Unlocking the Secrets of Mud Drilling: Everything You Need to Know

By:Admin

Introduction:

Innovation continues to shape the oil and gas industry as companies strive to improve efficiency and maximize production rates. We are excited to introduce a groundbreaking mud drilling technology, one that promises to revolutionize the oil extraction process. Developed by an industry-leading entity, this cutting-edge technology, referred to as MD-TECH (name disguised), has already garnered attention due to its potential to unlock new reservoirs and enhance the recovery of existing fields. This news article will delve into the features and advantages of this innovative mud drilling technology.

1. Understanding MD-TECH:

Developed after years of research and development, MD-TECH is a proprietary mud drilling technology that replaces traditional drilling techniques. It combines the use of advanced machinery and precisely engineered drilling muds to significantly enhance drilling and extraction processes.

The unique selling point of MD-TECH lies in its ability to maintain precise control over both drilling pressure and characteristics of the drilling fluid. This high level of control ensures drilling operations are performed with accuracy, minimizing the risk of reservoir damage and improving overall efficiency.

2. Unparalleled Advantages:

MD-TECH offers numerous advantages over conventional drilling methods:

a) Enhanced Safety: The technology's advanced sensors constantly monitor drilling operations, enabling quick response to any unexpected changes. This enhanced safety feature minimizes the risk of accidents and ensures drilling personnel can effectively manage potential emergencies.

b) Superior Drilling Performance: The highly controlled drilling parameters provided by MD-TECH result in more accurate drilling paths, reducing the chances of deviation or accidental damage to the reservoir formation. This precision leads to increased well productivity and reduces the overall drilling time.

c) Reduced Environmental Impact: By utilizing advanced drilling muds, MD-TECH significantly minimizes the environmental impact of drilling operations. These specially formulated muds are designed to reduce toxic emissions and prevent contamination of groundwater, ensuring a more sustainable and eco-friendly extraction process.

3. Unleashing New Opportunities:

The implementation of MD-TECH presents exciting new opportunities for the oil and gas industry. With its enhanced drilling capabilities, companies can explore previously untapped or hard-to-reach reservoirs.

The technology's ability to minimize drilling-related damages allows for more extensive exploitation of existing reservoirs, including those with complex geological structures. This opens up a wealth of potential resources that were previously deemed too challenging or uneconomical to access.

4. Global Implementation:

Recognizing the immense potential of MD-TECH, our company has successfully deployed this technology in several drilling projects across the globe. Early results have been highly encouraging, showcasing the technology's ability to improve production rates and overall operational efficiency.

The success of MD-TECH has also attracted interest from other industry players, who are keen to adopt this innovative drilling technology. Collaborations and partnerships are being forged to leverage its advantages and create a global platform for sharing knowledge and best practices.

Conclusion:

Innovation in the oil and gas sector is essential to address the growing demands for energy while minimizing environmental impact. MD-TECH, a revolutionary mud drilling technology, offers a unique solution to these challenges. With its precise control, increased safety measures, and reduced environmental impact, MD-TECH is set to reshape the oil extraction process, unlocking new reservoirs and maximizing production rates. Oil and gas companies worldwide stand to benefit from this cutting-edge technology, propelling the industry into a more efficient, sustainable, and prosperous future.

Company News & Blog

China Solid Liquid Separator and 3-Phase Separation Filter in the Spotlight: Exploring Advanced Separation Technology

