Efficient Decanter Centrifuge for Municipal Sewage Management in China

By:Admin

China Municipal Sewage Decanter Centrifuge has expertise in designing, manufacturing, and providing the most advanced sewage treatment equipment for both industrial and municipal wastewater treatment applications. The company's technological advancements are aimed at reducing the environmental impact of wastewater treatment plants while ensuring compliance with stringent local and international wastewater regulations.

The new wastewater treatment solutions are capable of processing high volumes of municipal and industrial sewage with exceptional efficiency. By using durable and high-quality materials, the company has also ensured that the technology is affordable and lasts longer. The new sewage treatment solutions are equipped with innovative features and are automated with user-friendly interfaces. This combination ensures easy operation, safety and low maintenance.

In addition, the new high-speed centrifugal decanter technology is changing the landscape of the wastewater treatment industry. The new technology allows the decanter to spin faster and separate more waste material from wastewater. This results in cleaner and more effective wastewater treatment solutions. With the removal of waste materials, the resulting clean water can be recycled or returned to the natural environment, reducing water pollution.

The China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge's wastewater treatment solutions are applicable in various fields. Municipal wastewater treatment plants, industrial food processing facilities, petrochemical plants, oil and gas refineries, metal and mining industries can all benefit from this cutting-edge technology.

In addition to wastewater treatment, the Decanter Centrifuge has several other uses. Decanter centrifuges can also be used to separate solids and liquids in chemical and pharmaceutical industries. They are also used to separate water and oil, and fruit juice clarification. This is a testament to the versatility of the Decanter Centrifuge and its vast array of applications.

The company adheres to the highest manufacturing standards to make sure that the final products are of the highest quality. To achieve this, China Municipal Sewage Decanter Centrifuge has assembled a team of experienced professionals who are specialized in different aspects of the production process. They work closely together to deliver superior products. In addition, the company has established a quality management system to ensure compliance with ISO and other international standards.

China Municipal Sewage Decanter Centrifuge is committed to innovation, research, and development. The company has invested heavily in research and development to ensure that their products are at the forefront of technology. This investment has resulted in the development of patented technologies that are setting new standards in the wastewater treatment industry.

The company has also established a competent after-sales service, and the customer service teams are always available to help clients whenever they need assistance. They provide technical support, installation, maintenance, as well as training on how to operate the equipment.

In conclusion, China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge have introduced revolutionary wastewater treatment solutions that are improving the efficiency of wastewater treatment plants while ensuring compliance with local and international wastewater regulations. The company's ability to develop innovative technologies that are at the forefront of the industry makes them a leader in the centrifuge manufacturing industry. Their focus on producing high-quality products and their excellent customer service has made them one of the most dependable centrifuge manufacturers globally. It is clear that China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge are committed to making the world a better place through their innovative and sustainable wastewater treatment solutions.

Company News & Blog

Effective Mud Gas Separator for Oil and Gas Drilling Operations

[Company Name] Introduces New Mud Gas Separator for Safer Drilling Operations[City, State] - [Company Name], a global leader in drilling equipment and technology, has introduced a new Mud Gas Separator to their extensive line of products. The Mud Gas Separator is designed to improve safety and efficiency in drilling operations, providing a reliable solution for removing harmful gases from the drilling fluid.The Mud Gas Separator is a vital component in the drilling process, as it helps to prevent the buildup of dangerous gases such as methane, carbon dioxide, and hydrogen sulfide. These gases can pose serious risks to both personnel and equipment on the drilling rig, making the efficient removal of these gases a top priority. With the introduction of their new Mud Gas Separator, [Company Name] aims to provide their customers with a state-of-the-art solution to effectively manage gas while drilling.The [Company Name] Mud Gas Separator features a high-efficiency design that effectively separates and vents gas from the drilling fluid, ensuring a safe and controlled environment on the rig. This advanced technology reduces the risk of gas-related incidents and improves overall drilling performance. Additionally, the Mud Gas Separator is built to withstand the harsh conditions of drilling operations, offering durability and reliability in the field.[Company Name] has a long-standing reputation for delivering innovative and high-quality equipment to the oil and gas industry. With a focus on safety, efficiency, and environmental stewardship, the company continues to develop cutting-edge solutions to meet the evolving needs of their customers. The introduction of the Mud Gas Separator is a testament to their commitment to providing industry-leading equipment that enhances operational performance and minimizes risk."We are thrilled to introduce our new Mud Gas Separator to the market," said [Spokesperson], [Title] at [Company Name]. "Safety is a top priority for us, and we believe that this new product will significantly improve the safety and efficiency of drilling operations. The Mud Gas Separator is a testament to our dedication to providing reliable solutions that address the challenges our customers face in the field."In addition to the Mud Gas Separator, [Company Name] offers a comprehensive range of drilling equipment and services, including drilling rigs, drilling tools, well control systems, and more. Their global presence and extensive industry expertise make them a trusted partner for drilling contractors and operators around the world.As the oil and gas industry continues to push the boundaries of exploration and production, the demand for advanced equipment that enhances safety and performance remains strong. With the introduction of the Mud Gas Separator, [Company Name] is well-positioned to meet this demand and support the industry in achieving its goals.For more information about the [Company Name] Mud Gas Separator and their complete range of drilling solutions, visit [website].

