HDD Drilling Fluid: A Comprehensive Guide to Enhance Drilling Operations

By:Admin

Based in Texas, Hdd drilling fluid is a carefully formulated drilling solution designed to cater to the specific needs of the drilling industry. The unique composition of this drilling fluid helps to improve lubrication, reduce friction, and decrease wear and tear on drilling equipment. Driven by innovation and technology, Hdd drilling fluid provides a cutting-edge solution that has been tested and proven to perform effectively, regardless of the environment.

"This is a game-changer for drilling operators," explained the marketing director at Hdd drilling fluid. "It simplifies drilling operations and provides an efficient solution, reducing the overall time, effort, and capital required for drilling. With our product, the drilling process is now smoother and more accurate, and we are happy to report a 99% success rate with it."

Indeed, Hdd drilling fluid has helped the drilling industry evolve, and has become an essential component in drilling operations. The company is known for providing the best value for money drilling fluid in the market and has been praised for its product's effectiveness across different categories.

"Hdd drilling fluid is a perfect example of what can be achieved with innovation and diligent work," stated the CEO. "Our team has been dedicated to providing an outstanding drilling solution, ensuring that we're meeting the high standards of our customers. We're proud of the impact our product has had on the drilling industry, making the drilling process more agile and cost-effective."

Hdd drilling fluid is eco-friendly and non-toxic, making it safe for drilling operations, even in the most sensitive environments. The company's commitment to the environment is evident in every aspect of its production process, from sourcing the raw material to the final products.

In addition to producing a reliable and effective drilling fluid, Hdd drilling fluid also provides excellent customer service. The company has a team of experienced drilling experts who provide dedicated customer care to ensure that their product is working at optimum levels at all times. With a 24/7 service hotline, the company can be easily reached, and any feedback or questions can be addressed promptly.

Hdd drilling fluid has continued to impact the drilling industry positively. The company's commitment to quality, customer service, and innovation has seen it win the hearts of many drilling operators across the globe. Today, the company has managed to create a name for itself and has become a household name in the drilling industry.

In conclusion, Hdd drilling fluid is a perfect blend of quality and innovation. The company offers a quality product that has been tested and proven to work, providing drilling operators with a reliable and cost-effective solution that significantly enhances drilling operations. Hdd drilling fluid is certainly the go-to drilling solution for any drilling operation, regardless of the scale, environment, or requirements.

Company News & Blog

Best Shaker for Protein Drinks: The Ultimate Mixing Solution

MONGOOSE PRO, a leading manufacturer of high-quality protein shakers, has recently launched its newest product, the MONGOOSE PRO Shaker. This revolutionary shaker is designed to provide athletes and fitness enthusiasts with a convenient and efficient way to mix their protein shakes on the go.The MONGOOSE PRO Shaker features a sleek and stylish design, making it the perfect accessory for anyone who leads an active lifestyle. Its durable construction ensures that it can withstand the rigors of daily use, while its leak-proof design gives users the confidence to carry it with them wherever they go. Additionally, the shaker is equipped with a secure, screw-on lid and a flip cap that allows for easy access to the contents inside.One of the most impressive features of the MONGOOSE PRO Shaker is its advanced mixing technology. The shaker is equipped with a powerful mixing system that ensures a smooth and lump-free shake every time. This is made possible by the shaker's specially designed mixing mechanism, which effectively blends the protein powder and liquid to create a perfectly mixed drink.In addition to its practical features, the MONGOOSE PRO Shaker is also designed with the user's convenience in mind. It boasts a large capacity, allowing users to mix up to 24 ounces of their favorite protein shake at once. The shaker also features easy-to-read measurement markings, making it simple to portion out the perfect amount of protein powder and liquid.As a company, MONGOOSE PRO is committed to providing its customers with high-quality products that enhance their active lifestyles. The MONGOOSE PRO Shaker is a testament to this commitment, as it is designed to meet the needs of athletes and fitness enthusiasts who demand the best from their workout accessories. With its unparalleled quality and innovative design, the MONGOOSE PRO Shaker is poised to become a staple in the fitness community.MONGOOSE PRO takes pride in being a pioneer in the fitness industry, and the launch of the MONGOOSE PRO Shaker is a reflection of the company's dedication to innovation and excellence. With this latest addition to its product lineup, MONGOOSE PRO aims to set a new standard for protein shakers and solidify its position as a leader in the market.The MONGOOSE PRO Shaker is now available for purchase on the company's website and through select retailers. With its unparalleled quality, advanced mixing technology, and user-friendly design, it is sure to become a must-have accessory for anyone who is serious about their fitness goals. Whether you're hitting the gym, going for a run, or simply need a convenient way to mix your protein shakes on the go, the MONGOOSE PRO Shaker is the perfect solution. Experience the difference that this exceptional shaker can make in your fitness routine and elevate your workout experience to new heights.