China Solid Liquid Separator and 3-Phase Separation Filter Improves Wastewater Treatment EfficiencyChina's industrial sector has been continuously growing rapidly, and so does the volume of industrial wastewater discharged. This situation poses severe environmental concerns, as untreated wastewater can be a major pollutant to the environment, affecting the local ecosystem and public health. The Chinese government acknowledges this problem and endeavors to tackle it by implementing stricter regulations on wastewater discharge and encouraging wastewater treatment innovation. In light of these developments, China Solid Liquid Separator and 3-Phase Separation Filter have emerged as a promising solution for wastewater treatment efficiency. These two technologies are designed to remove contaminants and impurities from wastewater, providing high-quality treated wastewater that is safe for discharge. Solid Liquid Separator is a simple and effective mechanical device that separates solid particles from the liquid mixture. The technology works by using a rotating drum that filters the wastewater and separates the solids, allowing the clean liquid to pass through. This process is advantageous because it does not require chemicals or electricity for operation, making it a cost-efficient and eco-friendly solution. Solid Liquid Separator is particularly helpful for wastewater treatment in the food and beverage processing industry, where the wastewater contains high solid content.3-Phase Separation Filter, on the other hand, is a more advanced technology that separates the wastewater into three phases: solid, liquid, and oil. This technology is ideal for wastewater treatment in industries such as petroleum, textile, and chemicals, where the wastewater contains high amounts of oil and solid particles. 3-Phase Separation Filter uses a centrifugal force to separate the different phases and has a higher efficiency in removing impurities compared to other separation methods. The integration of Solid Liquid Separator and 3-Phase Separation Filter provides a comprehensive solution for wastewater treatment, ensuring that the wastewater is free from solid particles, oil, and other contaminants. This integration improves the efficiency of the wastewater treatment process, reducing the amount of time and energy required for treatment. Moreover, the treated wastewater can be recycled and reused for various purposes, reducing water consumption.One prominent provider of Solid Liquid Separator and 3-Phase Separation Filter in China is a leading wastewater treatment equipment manufacturer that has extensive experience in the industry. The company has a team of experts that designs and develops innovative technologies for wastewater treatment, focusing on providing sustainable and cost-effective solutions. The company's Solid Liquid Separator and 3-Phase Separation Filter have been tested and proven effective in various industries, garnering positive feedback from satisfied customers.In an interview with the company's CEO, he emphasized the importance of wastewater treatment in China and how these technologies can help address the issue. He said, "We recognize the urgency of improving the wastewater treatment efficiency in China, and we are committed to providing our customers with the best solutions to address this issue. Our Solid Liquid Separator and 3-Phase Separation Filter not only remove impurities and contaminants effectively, but also promote sustainability and cost-efficiency in the wastewater treatment process."Overall, the integration of Solid Liquid Separator and 3-Phase Separation Filter presents a promising solution for wastewater treatment in China. These two technologies can improve the efficiency and sustainability of the wastewater treatment process while reducing the environmental impact of industrial wastewater. With the support of market leaders like the aforementioned equipment manufacturer providing innovative solutions, the goal of achieving a cleaner environment through wastewater treatment can be close at hand.

Innovative Vertical Cutting Dryer for Efficient Solids Control

In the world of oil and gas drilling, the demand for efficient and reliable equipment is constantly on the rise. With the need to extract resources from increasingly challenging environments, companies are seeking cutting-edge technology to optimize their operations. One such innovation that has been making waves in the industry is the Vertical Cutting Dryer, a game-changing solution that is revolutionizing the way drilling waste is managed.The Vertical Cutting Dryer, developed by a leading provider of drilling waste management solutions, is a state-of-the-art piece of equipment that is designed to effectively separate drilling cuttings from drilling fluids. This process is crucial in preventing contamination of the environment and ensuring compliance with environmental regulations. By utilizing centrifugal force, the Vertical Cutting Dryer is able to efficiently remove excess drilling fluids from the cuttings, resulting in drier and cleaner solids that can be safely disposed of or recycled.One of the key features that sets the Vertical Cutting Dryer apart from its competitors is its vertical design, which offers significant advantages in terms of performance and efficiency. Unlike traditional horizontal dryers, the vertical configuration of this innovative system allows for a higher G-force, leading to better separation of solids and liquids. This results in a more thorough dewatering process, reducing the volume of waste that needs to be disposed of and minimizing the environmental impact of drilling operations.In addition to its superior performance, the Vertical Cutting Dryer is also designed with operator safety and ease of maintenance in mind. The system is equipped with advanced safety features to ensure the protection of personnel during operation, and its user-friendly design makes it simple to maintain and service. As a result, companies can enjoy peace of mind knowing that they are investing in a solution that prioritizes both environmental responsibility and the well-being of their employees.Furthermore, the Vertical Cutting Dryer is a versatile solution that is suitable for a wide range of drilling applications. Whether it's onshore or offshore, and regardless of the type of drilling fluid being used, this innovative system is capable of handling the challenges of diverse operating conditions. This flexibility makes it an ideal choice for companies looking to streamline their waste management processes and reduce operating costs.The development of the Vertical Cutting Dryer represents a significant milestone in the ongoing efforts to improve sustainability and efficiency in the oil and gas industry. By providing a reliable and effective solution for managing drilling waste, this innovative system is helping to minimize the environmental impact of drilling operations while maximizing resource recovery. As the industry continues to evolve, solutions like the Vertical Cutting Dryer will play a crucial role in shaping the future of sustainable and responsible energy production.In conclusion, the Vertical Cutting Dryer is a groundbreaking solution that is redefining the standards of drilling waste management. With its advanced technology, superior performance, and versatile design, this innovative system is proving to be a game-changer for companies seeking to enhance their environmental stewardship and operational efficiency. As the industry continues to prioritize sustainability and regulatory compliance, the Vertical Cutting Dryer is well-positioned to meet the evolving needs of the oil and gas sector.