Mud Cleaner and Desilter Equipments for China Oil and Gas Industry

China Mud Cleaner and Mud DesilterChina has always been known for its innovation and advancement in technology, and this is no different when it comes to the oil and gas industry. With the increasing demand for efficient drilling operations, China has developed state-of-the-art equipment to meet these demands. One of the key players in this industry is a leading company in China, specializing in the production of high-quality Mud Cleaner and Mud Desilter.The Mud Cleaner and Mud Desilter are essential components in the drilling process, as they are used to remove solid particles and impurities from the drilling mud, ensuring smooth and efficient drilling operations. These machines play a crucial role in maintaining the integrity of the drilling fluid by separating out the solids and allowing the clean mud to be reused.The Mud Cleaner is a combination of a desander, desilter, and a shale shaker, providing a more efficient and compact solution for removing solids from the drilling mud. It is designed to effectively separate and remove the solid particles from the drilling fluid, allowing for the reuse of the clean mud and reducing waste.On the other hand, the Mud Desilter is designed to remove fine solids from the drilling mud, ensuring that the drilling fluid remains in optimal condition for the drilling process. By using hydrocyclones, the Mud Desilter is able to efficiently separate the fine solids from the drilling mud, ensuring that the drilling operation runs smoothly and effectively.The company behind these innovative products is a leading manufacturer and supplier of drilling equipment, with a strong focus on research and development. With cutting-edge technology and a commitment to quality, the company is dedicated to providing solutions that meet the evolving needs of the oil and gas industry.The company's Mud Cleaner and Mud Desilter are designed with the latest advancements in technology, ensuring high performance, efficiency, and reliability. These machines are also designed to withstand the harsh conditions of drilling operations, making them a durable and long-lasting solution for the industry.In addition to their innovative products, the company also provides exceptional customer service and technical support, ensuring that their clients receive the necessary assistance and guidance for their drilling operations. With a team of experienced professionals, the company is able to offer customized solutions to meet the specific requirements of their clients, further reinforcing their commitment to excellence.The company's Mud Cleaner and Mud Desilter have been widely recognized and well-received in the oil and gas industry, with a strong track record of successful installations and operations. Their dedication to quality, innovation, and customer satisfaction has earned them a solid reputation in the industry, making them a trusted and reliable partner for drilling equipment.As the demand for efficient drilling operations continues to grow, the company remains at the forefront of technological advancements, continuously improving and expanding their product line to meet the evolving needs of the industry. With a focus on quality, reliability, and performance, the company continues to set the standard for drilling equipment in the oil and gas industry.In conclusion, China's Mud Cleaner and Mud Desilter, developed by a leading company in the industry, provide a cutting-edge solution for the removal of solid particles and impurities from drilling mud. With a strong focus on quality, innovation, and customer satisfaction, the company has solidified its position as a trusted and reliable partner for drilling equipment in the oil and gas industry. Their commitment to excellence and continuous advancements in technology make them a key player in the industry, ensuring smooth and efficient drilling operations for their clients.

