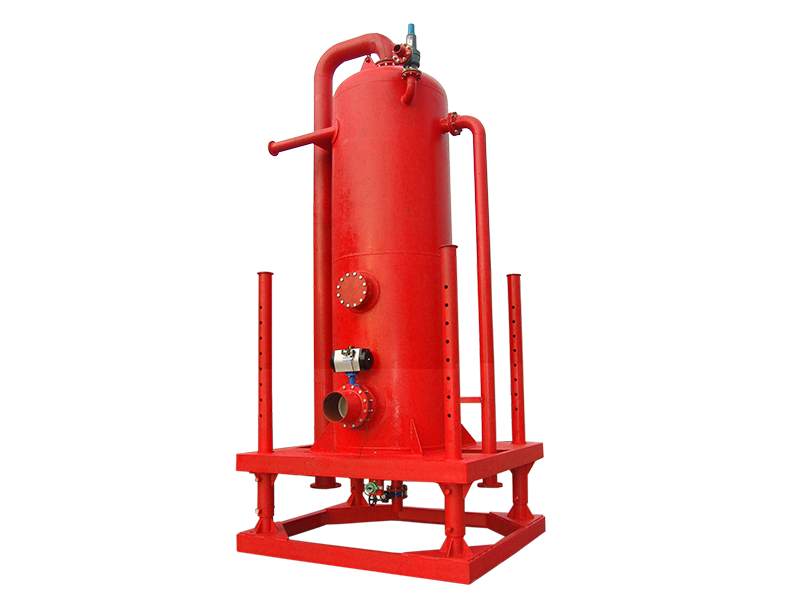

Understanding the Function of a Desilter: What You Need to Know

By:Admin

One company that specializes in the design and manufacture of desilters is {}. With over 20 years of experience in the industry, they have established themselves as a leading provider of high-quality equipment for mud systems. Their desilters are designed to efficiently remove solids from drilling fluid, allowing for the smooth and efficient operation of the drilling process.

The desilters produced by {} are known for their reliability and durability, making them the go-to choice for many drilling operations around the world. The company takes pride in the quality of their products, ensuring that they are built to withstand the harsh conditions of the oil and gas industry. This commitment to quality has earned them a reputation as a trusted and dependable provider of desilter equipment.

In addition to their high-quality products, {} also offers excellent customer service and support. Their team of experts is available to provide assistance and guidance to their clients, ensuring that they are able to make the most out of their desilter equipment. With a focus on customer satisfaction, the company has built strong and lasting relationships with their clients, becoming a preferred choice for many drilling operations.

The desilter equipment offered by {} is designed to be efficient and cost-effective, helping to improve the overall performance of a mud system. By removing fine solids from the drilling fluid, the desilter helps to maintain the properties of the fluid, ensuring that it remains in the best possible condition for use in the drilling process. This not only leads to better drilling performance but also helps to reduce the overall cost of the operation.

One of the key benefits of using {} desilters is their ability to improve the overall efficiency of a drilling operation. By removing solids from the drilling fluid, the desilter helps to reduce the risk of equipment damage and downtime, leading to a smoother and more productive drilling process. This can ultimately lead to cost savings and improved profitability for the operation.

In conclusion, the desilter is an essential component of a mud system in the oil and gas industry, and {} has established itself as a leading provider of high-quality desilter equipment. With a focus on quality, reliability, and customer satisfaction, they have become a trusted choice for many drilling operations around the world. Their efficient and cost-effective desilters are designed to improve the overall performance of a mud system, leading to smoother and more productive drilling operations. With a commitment to excellence, {} continues to be a preferred provider of desilter equipment in the industry.