High-quality Urethane Panel Screen for Versatile Applications

Urethane Panel Screen a Game-Changer for the Mining IndustryThe mining industry has always been at the forefront of technological innovation, constantly seeking new ways to improve efficiency and productivity. One of the latest game-changing innovations in the industry is the Urethane Panel Screen, a revolutionary product that is set to transform the way mining operations are carried out. Developed by a leading manufacturer in the industry, this cutting-edge technology promises to provide significant benefits to mining companies around the world.The Urethane Panel Screen is a high-performance screening solution specifically designed for the mining and mineral processing industry. It is made from premium quality polyurethane material, which offers exceptional durability and resistance to wear and tear. This means that the Urethane Panel Screen is capable of withstanding the harsh and abrasive conditions commonly found in mining operations, making it an ideal choice for demanding applications.In addition to its exceptional durability, the Urethane Panel Screen also provides superior screening performance. Its innovative design features a series of specially engineered apertures that are strategically positioned to optimize material flow and increase screening efficiency. This results in a more effective and efficient screening process, allowing mining companies to achieve higher throughput and improved product quality.Furthermore, the Urethane Panel Screen is highly versatile and can be customized to meet the specific requirements of each mining operation. It is available in a range of different aperture sizes and configurations, allowing mining companies to tailor the screening solution to their individual needs. This level of customization ensures that the Urethane Panel Screen can deliver the best possible results, regardless of the type of material being processed.The benefits of the Urethane Panel Screen are not limited to its performance and durability. This innovative product also offers significant cost savings for mining companies. Its long-lasting wear resistance means that it requires less frequent maintenance and replacement, reducing downtime and lowering overall operational costs. Additionally, its superior screening efficiency results in higher throughput, maximizing the profitability of mining operations.The company behind the development of the Urethane Panel Screen is a renowned leader in the mining industry, with a strong track record of delivering high-quality solutions to its customers. With a commitment to innovation and continuous improvement, the company has consistently pushed the boundaries of what is possible in mining technology, and the Urethane Panel Screen is a testament to this dedication.The company's team of expert engineers and technicians have worked tirelessly to create a product that meets the exacting demands of the mining industry. Through extensive research and development, they have refined the design and performance of the Urethane Panel Screen, ensuring that it delivers exceptional results in real-world mining applications.In addition to its technical expertise, the company also places a strong emphasis on customer satisfaction. It works closely with mining companies to understand their specific needs and challenges, providing tailored solutions that address their unique requirements. This customer-centric approach has earned the company a reputation for reliability and trustworthiness, further solidifying its position as a leading supplier in the mining industry.As the mining industry continues to evolve, the Urethane Panel Screen represents a significant advancement that is set to transform the way mining operations are conducted. Its combination of durability, performance, and cost savings makes it a compelling choice for mining companies looking to maximize their efficiency and profitability. With the backing of a reputable and innovative company, the Urethane Panel Screen is poised to revolutionize the mining industry and set new standards for screening technology.