Discover the Latest Innovations in Sedimentation Centrifuges and Decanter Centrifuges from China

China Sedimentation Centrifuge and Decanter Centrifuge Changing the Game in Separation TechnologyChina sedimentation and decanter centrifuges have taken the separation technology to new heights with their state-of-the-art features and advanced capabilities. The technology has come a long way since its development, and the modern-day centrifuges are a result of years of technological evolution and innovation.Sedimentation CentrifugeA sedimentation centrifuge, commonly known as a clarifier, is used to separate solid particles from liquids. Sedimentation is one of the most efficient methods of separation, and the centrifuge enhances the process by providing a faster and more precise separation.The sedimentation process involves introducing a mixture of liquid and solid particles into the centrifuge. The rotational force created by the spinning motion causes the denser particles to settle at the bottom, creating a sediment layer.The decanter centrifugeThe decanter centrifuge, on the other hand, is used to separate a liquid from another liquid or solid. It works on the principle of centrifugal force, where the mixture is introduced into a horizontal bowl, rapidly spinning to create a high gravitational force.The centrifugal force separates the two liquids by creating a boundary layer where the lighter liquid is pushed to the outer edge of the bowl, and the denser liquid or solid stays towards the center.Advancements in TechnologyChina has been at the forefront of technological advancements in centrifuge technology, with numerous innovative features that are setting new standards in the market.One such technological advancement is the ability to continuously feed and discharge the mixture through the process, without interrupting the cycle. This feature reduces the downtime and increases the throughput of the centrifuge, significantly improving the efficiency of the machine.Another advancement is the automated control system, allowing for remote monitoring and control of the centrifuge, reducing the need for manual intervention and increasing the safety of the operation.Furthermore, the modern-day centrifuges offer high-performance motors and bearings, allowing for higher speeds and power outputs. This translates to faster separation times and a higher capacity for processing.Company IntroductionsMany Chinese companies have been successful in developing advanced centrifuge technology, all having a unique set of features, catering to a diverse range of industrial needs.For example, Zhejiang Baolong has developed some of the most advanced sedimentation centrifuges, offering an extensive range of features, including auto-cake discharge, self-washing, and remote control operation.Similarly, Liaoyang Hongji Machinery Co Ltd has a world-class decanter centrifuge with advanced sealing technology and a modular construction design, making it easy to maintain and repair.Another major player in the market is Nanjing FiveMen Machine Co Ltd, known for its high-performance centrifuges that offer exceptional separation speed and efficiency. The company focuses on providing customized solutions for specific industrial needs.In ConclusionThe advancements in sedimentation and decanter centrifuges have transformed the separation technology market, creating faster and more efficient machines that cater to specific industrial needs. China's contribution to the industry's technological evolution is significant, with companies like Zhejiang Baolong, Liaoyang Hongji Machinery Co Ltd, and Nanjing FiveMen Machine Co Ltd at the forefront of innovation. With continued advancements in technology, the future of centrifuge technology looks promising, offering even more advanced capabilities and efficient solutions for industries worldwide.

Optimizing Petroleum Solids Control Mud Tanks: Enhancing Drilling Waste Management and Mud Circulation