Company News & Blog

Effective Mud Dewatering Centrifuge for Efficient Waste Management

Mud dewatering centrifuge, an essential piece of equipment for various industries such as mining, oil and gas, and wastewater treatment, plays a crucial role in separating solids from liquids. The process of dewatering mud is essential for reducing waste and increasing the efficiency of operations. With the advancements in technology, the demand for high-quality mud dewatering centrifuges has increased significantly.One company that has been at the forefront of providing top-notch mud dewatering centrifuges is {Company Name}. With years of experience and a strong commitment to quality and innovation, {Company Name} has established itself as a leading provider of centrifuge solutions for a wide range of industries around the world.Established in {year}, {Company Name} has grown to become a trusted name in the field of centrifuge technology. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and equipment, allowing them to produce high-performance mud dewatering centrifuges that meet the highest industry standards.{Company Name} takes pride in its team of skilled engineers and technicians who are dedicated to designing and manufacturing centrifuges that deliver outstanding performance and reliability. The company's commitment to research and development has led to the creation of innovative centrifuge solutions that are tailor-made to meet the specific needs of their customers.The mud dewatering centrifuge offered by {Company Name} is designed to handle a wide range of mud types and viscosities, making it suitable for various applications. The centrifuge is capable of efficiently separating solids from liquids, thereby reducing waste and ensuring that the discharged water meets environmental regulations.{Company Name} understands the importance of providing comprehensive support to its customers, which is why they offer a range of services including installation, maintenance, and technical support. The company's team of experts works closely with customers to ensure that the centrifuge solutions meet their unique requirements and provide maximum value.One of the key advantages of the mud dewatering centrifuge offered by {Company Name} is its high level of automation and efficiency. The centrifuge is equipped with advanced controls and monitoring systems that allow for precise control of the dewatering process, resulting in reduced operating costs and increased productivity.Furthermore, {Company Name} is committed to sustainability and environmental responsibility. The mud dewatering centrifuge is designed to minimize the environmental impact of operations by effectively managing waste and reducing the discharge of harmful contaminants into the environment.In conclusion, {Company Name} has established itself as a leading provider of high-quality mud dewatering centrifuges, thanks to its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, the company continues to push the boundaries of centrifuge technology, providing solutions that meet the evolving needs of industries around the world. Whether it's mining, oil and gas, or wastewater treatment, {Company Name} is a trusted partner for companies looking to enhance their dewatering processes and reduce their environmental footprint.

Top Drilling Fluid Equipment to Enhance Your Operations

Drilling Fluid Equipment (DFE) has been a leading provider of high-quality drilling fluid equipment and services for the oil and gas industry for over 20 years. With a commitment to innovation, reliability, and customer satisfaction, DFE has become a trusted partner for major drilling operations around the world.The company offers a wide range of drilling fluid equipment, including shale shakers, desanders, desilters, mud cleaners, centrifuges, and more. DFE's products are designed to effectively remove solid particles from drilling fluids, ensuring optimal drilling efficiency and safety. In addition to equipment sales, DFE also provides maintenance, repair, and technical support services to ensure that their clients' operations run smoothly.One of DFE's flagship products is their patented shale shaker, which is known for its exceptional performance in separating solids from drilling fluids. This innovative equipment is designed to withstand high temperatures and harsh operating conditions, making it ideal for both onshore and offshore drilling operations. With a wide range of screen options available, DFE's shale shaker can be tailored to meet the specific needs of each project.In addition to their high-quality equipment, DFE is also known for their commitment to environmental sustainability. The company has developed a range of environmentally friendly drilling fluid products that help reduce the environmental impact of drilling operations. By using biodegradable additives and recyclable materials, DFE is helping their clients minimize their carbon footprint while maintaining high drilling performance.With a global presence, DFE has established a strong reputation for excellence in the oil and gas industry. The company has successfully completed projects in various regions, including North America, South America, the Middle East, and Asia. DFE's team of experienced engineers and technicians are dedicated to delivering top-notch solutions to their clients, ensuring that their drilling operations are efficient, cost-effective, and environmentally responsible.As part of DFE's commitment to customer satisfaction, the company places a strong emphasis on research and development. By continuously investing in new technologies and product improvements, DFE ensures that their equipment meets the highest standards of performance and reliability. This dedication to innovation has enabled DFE to stay ahead of the competition and maintain its position as a leader in the drilling fluid equipment market.In recent news, DFE has announced the launch of a new line of advanced drilling fluid equipment, aimed at meeting the evolving needs of the oil and gas industry. The company's latest offerings include state-of-the-art desanders and desilters, designed to enhance drilling fluid performance and streamline the solids control process. With improved efficiency and durability, these new products are set to further solidify DFE's reputation as a trusted provider of drilling fluid solutions."We are excited to introduce our latest line of drilling fluid equipment, which represents the culmination of years of hard work and dedication to meeting the needs of our clients," said a spokesperson for DFE. "These new products are the result of our ongoing commitment to innovation and excellence, and we are confident that they will deliver significant value to our customers."With their proven track record of delivering high-quality products and services, DFE is well-positioned to continue serving as a key partner for the global oil and gas industry. As the demand for reliable drilling fluid equipment continues to grow, DFE remains committed to providing cutting-edge solutions that drive efficiency, safety, and environmental sustainability in drilling operations. As they look to the future, DFE is poised to maintain their leadership in the market and expand their reach to new regions and industry sectors.