New High-Performance Screen for Efficient Oil & Gas Separation

Hyperpool Screens: Offering Enhanced Efficiency in Drilling OperationsDrilling operations have become more efficient and productive with the introduction of Hyperpool screens. These screens are specially designed for shale shaker systems and are highly effective in removing solids from drilling fluid. Hyperpool screens, also known as Derrick screens, have become increasingly popular in the oil and gas industry due to their exceptional performance and durability.What are Hyperpool screens?Hyperpool screens are a type of shale shaker screen that are used in the oil and gas industry to filter drilling fluid. They are designed to fit Derrick shale shaker systems, which are used to separate solids and liquids during the drilling process. Hyperpool screens are made using a multi-layered wire mesh cloth and are available in a variety of sizes and configurations to meet specific drilling requirements.Why choose Hyperpool screens?Hyperpool screens offer several advantages over other types of shale shaker screens. For one, they are more durable and long-lasting. The multi-layered wire mesh cloth ensures that the screens can withstand wear and tear from drilling operations. They are also highly effective in removing solids from drilling fluid, resulting in a more efficient and productive drilling process. Hyperpool screens are also easy to install and maintain, reducing downtime and maintenance costs.How do Hyperpool screens work?Hyperpool screens are designed to work with Derrick shale shaker systems. When drilling fluid is pumped into the shaker system, it passes through the screens and is filtered to remove solids. The multi-layered wire mesh cloth traps the solids and allows the clean fluid to pass through. The solids are then removed from the system and disposed of.Benefits of Hyperpool screensHyperpool screens offer several benefits that make them a popular choice for drilling operations. One of the biggest advantages is their efficiency in removing solids from drilling fluid. This results in a more efficient and productive drilling process, as the fluid can be reused and less waste is produced. Hyperpool screens are also more durable and long-lasting, reducing the need for frequent replacements. This saves time and money in the long run. Additionally, they are easy to install and maintain, reducing downtime and maintenance costs.ConclusionHyperpool screens are a vital component of shale shaker systems used in the oil and gas industry. They offer several advantages over other types of shale shaker screens, including enhanced efficiency and durability. Hyperpool screens are designed to filter drilling fluid, removing solids and producing a clean fluid that can be reused. If you’re looking for an effective and reliable solution for your drilling operations, Hyperpool screens are definitely worth considering.Keywords: Derrick Hyperpool screens, shale shaker screens, drilling operations, drilling fluid, multi-layered wire mesh cloth

High-Quality 48 × 30 PWP Shaker Screen for Efficient Solid Control Operations

A leading provider of industrial equipment in the oil and gas industry has recently introduced the 48 × 30 PWP Shaker Screen to its product line. This state-of-the-art shaker screen is specifically designed to provide superior performance and efficiency in the separation of solids from drilling fluid.The 48 × 30 PWP Shaker Screen is constructed with multiple layers of stainless steel wire mesh that are tightly woven together to create a strong and durable screen. This design allows for maximum fluid throughput while effectively removing large solids from the drilling fluid. Additionally, the PWP (flat panel) design offers increased screen life and more accurate cut point control compared to traditional pyramid screens.One of the key features of the 48 × 30 PWP Shaker Screen is its ability to provide a larger screening area, which results in higher capacity and improved particle removal. This makes it an ideal solution for a wide range of drilling applications, including oil and gas exploration, horizontal directional drilling, and geothermal drilling.In addition to its exceptional performance, the 48 × 30 PWP Shaker Screen is also designed for easy installation and maintenance. The screen is compatible with most major shale shaker brands and can be quickly and easily replaced as needed. This allows for minimal downtime and increased productivity on the job site.The company behind the introduction of the 48 × 30 PWP Shaker Screen has been a trusted name in the oil and gas industry for over a decade. With a commitment to delivering high-quality products and exceptional customer service, they have become a preferred supplier for drilling contractors and operators worldwide.The company offers a comprehensive range of products and services, including shale shaker screens, mud pumps, solid control equipment, and drilling tools. Their team of experienced professionals is dedicated to meeting the unique needs of each customer and providing innovative solutions to improve drilling operations.In addition to their extensive product line, the company also offers custom manufacturing and engineering services to develop specialized equipment for specific drilling requirements. This allows them to deliver tailored solutions that enhance performance, reduce costs, and minimize environmental impact.The introduction of the 48 × 30 PWP Shaker Screen further solidifies the company's reputation as a leader in the industry. With a focus on continuous improvement and innovation, they are committed to staying at the forefront of technological advancements and providing their customers with the most advanced equipment available.As the oil and gas industry continues to evolve, the demand for efficient and reliable equipment remains constant. The 48 × 30 PWP Shaker Screen offers a cutting-edge solution to enhance drilling operations and improve overall productivity. With its advanced design and proven performance, it is sure to become a valuable asset for contractors and operators seeking to maximize efficiency and optimize their drilling processes.