Title: Drilling Mud Circulation System: Enhancing Efficiency and Environmental SustainabilityIntroduction:In the oil and gas industry, drilling mud plays a crucial role in successful drilling operations. It helps control pressure, cool and lubricate the drill bit, and carry cuttings to the surface for proper disposal. To ensure the effective management of drilling mud, petroleum solids control mud tanks are utilized. These tanks, known as mixing tanks, storage tanks, or supply tanks, facilitate the transportation and storage of mud between the wellhead and mud pumps. In this blog, we will explore the significance of drilling mud circulation systems and the various types of petroleum solids control mud tanks.1. The Importance of Drilling Mud Circulation System:The drilling mud circulation system is a vital component of any drilling operation. It ensures the functionality of the mud, maximizes drilling efficiency, and promotes safety in oilfield activities. This system assists in the following:- Pressure control: The mud exerts hydrostatic pressure, which balances the formation pressure, thus preventing blowouts.- Cooling and lubrication: The mud cools and lubricates the drill bit, increasing its lifespan and reducing downtime.- Cuttings removal: It carries the solid debris, or cuttings, out of the wellbore, minimizing the risk of clogging and preserving the integrity of the drilling process.- Wellbore stability: Drilling mud helps form a protective barrier, preventing well collapse and maintaining wellbore stability.2. Types of Petroleum Solids Control Mud Tanks:There are several types of petroleum solids control mud tanks designed for specific purposes within the drilling mud circulation system:- Replenishment tanks: These tanks store drilling mud additives and help maintain the required mud properties during drilling operations.- Metering tanks: They provide accurate measurements of drilling mud additives, ensuring precise control over the mud properties.- Trailer-mounted mud tanks: These portable tanks are designed for easy transportation to remote drilling locations, ensuring uninterrupted mud supply.- Cooling tanks: As the name suggests, these tanks cool down the drilling mud, preventing damage to the machinery and enhancing drilling efficiency.3. Advancing Environmental Sustainability:In recent years, the oil and gas industry has placed immense focus on minimizing its environmental impact. Drilling waste management has become a vital aspect of drilling mud circulation systems. These systems incorporate various techniques to ensure the responsible handling of drilling waste, including cuttings and used drilling fluids. Several approaches are being implemented to enhance waste management practices, such as:- Zero discharge systems: These systems enable the treatment and recycling of drilling mud, reducing the need for fresh mud and minimizing waste generation.- Advanced separation technology: Utilization of centrifuges, shakers, and filters helps separate and recover valuable drilling mud components while safely disposing of solids.- Environmental regulations and compliance: Governments worldwide are implementing stricter regulations to ensure proper waste disposal and minimize ecological impact.Conclusion:The drilling mud circulation system, supported by petroleum solids control mud tanks, is instrumental in oil and gas drilling. Efficient management of drilling mud not only optimizes drilling operations but also contributes to environmental sustainability. The industry's increasing focus on waste management and environmental responsibility highlights the importance of utilizing advanced technologies and complying with regulations. By adopting these practices, drilling companies contribute to a safer, greener, and more sustainable future.[Keywords: Drilling Mud Circulation System, Petroleum Mud Tank, Drilling Waste Management, Oil-Based Mud Treatment, Environmental Sustainability, Waste Disposal, Zero Discharge Systems, Separation Technology, Environmental Regulations]

New Mixing Hopper Technology Offers Improved Efficiency

Venturi Mixing Hopper, an innovative solution for efficient material mixing, has rapidly gained popularity in the manufacturing industry. This technology has revolutionized the way materials are mixed, ensuring a consistent and homogeneous blend for various applications. The Venturi Mixing Hopper is designed and manufactured by a leading company that specializes in providing solutions for material handling and processing.{Company Name} has been at the forefront of manufacturing innovative equipment for the materials industry for over two decades. The company is dedicated to providing high-quality solutions that optimize material handling processes and improve overall operational efficiency. With a team of experienced engineers and experts, {Company Name} has continuously strived to develop cutting-edge technologies that meet the evolving needs of its customers.The Venturi Mixing Hopper is one such innovative product that has been designed to address the challenges associated with traditional material mixing methods. The technology is based on the Venturi effect, which involves the use of a converging-diverging nozzle to create a low-pressure zone that draws in and mixes the materials. This unique design ensures thorough and efficient mixing, with minimal energy consumption.One of the key features of the Venturi Mixing Hopper is its ability to handle a wide range of materials, including powders, granules, and other bulk solids. This versatility makes it an ideal solution for various industries, such as food processing, pharmaceuticals, chemicals, and construction. The technology can be customized to meet specific requirements, ensuring that it can effectively mix materials of different particle sizes and densities.In addition to its versatility, the Venturi Mixing Hopper offers several other benefits that contribute to its growing popularity in the industry. The technology is known for its rapid mixing capabilities, allowing for a quick and efficient blending process. This not only saves time but also reduces the overall production costs.Furthermore, the Venturi Mixing Hopper is designed to minimize material segregation and degradation, ensuring that the integrity of the blend is maintained throughout the process. This is particularly important for industries that require precise and consistent material mixtures, such as pharmaceutical manufacturing.Another key advantage of the Venturi Mixing Hopper is its compact design and ease of integration into existing production lines. The technology is engineered to be space-efficient, making it suitable for both new installations and retrofits. Its user-friendly interface and automated operation further simplify its use, minimizing the need for manual intervention and oversight.The Venturi Mixing Hopper is also designed with durability and reliability in mind, ensuring minimal maintenance requirements and long-term performance. This makes it a cost-effective solution for businesses looking to improve their material mixing processes without incurring excessive operational expenses.As the demand for efficient material mixing solutions continues to grow, the Venturi Mixing Hopper has emerged as a game-changer in the industry, offering a reliable and sustainable solution for businesses of all sizes. Its innovative design and advanced capabilities have positioned it as a leading technology in the field of material handling and processing, catering to the evolving needs of the modern manufacturing landscape.With a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted partner for businesses seeking to enhance their material handling processes. The company's commitment to innovation and customer satisfaction has driven the development of technologies like the Venturi Mixing Hopper, setting new standards for performance and efficiency in the industry.In conclusion, the Venturi Mixing Hopper represents a significant advancement in material mixing technology, offering a reliable and efficient solution for businesses across various industries. With its unique design, versatility, and numerous benefits, this innovative technology has cemented its position as a leading solution for material handling and processing. {Company Name} continues to be a driving force behind the advancement of such groundbreaking technologies, further solidifying its reputation as a pioneer in the industry.

