- Home

- News

- Discover the Latest Innovations in Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pumps

Discover the Latest Innovations in Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pumps

By:Admin

China has once again proven its technological prowess by introducing two groundbreaking products - the Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pump. These cutting-edge pumps promise to revolutionize the pumping industry with their exceptional performance and advanced features.

The Fully Automatic Dry Priming Vacuum Assisted Pump, developed by a leading Chinese company, is a game-changer in the field of pumping technology. This pump is designed to handle various liquids, including sewage, industrial wastewater, and stormwater. It offers a maximum flow rate of up to 2,000 cubic meters per hour, making it ideal for large-scale applications.

One of the key features of this pump is its fully automatic operation, which eliminates the need for constant monitoring and manual adjustments. The pump is equipped with intelligent sensors and controls that optimize its performance based on the specific pumping requirements. This ensures efficient and reliable operation while minimizing human intervention.

Furthermore, the vacuum-assisted priming system integrated into the pump enables it to start and operate without any manual intervention. This feature is particularly useful in applications where the pump may need to start and stop frequently, as it eliminates the need for priming the pump every time it is started.

The Automatic Dry Priming Pump, on the other hand, is a versatile pump that can handle a wide range of fluids, including liquid with solids, abrasive liquids, and viscous liquids. Its dry priming technology allows it to operate even when the pump is not filled with liquid, making it highly suitable for challenging environments where other pumps may fail.

This pump incorporates self-priming technology, which allows it to handle air and water mixture without losing priming. As a result, it can quickly and efficiently evacuate air from the suction pipe system, ensuring a continuous flow of liquid without any breaks.

Both the Fully Automatic Dry Priming Vacuum Assisted Pump and the Automatic Dry Priming Pump come equipped with advanced control panels that offer various monitoring and diagnostic functions. These panels provide real-time information about the pump's operating conditions, allowing for immediate action in case of any issues or abnormalities.

Moreover, these pumps are designed to be energy-efficient, ensuring minimum power consumption while delivering maximum performance. This not only reduces the operational costs but also contributes to environmental sustainability.

The Chinese company behind these innovative pumps has a strong foothold in the pumping industry. With years of experience and continuous research and development, they have achieved significant milestones in pump design and manufacturing. Their commitment to meeting customer demands and needs drives them to develop groundbreaking solutions that push the boundaries of technology.

The introduction of the Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pump marks a significant milestone in China's industrial landscape. These pumps not only showcase China's technological advancements but also demonstrate the country's commitment to driving innovation and achieving self-sufficiency in critical industries.

China's relentless pursuit of excellence and continuous investment in research and development have positioned the country as a global leader in manufacturing and engineering. The introduction of these advanced pumps further solidifies China's position and sets new benchmarks for the pumping industry worldwide.

In conclusion, the Fully Automatic Dry Priming Vacuum Assisted Pump and Automatic Dry Priming Pump are groundbreaking products that have the potential to revolutionize the pumping industry. With their advanced features, superior performance, and energy efficiency, these pumps showcase China's technological capabilities and commitment to innovation.

