Exploring the Efficiency of Mud Shale Shakers in China's Drilling Industry

By:Admin

Shale shakers are used to separate drilling cuttings from drilling mud, which is essential for the smooth functioning of oil drilling operations. China Mud Shale Shakers and Mud Shale Shaker are two of the leading manufacturers of shale shakers. Their high-quality products have won the hearts of many clients in the oil and gas industry, including drilling contractors, rig manufacturers, and oil companies. This article will take a closer look at these two companies and their products.

China Mud Shale Shakers

China Mud Shale Shakers was established in 1954 and is one of the oldest shale shaker manufacturers in China. The company is headquartered in Tangshan, Hebei Province. It has a state-of-the-art manufacturing plant and a team of highly qualified engineers and technicians. The company is committed to providing its clients with innovative and efficient solutions for drilling waste management.

China Mud Shale Shakers offers a wide range of shale shakers, including linear motion shale shakers, balanced elliptical motion shale shakers, and dual motion shale shakers. All of their products are designed to handle high-capacity solids and offer low maintenance costs. The company has a strong focus on research and development and has several patents to its name.

One of the flagship products of China Mud Shale Shakers is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique screen deck with a three-layer structure. The top layer is used for coarse screening, the middle layer for fine screening, and the bottom layer for final recovery of the mud. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.

Mud Shale Shaker

Mud Shale Shaker was established in 2014 and is a relatively new shale shaker manufacturer. The company is headquartered in Beijing, China, and has a modern manufacturing facility. Mud Shale Shaker offers a range of high-quality shale shakers, including linear motion shale shakers and balanced elliptical motion shale shakers.

Mud Shale Shaker's products are designed to handle high-capacity solids, offer low maintenance costs, and are easy to operate. The company has a strong focus on customer service and aims to build long-term relationships with its clients. Mud Shale Shaker's products have won many accolades and are well-regarded in the oil and gas industry.

One of the flagship products of Mud Shale Shaker is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique dual-motor configuration, which ensures high screening efficiency and reduced vibration. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.

Conclusion

In conclusion, China Mud Shale Shakers and Mud Shale Shaker are two highly respected shale shaker manufacturers in China. Both companies have a strong focus on innovation, quality, and customer service. They offer a range of high-quality shale shakers that are designed to handle high-capacity solids and offer low maintenance costs. Whether you are a drilling contractor, rig manufacturer, or an oil company, China Mud Shale Shakers and Mud Shale Shaker can provide you with innovative and efficient solutions for drilling waste management.

Company News & Blog

Efficient Drilling Mud Cleaning System for Oil and Gas Operations

The use of drilling mud cleaning systems has become increasingly important in the oil and gas industry as companies strive to improve the efficiency and environmental impact of their drilling operations. One company at the forefront of this technology is {Company X}, a leading provider of innovative drilling equipment and solutions.{Company X} was established in 2005 and has since become a trusted name in the industry, known for their commitment to quality, reliability, and environmental sustainability. They offer a wide range of products and services, including drilling mud cleaning systems that are designed to efficiently remove solids and other impurities from drilling mud, allowing for the recycled use of the mud and minimizing waste.The drilling mud cleaning system offered by {Company X} is equipped with advanced technology and a high-performance design that enables it to effectively separate and remove solids, ensuring that the drilling mud remains optimal for ongoing drilling operations. This not only improves the efficiency of the drilling process but also helps to lower the overall environmental impact by reducing the amount of waste generated.One of the key features of {Company X}'s drilling mud cleaning system is its modular design, which allows for easy customization and integration into existing drilling operations. This flexibility makes it suitable for a wide range of drilling applications, from onshore to offshore and from conventional to unconventional drilling methods.In addition to its innovative technology, {Company X} also prides itself on its commitment to providing exceptional service and support to its customers. Their team of experienced engineers and technicians are dedicated to ensuring that each drilling mud cleaning system is installed, operated, and maintained to the highest standards, maximizing its performance and longevity.The importance of effective drilling mud cleaning systems cannot be understated, particularly in the current climate of increasing environmental awareness and regulations. By investing in a high-quality system from {Company X}, drilling companies can not only improve their operational efficiency and reduce costs but also demonstrate their commitment to sustainability and responsible environmental stewardship.Furthermore, with an ever-growing demand for energy and natural resources, the need for efficient and sustainable drilling practices will only continue to increase. By choosing {Company X} as their partner, drilling companies can rest assured that they are investing in a solution that is not only technologically advanced but also aligned with the principles of environmental responsibility and sustainability.As the industry continues to evolve, {Company X} remains dedicated to advancing the state-of-the-art in drilling equipment and solutions, including drilling mud cleaning systems. Their ongoing commitment to innovation and excellence ensures that they will remain a trusted and valued partner for drilling companies around the world.In conclusion, the drilling mud cleaning system offered by {Company X} represents a significant advancement in the field of drilling technology, providing a solution that is not only efficient and effective but also environmentally responsible. With their track record of excellence and commitment to customer satisfaction, {Company X} stands as a leader in the industry, poised to meet the evolving needs of the oil and gas sector for years to come.