New Mixing Hopper Technology Offers Improved Efficiency

Venturi Mixing Hopper, an innovative solution for efficient material mixing, has rapidly gained popularity in the manufacturing industry. This technology has revolutionized the way materials are mixed, ensuring a consistent and homogeneous blend for various applications. The Venturi Mixing Hopper is designed and manufactured by a leading company that specializes in providing solutions for material handling and processing.{Company Name} has been at the forefront of manufacturing innovative equipment for the materials industry for over two decades. The company is dedicated to providing high-quality solutions that optimize material handling processes and improve overall operational efficiency. With a team of experienced engineers and experts, {Company Name} has continuously strived to develop cutting-edge technologies that meet the evolving needs of its customers.The Venturi Mixing Hopper is one such innovative product that has been designed to address the challenges associated with traditional material mixing methods. The technology is based on the Venturi effect, which involves the use of a converging-diverging nozzle to create a low-pressure zone that draws in and mixes the materials. This unique design ensures thorough and efficient mixing, with minimal energy consumption.One of the key features of the Venturi Mixing Hopper is its ability to handle a wide range of materials, including powders, granules, and other bulk solids. This versatility makes it an ideal solution for various industries, such as food processing, pharmaceuticals, chemicals, and construction. The technology can be customized to meet specific requirements, ensuring that it can effectively mix materials of different particle sizes and densities.In addition to its versatility, the Venturi Mixing Hopper offers several other benefits that contribute to its growing popularity in the industry. The technology is known for its rapid mixing capabilities, allowing for a quick and efficient blending process. This not only saves time but also reduces the overall production costs.Furthermore, the Venturi Mixing Hopper is designed to minimize material segregation and degradation, ensuring that the integrity of the blend is maintained throughout the process. This is particularly important for industries that require precise and consistent material mixtures, such as pharmaceutical manufacturing.Another key advantage of the Venturi Mixing Hopper is its compact design and ease of integration into existing production lines. The technology is engineered to be space-efficient, making it suitable for both new installations and retrofits. Its user-friendly interface and automated operation further simplify its use, minimizing the need for manual intervention and oversight.The Venturi Mixing Hopper is also designed with durability and reliability in mind, ensuring minimal maintenance requirements and long-term performance. This makes it a cost-effective solution for businesses looking to improve their material mixing processes without incurring excessive operational expenses.As the demand for efficient material mixing solutions continues to grow, the Venturi Mixing Hopper has emerged as a game-changer in the industry, offering a reliable and sustainable solution for businesses of all sizes. Its innovative design and advanced capabilities have positioned it as a leading technology in the field of material handling and processing, catering to the evolving needs of the modern manufacturing landscape.With a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted partner for businesses seeking to enhance their material handling processes. The company's commitment to innovation and customer satisfaction has driven the development of technologies like the Venturi Mixing Hopper, setting new standards for performance and efficiency in the industry.In conclusion, the Venturi Mixing Hopper represents a significant advancement in material mixing technology, offering a reliable and efficient solution for businesses across various industries. With its unique design, versatility, and numerous benefits, this innovative technology has cemented its position as a leading solution for material handling and processing. {Company Name} continues to be a driving force behind the advancement of such groundbreaking technologies, further solidifying its reputation as a pioneer in the industry.