Metal Scale Briquetter and Metal Swarf Briquetter: The Latest News from China

China Metal Scale Briquetter and Metal Swarf BriquetterIn the ever-evolving landscape of metal recycling and environmental sustainability, the market for innovative and efficient tools continues to grow. With a focus on reducing waste and maximizing the value of metal scrap, {Company Name} has emerged as a leader in the development and production of metal scale briquetters and metal swarf briquetters.As the name suggests, a metal scale briquetter is a machine designed to compact metal scales, which are thin pieces of metal that are produced during various metalworking processes. By compressing these metal scales into dense, uniform briquettes, {Company Name}'s metal scale briquetter makes it easier to handle and transport metal scrap, ultimately increasing its value and reducing its environmental impact.Similarly, a metal swarf briquetter is specifically designed to handle metal swarf, which consists of small, fine chips and turnings that are produced during metal cutting and shaping processes. By compressing metal swarf into dense, easily manageable briquettes, {Company Name}'s metal swarf briquetter facilitates the handling and recycling of this valuable metal scrap.These innovative machines are a testament to {Company Name}'s commitment to providing cutting-edge solutions for the metal recycling industry. With a focus on efficiency, productivity, and environmental sustainability, the company has established itself as a trusted partner for metal recyclers around the world.Beyond its innovative products, {Company Name} stands out for its dedication to customer satisfaction and continuous improvement. The company's team of experts is constantly researching and developing new technologies to meet the evolving needs of the metal recycling industry, ensuring that their customers always have access to the most advanced and effective equipment on the market.Moreover, {Company Name} places a strong emphasis on quality and reliability, ensuring that every metal scale briquetter and metal swarf briquetter that bears its name is built to the highest standards. This commitment to excellence has earned {Company Name} a reputation for delivering durable, high-performance machines that consistently exceed customers' expectations.In addition to its focus on product development and quality, {Company Name} prides itself on its comprehensive customer support. From initial inquiry to installation and ongoing maintenance, the company's knowledgeable and responsive team is dedicated to providing customers with the guidance and expertise they need to make the most of their investment in {Company Name}'s products.As the demand for sustainable metal recycling solutions continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its metal scale briquetter and metal swarf briquetter. By providing innovative, reliable, and efficient equipment, the company is not only helping its customers improve their operations but also contributing to the larger goal of reducing waste and protecting the environment.In conclusion, the metal scale briquetter and metal swarf briquetter offered by {Company Name} represent a significant advancement in the field of metal recycling. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted leader in the industry, providing valuable solutions for metal recyclers around the world.