Highly-Durable Mud Gun Nozzle Provides Effective Solutions for Industrial Operations

Mud Gun Nozzle, a vital component in the oil and gas industry, plays a crucial role in the drilling process. The mud gun nozzle is used to spray drilling mud, a mixture of water, clay, and other chemicals, into the drilling well to lubricate the drill bit, carry rock cuttings to the surface, and maintain pressure in the well. It is an essential tool for optimizing the drilling process and ensuring the success of oil and gas extraction operations.In this context, one company, which is a leading manufacturer of drilling equipment and tools, has recently launched its latest mud gun nozzle, designed to enhance drilling efficiency and reliability. With over 20 years of experience in the industry, the company has become a trusted name in providing high-quality products and innovative solutions for oil and gas exploration and production.The new mud gun nozzle features a cutting-edge design that offers improved performance and durability. Its advanced nozzle configuration allows for better spray coverage and distribution of drilling mud, resulting in more efficient drilling operations. The material used in the construction of the nozzle is highly resistant to corrosion and abrasion, ensuring long-lasting performance even in the harshest drilling environments.Furthermore, the company's mud gun nozzle is engineered to provide easy maintenance and servicing, reducing downtime and operational costs for drilling companies. The design incorporates quick-connect fittings and accessible components, allowing for effortless disassembly and reassembly when necessary. This user-friendly approach reflects the company's commitment to delivering practical and reliable solutions to its customers.In addition to the superior design and functionality, the mud gun nozzle is also backed by the company's renowned technical support and customer service. The company's team of experienced engineers and technicians are available to provide assistance with installation, maintenance, and troubleshooting, ensuring that customers can maximize the performance of the mud gun nozzle and their overall drilling operations.As part of its dedication to quality and customer satisfaction, the company conducts rigorous testing and quality assurance procedures to ensure that its mud gun nozzles meet the highest standards of performance and reliability. This attention to detail and commitment to excellence have earned the company the trust and loyalty of numerous drilling companies around the world.The launch of the new mud gun nozzle represents the company's ongoing efforts to innovate and improve its product offerings to meet the evolving needs of the oil and gas industry. By leveraging its expertise and technical capabilities, the company aims to continue playing a significant role in advancing drilling technologies and supporting the exploration and production activities of its customers.In conclusion, the introduction of the new mud gun nozzle by the company signifies a significant development in the realm of drilling equipment and tools for the oil and gas industry. With its advanced design, exceptional performance, and unwavering commitment to customer support, the company continues to solidify its position as a leading provider of reliable and innovative solutions for drilling operations. As the industry continues to evolve, the company remains poised to meet the challenges and demands of the future, driven by its dedication to excellence and customer satisfaction.

