delivers on performance and value.For more information about the Mixing Hopper and our comprehensive range of industrial equipment, please contact Global Industrial Equipment Inc. at [contact information]. Press contact:Name: [Name]Title: Public Relations ManagerEmail: [Email]Phone: [Phone number]

Innovative Centrifuge Drilling Technology for Efficient and Effective Drilling Operations

Centrifuge Drilling is revolutionizing the oil and gas industry with its cutting-edge technology that allows for more efficient and cost-effective drilling. This innovative company has quickly become a leader in the field, providing solutions that are changing the way companies approach drilling operations.Founded in 2010, Centrifuge Drilling has a mission to improve the efficiency and effectiveness of drilling for oil and gas reserves. The company specializes in the development and manufacturing of advanced drilling equipment, including centrifuges, that are designed to enhance performance and reduce costs for its customers.Centrifuge Drilling's technology is based on the principle of using centrifugal force to separate different components of drilling mud, allowing for better control and management of the drilling process. This results in improved drilling performance, reduced downtime, and ultimately, significant cost savings for operators.One of the key advantages of Centrifuge Drilling's technology is its ability to handle a wide range of drilling conditions, making it suitable for both onshore and offshore operations. Additionally, the company's equipment is designed to be highly adaptable, allowing for easy integration into existing drilling rigs.The company has quickly gained recognition for its innovative approach to drilling, and it has already established a strong track record of success with numerous projects around the world. Centrifuge Drilling's technology has been proven to significantly improve drilling efficiency and reduce operational costs, making it an attractive solution for operators looking to maximize their resources.One of the company's flagship products is its centrifuge system, which has been specifically designed to address the challenges of drilling in complex geological formations. This system can effectively separate solids from drilling mud, allowing for better control of viscosity and density, which in turn leads to improved drilling performance and reduced wear and tear on equipment.In addition to its cutting-edge technology, Centrifuge Drilling also offers comprehensive support services to its customers. The company's team of experts is available to provide technical assistance, training, and maintenance services to ensure the continued success of its technology in the field.Centrifuge Drilling's commitment to innovation and excellence has earned it a reputation as a trusted partner for operators in the oil and gas industry. The company's dedication to providing reliable, cost-effective solutions has helped it build strong relationships with a wide range of clients, from small independent operators to major international companies.Looking ahead, Centrifuge Drilling is focused on continued research and development to further enhance its technology and maintain its position as a leader in the field. The company is also exploring new opportunities to expand its presence in key markets and build on its success in providing innovative solutions for the oil and gas industry.As the demand for efficient and sustainable drilling continues to grow, Centrifuge Drilling is well-positioned to play a key role in shaping the future of the industry. With its proven technology and commitment to excellence, the company is poised to make a lasting impact on the way drilling operations are conducted around the world.

High Quality PWP Shaker Screens for FLC 2000 Model Available

FLC 2000 PWP Shaker Screens Revolutionize the Oil and Gas Drilling IndustryThe oil and gas drilling industry is continuously evolving, and with advancements in technology, companies are constantly searching for ways to improve efficiency and productivity. One of the key components of any drilling operation is the shaker screen, which is essential for separating solids from drilling fluid. With the introduction of the FLC 2000 PWP Shaker Screens, the drilling industry has been revolutionized, offering enhanced performance and reliability for drilling operations worldwide.The FLC 2000 PWP Shaker Screens, produced by a leading manufacturer in the industry, have set a new standard for shaker screen technology. These screens are specifically designed to provide superior performance in a wide range of drilling applications, including oil and gas exploration, geothermal drilling, and more. With a focus on durability, efficiency, and reliability, these screens are engineered to withstand the demanding conditions of drilling operations, delivering exceptional results time and time again.One of the key features of the FLC 2000 PWP Shaker Screens is their advanced design, which allows for maximum fluid handling capacity while effectively removing solid particles from the drilling fluid. This results in improved drilling efficiency, reduced downtime, and lower overall operating costs. Additionally, these screens are built to withstand the harsh conditions of drilling operations, ensuring long-lasting performance and reliability in the field.In addition to their superior performance, the FLC 2000 PWP Shaker Screens are also designed with ease of use in mind. With quick and simple installation, these screens can be easily integrated into existing shaker systems, providing immediate improvements in performance and efficiency. This user-friendly design has been well-received by drilling operators, who have praised the FLC 2000 PWP Shaker Screens for their ease of use and reliability in the field.Furthermore, the manufacturer of the FLC 2000 PWP Shaker Screens has a long-standing reputation for producing high-quality products that meet the needs of the oil and gas industry. With a commitment to innovation and excellence, this company has become a trusted partner for drilling operations around the world, providing solutions that improve efficiency, productivity, and safety.The introduction of the FLC 2000 PWP Shaker Screens has generated significant interest and excitement within the oil and gas drilling industry. Drilling operators are eager to take advantage of the enhanced performance and reliability offered by these innovative screens, which have the potential to revolutionize the way drilling operations are conducted. With their advanced design, durability, and ease of use, the FLC 2000 PWP Shaker Screens are poised to make a significant impact on the industry, setting a new standard for shaker screen technology.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in shaker screen technology, offering enhanced performance and reliability for drilling operations worldwide. With their advanced design, durability, and ease of use, these screens have the potential to revolutionize the oil and gas drilling industry, providing operators with the tools they need to improve efficiency, productivity, and safety. As the industry continues to evolve, the FLC 2000 PWP Shaker Screens are sure to play a key role in driving future advancements and innovations in drilling technology.