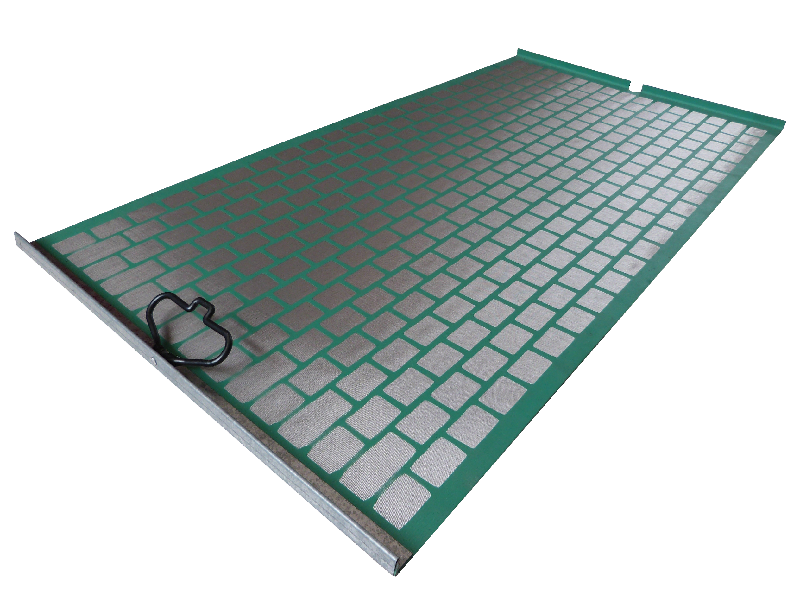

Top Quality Screen Mesh and Screen for Various Industries in China

China Screen Mesh and Screen Company, known for its high-quality and durable screen products, has recently announced the launch of a new and improved screen mesh designed to meet the specific needs of various industries. The company, which has been a leader in the screen manufacturing industry for over a decade, has consistently provided innovative and reliable solutions to its customers, and the new mesh is a testament to its commitment to delivering top-notch products.The new screen mesh is constructed using advanced materials and technology, ensuring superior strength and durability. It is designed to withstand harsh environmental conditions, making it suitable for a wide range of applications, including mining, construction, agriculture, and pharmaceuticals. The mesh is available in various sizes and configurations, allowing for customization to meet the specific requirements of different industries.One of the key features of the new screen mesh is its high tensile strength, which enables it to effectively withstand heavy loads and abrasive materials. This makes it ideal for use in mining and construction, where the screens are often subjected to extreme wear and tear. The mesh also offers excellent resistance to corrosion, ensuring long-lasting performance in outdoor and industrial environments.In addition to its physical properties, the new screen mesh is also designed for easy installation and maintenance. Its modular design allows for quick and hassle-free replacement, reducing downtime and increasing productivity. The company has also developed a range of accessories and support systems to facilitate the installation and use of the mesh, further enhancing its overall usability.The launch of the new screen mesh is a result of China Screen Mesh and Screen Company's continuous research and development efforts. The company has a dedicated team of engineers and technicians who are constantly striving to improve and innovate its product offerings. By leveraging the latest technologies and materials, the company is able to stay ahead of the competition and provide cutting-edge solutions to its customers.The company's commitment to quality and customer satisfaction has earned it a strong reputation in the industry. Its products are trusted by businesses and organizations around the world, and the new screen mesh is expected to further solidify its position as a leading provider of screen solutions. With a focus on performance, reliability, and innovation, China Screen Mesh and Screen Company continues to set the bar for the industry.In addition to its product offerings, the company also provides comprehensive technical support and customer service. Its team of experts is available to assist customers with product selection, installation, and troubleshooting, ensuring a seamless experience from start to finish. This level of support has helped the company build long-lasting relationships with its clients and establish itself as a trusted partner in the industry.As China Screen Mesh and Screen Company continues to grow and expand its product line, it remains committed to upholding its core values of quality, innovation, and customer satisfaction. The launch of the new screen mesh is just one example of the company's dedication to providing top-of-the-line solutions to its clients. With its proven track record and forward-thinking approach, China Screen Mesh and Screen Company is poised to remain a driving force in the screen manufacturing industry for years to come.