Efficient Vertical Cutting Dryer for Improved Solids Control

The revolutionary Vertical Cutting Dryer, developed by a leading provider of drilling waste management solutions, is set to transform the oil and gas industry. This innovative technology is designed to efficiently remove drilled solids from drilling fluids, providing significant cost savings and environmental benefits for companies operating in the sector.The Vertical Cutting Dryer is a key component of the company's comprehensive range of drilling waste management equipment, which is used to separate and recover valuable drilling fluids from solid waste materials. The dryer is capable of processing large volumes of drilled solids, effectively reducing waste volumes and minimizing environmental impact.Designed with a vertical configuration, the cutting dryer utilizes centrifugal force to remove excess liquid from drill cuttings, resulting in drier cuttings and improved overall drilling fluid recovery. The machine's advanced design also reduces the need for dilution and disposal of drilling fluids, leading to substantial cost savings for operators.In addition to its cost-saving benefits, the Vertical Cutting Dryer is also an environmentally friendly solution for managing drilling waste. By effectively separating solids from liquids, the dryer helps to minimize the volume of waste material that requires disposal, reducing the overall environmental footprint of drilling operations.The company behind the Vertical Cutting Dryer is a global leader in providing innovative and sustainable solutions for managing drilling waste. With a strong focus on research and development, the company has continuously pushed the boundaries of technological innovation in the oil and gas industry, delivering products that optimize operational efficiency while reducing environmental impact.The company's extensive experience and expertise in the field of drilling waste management have positioned it as a trusted partner for oil and gas companies seeking sustainable and cost-effective solutions. By offering a comprehensive range of equipment and services, including the Vertical Cutting Dryer, the company helps its clients meet and exceed regulatory requirements while enhancing their overall operational performance.The Vertical Cutting Dryer has already garnered attention from industry experts and operators, who recognize its potential to revolutionize drilling waste management processes. By incorporating this cutting-edge technology into their operations, companies can expect to see improved efficiency, reduced costs, and enhanced environmental stewardship.In a statement, a spokesperson for the company commented, "We are thrilled to introduce the Vertical Cutting Dryer to the market. This innovative technology represents a significant leap forward in the field of drilling waste management, and we believe it will deliver substantial benefits to our clients. By offering a more efficient and sustainable solution for processing drilling waste, we are proud to support our customers in their efforts to operate responsibly and profitably."As the oil and gas industry continues to prioritize sustainability and operational efficiency, the Vertical Cutting Dryer is poised to become an indispensable tool for companies seeking to optimize their drilling waste management processes. With its advanced technology and proven performance, this innovative equipment is set to make a lasting impact on the sector, delivering tangible benefits for both companies and the environment.

Efficient and Powerful Submersible Slurry Pump- A Game-Changer in Pumping Solutions