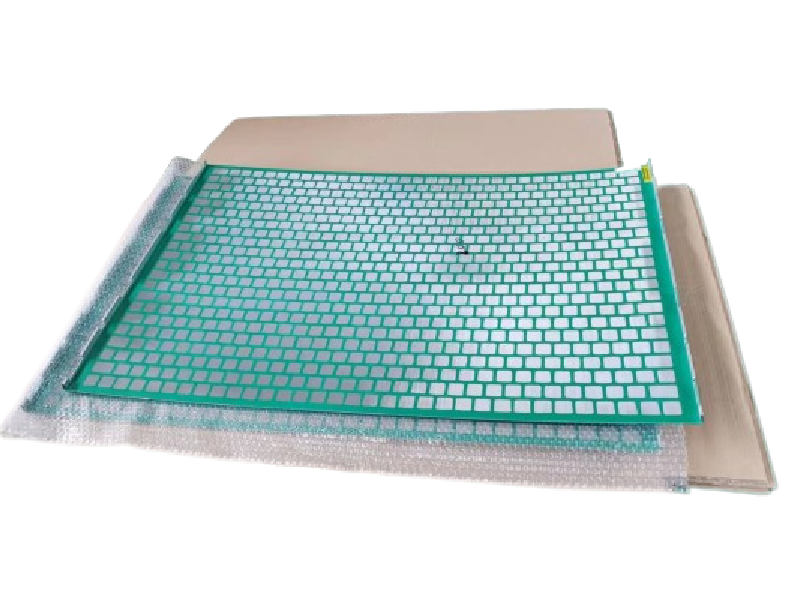

High-Quality 48 × 30 PWP Shaker Screen for Efficient Solid Control Operations

A leading provider of industrial equipment in the oil and gas industry has recently introduced the 48 × 30 PWP Shaker Screen to its product line. This state-of-the-art shaker screen is specifically designed to provide superior performance and efficiency in the separation of solids from drilling fluid.The 48 × 30 PWP Shaker Screen is constructed with multiple layers of stainless steel wire mesh that are tightly woven together to create a strong and durable screen. This design allows for maximum fluid throughput while effectively removing large solids from the drilling fluid. Additionally, the PWP (flat panel) design offers increased screen life and more accurate cut point control compared to traditional pyramid screens.One of the key features of the 48 × 30 PWP Shaker Screen is its ability to provide a larger screening area, which results in higher capacity and improved particle removal. This makes it an ideal solution for a wide range of drilling applications, including oil and gas exploration, horizontal directional drilling, and geothermal drilling.In addition to its exceptional performance, the 48 × 30 PWP Shaker Screen is also designed for easy installation and maintenance. The screen is compatible with most major shale shaker brands and can be quickly and easily replaced as needed. This allows for minimal downtime and increased productivity on the job site.The company behind the introduction of the 48 × 30 PWP Shaker Screen has been a trusted name in the oil and gas industry for over a decade. With a commitment to delivering high-quality products and exceptional customer service, they have become a preferred supplier for drilling contractors and operators worldwide.The company offers a comprehensive range of products and services, including shale shaker screens, mud pumps, solid control equipment, and drilling tools. Their team of experienced professionals is dedicated to meeting the unique needs of each customer and providing innovative solutions to improve drilling operations.In addition to their extensive product line, the company also offers custom manufacturing and engineering services to develop specialized equipment for specific drilling requirements. This allows them to deliver tailored solutions that enhance performance, reduce costs, and minimize environmental impact.The introduction of the 48 × 30 PWP Shaker Screen further solidifies the company's reputation as a leader in the industry. With a focus on continuous improvement and innovation, they are committed to staying at the forefront of technological advancements and providing their customers with the most advanced equipment available.As the oil and gas industry continues to evolve, the demand for efficient and reliable equipment remains constant. The 48 × 30 PWP Shaker Screen offers a cutting-edge solution to enhance drilling operations and improve overall productivity. With its advanced design and proven performance, it is sure to become a valuable asset for contractors and operators seeking to maximize efficiency and optimize their drilling processes.

Discover the Advantages of Ceramic Liner and Zirconia Cylinder Liners in China

Title: China's Ceramic Liner and Zirconia Cylinder Liners Boost Efficiency and Durability in ManufacturingIntroduction:In recent years, China has witnessed a rapid growth in advanced manufacturing technologies. As a part of this dynamic sector, China's Ceramic Liner and Zirconia Cylinder Liner industry have emerged as indispensable components in various industrial applications. Their superior attributes, including high wear resistance, exceptional mechanical strength, and improved performance, have revolutionized manufacturing processes across industries.Unveiling the China Ceramic Liner and Zirconia Cylinder Liners:China's Ceramic