Company News & Blog

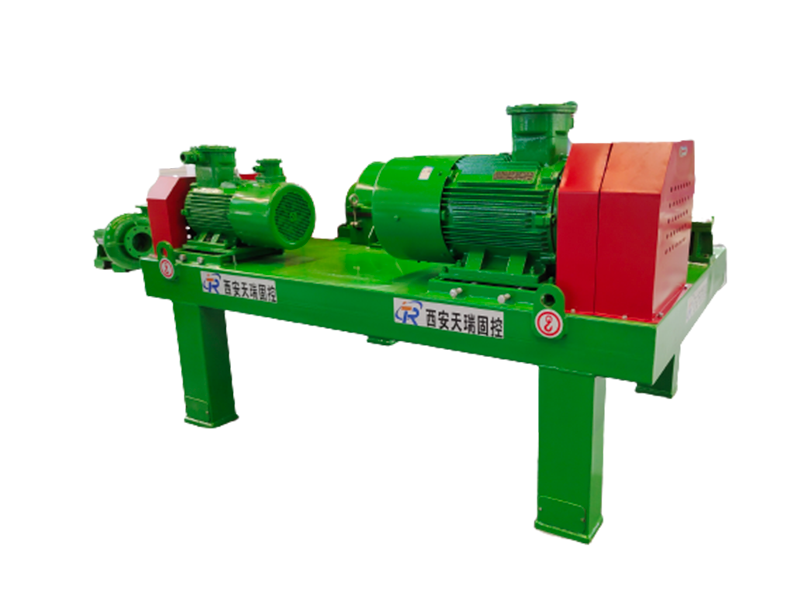

Top-quality Chemical Wastewater Decanter Centrifuge and Drilling Sludge Dewatering Supplier in China

China's leading supplier of chemical wastewater decanter centrifuges and drilling sludge dewatering equipment (Company), has become the go-to provider in the industry for high-quality and reliable solutions. With a strong focus on innovation and sustainability, the (Company) has established itself as a trusted partner for businesses looking to effectively manage their wastewater and sludge treatment processes.The (Company) offers a wide range of decanter centrifuges specifically designed for the efficient separation and dewatering of chemical wastewater. These centrifuges are capable of handling high volumes of wastewater while delivering exceptional performance and reliability. Additionally, the (Company) provides customized solutions to meet the unique needs of each client, ensuring that their specific requirements are met with precision and efficiency.In the field of drilling sludge dewatering, the (Company) has developed advanced equipment that enables businesses to effectively manage and treat drilling waste. The company's sludge dewatering solutions are designed to significantly reduce the volume of waste produced, allowing for easier and more cost-effective disposal. By implementing these innovative technologies, businesses can minimize their environmental impact and adhere to strict regulations while optimizing their operational processes.The (Company) prides itself on its commitment to sustainability and environmental responsibility. With a team of experienced engineers and technicians, the company continuously seeks to develop new and improved solutions that contribute to a more sustainable industrial landscape. By focusing on energy efficiency and waste reduction, the (Company) is dedicated to helping businesses minimize their environmental footprint and operate in a more sustainable manner.In addition to its high-quality equipment, the (Company) offers comprehensive technical support and after-sales services to ensure that clients receive ongoing assistance and guidance. The company's team of experts is readily available to provide advice, training, and maintenance services, helping clients maximize the performance and longevity of their equipment. This commitment to customer satisfaction has earned the (Company) a reputation for reliability and professionalism in the industry.Furthermore, the (Company) is dedicated to fostering strong partnerships with its clients, working closely with them to understand their specific needs and challenges. By building collaborative relationships, the company aims to provide tailored solutions that deliver maximum value and effectiveness. This customer-centric approach has enabled the (Company) to establish long-term relationships with businesses across various industries, earning their trust and loyalty.As the demand for efficient and sustainable wastewater and sludge treatment solutions continues to grow, the (Company) remains at the forefront of the industry, driving innovation and setting new standards for excellence. With its cutting-edge technologies, unwavering commitment to sustainability, and dedication to customer satisfaction, the (Company) is poised to lead the way in providing advanced decanter centrifuges and sludge dewatering solutions for businesses in China and beyond.In conclusion, the (Company) stands out as a pioneering provider of chemical wastewater decanter centrifuges and drilling sludge dewatering equipment, offering innovative and sustainable solutions that help businesses effectively manage their wastewater and sludge treatment processes. With a focus on quality, reliability, and customer satisfaction, the (Company) continues to set the bar for excellence in the industry, driving positive change and making a significant impact on the environmental and operational performance of its clients.