Title: Groundbreaking Submersible Slurry Pump Revolutionizes Industrial Dredging OperationsIntroduction:Innovative engineering company {} has recently unveiled a game-changing advancement in the field of industrial pumping with their revolutionary Submersible Slurry Pump. This cutting-edge technology is poised to transform dredging operations across a broad range of industries, from mining and construction to oil and gas. With its unparalleled efficiency and durability, this pump is set to streamline operations, minimize downtime, and significantly enhance productivity.Section 1: The Submersible Slurry Pump's Unmatched PerformanceThe Submersible Slurry Pump developed by {} stands out among its competitors due to its outstanding performance capabilities. Its design enables it to handle high-viscosity, abrasive, and corrosive materials, ensuring reliable pumping operations in the harshest environments. The pump's highly efficient motor delivers improved energy consumption, reducing costs and contributing to a greener future.Section 2: Features and TechnologyThe Submersible Slurry Pump is equipped with state-of-the-art features that revolutionize the pumping industry. Its robust construction, built with high-quality materials, ensures long service life even under demanding conditions. The pump's innovative impeller design enables it to handle larger solids with ease, preventing clogging and reducing maintenance needs.One of the most impressive features of this groundbreaking pump is its dynamic sealing system. The advanced sealing technology allows the pump to operate in submerged conditions, preventing leakage and avoiding costly damage. This feature alone sets it apart from traditional slurry pumps, making it an indispensable tool in challenging pumping applications.Section 3: Versatility and ApplicationsThe versatility of the Submersible Slurry Pump opens up a wide range of applications across diverse industries. In mining operations, it effectively manages slurry transportation, improving efficiency and reducing operational costs. For the construction industry, this pump proves invaluable for excavation and dewatering processes, ensuring uninterrupted workflow and increased project timelines.Furthermore, in the oil and gas sector, the Submersible Slurry Pump proves to be a game-changer. It efficiently handles drilling mud, mitigating risks associated with fluid transportation and minimizing environmental impacts. Its versatile design also enables it to excel in wastewater treatment and power plant applications, positioning itself as an essential tool for achieving sustainable and efficient operations.Section 4: The Future of PumpingWith the introduction of the Submersible Slurry Pump, {} has set a new standard for industrial pumping technology. The future of pumping operations now lies in the hands of this groundbreaking innovation. By combining efficiency, durability, and versatility, this pump delivers exceptional performance across a plethora of industries, transforming the way we approach pumping applications.The Submersible Slurry Pump developed by {} is not only a marvel of engineering but also a testament to the company's commitment to providing cutting-edge solutions for the most challenging projects. Their dedication to research and development has yielded a remarkable product that empowers industries worldwide.Conclusion:With its unmatched performance, innovative features, and a wide range of applications, the Submersible Slurry Pump represents a groundbreaking advancement in industrial pumping technology. {}'s commitment to revolutionizing the industry ensures that projects involving slurry pumping operations can now be completed more efficiently, cost-effectively, and sustainably. As the future of pumping takes shape, this remarkable pump positions itself as an indispensable tool for industries seeking enhanced productivity and environmental responsibility.

Top Mini Agitator and Mixing Agitator Options in China

China Mini Agitator and Mixing Agitator (need remove brand name) have quickly become the go-to solution for many industries in need of efficient and reliable mixing equipment. These agitators are designed to handle a wide range of viscosities and can be used in various applications, making them an ideal choice for many different industries.The China Mini Agitator and Mixing Agitator are both designed and manufactured by a leading company in the field of industrial mixing equipment. With years of experience and a strong commitment to innovation and quality, this company has earned a reputation for producing some of the most reliable and efficient agitators on the market.The Mini Agitator is a compact and powerful mixing solution that is perfect for small-scale operations or for use in confined spaces. Despite its small size, this agitator is capable of delivering high levels of torque and can easily handle a wide range of viscosities. This makes it an ideal choice for industries such as pharmaceuticals, chemicals, and food and beverage production.The Mixing Agitator, on the other hand, is a more versatile solution that is designed to handle larger volumes and a wider range of viscosities. This agitator can be easily customized to meet the specific needs of different industries, and its robust construction ensures that it can withstand the demands of even the most challenging applications. This makes it an ideal choice for industries such as petrochemicals, mining, and wastewater treatment.Both the Mini Agitator and the Mixing Agitator are designed with efficiency and reliability in mind. They are equipped with advanced features such as variable speed control, multiple agitator options, and easy-to-use controls, making them easy to operate and maintain. This ensures that businesses can enjoy consistent and reliable mixing performance, reducing downtime and increasing productivity.In addition to their impressive performance, the China Mini Agitator and Mixing Agitator are also designed with safety in mind. They are equipped with various safety features to ensure that they can be operated with peace of mind, and their robust construction ensures that they can withstand the demands of even the most challenging applications. This makes them an ideal choice for industries where safety is a top priority, such as pharmaceuticals and food production.As a leading company in the field of industrial mixing equipment, the company behind the China Mini Agitator and Mixing Agitator is committed to providing the highest levels of quality and customer satisfaction. They have a team of experienced engineers and technicians who work tirelessly to develop and manufacture innovative and reliable mixing solutions. This, coupled with their strong focus on customer service, has made them a trusted partner for businesses in a wide range of industries.In conclusion, the China Mini Agitator and Mixing Agitator are two of the most efficient and reliable mixing solutions on the market. With their advanced features, robust construction, and commitment to quality, they are the ideal choice for businesses in a wide range of industries. Whether it's for small-scale operations or large-scale industrial applications, these agitators are designed to deliver consistent and reliable performance, helping businesses to increase productivity and reduce downtime.