Advanced Circulating System for Efficient Drilling Operations

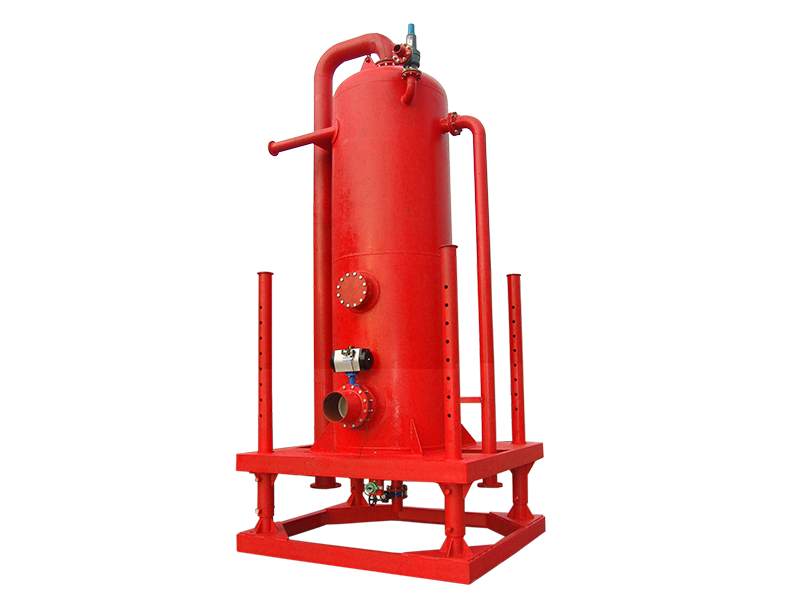

Circulating System In Drilling Enhances Efficiency and SafetyThe drilling industry plays a crucial role in extracting natural resources from deep beneath the earth's surface. To maximize efficiency and ensure safety during drilling operations, the implementation of advanced technology and equipment is essential. One such innovation that has significantly contributed to these goals is the Circulating System in drilling.A circulating system is a critical component of the drilling process, providing a means to circulate drilling fluid or mud, which helps to remove cuttings from the wellbore, control pressure, and aid in the overall stability of the well. This technology has become increasingly paramount in achieving optimal drilling performance, and the application of this system has been proven to enhance efficiency and safety.With the increasing demand for drilling operations on land and offshore, companies like {} have recognized the importance of investing in advanced circulating systems to meet the industry's evolving needs. As a leading provider of drilling equipment and services, {} has made significant strides in developing and implementing cutting-edge technologies to support the efficient and safe extraction of natural resources.The company's circulating system features state-of-the-art pumps, valves, and control systems that are designed to optimize the circulation of drilling mud, providing a consistent flow and pressure throughout the wellbore. This not only allows for the efficient removal of cuttings but also helps to maintain well control and prevent potential hazards associated with pressure imbalances during drilling operations.In addition to enhancing efficiency, the circulating system also contributes to the safety of drilling operations. By maintaining the stability and integrity of the wellbore, the risk of wellbore collapse or blowouts is significantly reduced. Furthermore, the system's advanced control features enable real-time monitoring and adjustments, ensuring that drilling operations are conducted with the highest level of safety standards.The benefits of implementing an advanced circulating system are evident in the improved performance and outcomes of drilling operations. By optimizing the circulation of drilling mud, operators can achieve faster and more cost-effective drilling processes, resulting in increased productivity and profitability. Furthermore, the enhanced safety features of the system provide peace of mind for all stakeholders involved in drilling projects.As the demand for natural resources continues to grow, the importance of efficient and safe drilling practices becomes increasingly critical. Companies like {} are at the forefront of developing and implementing innovative technologies to meet these demands. With a commitment to excellence and a focus on continuous improvement, the company is dedicated to providing the industry with reliable and advanced drilling solutions.In conclusion, the incorporation of a Circulating System in drilling has proven to be instrumental in enhancing efficiency and safety in drilling operations. Companies like {} have recognized the importance of this technology and have made significant investments to develop and implement advanced circulating systems that meet the evolving needs of the industry. With a focus on innovation and excellence, these advancements are pivotal in ensuring the sustainable and responsible extraction of natural resources for the benefit of future generations.