Liner and Zirconia Cylinder Liners have garnered significant attention due to their unique properties. These liners exhibit exceptional thermal stability, resistance to corrosive environments, and reduced friction, making them highly sought-after in machinery manufacturing, mining, petrochemical refining, and other vital industrial sectors.Ceramic Liner: A Game-Changer in Industrial ManufacturingThe Ceramic Liner industry in China has experienced substantial growth owing to its numerous advantages over traditional liner materials. These liners, often made from alumina ceramics, exhibit outstanding hardness and high-temperature resistance, making them ideal for applications in demanding environments. Moreover, Ceramic Liners possess exceptional wear resistance, ensuring extended durability and reduced maintenance costs.One of the key merits of Ceramic Liners is their ability to effectively minimize friction, resulting in reduced energy consumption and enhanced operational efficiency. Manufacturers across various sectors have embraced these liners, witnessing improvements in equipment longevity and decreased system downtime.Leading the Zirconia Cylinder Liner Innovations:China's Zirconia Cylinder Liner industry has emerged as an integral part of the automotive and machinery manufacturing sectors. Zirconia Cylinder Liners, made from advanced zirconium oxide ceramics, have revolutionized engine efficiency and durability. These liners exhibit reduced friction, outstanding thermal insulation properties, and exceptional resistance to wear, corrosion, and thermal shock.Automobile manufacturers worldwide have recognized the significance of Zirconia Cylinder Liners in improving fuel efficiency and reducing emissions. As a result, China has become a major supplier of Zirconia Cylinder Liners, catering to the global automotive industry's increasing demand.Surpassing Industry Standards:China's Ceramic Liner and Zirconia Cylinder Liner manufacturers have continuously focused on surpassing industry standards. By leveraging advanced manufacturing techniques, stringent quality control procedures, and cutting-edge technologies, these manufacturers have developed innovative solutions to meet diverse customer requirements.In addition to their high-performance characteristics, China's Ceramic Liner and Zirconia Cylinder Liner manufacturers prioritize the delivery of customized products to suit various industrial needs. By collaborating with research institutions, they constantly strive for improvements in materials science and engineering, resulting in enhanced product durability and reliability.Global Impact and Future Prospects:China's Ceramic Liner and Zirconia Cylinder Liner industry have achieved global recognition and are experiencing substantial growth in international markets. The exceptional quality, cost-effectiveness, and adaptability of these liners have made China a world leader in this sector.Furthermore, with the ongoing advancements in additive manufacturing, China aims to revolutionize the production process of Ceramic Liners and Zirconia Cylinder Liners. Novel manufacturing techniques, such as 3D printing, are expected to further enhance the versatility, efficiency, and affordability of these liners, cementing China's dominance in the global market.Conclusion:China's Ceramic Liner and Zirconia Cylinder Liner industry have fueled advancements in manufacturing processes, optimizing efficiency and durability across various sectors. The exceptional attributes of these liners, including wear resistance, thermal stability, and reduced friction, have propelled their adoption in machinery manufacturing, refining, and automotive sectors worldwide. China's commitment to innovation, stringent quality control, and customized solutions ensure that its Ceramic Liners and Zirconia Cylinder Liners continue to remain at the forefront of global manufacturing technologies.