Basic Overview of Leak Testing Methods for Manufacturing Processes in China

Title: Leak Testing in Casting Processes: A Comprehensive Overview in ChinaIntroduction:Leak testing plays a critical role in ensuring the quality and reliability of various casting processes, including die casting, sand casting, and investment casting. By carefully inspecting and identifying any potential leaks or defects within cast components, manufacturers in China can deliver products of the highest standard. In this blog, we will explore the key aspects of leak testing in casting processes, with a focus on China's sand investment casting and coated sand investment castings. Throughout, we will emphasize the importance of leak testing, its benefits, and how it contributes to the success of these casting techniques in China.1. Importance of Leak Testing in Casting:Leak testing involves verifying the efficiency of cast components, confirming their ability to contain fluids, gases, or pressure. By identifying leaks, manufacturers ensure that their products meet stringent quality standards, while also minimizing the risk of potential failures that could cause harm to end-users or result in costly recalls. Leak testing is a crucial step in the production process, providing manufacturers with confidence in the reliability and safety of their castings.2. Leak Testing Methods:Various leak testing methods are employed in the casting industry, each catering to different requirements and casting processes. These techniques include pressure decay testing, helium leak testing, bubble testing, vacuum testing, and more. Depending on the casting process, such as sand investment casting or coated sand investment castings, specific leak testing methods are chosen to ensure accurate results.2.1 Sand Investment Casting Leak Testing:Sand investment casting is a widely used casting technique in China for complex components. To assess the integrity of sand investment castings, manufacturers typically employ pressure decay testing. This method involves pressurizing the casting and monitoring pressure decay over time. Any pressure drop indicates the presence of leaks, enabling manufacturers to identify and rectify issues promptly.2.2 Coated Sand Investment Casting Leak Testing:Coated sand investment casting, also known as shell molding casting, is another popular technique in China. Leak testing methods such as bubble testing or pressure decay testing are commonly employed. Bubble testing involves submerging castings in a solution and introducing air pressure, creating bubbles at leak points. Pressure decay testing, similar to sand investment casting, assesses pressure variations to detect leaks within the components.3. Advantages and Challenges in Leak Testing:Leak testing offers numerous advantages, including improved product quality, enhanced reliability, compliance with industry standards, and ultimately, customer satisfaction. It ensures the castings meet technical specifications and function effectively. However, challenges such as selecting the appropriate leak testing method and ensuring accurate and consistent results can arise. Manufacturers in China must carefully consider these factors during the leak testing process.Conclusion:Leak testing is an integral part of the casting industry in China, especially when it comes to sand investment casting and coated sand investment castings. By conducting comprehensive leak testing procedures, manufacturers can guarantee the reliability and quality of their cast components. Additionally, leak testing plays a significant role in meeting regulatory requirements and ensuring customer satisfaction. With continuous advancements in leak testing techniques and equipment, China's casting industry remains at the forefront of ensuring robust and flawless castings.