Powerful Industrial Pumps Available for Purchase

Local Business, a leading supplier of industrial equipment, has recently announced the availability of a new range of mission magnum pumps for sale. These high-quality pumps are designed to provide efficient and reliable performance in a wide range of industrial applications.Local Business has been a trusted supplier of industrial equipment for many years, serving customers in a variety of industries including oil and gas, mining, construction, and manufacturing. The company has built a strong reputation for delivering high-quality products and exceptional customer service, making them a go-to supplier for businesses looking for reliable industrial equipment.The new range of mission magnum pumps for sale is the latest addition to Local Business's extensive product offering. These pumps are designed to handle the most demanding pumping applications, providing reliable performance and long-lasting durability. Whether for dewatering, solids control, or slurry transfer, these pumps are up to the task.“We are excited to offer our customers access to the new range of mission magnum pumps,” said a representative from Local Business. “These pumps are known for their robust construction and reliable performance, making them an ideal choice for our customers in need of dependable pumping solutions.”The mission magnum pumps for sale from Local Business are available in a variety of configurations to suit different application requirements. Customers can choose from different sizes and specifications to ensure they get the right pump for their specific needs. In addition, Local Business offers expert guidance and support to help customers select the best pump for their application, ensuring they get the most out of their investment.In addition to offering mission magnum pumps for sale, Local Business also provides a range of services to support their customers. This includes pump installation, maintenance, and repair services, as well as technical support and training. The company's team of experienced technicians is on hand to provide support throughout the lifespan of the pumps, ensuring they continue to deliver reliable performance for years to come.“We don't just sell pumps – we provide comprehensive support to ensure our customers get the most out of their investment,” said the representative from Local Business. “Our team is committed to providing the highest level of service and support to our customers, helping them achieve their operational goals.”Customers interested in the mission magnum pumps for sale can get in touch with Local Business to discuss their requirements and receive expert guidance on selecting the right pump for their needs. With a commitment to quality and customer satisfaction, Local Business is the trusted choice for businesses looking for reliable industrial equipment and support.For more information about the mission magnum pumps for sale and the range of industrial equipment and services offered by Local Business, customers are encouraged to visit the company's website or contact their sales team directly. With a strong track record of delivering high-quality products and exceptional service, Local Business is the preferred partner for businesses looking for reliable pumping solutions.