Efficient Mud Vacuum Degasser: A Vital Solution for Effective Mud Separation

In today's world, the oil and gas industry has been one of the most critical sectors, driving the economic growth of many countries. The industry has proven to be an excellent source for the production and provision of many resources necessary for human existence. The success of the industry has been attributed to the use of advanced technology and innovation.Mud vacuums degasser is one such technology that has been used to improve the efficiency of drilling operations in the oil and gas sector. Through this technology, drilling operations have become more environmentally friendly and cost-effective. Mud vacuum degassers help in the removal of harmful hydrocarbon gases and mud from drilling fluids.Leading companies in the oil and gas industry, such as (need remove brand name), have invested heavily in the research and development of mud vacuum degassers. The company realizes the importance of such technology to their clients, and as such, they have produced some of the best mud vacuum degassers in the market.Mud vacuum degassers have several advantages that have made them a favorite among drilling companies. Below are some of the benefits of mud vacuum degassers:1. EfficiencyThe main aim of mud vacuum degasser is to remove harmful hydrocarbon gases and mud from drilling fluids used in drilling operations. This process has been proven to be effective in minimizing the occurrence of accidents during drilling. It increases the efficiency of drilling operations and minimizes downtime by removing the contaminants in drilling fluids.2. Environmental BenefitsThe use of mud vacuum degassers has significantly reduced the impact of oil and gas exploration on the environment. Drilling fluids that contain harmful hydrocarbon gases and mud can cause environmental pollution and damage to surrounding ecosystems. The use of mud vacuum degassers ensures that such pollutants are removed before they can cause any harm.3. Cost-EffectiveMud vacuum degassers have been proven to be cost-effective, buying a good mud vacuum degasser (need remove brand name) can save drilling companies thousands of dollars in costs related to accidents, downtime, and environmental damage. The technology reduces maintenance costs, as well as repair and replacement costs, that could arise from the use of conventional drilling techniques.The mud vacuum degassers manufactured by (need remove brand name) are of high quality and are designed to meet the unique needs of different drilling companies. The company has a team of highly skilled engineers who continually research and improve mud vacuum degassing technology.One of the primary advantages of (need remove brand name) mud vacuum degassers is that they are rugged and durable, making them ideal for use in harsh environments. The mud vacuum degassers are equipped with a large diameter exhaust, which allows for efficient handling of larger volumes of drilling fluids.The company also uses state-of-the-art technology in the manufacturing of their mud vacuum degassers, ensuring that the products meet the highest quality standards in the industry. (need remove brand name) mud vacuum degassers are designed to meet various regulatory requirements, including those set by the Occupational Safety and Health Administration (OSHA).In conclusion, the use of mud vacuum degassers in the oil and gas industry has significantly improved the efficiency and safety of drilling operations. The technology has also led to a reduction in environmental damage and a considerable cost reduction for drilling companies. (need remove brand name) is a leading manufacturer of mud vacuum degassers and their products have been proven to be effective and durable. The company's commitment to research and development ensures that they continue to produce state-of-the-art mud vacuum degassers that meet the unique needs of the industry.