Top Water Purifier and Treatment Solutions in China

China's leading water purification and water treatment company, with a strong focus on providing clean and safe drinking water for all, has been making waves in the industry with its innovative and high-quality products.With a reputation for excellence and a commitment to sustainability, the company has become a trusted name in the field of water purification. Their products are designed to remove impurities and contaminants from water, ensuring that it is safe for consumption and free from any harmful substances.One of the main reasons behind the company's success is its dedication to research and development. They employ a team of highly skilled and experienced professionals who are constantly working on improving their products and developing new technologies to better serve their customers.In addition to their innovative products, the company also places a strong emphasis on environmental responsibility. They strive to minimize their impact on the environment by using sustainable manufacturing practices and reducing their carbon footprint. This commitment to sustainability has earned them the respect and admiration of both customers and industry experts alike.The company's water purifiers and treatment systems are designed to meet the needs of a wide range of customers, from individual households to large-scale industrial applications. Their products are known for their reliability, efficiency, and durability, making them a popular choice for consumers and businesses alike.In recent years, the company has expanded its reach beyond the borders of China, exporting its products to countries around the world. This global expansion has further solidified their position as a leader in the water purification and treatment industry.One of the company's most notable achievements is its involvement in providing clean drinking water to areas affected by natural disasters and other humanitarian crises. Their portable water purification systems have been deployed in various disaster-stricken regions, providing vital support to communities in need.Looking ahead, the company remains committed to driving innovation and excellence in the field of water purification and treatment. They continue to invest in research and development, seeking to further improve their products and develop new solutions to address the ever-evolving challenges of water purification.In conclusion, China Water Purifier and Water Treatment is a company that has made a significant impact in the field of water purification and treatment. With their commitment to excellence, sustainability, and innovation, they have become a trusted name in the industry, both in China and around the world. As they continue to grow and expand, they are sure to set new standards for the industry and continue to provide clean and safe drinking water for all.

High-Quality Centrifugal Water Pumps Manufactured in China

China Pumps, a leading manufacturer of industrial pumps, has recently announced the launch of their new line of Centrifugal Water Pumps. With a strong focus on innovation and quality, China Pumps has quickly become a trusted partner for businesses in a wide range of industries.The new Centrifugal Water Pumps are designed to meet the growing demand for efficient and reliable pumping solutions in water treatment, agricultural irrigation, and industrial processes. These pumps are built to deliver high flow rates and are capable of handling large volumes of water with ease. With a robust design and high-quality materials, the Centrifugal Water Pumps from China Pumps are built to withstand the most demanding applications.The launch of the new line of Centrifugal Water Pumps is a testament to China Pumps' commitment to providing cutting-edge solutions to their customers. The company has a strong track record of delivering high-performance pumps that meet the needs of a wide range of industries. With a focus on continuous improvement and innovation, China Pumps is constantly striving to push the boundaries of what is possible in the world of pumping technology.In addition to their new line of Centrifugal Water Pumps, China Pumps offers a comprehensive range of pumping solutions for various applications. From submersible pumps to sewage pumps, the company's product portfolio is designed to cater to the unique needs of their customers. With a team of experienced engineers and technicians, China Pumps is able to provide customized pumping solutions to meet specific requirements.The company's dedication to quality and reliability is evident in their state-of-the-art manufacturing facilities. China Pumps has invested heavily in advanced manufacturing technologies to ensure that their pumps meet the highest standards of quality. This commitment to excellence has earned China Pumps a solid reputation as a trusted partner for businesses looking for reliable pumping solutions.With a strong focus on customer satisfaction, China Pumps provides comprehensive after-sales support to ensure that their customers get the most out of their pumping systems. The company's team of experts is available to provide technical assistance, maintenance services, and spare parts to keep their pumps running at peak performance.As China Pumps continues to expand its presence in the global market, the company is poised to become a leading player in the pumping industry. With a strong focus on innovation, quality, and customer service, China Pumps is well-positioned to meet the evolving needs of businesses in various industries.With the launch of their new line of Centrifugal Water Pumps, China Pumps is set to further solidify their position as a trusted provider of high-performance pumping solutions. As businesses continue to seek efficient and reliable pumping solutions, China Pumps is ready to meet the demand with their innovative and high-quality pumps.In conclusion, China Pumps' new line of Centrifugal Water Pumps demonstrates the company's commitment to providing cutting-edge pumping solutions to their customers. With a focus on innovation, quality, and customer satisfaction, China Pumps is well-positioned to meet the evolving needs of businesses in various industries. As the company continues to expand its presence in the global market, China Pumps is set to become a leading player in the pumping industry.