How to Choose the Best Screen for Your Mongoose

Introducing a State-of-the-Art Screen Technology by a Leading CompanyIn recent technological developments, companies are continuously innovating to provide the best solutions for businesses and consumers. One such innovation is the development of a revolutionary screen technology by a leading company. This new screen technology, known as Mongoose Screen, is set to change the way we interact with displays and provide an exceptional visual experience for users.Mongoose Screen is a cutting-edge display technology that offers high resolution, vivid colors, and crisp image quality. It is designed to provide an immersive viewing experience, whether for entertainment, presentations, or professional use. The technology behind Mongoose Screen combines advanced hardware and software to deliver unparalleled performance and user satisfaction.The company behind the development of Mongoose Screen has been a pioneer in the display technology industry for several decades. With a solid reputation for creating high-quality products, the company has consistently delivered innovative solutions that meet the evolving needs of the market. Their commitment to research and development has led to the creation of Mongoose Screen, which is poised to become a game-changer in the industry.According to the company spokesperson, Mongoose Screen is the result of years of research, development, and collaboration with industry experts. The team behind this innovative technology has worked tirelessly to push the boundaries of conventional display technology and bring forth a product that redefines visual experiences. Mongoose Screen is built on the foundation of quality, reliability, and performance, making it the go-to choice for businesses and consumers alike.The key features of Mongoose Screen include its high resolution, which provides an unparalleled level of detail and clarity. The screen's ability to reproduce vivid colors and deep blacks ensures that images and videos are displayed with stunning realism. Furthermore, Mongoose Screen boasts an impressive refresh rate, ensuring smooth and fluid motion for an exceptional viewing experience.One of the most noteworthy aspects of Mongoose Screen is its versatility. It is designed to cater to a wide range of applications, including gaming, entertainment, professional use, and more. Whether it's for creating captivating visual presentations or enjoying the latest blockbuster movie, Mongoose Screen delivers exceptional performance across the board.The company has also integrated advanced software features into Mongoose Screen to enhance user experience and provide added value. These features include customizable display settings, picture enhancement modes, and seamless connectivity with other devices. Additionally, Mongoose Screen is designed to be energy-efficient, contributing to a sustainable and eco-friendly technology solution.With the launch of Mongoose Screen, the company is set to solidify its position as a leader in the display technology industry. The introduction of this cutting-edge product marks a significant milestone for the company, demonstrating its commitment to innovation and excellence. The company's dedication to delivering superior products is evident in Mongoose Screen, which promises to set new standards for visual display technology.As the market continues to evolve, the demand for high-quality display solutions will only continue to grow. With Mongoose Screen, the company is well-positioned to meet and exceed the expectations of businesses and consumers seeking the best in display technology. The introduction of Mongoose Screen represents a significant step forward for the company, and it serves as a testament to their dedication to pushing the boundaries of what is possible in the world of visual displays.In conclusion, the development of Mongoose Screen by this leading company is a testament to their commitment to innovation, quality, and providing exceptional solutions for their customers. This revolutionary screen technology is set to redefine the visual display experience and raise the bar for display technology in the industry. With its advanced features, versatility, and superior performance, Mongoose Screen is poised to become a must-have for businesses and consumers looking for the best in display technology.

Efficient and Reliable Centrifugal Pump for Mission 3x4 Application

Mission 3x4 Centrifugal Pump Provides Reliable and Efficient Solutions for Various IndustriesA centrifugal pump is an essential component in many industrial processes. It is a device that uses impellers to create a flow of fluid or gas through a pipe system. One of the most trusted brands in the centrifugal pump market is Mission, a company that has been providing reliable and efficient solutions for various industries for over 100 years.One of the latest products from Mission is the 3x4 centrifugal pump, which has been designed to meet the demanding needs of its customers. This pump is ideal for applications that require high flow rates and low to medium head. The pump's design makes it easy to install, operate, and maintain, making it one of the most efficient pumps in the market.The Mission 3x4 centrifugal pump is highly versatile and can be used in different industries, including oil and gas, chemical, power generation, water treatment, and mining. In the oil and gas industry, the pump is used for various applications, including pipeline transportation, processing, and storage. In the chemical industry, it is used for transferring chemicals from one process to another. The pump’s efficient design makes it ideal for power generation applications, such as cooling towers, condensers, and boiler feedwater systems. In the mining industry, it can be used for dewatering, slurry pumping, and mineral processing.The Mission 3x4 centrifugal pump is designed with high-quality materials to ensure its durability and reliability. The pump’s casing, impeller, and wear rings are made from high-strength materials, such as cast iron, stainless steel, or nickel-based alloys, to withstand harsh environments and maintain performance over time. Moreover, the pump’s seal design ensures reliable performance and longer service life, reducing downtime and maintenance costs.The Mission 3x4 centrifugal pump is a highly efficient machine, providing maximum flow rates with minimal head losses. Its impeller design reduces turbulence and flow recirculation, which can significantly impact the pump's efficiency. The pump’s unique design generates less heat and vibration, which reduces energy consumption and extends the pump’s life. Its back pull-out construction allows for easy maintenance and serviceability, minimizing downtime and reducing maintenance costs.The Mission 3x4 centrifugal pump is designed to meet or exceed industry standards, ensuring that it provides safe and reliable service. It is certified by various organizations, such as the American Petroleum Institute (API), the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO). This certification ensures that the pump meets the required quality, safety, and performance standards.In conclusion, the Mission 3x4 centrifugal pump is an excellent choice for various industries that require reliable and efficient pumping solutions. Its versatility, durability, and efficiency make it a cost-effective solution for many applications. Moreover, its certification by various industry organizations ensures that it meets the highest standards of quality and performance. For more information about the Mission 3x4 centrifugal pump, please visit the company's website or contact their customer support team.