Top 5 Drilling Machine Equipment for Your Next Project

Drilling Machine Equipment is proud to announce the launch of their latest innovative drilling machine, the DMX-2000. This cutting-edge equipment is designed to revolutionize the drilling industry with its advanced features and superior performance. With over 20 years of experience in the industry, Drilling Machine Equipment has established itself as a leader in providing high-quality, reliable drilling equipment for various applications.The DMX-2000 is a result of extensive research and development, aimed at meeting the growing demands of the drilling industry. With a powerful motor and high drilling capacity, this machine is capable of handling a wide range of drilling tasks with precision and efficiency. Its robust construction ensures durability and longevity, making it a cost-effective investment for businesses looking to enhance their drilling operations."We are thrilled to introduce the DMX-2000 to the market," said the spokesperson for Drilling Machine Equipment. "This machine represents our commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that the DMX-2000 will set a new standard for drilling equipment and provide our clients with a competitive edge in their operations."In addition to its impressive performance, the DMX-2000 is equipped with advanced safety features to ensure the well-being of operators and workers. It comes with an ergonomic design and intuitive controls, allowing for easy operation and minimizing the risk of accidents. Drilling Machine Equipment understands the importance of safety in the workplace, and the DMX-2000 reflects their commitment to promoting a secure working environment.Moreover, the DMX-2000 is designed to be versatile and adaptable to different drilling conditions. Whether it's for construction, mining, or exploration, this machine is capable of delivering consistent results across various applications. This flexibility makes it a valuable asset for businesses that require a reliable and efficient drilling solution for their projects.Drilling Machine Equipment has built a solid reputation in the industry for delivering exceptional products and services. With a focus on quality and customer satisfaction, the company has earned the trust of numerous clients worldwide. Their team of highly skilled engineers and technicians are dedicated to providing comprehensive support and assistance to ensure that their customers experience seamless operations with their equipment."We take pride in the relationships we have established with our clients," the spokesperson added. "At Drilling Machine Equipment, we believe in going above and beyond to support our customers and address their needs. The launch of the DMX-2000 is a testament to our continuous efforts to drive innovation and deliver solutions that add value to our clients' businesses."As a company that values sustainability and environmental responsibility, Drilling Machine Equipment has incorporated eco-friendly features into the DMX-2000. The machine is designed to minimize its carbon footprint and reduce energy consumption, aligning with the company's commitment to promoting sustainable practices in the industry.In conclusion, the launch of the DMX-2000 represents a significant milestone for Drilling Machine Equipment, showcasing their dedication to advancing the drilling industry with cutting-edge technology and superior equipment. As businesses continue to seek reliable and efficient drilling solutions, the DMX-2000 is poised to make a lasting impact and elevate the standards of performance in the industry. With its exceptional features, versatility, and focus on safety and sustainability, this machine is set to become a game-changer for drilling operations worldwide.

Innovative Centrifuge Drilling Technology for Efficient and Effective Drilling Operations