Ultimate Guide to Drilling Fluid Mud: What You Need to Know

Drilling Fluid Mud has been an integral part of the oil and gas industry for decades. It is used to lubricate drill bits, remove cuttings from the wellbore, and maintain pressure and stability during drilling operations. One industry leader in the production of drilling fluid mud is {Company Name}.{Company Name} has been in the business of providing high-quality drilling fluid mud and other related products for over 30 years. Their commitment to innovation and customer satisfaction has made them a trusted partner for many major oil and gas companies around the world.The key to {Company Name}'s success is their dedication to research and development. They invest heavily in state-of-the-art laboratories and testing facilities to ensure that their products meet the highest industry standards. As a result, their drilling fluid mud is known for its superior performance and reliability in even the most challenging drilling environments.In addition to their cutting-edge technology, {Company Name} places a strong emphasis on environmental responsibility. They constantly strive to develop products that minimize their impact on the environment, and they work closely with regulatory agencies to ensure that their operations are in compliance with all relevant laws and regulations.One of the company's most recent achievements is the development of a new line of drilling fluid mud that is specifically designed for use in deepwater drilling operations. This product has been rigorously tested and has already received positive feedback from industry experts. Its unique formulation allows it to maintain stability and performance even at extreme depths, making it an invaluable tool for companies involved in deepwater drilling projects.In addition to their commitment to quality and innovation, {Company Name} is also known for their outstanding customer service. Their experienced team of engineers and technicians are always available to provide technical support and assistance to their clients. Whether it's recommending the right product for a specific application or troubleshooting a problem on-site, {Company Name} is dedicated to helping their customers achieve success in their drilling operations.Furthermore, {Company Name} has a global presence, with distribution and support centers located in key regions around the world. This ensures that their customers have access to their products and services wherever they may be operating. Whether it's a remote drilling site in the middle of the ocean or a major production facility on land, {Company Name} is there to support their customers every step of the way.In conclusion, {Company Name} is a leading provider of drilling fluid mud and related products, with a proven track record of quality, innovation, and customer service. Their commitment to excellence and dedication to environmental responsibility make them a trusted partner for oil and gas companies around the world. With a strong focus on research and development, as well as a global presence, {Company Name} is well-positioned to continue meeting the needs of the industry for years to come.

