High-Quality Centrifuges for Laboratory and Medical Use, Hand-Operated Options Available

By:Admin

The high-speed centrifuge is designed to provide efficient and reliable separation of substances, such as blood, urine, and other biological samples. With its advanced technology, the high-speed centrifuge is able to rapidly spin samples at high speeds, resulting in quick and precise separation of components. This is particularly beneficial in medical laboratories and research facilities where time is crucial and accurate results are paramount.

On the other hand, the hand-operated centrifuge is a portable and versatile solution for smaller-scale separation tasks. This compact device is designed for situations where access to a power source is limited or when a smaller volume of samples needs to be processed. It can be used in various settings, such as field research, remote clinics, and educational laboratories.

[Company Name] has a long history of developing and manufacturing high-quality centrifuge equipment for various applications. With a focus on technological innovation and product excellence, the company has established itself as a trusted supplier of centrifuge solutions in the global market.

The company's commitment to quality and performance is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. Each centrifuge product undergoes comprehensive testing and inspection to ensure it meets the highest standards of reliability and efficiency.

In addition to its technical expertise, [Company Name] also prides itself on providing exceptional customer service and support. The company's dedicated team of professionals is well-equipped to offer personalized advice and assistance to customers, helping them select the most suitable centrifuge solution for their specific needs.

The introduction of the new high-speed and hand-operated centrifuge products further demonstrates [Company Name]'s dedication to meeting the evolving needs of its customers. By continuously expanding its product range and incorporating the latest technological advancements, the company aims to remain at the forefront of the centrifuge industry.

The global demand for centrifuge equipment continues to grow, driven by increasing applications in the fields of healthcare, biotechnology, and research. [Company Name] is well-positioned to capitalize on this trend through its innovative product offerings and commitment to customer satisfaction.

While the high-speed centrifuge is designed for high-throughput laboratories and facilities with demanding separation requirements, the hand-operated centrifuge is expected to appeal to customers seeking a portable and cost-effective solution for smaller-scale applications. Both products are expected to contribute to [Company Name]'s continued success in the centrifuge market.

As [Company Name] looks to the future, it remains steadfast in its commitment to innovation, quality, and customer satisfaction. With its new line of centrifuge products, the company is poised to make a significant impact in the global market and solidify its reputation as a leading provider of centrifuge solutions.