Centrifuge Drilling is revolutionizing the oil and gas industry with its cutting-edge technology that allows for more efficient and cost-effective drilling. This innovative company has quickly become a leader in the field, providing solutions that are changing the way companies approach drilling operations.Founded in 2010, Centrifuge Drilling has a mission to improve the efficiency and effectiveness of drilling for oil and gas reserves. The company specializes in the development and manufacturing of advanced drilling equipment, including centrifuges, that are designed to enhance performance and reduce costs for its customers.Centrifuge Drilling's technology is based on the principle of using centrifugal force to separate different components of drilling mud, allowing for better control and management of the drilling process. This results in improved drilling performance, reduced downtime, and ultimately, significant cost savings for operators.One of the key advantages of Centrifuge Drilling's technology is its ability to handle a wide range of drilling conditions, making it suitable for both onshore and offshore operations. Additionally, the company's equipment is designed to be highly adaptable, allowing for easy integration into existing drilling rigs.The company has quickly gained recognition for its innovative approach to drilling, and it has already established a strong track record of success with numerous projects around the world. Centrifuge Drilling's technology has been proven to significantly improve drilling efficiency and reduce operational costs, making it an attractive solution for operators looking to maximize their resources.One of the company's flagship products is its centrifuge system, which has been specifically designed to address the challenges of drilling in complex geological formations. This system can effectively separate solids from drilling mud, allowing for better control of viscosity and density, which in turn leads to improved drilling performance and reduced wear and tear on equipment.In addition to its cutting-edge technology, Centrifuge Drilling also offers comprehensive support services to its customers. The company's team of experts is available to provide technical assistance, training, and maintenance services to ensure the continued success of its technology in the field.Centrifuge Drilling's commitment to innovation and excellence has earned it a reputation as a trusted partner for operators in the oil and gas industry. The company's dedication to providing reliable, cost-effective solutions has helped it build strong relationships with a wide range of clients, from small independent operators to major international companies.Looking ahead, Centrifuge Drilling is focused on continued research and development to further enhance its technology and maintain its position as a leader in the field. The company is also exploring new opportunities to expand its presence in key markets and build on its success in providing innovative solutions for the oil and gas industry.As the demand for efficient and sustainable drilling continues to grow, Centrifuge Drilling is well-positioned to play a key role in shaping the future of the industry. With its proven technology and commitment to excellence, the company is poised to make a lasting impact on the way drilling operations are conducted around the world.

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

Efficient Mud Tank System for Drilling Rigs

Mud Tank System Drilling Rig: Revolutionizing the Oil and Gas IndustryThe oil and gas industry has long been reliant on drilling rigs to extract hydrocarbons from deep beneath the earth's surface. These rigs are vital in the production of crude oil and natural gas, and their efficiency and reliability directly impact the industry's productivity. One company at the forefront of revolutionizing drilling rig technology is {}, a leading provider of innovative solutions for the oil and gas sector.At the heart of their groundbreaking offerings is the Mud Tank System Drilling Rig, a technological marvel that has been hailed as a game-changer in the industry. This state-of-the-art rig is designed to maximize operational efficiency, streamline drilling processes, and enhance safety measures, ultimately leading to increased productivity and reduced downtime.The Mud Tank System Drilling Rig features a cutting-edge mud tank system that is integral to its performance. This system is designed to efficiently handle drilling waste and regulate the flow of drilling fluids, ensuring a clean and controlled environment for the drilling operation. By effectively managing mud and drilling fluids, the rig minimizes the impact on the surrounding environment and reduces the risk of operational hazards.Moreover, the Mud Tank System Drilling Rig is equipped with advanced monitoring and control systems that provide real-time data on drilling parameters. This enables operators to make quick and informed decisions, optimize drilling processes, and mitigate potential issues before they escalate. The rig's automated features and remote monitoring capabilities further enhance operational control and contribute to a safer working environment for personnel.In addition to its technological prowess, the Mud Tank System Drilling Rig is designed with versatility in mind. It can be customized to meet the specific requirements of different drilling projects, whether in onshore or offshore locations. Its modular design allows for easy transportation and assembly, making it well-suited for remote and challenging environments.This innovative drilling rig has already made a significant impact in the oil and gas industry, with numerous successful deployments and favorable feedback from operators. Its performance has been commended for its reliability, operational efficiency, and environmental stewardship. As the industry continues to adapt to evolving challenges and demands, the Mud Tank System Drilling Rig is poised to play a pivotal role in shaping the future of drilling operations.In line with this commitment to innovation and excellence, {} has established itself as a driving force in the oil and gas sector. With a rich history of delivering cutting-edge solutions and a strong focus on research and development, the company is dedicated to pushing the boundaries of technology to address the industry's evolving needs.{} has solidified its reputation as a trusted partner for oil and gas companies seeking reliable and efficient solutions. Their comprehensive portfolio of products and services spans the entire spectrum of drilling and production operations, encompassing drilling rigs, well services, and environmental solutions. Coupled with their unwavering commitment to safety and sustainability, the company has earned the trust and confidence of industry stakeholders worldwide.Looking ahead, {} remains steadfast in its pursuit of innovation and advancement. The company continues to invest in research and development, collaborating with industry partners and experts to push the boundaries of drilling technology. With a keen eye on emerging trends and challenges, {} is poised to lead the industry towards a more sustainable and efficient future.In conclusion, the Mud Tank System Drilling Rig stands as a testament to the transformative potential of technological innovation in the oil and gas industry. Through its cutting-edge design, advanced features, and versatility, this rig exemplifies the strides being made towards enhancing operational efficiency, safety, and environmental responsibility. In partnership with companies like {}, the industry is primed to embrace a new era of drilling excellence.