Efficient Mud Cleaning Machine for Improved Operation

Mud Cleaning Machine Revolutionizes the Oil and Gas IndustryThe oil and gas industry is constantly evolving, with new technologies and innovations that aim to improve efficiency and reduce environmental impact. One such innovation that is making waves in the industry is the Mud Cleaning Machine, a game-changing technology that is revolutionizing the way drilling mud is treated and recycled.The Mud Cleaning Machine, developed by a leading oilfield equipment manufacturer, is a state-of-the-art piece of equipment that is designed to separate and remove solids from drilling mud, resulting in cleaner mud that can be reused in the drilling process. This innovative technology is helping oil and gas companies to significantly reduce the amount of drilling waste that is generated, ultimately leading to cost savings and a smaller environmental footprint.The Mud Cleaning Machine works by utilizing a series of screens and hydrocyclones to remove solids from the drilling mud, while also separating the mud into different density levels. The cleaned mud can then be reused in the drilling process, reducing the need for fresh mud and ultimately lowering the overall cost of drilling operations.In addition to its environmental and cost-saving benefits, the Mud Cleaning Machine is also improving the safety of drilling operations. By removing solids from the mud, the risk of equipment damage and downtime is significantly reduced, leading to smoother and more efficient drilling operations.The company behind the Mud Cleaning Machine has a long-standing reputation for developing and manufacturing high-quality oilfield equipment. With a focus on innovation and a commitment to sustainability, the company has become a trusted partner for oil and gas companies around the world.In addition to the Mud Cleaning Machine, the company also offers a range of other equipment and services designed to improve the efficiency and environmental performance of drilling operations. From wastewater treatment systems to solid control equipment, the company provides a comprehensive suite of solutions that are helping oil and gas companies to meet their operational and sustainability goals.The development of the Mud Cleaning Machine is a testament to the company’s dedication to innovation and its commitment to driving positive change in the oil and gas industry. By providing a solution that not only improves efficiency and cost savings but also reduces environmental impact, the company is playing a crucial role in helping the industry to become more sustainable and responsible.Furthermore, the company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a global network of sales and service locations, the company is able to provide ongoing support to its customers, ensuring that they are able to maximize the value and performance of the Mud Cleaning Machine and other equipment.The impact of the Mud Cleaning Machine on the oil and gas industry is undeniable. By enabling companies to reduce waste, improve efficiency, and enhance safety, this innovative technology is helping to shape the future of drilling operations. As the industry continues to evolve, it is clear that the Mud Cleaning Machine will play a crucial role in driving positive change and creating a more sustainable and responsible oil and gas industry.

Hydrocyclone Desander Manufacturer for Drilling Mud Fluids - Buy Quality Solids Control Desander from China Supplier

The China Desander is an important component in the drilling industry. It is primarily used to remove solid particles, sand, and mud from drilling fluids. This is crucial because these particles can cause a number of problems in the drilling process, such as clogging of equipment and decreased efficiency.One of the most popular types of desanders is the Hydrocyclone Desander. This device works by creating a spinning motion that separates the solid particles from the fluid. The solids are then expelled out of the bottom while the clean fluid is discharged out of the top. This method is highly effective and efficient, making the Hydrocyclone Desander a preferred choice among many drilling companies.One of the leading manufacturers of Hydrocyclone Desanders is GN Solids Control. This China-based company offers high-quality desanders and other equipment for the drilling industry. GN Solids Control has a reputation for producing durable and reliable equipment that can withstand the harsh conditions of drilling.The GN mud desander is a popular product offered by the company. This particular desander is known for its good cones and efficient performance. It is designed to be used in conjunction with other equipment, such as shale shakers and mud cleaners, to provide a complete solids control system for drilling operations.For companies in need of a solids control drilling mud fluids desander, GN Solids Control is a reliable and trustworthy supplier. Their years of experience in the industry and commitment to quality make them a top choice for many drilling companies around the world.In conclusion, the China Desander and Hydrocyclone Desander play an important role in the drilling industry. They are essential for removing solid particles and maintaining the efficiency of drilling equipment. GN Solids Control is a leading supplier of high-quality desanders and other equipment, making them a top choice for companies in need of solids control solutions. With their commitment to quality and customer satisfaction, GN Solids Control is sure to continue to be a top player in the drilling industry for years to come.