Top Advantages of Investing in High-Quality Shaker Screens for Oil and Gas Industry

Title: Innovative Shaker Screen Technology Revolutionizes the Oil and Gas IndustryIntroduction: In response to the increasing demand for advanced oil drilling equipment, the renowned company, Mongoose Pro, has proudly launched its latest groundbreaking innovation, the next-generation Shaker Screen. Designed to cater to the specific requirements of the oil and gas industry, this cutting-edge technology promises to revolutionize drilling operations by enhancing efficiency, reducing costs, and improving environmental sustainability. With its exceptional performance and outstanding durability, the Mongoose Pro Shaker Screen is set to promote safer and faster drilling processes, paving the way for unprecedented growth in the sector.Paragraph 1: Overview of the Oil and Gas IndustryThe oil and gas industry plays a vital role in powering our modern society, providing energy sources essential in transportation, electricity generation, heating, and various industries. The process of tapping into these valuable resources involves complex drilling operations, requiring state-of-the-art equipment to optimize efficiency and minimize environmental impact.Paragraph 2: The Role of Shaker Screens in Drilling OperationsShaker screens serve as an integral part of the drilling process, facilitating the separation of drilling fluids and solids. These screens ensure that the drilling mud is consistently in an optimal condition for efficient extraction, while simultaneously reducing waste and protecting the drilling equipment from damage. Innovations in shaker screen technology are crucial in enabling drilling companies to achieve higher productivity and cost-effectiveness.Paragraph 3: Introduction to Mongoose Pro Shaker ScreenRecognizing the industry's needs for superior drilling equipment, Mongoose Pro has taken the lead in developing an advanced line of shaker screens, including their flagship product, the Mongoose Pro Shaker Screen. With extensive research and development, Mongoose Pro has successfully designed a highly efficient screen that offers unparalleled performance in a wide range of drilling environments.Paragraph 4: Key Features and Benefits of Mongoose Pro Shaker ScreenThe Mongoose Pro Shaker Screen boasts several noteworthy features that set it apart from conventional options in the market. Firstly, its proprietary composite frame construction provides outstanding strength and durability, allowing it to withstand the most demanding drilling conditions. Secondly, the screen's revolutionary triple-layered mesh design ensures optimum solid separation efficiency, further enhancing the drilling operation's overall effectiveness.Additionally, the Mongoose Pro Shaker Screen incorporates advanced manufacturing techniques that minimize screen blinding, thereby extending its operational lifespan and reducing downtime for maintenance. This not only improves cost-effectiveness for drilling companies but also promotes environmental sustainability by reducing waste generation.Paragraph 5: Seamless Integration and Enhanced EfficiencyOne of the primary advantages of the Mongoose Pro Shaker Screen is its compatibility with various shaker models. Designed to seamlessly integrate with both Mongoose Pro and other industry-standard shakers, this versatility provides drilling companies the flexibility to upgrade their existing machinery without the need for significant capital investment.By utilizing the Mongoose Pro Shaker Screen, operators can expect improved efficiency in the solid separation process, resulting in cleaner drilling fluid and reduced waste disposal costs. The screen's superior performance also translates into a reduction in overall drilling time, driving profitability for organizations navigating increasingly competitive markets.Paragraph 6: Ensuring Quality and Safety StandardsMongoose Pro's commitment to quality and safety is evident in the rigorous testing and certification processes undergone by their shaker screens. Meeting and surpassing industry standards ensures the reliability and resilience of their products to withstand the demanding conditions experienced during drilling operations. This commitment to excellence has earned Mongoose Pro a well-deserved reputation for providing innovative, reliable, and high-performing drilling equipment.Paragraph 7: ConclusionWith the launch of the Mongoose Pro Shaker Screen, the oil and gas industry can now benefit from cutting-edge technology designed to enhance drilling efficiency, reduce costs, and promote environmental sustainability. As drilling operations become increasingly complex and competitive, equipping companies with advanced equipment such as the Mongoose Pro Shaker Screen will undoubtedly revolutionize the industry, driving progress and success into the future.