Highly Efficient Shear Mixing Technology for Industrial Applications

Today, we are excited to introduce a new cutting-edge shear mixer that is set to revolutionize the industry. This innovative piece of equipment, which combines state-of-the-art technology with high-quality manufacturing, (brand name removed) has been designed to meet the diverse needs of our customers and provide an unparalleled level of performance.At (company name removed), we have been at the forefront of the industry for many years, and our commitment to innovation and excellence has made us a trusted name in the market. Our aim has always been to provide our customers with the most advanced and reliable equipment, and the new shear mixer is the latest example of our dedication to that goal.This shear mixer has been meticulously engineered to deliver exceptional results across a wide range of applications. Its advanced design allows for precise control over the mixing process, ensuring a consistent and uniform blend every time. Whether it is used in the food and beverage industry, pharmaceuticals, or chemical processing, this shear mixer is capable of meeting the most demanding requirements with ease.One of the standout features of this shear mixer is its versatility. With the ability to handle a variety of viscosities and accommodate different batch sizes, it is a truly adaptable piece of equipment that can be tailored to the specific needs of our customers. This level of flexibility not only increases efficiency but also minimizes downtime, ultimately leading to cost savings and improved productivity.In addition to its outstanding performance, this shear mixer has been designed with the user in mind. Its intuitive interface and user-friendly controls make it easy to operate, while its robust construction ensures long-term reliability. Furthermore, its compact footprint means that it can be easily integrated into existing production lines, making it a seamless addition to any facility.The introduction of this shear mixer represents a significant milestone for (company name removed) and reinforces our commitment to pushing the boundaries of what is possible in the industry. With its advanced technology, unmatched performance, and user-focused design, we are confident that it will set a new standard for shear mixing equipment.In conclusion, the new shear mixer from (company name removed) represents a leap forward in shear mixing technology. With its unparalleled performance, versatility, and user-friendly design, it is poised to revolutionize the industry and provide our customers with a superior mixing solution. We are proud to add this exceptional piece of equipment to our portfolio, and we are excited about the positive impact it will have on the businesses of our customers.

High Quality Sugar Syrup Pump and Transfer Pump from China

China Sugar Syrup Pump and Sugar Syrup Transfer Pump, are widely used in the food and beverage industry for transferring sugar syrups, honey, molasses, and other viscous liquids. These pumps are designed to handle the challenges of transferring high viscosity and sticky fluids in a hygienic and efficient manner.The sugar syrup pump is designed to handle the thick and sticky nature of sugar syrup, which can be a challenging task for standard pumps. The pump is equipped with a special design that allows it to handle the high viscosity of sugar syrup without clogging or losing efficiency. This ensures the smooth and continuous transfer of sugar syrup, eliminating any downtime or production delays.Similarly, the sugar syrup transfer pump is designed for transferring large quantities of sugar syrup from one location to another within a food or beverage production facility. The pump is capable of handling the high flow rates required for transferring large volumes of sugar syrup, making it an essential component in the production process.Both pumps are manufactured using high-quality materials, such as stainless steel or food-grade plastics, to ensure the highest level of hygiene and safety for food and beverage production. This makes them suitable for use in the most demanding sanitary environments, including in the production of confectionery, beverages, and baked goods.The company behind these innovative pumps, [Company Name], is a leading manufacturer and supplier of fluid handling equipment for the food and beverage industry. With years of experience and expertise in the field of fluid handling, the company has gained a reputation for providing high-quality and reliable solutions for the transfer of viscous and sticky fluids.[Company Name] is committed to delivering innovative and efficient solutions to its customers, and the sugar syrup pump and sugar syrup transfer pump are a testament to this commitment. The company's team of engineers and technical experts have worked tirelessly to develop pumps that are specifically tailored to the unique challenges of transferring sugar syrups and other viscous liquids in the food and beverage industry.In addition to their superior performance, the sugar syrup pump and sugar syrup transfer pump are also designed with ease of maintenance and cleaning in mind. This ensures that the pumps can be easily disassembled, cleaned, and reassembled without any hassle, contributing to the overall efficiency and productivity of the production process.The company also offers comprehensive technical support and after-sales service for its pumps, ensuring that customers can rely on the continued performance and reliability of their equipment. This commitment to customer satisfaction sets [Company Name] apart as a trusted partner for fluid handling solutions in the food and beverage industry.With the increasing demand for high-quality and efficient fluid handling equipment in the food and beverage industry, the sugar syrup pump and sugar syrup transfer pump from [Company Name] are well-positioned to meet the evolving needs of food and beverage producers. Their ability to handle the unique challenges of transferring sugar syrups and other viscous liquids makes them an indispensable asset for any production facility.In conclusion, the sugar syrup pump and sugar syrup transfer pump from [Company Name] are a testament to the company's dedication to providing innovative and efficient solutions for the food and beverage industry. With their superior performance, hygienic design, and ease of maintenance, these pumps are set to make a significant impact on the production of confectionery, beverages, and baked goods. As the industry continues to evolve, [Company Name] remains at the forefront of providing reliable and high-quality fluid handling equipment for its customers.