Revolutionary Solution: Discover the Power of a High-performance Mud Mixer

Title: Innovative Mud Mixing Solution Optimizes Drilling Efficiency in the Oil and Gas IndustryIntroduction:In the oil and gas industry, the efficient extraction of resources relies heavily on advanced technology and equipment. A key component crucial to drilling operations is the mud mixer, a device that blends drilling fluids or mud to maintain stability and enhance performance during drilling processes. Addressing the increasing demand for improved efficiency and performance, a leading engineering company has introduced their cutting-edge Jet Mud Mixer system, revolutionizing the field of drilling and excavation.Body:1. Understanding the Importance of Mud Mixing: The drilling process generates enormous amounts of heat and pressure, demanding fluids that effectively cool, lubricate, and stabilize the drill bit. Mud mixing systems play a critical role by preparing drilling fluids that are essential for successful drilling operations. The fluids facilitate removing cuttings from the wellbore, preventing formation damage, controlling well pressure, and stabilizing the excavation.2. Introducing the Innovative Jet Mud Mixer System: Recognizing the need for a high-performance and efficient mud mixing solution, [Company Name] has developed the Jet Mud Mixer system. This technology combines precise engineering and state-of-the-art design, enabling drilling companies to achieve unparalleled performance in their operations. By integrating advanced processes and materials, this mud mixer surpasses industry standards, providing enhanced drilling efficiency and cost-effectiveness.3. Cutting-edge Features and Functionality: The Jet Mud Mixer system boasts several innovative features that set it apart from existing mud mixing solutions: a. Superior Mixing Performance: [Company Name]'s technology combines robust jet nozzles with a high-power discharge pump, ensuring thorough blending of drilling fluids at optimum consistency and density. b. Versatility and Scalability: The Jet Mud Mixer system is designed to accommodate a wide range of drilling environments, from small-scale onshore projects to large offshore rigs, providing adaptability and scalability for various drilling operations. c. Precision Controls: Equipped with user-friendly controls, drilling operators can easily configure the desired mud consistency, density, and flow rates, improving overall operational control and efficiency. d. Enhanced Safety Measures: Complying with stringent safety regulations, this cutting-edge system incorporates safety features such as emergency stop mechanisms, leakage protection, and excess pressure triggers, ensuring the well-being of personnel and the environment.4. Optimizing Drilling Efficiency and Cost-effectiveness: The Jet Mud Mixer system offers significant advantages to drilling companies seeking to enhance their operational efficiency and reduce costs: a. Increased Drilling Rates: With precise control of drilling mud density and composition, the Jet Mud Mixer system enables faster drilling rates, reducing overall drilling time and costs. b. Reduced Waste and Environmental Impact: By systematically and accurately managing the drilling fluids, this advanced mixing solution minimizes waste and environmental impact, promoting sustainability within the industry. c. Lower Maintenance and Downtime: The robust construction and durability of the Jet Mud Mixer system ensure minimal maintenance requirements. Consequently, downtime caused by equipment breakdowns is significantly reduced, optimizing overall drilling productivity. d. Enhanced Operator Safety: Incorporating safety mechanisms and protocols, the system prioritizes operator safety during mud mixing operations, minimizing accidents and injuries.Conclusion:The introduction of the Jet Mud Mixer system by [Company Name] marks a significant advancement in drilling technology within the oil and gas industry. With its cutting-edge features, precision controls, and focus on efficiency, this innovative mud mixing solution enhances drilling rates, reduces environmental impact, and improves overall operational cost-effectiveness. Embarking on a journey towards a more sustainable and efficient future, [Company Name] is revolutionizing the drilling industry, setting new benchmarks for performance and safety.