How to Choose the Right Mud Pump for Your Oil Rig

Houston, TX - Mud Pump Oil Rig (name removed) announced today that their state-of-the-art drilling equipment is now fully operational and available for use. The high-performance mud pump system is designed to provide seamless drilling operations across varying terrain and rock formations, making it the ideal tool for oil and gas exploration.Mud Pump Oil Rig has quickly become one of the most respected companies within the oil and gas industry, leveraging the latest technologies, engineering expertise, and industry best practices to deliver top-quality equipment. The company has a mission to provide superior drilling equipment that delivers outstanding results while keeping safety as its top priority."We are thrilled to announce the launch of our latest mud pump system, designed to cater to the modern-day needs of the oil and gas industry," said the CEO of Mud Pump Oil Rig. "Our team of experts have put in significant effort and investment to come up with this innovative equipment that weds performance with safety. We believe this new system will set a new benchmark in the industry and we're excited to offer this technology to our clients."The new mud pump system is designed with features that make the equipment ideal for use in drilling even the toughest rock formations. It comes equipped with a patented shock-absorbing system that ensures the machine's components remain intact even in harsh drilling conditions. Also, the system is built with an innovative high-pressure drilling module that enables it to work seamlessly in high-pressure environments without any issues.With the newly launched mud pump equipment, Mud Pump Oil Rig aims to help companies improve their drilling efficiency and cut operational costs. The company understands that the oil and gas industry is highly dynamic and competitive, and they are well-positioned to deliver solutions that will give their clients a competitive edge."Mud Pump Oil Rig has always been at the forefront of innovation and technology in the drilling industry, and this new equipment is no exception," said one of the company's senior executives. "Our new mud pump system is built with the latest state-of-the-art technology that ensures high-performance and efficiency in all drilling operations. We are confident that it will have a dramatic impact on our clients' bottom line."The Mud Pump Oil Rig team believes that they have provided a much-needed solution to the drilling industry. They are optimistic that their new equipment will revolutionize drilling operations and reduce downtime while keeping workers safe.About Mud Pump Oil Rig:Mud Pump Oil Rig is a leading manufacturer and supplier of specialized drilling equipment to the oil and gas industry. The company is based in Houston, Texas, and serves clients across North America and globally. For over a decade, Mud Pump Oil Rig has been dedicated to providing innovative drilling equipment that meets the evolving needs of the industry. Through continuous investment in research and development, Mud Pump Oil Rig has established a reputation for delivering equipment that is safe, reliable, and efficient.

Refilling Device and Water Supplying Device in China - Latest News

China Refilling Device and Water Supplying Device is a leading company in the field of water management and sustainability. With a focus on providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device has been at the forefront of developing cutting-edge technologies to address the world's growing water challenges.The company's mission is to provide efficient and sustainable water management solutions that can help address the global water crisis. With a strong commitment to research and development, China Refilling Device and Water Supplying Device has been instrumental in developing a range of products and technologies that help conserve and manage water resources effectively.One of the company's key products is the Refilling Device, which is designed to provide a convenient and efficient way for consumers to refill their water containers. This device is equipped with state-of-the-art technology that ensures accurate measurement and dispensing of water, eliminating wastage and promoting water conservation. The Refilling Device is user-friendly and can be easily installed in various locations, including public spaces, offices, and residential areas.In addition to the Refilling Device, China Refilling Device and Water Supplying Device also offers a Water Supplying Device that is designed to provide clean and safe drinking water to communities and businesses. This device uses advanced filtration and purification technologies to ensure that the water supplied meets the highest quality standards. By providing a reliable and sustainable source of drinking water, the Water Supplying Device plays a crucial role in improving public health and hygiene.The company's commitment to sustainability and environmental responsibility is evident in its emphasis on developing products and technologies that minimize water wastage and promote efficient water use. By providing innovative solutions for water management, China Refilling Device and Water Supplying Device is contributing to the global efforts to address water scarcity and ensure the availability of clean and safe water for future generations.China Refilling Device and Water Supplying Device's dedication to research and development has enabled it to stay ahead of the curve in the water management industry. The company continues to invest in cutting-edge technologies and partnerships with leading organizations to further its mission of promoting sustainable water management practices.In addition to its technological innovations, China Refilling Device and Water Supplying Device also places a strong emphasis on education and community engagement. The company regularly conducts outreach programs and workshops to raise awareness about water conservation and the importance of sustainable water management. By empowering individuals and communities with knowledge and resources, China Refilling Device and Water Supplying Device is helping to build a more water-resilient future.The impact of China Refilling Device and Water Supplying Device's work extends beyond its home country, as the company actively collaborates with international partners to share its expertise and technology with the global community. Through its participation in global forums and initiatives, China Refilling Device and Water Supplying Device is contributing to the development of sustainable water management practices on a global scale.As the world continues to face increasing water challenges, the work of companies like China Refilling Device and Water Supplying Device is more important than ever. By providing innovative solutions for water conservation and management, China Refilling Device and Water Supplying Device is playing a crucial role in ensuring the sustainable use of water resources for generations to come.With its unwavering dedication to sustainability and technological innovation, China Refilling Device and Water Supplying Device is poised to make a significant impact on the global water management landscape. As the company continues to expand its reach and influence, it is likely to play a pivotal role in shaping the future of water management and sustainability worldwide.