Solid Liquid Separator and 3-Phase Separation Filter for Industrial Use in China

China Solid Liquid Separator and 3-Phase Separation FilterIn the world of industrial manufacturing, the need for efficient and reliable solid-liquid separation solutions is paramount. This is where the China Solid Liquid Separator and 3-Phase Separation Filter, developed by [company name], comes into play. This innovative product offers a range of benefits to industries such as wastewater treatment, food processing, mining, and oil and gas production, making it a vital tool for businesses worldwide.The China Solid Liquid Separator and 3-Phase Separation Filter is designed to effectively separate solid and liquid components from a mixture, providing a high level of efficiency and precision. By utilizing advanced filtration technology, this product is able to remove contaminants and impurities from a variety of substances, resulting in a cleaner and more refined end product.One of the key features of the China Solid Liquid Separator and 3-Phase Separation Filter is its versatility. This product is capable of handling a wide range of materials, including sludge, slurries, and other complex mixtures. This flexibility makes it an ideal solution for industries with diverse separation needs, allowing for seamless integration into existing production processes.In addition to its solid-liquid separation capabilities, the China Solid Liquid Separator and 3-Phase Separation Filter also offers a unique 3-phase separation function. This feature allows for the simultaneous extraction of oil, water, and solid particles from a mixture, further enhancing its utility in industries such as oil and gas production.[company name] is at the forefront of the development and manufacturing of innovative separation solutions. With a strong focus on research and development, the company has consistently delivered cutting-edge products that address the evolving needs of modern industries.The China Solid Liquid Separator and 3-Phase Separation Filter is a testament to [company name]'s commitment to excellence and innovation. By leveraging the latest technological advancements, the company has created a product that sets a new standard for solid-liquid separation, offering unmatched performance and reliability.As a leading provider of separation solutions, [company name] is dedicated to supporting its customers with top-quality products and exceptional service. The China Solid Liquid Separator and 3-Phase Separation Filter is backed by the company's extensive technical expertise, ensuring that customers receive the support they need to maximize the benefits of this innovative product.In conclusion, the China Solid Liquid Separator and 3-Phase Separation Filter represents a significant advancement in solid-liquid separation technology. With its exceptional performance, versatility, and 3-phase separation capabilities, this product is poised to make a lasting impact on a wide range of industries. Backed by [company name]'s unwavering commitment to excellence, the China Solid Liquid Separator and 3-Phase Separation Filter is set to become a cornerstone of modern industrial manufacturing.