Efficient Mud Cleaning Machine for Improved Operation

Mud Cleaning Machine Revolutionizes the Oil and Gas IndustryThe oil and gas industry is constantly evolving, with new technologies and innovations that aim to improve efficiency and reduce environmental impact. One such innovation that is making waves in the industry is the Mud Cleaning Machine, a game-changing technology that is revolutionizing the way drilling mud is treated and recycled.The Mud Cleaning Machine, developed by a leading oilfield equipment manufacturer, is a state-of-the-art piece of equipment that is designed to separate and remove solids from drilling mud, resulting in cleaner mud that can be reused in the drilling process. This innovative technology is helping oil and gas companies to significantly reduce the amount of drilling waste that is generated, ultimately leading to cost savings and a smaller environmental footprint.The Mud Cleaning Machine works by utilizing a series of screens and hydrocyclones to remove solids from the drilling mud, while also separating the mud into different density levels. The cleaned mud can then be reused in the drilling process, reducing the need for fresh mud and ultimately lowering the overall cost of drilling operations.In addition to its environmental and cost-saving benefits, the Mud Cleaning Machine is also improving the safety of drilling operations. By removing solids from the mud, the risk of equipment damage and downtime is significantly reduced, leading to smoother and more efficient drilling operations.The company behind the Mud Cleaning Machine has a long-standing reputation for developing and manufacturing high-quality oilfield equipment. With a focus on innovation and a commitment to sustainability, the company has become a trusted partner for oil and gas companies around the world.In addition to the Mud Cleaning Machine, the company also offers a range of other equipment and services designed to improve the efficiency and environmental performance of drilling operations. From wastewater treatment systems to solid control equipment, the company provides a comprehensive suite of solutions that are helping oil and gas companies to meet their operational and sustainability goals.The development of the Mud Cleaning Machine is a testament to the company’s dedication to innovation and its commitment to driving positive change in the oil and gas industry. By providing a solution that not only improves efficiency and cost savings but also reduces environmental impact, the company is playing a crucial role in helping the industry to become more sustainable and responsible.Furthermore, the company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a global network of sales and service locations, the company is able to provide ongoing support to its customers, ensuring that they are able to maximize the value and performance of the Mud Cleaning Machine and other equipment.The impact of the Mud Cleaning Machine on the oil and gas industry is undeniable. By enabling companies to reduce waste, improve efficiency, and enhance safety, this innovative technology is helping to shape the future of drilling operations. As the industry continues to evolve, it is clear that the Mud Cleaning Machine will play a crucial role in driving positive change and creating a more sustainable and responsible oil and gas industry.

Discover the Advantages of Ceramic Liner and Zirconia Cylinder Liners in China

Title: China's Ceramic Liner and Zirconia Cylinder Liners Boost Efficiency and Durability in ManufacturingIntroduction:In recent years, China has witnessed a rapid growth in advanced manufacturing technologies. As a part of this dynamic sector, China's Ceramic Liner and Zirconia Cylinder Liner industry have emerged as indispensable components in various industrial applications. Their superior attributes, including high wear resistance, exceptional mechanical strength, and improved performance, have revolutionized manufacturing processes across industries.Unveiling the China Ceramic Liner and Zirconia Cylinder Liners:China's Ceramic Liner and Zirconia Cylinder Liners have garnered significant attention due to their unique properties. These liners exhibit exceptional thermal stability, resistance to corrosive environments, and reduced friction, making them highly sought-after in machinery manufacturing, mining, petrochemical refining, and other vital industrial sectors.Ceramic Liner: A Game-Changer in Industrial ManufacturingThe Ceramic Liner industry in China has experienced substantial growth owing to its numerous advantages over traditional liner materials. These liners, often made from alumina ceramics, exhibit outstanding hardness and high-temperature resistance, making them ideal for applications in demanding environments. Moreover, Ceramic Liners possess exceptional wear resistance, ensuring extended durability and reduced maintenance costs.One of the key merits of Ceramic Liners is their ability to effectively minimize friction, resulting in reduced energy consumption and enhanced operational efficiency. Manufacturers across various sectors have embraced these liners, witnessing improvements in equipment longevity and decreased system downtime.Leading the Zirconia Cylinder Liner Innovations:China's Zirconia Cylinder Liner industry has emerged as an integral part of the automotive and machinery manufacturing sectors. Zirconia Cylinder Liners, made from advanced zirconium oxide ceramics, have revolutionized engine efficiency and durability. These liners exhibit reduced friction, outstanding thermal insulation properties, and exceptional resistance to wear, corrosion, and thermal shock.Automobile manufacturers worldwide have recognized the significance of Zirconia Cylinder Liners in improving fuel efficiency and reducing emissions. As a result, China has become a major supplier of Zirconia Cylinder Liners, catering to the global automotive industry's increasing demand.Surpassing Industry Standards:China's Ceramic Liner and Zirconia Cylinder Liner manufacturers have continuously focused on surpassing industry standards. By leveraging advanced manufacturing techniques, stringent quality control procedures, and cutting-edge technologies, these manufacturers have developed innovative solutions to meet diverse customer requirements.In addition to their high-performance characteristics, China's Ceramic Liner and Zirconia Cylinder Liner manufacturers prioritize the delivery of customized products to suit various industrial needs. By collaborating with research institutions, they constantly strive for improvements in materials science and engineering, resulting in enhanced product durability and reliability.Global Impact and Future Prospects:China's Ceramic Liner and Zirconia Cylinder Liner industry have achieved global recognition and are experiencing substantial growth in international markets. The exceptional quality, cost-effectiveness, and adaptability of these liners have made China a world leader in this sector.Furthermore, with the ongoing advancements in additive manufacturing, China aims to revolutionize the production process of Ceramic Liners and Zirconia Cylinder Liners. Novel manufacturing techniques, such as 3D printing, are expected to further enhance the versatility, efficiency, and affordability of these liners, cementing China's dominance in the global market.Conclusion:China's Ceramic Liner and Zirconia Cylinder Liner industry have fueled advancements in manufacturing processes, optimizing efficiency and durability across various sectors. The exceptional attributes of these liners, including wear resistance, thermal stability, and reduced friction, have propelled their adoption in machinery manufacturing, refining, and automotive sectors worldwide. China's commitment to innovation, stringent quality control, and customized solutions ensure that its Ceramic Liners and Zirconia Cylinder Liners continue to remain at the forefront of global manufacturing technologies.