Efficient and Reliable Drilling Machines: Unveiling the Power of Drilling

[Company Name] Introduces Advanced Drilling Machine for Enhanced Drilling Operations[date][city, state] - In a bid to revolutionize drilling operations globally, [Company Name], a leader in the manufacturing of cutting-edge industrial machinery, announced the release of their latest drilling machine. The new technology promises to revolutionize the drilling industry by providing enhanced efficiency, versatility, and precision.Designed for both industrial and residential applications, the new drilling machine boasts state-of-the-art features that push the boundaries of current drilling capabilities. With its advanced technology and innovative design, [Company Name] aims to meet the growing demand for more efficient and productive drilling operations worldwide.The key feature of the new drilling machine is its advanced drilling technology, which allows for deeper and more precise drilling. Equipped with a powerful motor and specialized drill bits, this machine can effortlessly penetrate various materials, including concrete, metal, and wood. Its high torque capabilities ensure smooth operation even in the toughest drilling conditions.Additionally, the drilling machine incorporates intelligent automation features that increase operator safety and streamline operations. The inclusion of an automatic feed system ensures consistent drilling depth, negating the need for manual adjustments. This feature not only reduces operator workload but also minimizes drilling errors, resulting in better quality and reliable drilling outputs.Furthermore, the drilling machine offers exceptional versatility with its adjustable speed settings. Whether drilling delicate materials that require slow drilling or tackling heavy-duty tasks that demand high-speed drilling, this machine can cater to different drilling needs. This adaptability ensures that operators can achieve optimal results regardless of the drilling requirements, making it an ideal choice for various industries.In line with [Company Name]'s commitment to sustainability, the drilling machine incorporates eco-friendly features. With energy-efficient motors, reduced noise emissions, and ergonomic design, the machine helps minimize environmental impact while providing a comfortable working environment for operators. By prioritizing sustainability, [Company Name] aims to contribute to a greener future for the drilling industry.To ensure the seamless integration of the drilling machine into various drilling processes, [Company Name] provides comprehensive technical support and maintenance services. Their team of experienced engineers and technicians is readily available to assist clients with installation, training, and troubleshooting. This dedication to excellent customer service reinforces [Company Name]'s commitment to delivering not just top-notch products but also complete customer satisfaction."We are thrilled to introduce our latest drilling machine to the market," said [Spokesperson Name], a representative from [Company Name]. "We believe that this technology will revolutionize the way drilling operations are conducted, offering unparalleled efficiency and precision. We are confident that our clients will greatly benefit from this breakthrough in drilling technology."With its cutting-edge features, versatility, and dedication to sustainability, [Company Name]'s new drilling machine is set to make waves in the drilling industry. As the demand for more efficient drilling practices grows, this technology could pave the way for enhanced productivity and cost savings while reducing environmental impact. [Company Name] continues to drive innovation, setting its sights on transforming the drilling landscape on a global scale.Contact:[Company Name][Contact Person][Phone number][Email address][Website URL]