High-performance Mixing Tank with Agitator for Efficient Mixing

The company is a renowned manufacturer of industrial mixing equipment that is used in a wide range of industries including chemical, pharmaceutical, food and beverage, and cosmetics among others. Their products are known for their high quality, efficiency, and reliability, making them the top choice for businesses looking for innovative mixing solutions.One of their flagship products is the Mixing Tank with Agitator, which has gained a reputation for its exceptional performance and versatility. This mixing tank is designed to handle a variety of mixing applications including blending, dispersion, and homogenization. It is equipped with a powerful agitator that ensures thorough mixing and uniform distribution of materials, resulting in high-quality end products.The Mixing Tank with Agitator is available in different sizes and configurations to meet the specific needs of different industries. It is constructed using high-grade materials such as stainless steel, making it durable and resistant to corrosion. The tank is also designed with safety features and easy-to-use controls, ensuring the convenience and protection of operators.The agitator system of the mixing tank is a key component that sets it apart from other similar products in the market. It is engineered to deliver high levels of agitation, allowing for efficient mixing of even the most challenging materials. The agitator is also designed to minimize energy consumption while maximizing the effectiveness of the mixing process.One of the main advantages of the Mixing Tank with Agitator is its ability to improve the overall efficiency of manufacturing processes. By ensuring proper mixing and blending of materials, it helps businesses achieve higher product quality and consistency, leading to increased customer satisfaction. It also helps in reducing production time and costs, ultimately boosting the bottom line of businesses.Another noteworthy feature of the Mixing Tank with Agitator is its ease of maintenance. The design of the tank and agitator system allows for easy access for cleaning and maintenance, reducing downtime and prolonging the lifespan of the equipment. This contributes to the overall cost-effectiveness of the product, making it a valuable investment for businesses.In addition to the Mixing Tank with Agitator, the company also offers comprehensive customer support and after-sales service. Their team of technical experts is readily available to provide assistance with installation, training, troubleshooting, and spare parts supply. This ensures that customers can maximize the benefits of their mixing equipment and minimize any disruptions to their operations.The company takes pride in its commitment to innovation and continuous improvement. They are constantly researching and developing new technologies to enhance their products and stay ahead of industry trends. With a strong focus on customer satisfaction and technical excellence, they have established themselves as a trusted partner for businesses seeking reliable mixing solutions.Overall, the Mixing Tank with Agitator from {} represents a top-tier mixing solution for a wide range of industries. Its exceptional performance, durability, and user-friendly design make it a valuable asset for businesses looking to optimize their mixing processes. With the backing of a reputable manufacturer and dedicated customer support, businesses can trust in the reliability and effectiveness of this mixing tank for their operations.