Top Quality Screen Mesh and Screen for Various Industries in China

China Screen Mesh and Screen Company, known for its high-quality and durable screen products, has recently announced the launch of a new and improved screen mesh designed to meet the specific needs of various industries. The company, which has been a leader in the screen manufacturing industry for over a decade, has consistently provided innovative and reliable solutions to its customers, and the new mesh is a testament to its commitment to delivering top-notch products.The new screen mesh is constructed using advanced materials and technology, ensuring superior strength and durability. It is designed to withstand harsh environmental conditions, making it suitable for a wide range of applications, including mining, construction, agriculture, and pharmaceuticals. The mesh is available in various sizes and configurations, allowing for customization to meet the specific requirements of different industries.One of the key features of the new screen mesh is its high tensile strength, which enables it to effectively withstand heavy loads and abrasive materials. This makes it ideal for use in mining and construction, where the screens are often subjected to extreme wear and tear. The mesh also offers excellent resistance to corrosion, ensuring long-lasting performance in outdoor and industrial environments.In addition to its physical properties, the new screen mesh is also designed for easy installation and maintenance. Its modular design allows for quick and hassle-free replacement, reducing downtime and increasing productivity. The company has also developed a range of accessories and support systems to facilitate the installation and use of the mesh, further enhancing its overall usability.The launch of the new screen mesh is a result of China Screen Mesh and Screen Company's continuous research and development efforts. The company has a dedicated team of engineers and technicians who are constantly striving to improve and innovate its product offerings. By leveraging the latest technologies and materials, the company is able to stay ahead of the competition and provide cutting-edge solutions to its customers.The company's commitment to quality and customer satisfaction has earned it a strong reputation in the industry. Its products are trusted by businesses and organizations around the world, and the new screen mesh is expected to further solidify its position as a leading provider of screen solutions. With a focus on performance, reliability, and innovation, China Screen Mesh and Screen Company continues to set the bar for the industry.In addition to its product offerings, the company also provides comprehensive technical support and customer service. Its team of experts is available to assist customers with product selection, installation, and troubleshooting, ensuring a seamless experience from start to finish. This level of support has helped the company build long-lasting relationships with its clients and establish itself as a trusted partner in the industry.As China Screen Mesh and Screen Company continues to grow and expand its product line, it remains committed to upholding its core values of quality, innovation, and customer satisfaction. The launch of the new screen mesh is just one example of the company's dedication to providing top-of-the-line solutions to its clients. With its proven track record and forward-thinking approach, China Screen Mesh and Screen Company is poised to remain a driving force in the screen manufacturing industry for years to come.