Complete Guide to Pump Parts Manual: Everything You Need to Know

Mission Pump Parts Manual Now Available for CustomersThe renowned company, {}, has recently announced the release of its much-awaited Mission Pump Parts Manual. This comprehensive manual is designed to provide customers with detailed information on how to effectively maintain and troubleshoot their Mission pumps.The release of the Mission Pump Parts Manual is a reflection of the company’s commitment to providing exceptional customer service and support. With this manual, customers can expect to have access to a wealth of information that will enable them to maximize the performance and longevity of their Mission pumps.The Mission Pump Parts Manual covers a wide range of topics, including pump installation, operation, maintenance, and troubleshooting. It also provides detailed diagrams and technical specifications for all the parts and components of the Mission pumps, making it easier for customers to identify and address any issues that may arise.In addition to the detailed technical information, the manual also includes helpful tips and recommendations for maintaining and servicing Mission pumps. Customers will find step-by-step instructions for routine maintenance tasks, as well as guidance on how to diagnose and address common pump problems.One of the key features of the Mission Pump Parts Manual is its user-friendly layout and easy-to-follow instructions. Whether customers are experienced pump operators or new to the world of pump maintenance, they will find the manual to be an invaluable resource for keeping their Mission pumps in top condition.{} has been a leader in the pump industry for over 50 years, providing high-quality pumps and exceptional service to customers around the world. The release of the Mission Pump Parts Manual is yet another example of the company’s dedication to meeting the needs of its customers and ensuring the long-term reliability of its products.The company is known for its extensive product line, which includes a wide range of pumps for various applications, including oil and gas, mining, wastewater treatment, and industrial processes. With a focus on innovation and quality, {} has earned a reputation for excellence in the pump industry.The Mission Pump Parts Manual is now available to all customers and can be accessed through the company’s website or by contacting their customer service department. Customers are encouraged to take advantage of this valuable resource to ensure the optimal performance of their Mission pumps.In addition to the Mission Pump Parts Manual, {} also offers a range of other resources and support services for its customers. From technical support and training programs to aftermarket parts and field services, the company is committed to being a reliable partner for all of its customers’ pump needs.With the release of the Mission Pump Parts Manual, {} has once again demonstrated its dedication to providing exceptional service and support to its customers. The company’s strong commitment to customer satisfaction and product excellence sets it apart as a leader in the pump industry, and customers can be confident in the reliability and performance of their Mission pumps.

Essential Software Solutions and Technology Advancements for Effective Exploration Decision-Making