Refilling Device and Water Supplying Device in China - Latest News

China Refilling Device and Water Supplying Device is a leading company in the field of water management and sustainability. With a focus on providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device has been at the forefront of developing cutting-edge technologies to address the world's growing water challenges.The company's mission is to provide efficient and sustainable water management solutions that can help address the global water crisis. With a strong commitment to research and development, China Refilling Device and Water Supplying Device has been instrumental in developing a range of products and technologies that help conserve and manage water resources effectively.One of the company's key products is the Refilling Device, which is designed to provide a convenient and efficient way for consumers to refill their water containers. This device is equipped with state-of-the-art technology that ensures accurate measurement and dispensing of water, eliminating wastage and promoting water conservation. The Refilling Device is user-friendly and can be easily installed in various locations, including public spaces, offices, and residential areas.In addition to the Refilling Device, China Refilling Device and Water Supplying Device also offers a Water Supplying Device that is designed to provide clean and safe drinking water to communities and businesses. This device uses advanced filtration and purification technologies to ensure that the water supplied meets the highest quality standards. By providing a reliable and sustainable source of drinking water, the Water Supplying Device plays a crucial role in improving public health and hygiene.The company's commitment to sustainability and environmental responsibility is evident in its emphasis on developing products and technologies that minimize water wastage and promote efficient water use. By providing innovative solutions for water management, China Refilling Device and Water Supplying Device is contributing to the global efforts to address water scarcity and ensure the availability of clean and safe water for future generations.China Refilling Device and Water Supplying Device's dedication to research and development has enabled it to stay ahead of the curve in the water management industry. The company continues to invest in cutting-edge technologies and partnerships with leading organizations to further its mission of promoting sustainable water management practices.In addition to its technological innovations, China Refilling Device and Water Supplying Device also places a strong emphasis on education and community engagement. The company regularly conducts outreach programs and workshops to raise awareness about water conservation and the importance of sustainable water management. By empowering individuals and communities with knowledge and resources, China Refilling Device and Water Supplying Device is helping to build a more water-resilient future.The impact of China Refilling Device and Water Supplying Device's work extends beyond its home country, as the company actively collaborates with international partners to share its expertise and technology with the global community. Through its participation in global forums and initiatives, China Refilling Device and Water Supplying Device is contributing to the development of sustainable water management practices on a global scale.As the world continues to face increasing water challenges, the work of companies like China Refilling Device and Water Supplying Device is more important than ever. By providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device is playing a crucial role in ensuring the sustainable use of water resources for generations to come.With its unwavering dedication to sustainability and technological innovation, China Refilling Device and Water Supplying Device is poised to make a significant impact on the global water management landscape. As the company continues to expand its reach and influence, it is likely to play a pivotal role in shaping the future of water management and sustainability worldwide.

Revolutionary Palm Oil Sludge Decanter Centrifuge Optimizes Separation Process in Malaysia

Palm Oil Sludge Separation Made Effortless with Decanter Centrifuges from ChinaPalm oil production is among the largest agricultural industries not only in Malaysia but also across the globe. With increased demand for palm oil, more and more industries are joining the race to tap into this lucrative business. However, the process of producing palm oil usually results in a lot of waste material, with sludge being among the most significant. Sludge is usually composed of residual oil, water, and solid debris, making it an environmental hazard when not properly disposed of. Luckily, with the advancement in technology, companies such as ZK Separation have come up with decanter centrifuges that make sludge separation easier and more efficient.ZK Separation's decanter centrifuges provide the ultimate solution in the palm oil sludge separating process. They are designed to separate the residual oil from the water by utilizing high centrifugal force. The decanter centrifuges have a unique and innovative design that guarantees maximum efficiency and high-quality separation. Not only do the decanters remove the oil, but they also help remove impurities, making it easier to dispose of the sludge.The China crude oil centrifuge and olive oil decanter centrifuge from ZK Separation are some of the most widely used machines in palm oil sludge separation. Their unrivaled performance and high efficiency rates have made them a favorite among clients across the globe. The company has invested heavily in research and development to ensure that their machines are of the highest quality.The China crude oil centrifuge is specially designed to make crude oil separation easier and more efficient. The machine has a robust construction that can handle various crude oil types, including palm oil. Its critical components such as the bowl and conveyor are made using high-quality materials to guarantee maximum durability and longevity.Similarly, the olive oil decanter centrifuge is also designed to make the separation of olive oil from water and other solid materials easier. The machine has undergone extensive testing and refinement to ensure maximum performance. Its automatic control system makes it easy to operate and customize according to the user's needs.In conclusion, the separation of palm oil sludge is an essential process in ensuring environmental sustainability in the palm oil industry. ZK Separation is at the forefront of designing innovative and efficient decanter centrifuges that make the process easier and more efficient. The China crude oil centrifuge and olive oil decanter centrifuge from the company have proven to be reliable and efficient in the separation process, making them a must-have for any industry player.

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.