Effective Drilling Mud Management Techniques for Oil and Gas Industry

As a global leader in the energy industry, {company} has been at the forefront of providing cutting-edge solutions for the oil and gas sector. The company has a strong track record of delivering innovative technologies and services to streamline operations and maximize efficiency.One of the key challenges in the oil and gas industry is the management of drilling mud. Drilling mud, also known as drilling fluid, is a critical component in the drilling process. It is used to lubricate the drill bit, carry cuttings to the surface, control wellbore pressure, and provide stability to the wellbore. However, the proper management of drilling mud is essential to ensure the success of drilling operations and minimize environmental impact.To address this challenge, {company} has developed a state-of-the-art Drilling Mud Management system that is designed to optimize the performance of drilling mud while minimizing waste and environmental impact. The system incorporates advanced technologies and best practices to effectively treat, recycle, and dispose of drilling mud, ensuring compliance with environmental regulations and industry standards.One of the key features of {company}'s Drilling Mud Management system is its ability to efficiently separate solids from the drilling mud, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner. This not only reduces waste and lowers operational costs, but also minimizes the environmental footprint of drilling operations.In addition, the system is equipped with advanced filtration and purification technologies to ensure that the recycled drilling mud meets the required specifications for reuse in drilling operations. This not only improves the efficiency of the drilling process but also reduces the need for fresh water, which is a precious resource in many drilling locations.Furthermore, {company}'s Drilling Mud Management system is designed to adapt to the specific requirements of each drilling operation, providing a customized solution that is tailored to the unique challenges and objectives of each project. This ensures that the system can effectively address the complexities of different drilling environments and well conditions, while maximizing the performance and efficiency of drilling mud.Moreover, {company} also offers comprehensive support and services to accompany its Drilling Mud Management system, including engineering expertise, technical assistance, and training programs. This ensures that customers have access to the necessary knowledge and resources to fully leverage the capabilities of the system and achieve optimal results.By implementing {company}'s Drilling Mud Management system, oil and gas companies can benefit from improved operational efficiency, reduced environmental impact, and enhanced regulatory compliance. This not only contributes to the sustainability and responsible stewardship of natural resources but also enhances the overall profitability and competitiveness of drilling operations.It is clear that {company} remains committed to delivering innovative solutions that address the evolving needs of the energy industry. Through its Drilling Mud Management system, the company is empowering oil and gas companies to achieve greater efficiency, minimize waste, and uphold the highest standards of environmental stewardship. With its advanced technologies, industry expertise, and global presence, {company} is poised to continue leading the way in shaping the future of the energy sector.

Tunneling Mud Recycling and Sand Recycling Processing in China

China Tunneling Mud Recycling and Sand Recycling Processing Technology Reaches New MilestoneChina's tunneling mud and sand recycling processing technology has reached a new milestone with the development of innovative solutions to address environmental concerns and improve efficiency in tunneling projects. The technology is set to transform the way tunneling mud and sand are managed, providing a sustainable approach to construction waste management.With rapid urbanization and infrastructure development in China, the demand for tunneling projects has been on the rise. However, the generation of large volumes of tunneling mud and sand has posed significant environmental and logistical challenges. Traditional disposal methods such as landfills and open dumping have raised concerns about soil and water pollution, as well as the depletion of natural resources.In response to these challenges, innovative companies like [company name] have developed advanced tunneling mud recycling and sand recycling processing technology to address the environmental impact of tunneling projects. The technology incorporates a range of equipment and systems that enable the efficient separation, treatment, and recycling of tunneling mud and sand, thereby minimizing waste and reducing the ecological footprint of construction activities.[Company name] has been at the forefront of promoting sustainable construction practices in China and has established itself as a leading provider of tunneling mud recycling and sand recycling processing solutions. With a strong focus on research and development, the company has continuously worked to enhance its technology and equipment to meet the evolving needs of the construction industry.The tunneling mud recycling and sand recycling processing technology offered by [company name] is designed to address the specific requirements of tunneling projects, ensuring that the environmental impact of construction activities is minimized. The technology includes a range of equipment such as mud recycling systems, sand recycling systems, and dewatering units, all of which are designed to efficiently separate and treat tunneling mud and sand for reuse in construction activities.One of the key benefits of the tunneling mud recycling and sand recycling processing technology is its ability to significantly reduce the volume of waste generated from tunneling projects. Through the effective separation and treatment of tunneling mud and sand, the technology enables a high level of resource recovery, thereby reducing the need for new raw materials and minimizing the demand for landfill space.Furthermore, the technology is designed to improve the overall efficiency of tunneling projects by providing a reliable source of high-quality recycled materials for use in construction activities. This not only contributes to cost savings for project developers but also supports the sustainable use of resources, aligning with China's commitment to promoting green and sustainable development.As China continues to prioritize environmental protection and sustainable development, the adoption of tunneling mud recycling and sand recycling processing technology is set to play a crucial role in advancing the country's construction industry. By promoting the responsible management of construction waste and the efficient use of resources, the technology contributes to the realization of China's environmental and sustainable development goals.In conclusion, the advancement of tunneling mud recycling and sand recycling processing technology in China represents a significant milestone in the construction industry. By addressing environmental concerns and promoting resource efficiency, the technology is set to transform the way tunneling projects are managed, contributing to a more sustainable and environmentally friendly approach to construction waste management. With companies like [company name] leading the way with innovative solutions, tunneling mud and sand recycling processing technology is poised to be a game-changer for the construction industry in China.