Exploring for minerals and metals is a complex, costly and time-consuming process. However, technology advancements have significantly changed the exploration industry over the past decade by providing innovative solutions that enhance exploration efficiencies. From remote sensing to geophysical surveys, cutting-edge technologies have emerged to increase accuracy and reduce the risks associated with mineral exploration. One aspect of exploration that has benefited from advances in technology is drill cuttings management.Drill cuttings management is a critical aspect of any mining exploration program. It involves collecting and analyzing the rock fragments or cuttings produced during drilling operations. These cuttings can be analyzed to provide essential geological information such as the mineralogy, rock type, and structure of the underlying deposit. Information from drill cuttings is used by geologists and mining engineers to make informed decisions regarding the next drilling location, prioritize targets, and guide further exploration.In the past, the process of managing drill cuttings was time-consuming and human-intensive, which resulted in delays in decision-making and high exploration costs. Nowadays, however, due to advances in digital technologies, the process has become more efficient and cost-effective.One of the leading solutions to drill cuttings management is remote sensing, which relies on the use of unmanned aerial vehicles (UAVs) to capture high-resolution images of the drilled area. The images are then analyzed using machine learning algorithms, which can accurately identify and interpret geological features, automate data processing, and improve the accuracy of the exploration data.Another technology that has transformed drill cuttings management is the use of real-time data analytics. Instead of waiting for samples to be analyzed in a laboratory, real-time data analytics can provide information on the properties of the material being drilled. This technology has the potential to be a game-changer in the exploration industry, improving the efficiency of the exploration program by providing instant feedback to exploration teams while drilling is still in progress.The use of mobile apps is another technology that has revolutionized the management of drill cuttings. Exploration teams can use mobile apps to collect data, input geological information, and track drilling progress. The apps can also be used to upload and analyze the data, which provides an interactive platform for the exploration team to collaborate. The use of mobile apps promotes critical decision-making in real-time, thus reducing the risks associated with mineral exploration.In conclusion, the exploration industry has benefited greatly from technological advancements in drill cuttings management. The use of UAVs, real-time data analytics, mobile apps and machine learning algorithms offer a more efficient and cost-effective approach to exploration. As the exploration industry continues to evolve, it is expected that we will see further advances in drill cuttings management, which will continue to drive efficiencies in the exploration process.

Suction and Discharge Vehicle and Sewage Suction Truck in China

China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company, a leading manufacturer of industrial vehicles, has recently introduced a new line of suction and discharge vehicles and sewage suction trucks. The company, with its headquarters in China, has been providing high-quality industrial vehicles to customers around the world for over a decade.The new line of suction and discharge vehicles and sewage suction trucks is aimed at meeting the growing demand for efficient and reliable vehicles in the waste management and sanitation industry. With urbanization and population growth, there is an increasing need for advanced equipment to handle the collection and disposal of sewage and other waste materials. China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company aims to address this need with their latest products.The suction and discharge vehicles are equipped with powerful pumps and storage tanks, making them ideal for a variety of applications, including the transportation of sludge, liquid waste, and industrial materials. The company's sewage suction trucks are designed to efficiently collect and transport sewage from residential, commercial, and industrial areas. These vehicles are built to withstand the rigors of daily use and are equipped with advanced features to ensure reliable performance.One of the key strengths of China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company is its commitment to innovation and technology. The company invests heavily in research and development to continually improve its products and stay ahead of the competition. This dedication to innovation has allowed the company to develop state-of-the-art suction and discharge vehicles and sewage suction trucks that are not only efficient but also environmentally friendly.In addition to their commitment to innovation, the company also prioritizes quality and reliability. All of their products undergo rigorous testing and quality control measures to ensure that they meet the highest industry standards. This focus on quality has earned the company a reputation for producing durable and high-performance vehicles that can withstand the demands of the toughest working conditions.Furthermore, China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company prides itself on its customer-centric approach. The company works closely with its clients to understand their specific needs and develop customized solutions that meet their requirements. By providing personalized service and support, the company has built strong and lasting relationships with customers around the world.The introduction of the new line of suction and discharge vehicles and sewage suction trucks represents a significant milestone for China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company. With these new products, the company is poised to further expand its presence in the global market and continue its legacy of providing reliable and efficient industrial vehicles.As the demand for waste management and sanitation solutions continues to grow, China Suction and Discharge Vehicle and Sewage Suction Truck Manufacturing Company is well-positioned to capitalize on the opportunities in the industry. With its innovative products, commitment to quality, and customer-focused approach, the company is set to remain a key player in the industrial vehicle manufacturing sector for years to come.