High-quality Decanter Centrifuge for Sludge Dewatering in China

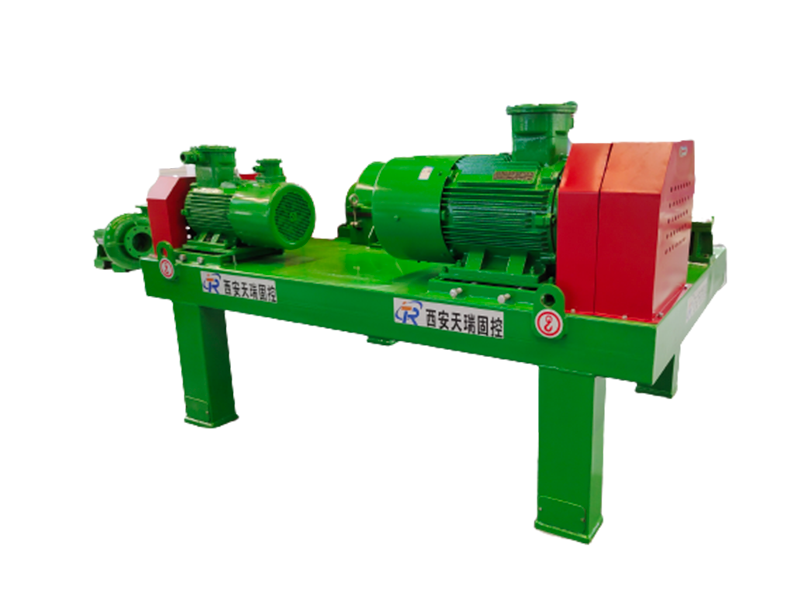

China Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge have become essential equipment in various industries such as wastewater treatment, food and beverage, pharmaceuticals, and mining, among others. These machines are known for their ability to separate solids from liquids, making them an indispensable tool for many businesses.One of the leading companies in the manufacturing of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is {}. Their dedication to quality and innovation has solidified their position as a top player in the industry. With a strong focus on research and development, they have been able to continuously improve their products, offering their customers cutting-edge solutions for their separation needs.With a wide range of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge models, the company is able to cater to the diverse requirements of different industries. Their equipment is designed to handle various materials, from sewage sludge to industrial wastes, and effectively separate the solid and liquid components. This not only helps in waste reduction but also in the recovery of valuable resources from the process.One of the key features of their Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is their high efficiency and low energy consumption. This not only reduces operational costs for the businesses but also makes the equipment more environmentally friendly. Additionally, the company also offers custom solutions for specific needs, ensuring that their customers get the perfect equipment for their applications.Furthermore, the company also provides excellent after-sales service, including installation, training, maintenance, and spare parts support. This ensures that their customers can maximize the performance and lifespan of their Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge, giving them peace of mind and confidence in their investment.In recent years, the demand for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge has been on the rise, driven by the increasing focus on environmental protection and resource recovery. With stricter regulations on waste disposal and a growing awareness of the importance of sustainability, businesses are turning to equipment like these to optimize their processes and minimize their impact on the environment.The global market for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is projected to continue growing, with a significant impact on industries such as wastewater treatment, food and beverage, and mining, among others. With their advanced technology and high-quality products, {} is well-positioned to capture a substantial share of this market and continue to be a leader in the industry.As businesses continue to prioritize efficiency, sustainability, and responsible waste management, the demand for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is only expected to increase. With their proven track record and commitment to excellence, {} is ready to meet this growing demand and help businesses worldwide achieve their separation and dewatering needs.In conclusion, the role of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge in various industries cannot be overstated. With their ability to effectively separate solids from liquids, these machines have become indispensable for businesses looking to optimize their processes and reduce their environmental footprint. With {}. as a leading manufacturer and provider of these equipment, businesses can look forward to high-quality solutions and excellent support for their separation and dewatering needs.

High-quality Urethane Panel for Various Applications

[Company Name], a leading manufacturer of high-quality industrial products, has recently announced the launch of their new TH48-30X.85MT Urethane Panel. This new addition to their extensive product line is expected to meet the growing demand for durable and reliable urethane panels in various industrial applications.The TH48-30X.85MT Urethane Panel is designed to provide exceptional performance and longevity in challenging environments. Made from high-grade urethane materials, this panel offers superior resistance to wear, impact, and abrasion, making it ideal for use in mining, aggregate, and other demanding industries. Its unique composition also ensures excellent flexibility and elasticity, allowing it to withstand heavy loads and harsh operating conditions.With a dimension of 48 inches by 30 inches and a thickness of 0.85 inches, the TH48-30X.85MT Urethane Panel is suitable for a wide range of applications, including screen decks, chute liners, and other material handling equipment. Its versatile design and customizable options make it a cost-effective solution for businesses looking to enhance the performance and longevity of their equipment.In addition to its exceptional durability, this urethane panel is also designed for easy installation and maintenance. Its lightweight construction and flexibility allow for quick and hassle-free fitting, reducing downtime and labor costs. Furthermore, its non-corrosive and non-conductive properties make it a safe and reliable choice for various industrial settings.[Company Name] takes pride in its commitment to quality and innovation. With decades of experience in the industry, they have established a reputation for delivering high-performance products that exceed customer expectations. The introduction of the TH48-30X.85MT Urethane Panel further demonstrates their dedication to providing cutting-edge solutions that address the evolving needs of their clients."We are excited to unveil our latest urethane panel offering, the TH48-30X.85MT," said [Spokesperson Name], [Position] at [Company Name]. "This new product exemplifies our ongoing efforts to deliver superior quality and reliability to our customers. We believe that the TH48-30X.85MT Urethane Panel will provide a competitive advantage to businesses seeking durable and cost-effective solutions for their operations."In line with their commitment to sustainability, [Company Name] ensures that their urethane panels are manufactured using eco-friendly processes and materials. By prioritizing environmental responsibility, they aim to contribute to a cleaner and greener industry while delivering top-notch products to their customers.The introduction of the TH48-30X.85MT Urethane Panel underscores [Company Name]'s dedication to staying at the forefront of technological advancements and industry trends. As they continue to expand their product offerings, they remain focused on delivering unwavering quality, performance, and value to their diverse clientele.In conclusion, the launch of the TH48-30X.85MT Urethane Panel marks another significant milestone for [Company Name] as they continue to reinforce their position as a leader in the industrial products market. With its exceptional durability, versatility, and ease of use, this new offering is poised to set a new standard for urethane panels in the industry. As businesses seek reliable and long-lasting solutions for their operations, [Company Name] remains dedicated to providing innovative products that meet and exceed customer expectations.