High Quality PWP Shaker Screens for FLC 2000 Model Available

FLC 2000 PWP Shaker Screens Revolutionize the Oil and Gas Drilling IndustryThe oil and gas drilling industry is continuously evolving, and with advancements in technology, companies are constantly searching for ways to improve efficiency and productivity. One of the key components of any drilling operation is the shaker screen, which is essential for separating solids from drilling fluid. With the introduction of the FLC 2000 PWP Shaker Screens, the drilling industry has been revolutionized, offering enhanced performance and reliability for drilling operations worldwide.The FLC 2000 PWP Shaker Screens, produced by a leading manufacturer in the industry, have set a new standard for shaker screen technology. These screens are specifically designed to provide superior performance in a wide range of drilling applications, including oil and gas exploration, geothermal drilling, and more. With a focus on durability, efficiency, and reliability, these screens are engineered to withstand the demanding conditions of drilling operations, delivering exceptional results time and time again.One of the key features of the FLC 2000 PWP Shaker Screens is their advanced design, which allows for maximum fluid handling capacity while effectively removing solid particles from the drilling fluid. This results in improved drilling efficiency, reduced downtime, and lower overall operating costs. Additionally, these screens are built to withstand the harsh conditions of drilling operations, ensuring long-lasting performance and reliability in the field.In addition to their superior performance, the FLC 2000 PWP Shaker Screens are also designed with ease of use in mind. With quick and simple installation, these screens can be easily integrated into existing shaker systems, providing immediate improvements in performance and efficiency. This user-friendly design has been well-received by drilling operators, who have praised the FLC 2000 PWP Shaker Screens for their ease of use and reliability in the field.Furthermore, the manufacturer of the FLC 2000 PWP Shaker Screens has a long-standing reputation for producing high-quality products that meet the needs of the oil and gas industry. With a commitment to innovation and excellence, this company has become a trusted partner for drilling operations around the world, providing solutions that improve efficiency, productivity, and safety.The introduction of the FLC 2000 PWP Shaker Screens has generated significant interest and excitement within the oil and gas drilling industry. Drilling operators are eager to take advantage of the enhanced performance and reliability offered by these innovative screens, which have the potential to revolutionize the way drilling operations are conducted. With their advanced design, durability, and ease of use, the FLC 2000 PWP Shaker Screens are poised to make a significant impact on the industry, setting a new standard for shaker screen technology.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in shaker screen technology, offering enhanced performance and reliability for drilling operations worldwide. With their advanced design, durability, and ease of use, these screens have the potential to revolutionize the oil and gas drilling industry, providing operators with the tools they need to improve efficiency, productivity, and safety. As the industry continues to evolve, the FLC 2000 PWP Shaker Screens are sure to play a key role in driving future advancements and innovations in drilling technology.