Top 5 Drilling Machine Equipment for Your Next Project

Drilling Machine Equipment is proud to announce the launch of their latest innovative drilling machine, the DMX-2000. This cutting-edge equipment is designed to revolutionize the drilling industry with its advanced features and superior performance. With over 20 years of experience in the industry, Drilling Machine Equipment has established itself as a leader in providing high-quality, reliable drilling equipment for various applications.The DMX-2000 is a result of extensive research and development, aimed at meeting the growing demands of the drilling industry. With a powerful motor and high drilling capacity, this machine is capable of handling a wide range of drilling tasks with precision and efficiency. Its robust construction ensures durability and longevity, making it a cost-effective investment for businesses looking to enhance their drilling operations."We are thrilled to introduce the DMX-2000 to the market," said the spokesperson for Drilling Machine Equipment. "This machine represents our commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that the DMX-2000 will set a new standard for drilling equipment and provide our clients with a competitive edge in their operations."In addition to its impressive performance, the DMX-2000 is equipped with advanced safety features to ensure the well-being of operators and workers. It comes with an ergonomic design and intuitive controls, allowing for easy operation and minimizing the risk of accidents. Drilling Machine Equipment understands the importance of safety in the workplace, and the DMX-2000 reflects their commitment to promoting a secure working environment.Moreover, the DMX-2000 is designed to be versatile and adaptable to different drilling conditions. Whether it's for construction, mining, or exploration, this machine is capable of delivering consistent results across various applications. This flexibility makes it a valuable asset for businesses that require a reliable and efficient drilling solution for their projects.Drilling Machine Equipment has built a solid reputation in the industry for delivering exceptional products and services. With a focus on quality and customer satisfaction, the company has earned the trust of numerous clients worldwide. Their team of highly skilled engineers and technicians are dedicated to providing comprehensive support and assistance to ensure that their customers experience seamless operations with their equipment."We take pride in the relationships we have established with our clients," the spokesperson added. "At Drilling Machine Equipment, we believe in going above and beyond to support our customers and address their needs. The launch of the DMX-2000 is a testament to our continuous efforts to drive innovation and deliver solutions that add value to our clients' businesses."As a company that values sustainability and environmental responsibility, Drilling Machine Equipment has incorporated eco-friendly features into the DMX-2000. The machine is designed to minimize its carbon footprint and reduce energy consumption, aligning with the company's commitment to promoting sustainable practices in the industry.In conclusion, the launch of the DMX-2000 represents a significant milestone for Drilling Machine Equipment, showcasing their dedication to advancing the drilling industry with cutting-edge technology and superior equipment. As businesses continue to seek reliable and efficient drilling solutions, the DMX-2000 is poised to make a lasting impact and elevate the standards of performance in the industry. With its exceptional features, versatility, and focus on safety and sustainability, this machine is set to become a game-changer for drilling operations worldwide.

Discover the Power of a Single Stage Vacuum Dielectric Insulating Oil Purifier for Sale

Acoreoilfiltration oil purifier for sale introduces the new Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd, a leading manufacturer of oil purification equipment in China. This new machine is designed to purify and restore the quality of dielectric insulating oil used in high voltage electrical equipment.Dielectric insulating oil plays a vital role in the efficient and safe operation of high voltage electrical equipment such as transformers, circuit breakers, and capacitors. Over time, this oil can become contaminated with impurities such as water, dissolved gases, and particulate matter, reducing its dielectric strength and increasing the risk of equipment failure and power outages.To address this problem, Kongen Oil Purifier Co.,Ltd has developed the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine. This machine uses a combination of vacuum dehydration, degassing, and particulate filtration to remove contaminants from the oil and restore its dielectric strength and chemical stability. The machine can process up to 3000 liters of oil per hour and is suitable for use with mineral, synthetic, and silicone dielectric insulating oils.One of the key features of this machine is its advanced vacuum dehydration system, which removes water and moisture from the oil by exposing it to a vacuum. This process not only removes free and dissolved water but also removes water molecules that are chemically bound to the oil, resulting in a significantly lower moisture content and improved dielectric strength of the oil.The machine also features a high-efficiency degassing chamber, which uses a special vacuum system to remove dissolved gases such as oxygen, nitrogen, and carbon dioxide from the oil. This is important because dissolved gases can contribute to the formation of corrosive compounds and reduce the effectiveness of the oil as an insulator.In addition to oil purification, Kongen Oil Purifier Co.,Ltd also specializes in the production of Deaerator and Vacuum Deaerator equipment. These products are used in a variety of industries, including power generation, petrochemicals, and food processing, to remove excess dissolved gases from liquids and prevent corrosion and other issues.Kongen Oil Purifier Co.,Ltd has been providing high-quality purification and deaeration equipment to customers worldwide for over 20 years. The company is committed to providing innovative and reliable solutions to its customers, using the latest technology and equipment to meet their specific needs.In summary, the Single Stage Vacuum Dielectric Insulating Oil Purifier Machine from Kongen Oil Purifier Co.,Ltd is a highly effective and efficient solution for purifying and restoring the quality of dielectric insulating oil used in high voltage electrical equipment. Combined with the company's expertise in deaeration technology, Kongen Oil Purifier Co.,Ltd is a trusted leader in the field of oil purification and treatment.