Optimizing Drilling Operations with the Revolutionary Mud Decanter Centrifuge

Title: Groundbreaking Drilling Mud Decanter Centrifuge Emerges as a Game Changer for the Oil and Gas IndustryIntroduction:In a breakthrough achievement, a leading technological firm has unveiled an innovative drilling mud decanter centrifuge that promises to revolutionize the oil and gas industry. With the ability to efficiently separate solids from drilling mud, this cutting-edge equipment is set to enhance drilling operations worldwide, improving overall productivity and reducing environmental impact. Let's delve deeper into the features and benefits of this remarkable device.Drilling Mud Decanter Centrifuge:This advanced drilling mud decanter centrifuge is designed to remove harmful solids from the drilling fluid, also known as drilling mud, allowing for a cleaner and more efficient drilling process. The centrifuge works on the principle of centrifugal force, separating solids based on their densities. The solids are separated from the drilling mud, resulting in clarified fluid that can be reused, reducing waste and minimizing the environmental footprint of drilling operations.Key Features and Benefits:1. Enhanced Efficiency:The drilling mud decanter centrifuge offers exceptional efficiency, with high-speed rotational capabilities ensuring rapid separation of solids from the drilling mud. This means drilling operations can continue uninterrupted, reducing downtime and boosting productivity.2. Improved Solids Control:This innovative equipment allows for precise control over the separation process, effectively removing fine solids and reducing the risk of equipment damage or blockage. This ensures smooth drilling operations, maximizing the lifespan of drilling tools and reducing maintenance costs.3. Cost-Effective:By recycling and reusing the clarified drilling mud, the decanter centrifuge significantly reduces the need for fresh drilling fluid. This not only saves costs associated with purchasing additional drilling mud but also minimizes waste disposal expenditure. The cost-effectiveness of this device is a considerable advantage for drilling companies.4. Environmental Friendliness:With the drilling mud decanter centrifuge, the environmental impact of drilling operations is significantly reduced. By efficiently separating and clarifying the drilling mud, the device enables reusing of the fluid, reducing the need for fresh water and minimizing waste generation. This promotes sustainable drilling practices, making it a valuable tool in the industry's quest for environmental responsibility.Company Introduction:The company responsible for this groundbreaking drilling mud decanter centrifuge is a renowned leader in the field of drilling equipment manufacturing. With a legacy of technological excellence and a commitment to innovation, they have established themselves as a trusted supplier to the oil and gas industry. Their years of experience and expertise have enabled the development of industry-leading equipment, revolutionizing drilling practices around the world.Conclusion:The introduction of the drilling mud decanter centrifuge marks a significant milestone in the oil and gas industry. With its remarkable ability to efficiently separate solids from drilling mud, this device offers improved efficiency, enhanced solids control, cost-effectiveness, and environmental friendliness. The innovative features of this equipment are set to elevate drilling operations to new heights and promote sustainable practices within the industry. As drilling continues to expand globally, this groundbreaking technology will undoubtedly play a vital role in shaping the future of the oil and gas sector.