High-Quality Mini and Mixing Agitators from China

China Mini Agitator and Mixing Agitator Made Available to Global MarketChina-based company, [Company Name], has announced the availability of their mini agitator and mixing agitator to the global market. These high-quality industrial agitators are designed to provide efficient mixing and agitation solutions for various industries including chemical, pharmaceutical, food and beverage, and many others.With a focus on innovation and quality, [Company Name] has gained a reputation for producing reliable and durable industrial equipment. The mini agitator and mixing agitator are the latest additions to their product line, and have been met with great enthusiasm from customers and partners around the world.The mini agitator is a compact and versatile solution for small-scale mixing applications. It is designed to fit into tight spaces and can be easily integrated into existing production lines. Despite its small size, the mini agitator is capable of delivering powerful agitation, making it suitable for a wide range of industries.On the other hand, the mixing agitator is a larger and more robust solution for industrial mixing applications. It is capable of handling large volumes of materials and is designed to meet the rigorous demands of industrial production. With its advanced mixing technology, the mixing agitator ensures thorough and consistent blending of materials, resulting in high-quality end products.Both the mini agitator and mixing agitator are equipped with advanced control systems that allow for precise adjustment of speed, agitation intensity, and other parameters. This level of control ensures that users can achieve the desired mixing results with ease and accuracy.In addition to their superior performance, the mini agitator and mixing agitator also boast a high level of reliability and durability. [Company Name] has utilized high-quality materials and rigorous manufacturing processes to ensure that their agitators can withstand the demands of industrial use and maintain consistent performance over time.[Company Name] has made a commitment to providing exceptional customer support for their products, and the mini agitator and mixing agitator are no exception. Customers can expect comprehensive technical assistance, spare parts availability, and maintenance services to ensure that their agitators continue to operate at peak efficiency.The availability of the mini agitator and mixing agitator to the global market represents a significant step for [Company Name]. By offering their high-quality industrial equipment to customers around the world, the company aims to establish itself as a leading provider of mixing and agitation solutions on a global scale."We are very excited to introduce our mini agitator and mixing agitator to the global market," said [Spokesperson Name], [Title] of [Company Name]. "These products represent the culmination of our dedication to innovation and quality, and we are confident that they will meet the needs of customers in various industries."With the introduction of the mini agitator and mixing agitator, [Company Name] is poised to make a significant impact in the global industrial equipment market. Customers in need of reliable and efficient mixing and agitation solutions can now turn to [Company Name] for high-quality products that meet the highest standards of performance and durability.

Efficient Mud Cleaning Machine for Industrial Use

The demand for efficient and cutting-edge technology in the oil and gas industry has been on the rise in recent years. In response to this, (Company Name), a leading provider of oilfield equipment and services, has announced the launch of their latest innovation - the Mud Cleaning Machine.The Mud Cleaning Machine is a state-of-the-art equipment that is designed to effectively clean mud, remove solids, and separate valuable drilling fluids during the oil and gas drilling process. This machine has been meticulously engineered to offer superior performance, maximum efficiency, and cost-effectiveness, making it an essential tool for oil and gas companies looking to enhance their drilling operations.With an increasing focus on sustainability and environmental responsibility, the Mud Cleaning Machine also features advanced technology that ensures minimal waste and environmental impact. (Company Name) is proud to offer this innovative solution to the industry, which embodies their commitment to delivering high-quality, environmentally conscious products and services.Furthermore, the Mud Cleaning Machine is part of (Company Name)'s comprehensive suite of oilfield equipment and services, which includes a range of products such as shale shakers, centrifuges, and pumps. Each product is designed and manufactured with the latest technology and industry standards in mind, ensuring superior performance and reliability in all drilling operations.In addition to their cutting-edge equipment, (Company Name) is distinguished by their team of experienced and highly skilled engineers, technicians, and support staff. With a wealth of industry knowledge and expertise, they provide custom solutions and technical support to meet the unique needs of their clients and ensure seamless integration of their products into existing operations.(Company Name) is a global leader in providing comprehensive oilfield equipment and services, with a commitment to delivering innovative, reliable, and environmentally conscious solutions to the oil and gas industry. Their dedication to excellence and customer satisfaction has earned them a solid reputation and a loyal client base worldwide.The launch of the Mud Cleaning Machine is a testament to (Company Name)'s ongoing commitment to innovation and excellence. This state-of-the-art equipment promises to revolutionize the drilling process, offering unparalleled efficiency and performance that will ultimately translate to cost savings and improved productivity for their clients.In conclusion, the introduction of the Mud Cleaning Machine is a significant milestone for (Company Name) and the oil and gas industry as a whole. This cutting-edge equipment, combined with the company's expertise and dedication to delivering high-quality, environmentally conscious solutions, has the potential to make a lasting impact in the field of oil and gas drilling. It is a reflection of (Company Name)'s commitment to driving innovation and excellence in the industry, and a testament to their ongoing leadership and success as a global provider of oilfield equipment and services.