Company News & Blog

Importance of Mud Recycling Systems for Efficient Drilling Processes

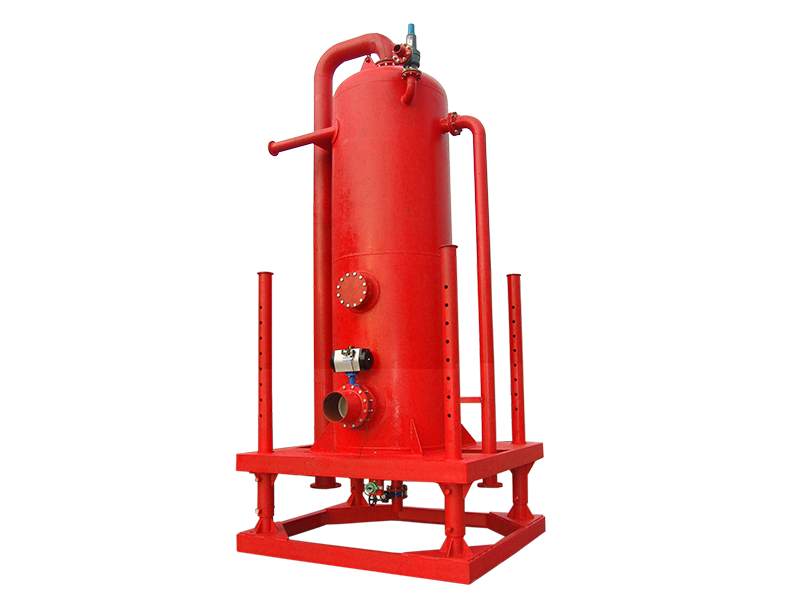

GN Solids America Provides High-Quality Drilling Mud Recycling System with CE and ATEX StandardsThe drilling process is an essential part of oil and gas exploration, and the mud recycling system plays a vital role in maintaining the drilling mud properties at an optimal level. It removes the unnecessary large-sized solids and protects the drilling equipment from being damaged by large solids. GN Solids America is a leading provider of high-quality drilling mud recycling systems that meet Europe CE standard and ATEX explosion-proof standard.The mud recycling system consists of 2 centrifugal pumps, 2 mixing pumps, and 20 agitators. It acts as the heart and blood of the rig, making sure that all the components work together in perfect harmony. Without a reliable mud recycling system, the drilling process would be inefficient and expensive.GN Solids America is committed to providing its customers with the best quality solid control equipment at a competitive price. The shale shakers' G force can reach up to 8 G, making it possible to discharge drier solids that meet environmental requirements. Moreover, GN Solids America's new and upgraded shaker screen possesses better performance, longevity, and can store longer than ever before. During the drilling process, the shaker screens undergo significant wear and tear. Hence, GN Solids America's composite screen is the perfect solution, lasting longer than other screens.Customers from Europe and North America appreciate the quality of GN Solids America's products, and are buying them in increasing numbers. GN Solids America aims to provide its customers with the best quality products at an affordable cost."We are pleased to provide our customers with high-quality drilling mud recycling systems that meet CE and ATEX standards. We are committed to ensuring our customers' satisfaction by providing them with reliable and cost-effective products," said the spokesperson for GN Solids America.In conclusion, GN Solids America is a reliable provider of high-quality drilling mud recycling systems that meet international standards. Its products are top-notch and cost-effective, making them ideal for various applications in the oil and gas industry. GN Solids America's commitment to quality and customer satisfaction is what sets it apart from other solid control equipment providers in the market. Visit the website www.gnsolidsamerica.com. For more information, send your inquiries to [email protected].

High-quality Chemical Wastewater Decanter Centrifuge and Drilling Sludge Dewatering Supplier in China

China is known for its rapid industrial development, but with that comes environmental challenges, particularly in the management of chemical wastewater and drilling sludge. However, one company is stepping up to the challenge by providing high-quality decanter centrifuges and dewatering solutions for these complex and critical processes.[Company] is a leading supplier of decanter centrifuges and drilling sludge dewatering equipment in China. With a strong focus on research and development, the company has established itself as a pioneer in the field of environmental protection and sustainable industrial practices.The company's decanter centrifuges are specially designed for the treatment of chemical wastewater, offering efficient separation and dewatering of solid particles from liquids. This technology is essential in the chemical industry, where the proper management of wastewater is crucial for environmental protection and regulatory compliance. By providing reliable and high-performance decanter centrifuges, [Company] is helping chemical plants reduce their environmental footprint and operate more sustainably.In addition to chemical wastewater treatment, [Company] also offers advanced solutions for drilling sludge dewatering. Drilling operations in the oil and gas industry generate large volumes of sludge, which contains a mixture of drilling fluids, cuttings, and other solid materials. Proper dewatering of this sludge is crucial for its safe disposal and for minimizing the environmental impact of drilling activities. [Company]'s dewatering equipment is designed to efficiently separate solid and liquid phases, allowing for the safe disposal of the dewatered sludge and the recovery of valuable drilling fluids.One of the key advantages of [Company]'s products is their versatility and adaptability to different operating conditions. The company's decanter centrifuges and dewatering equipment can be customized to meet the specific needs of different industries and applications. From small-scale chemical plants to large drilling operations, [Company] provides tailored solutions that ensure optimal performance and efficiency.Moreover, [Company] takes pride in its commitment to quality and reliability. All of the company's equipment is manufactured to the highest standards, using advanced materials and precision engineering. This dedication to quality has earned [Company] a reputation for excellence, making it a trusted partner for businesses seeking reliable and effective solutions for chemical wastewater and drilling sludge management.Beyond its product offerings, [Company] also provides comprehensive technical support and after-sales services. The company's team of experts is readily available to assist customers with installation, training, maintenance, and troubleshooting. By building strong relationships with its clients, [Company] ensures that its solutions continue to deliver long-term value and performance.Looking ahead, [Company] is poised to expand its presence in the global market, serving the needs of industries around the world that are seeking advanced and sustainable solutions for wastewater and sludge management. In an era of increasing environmental awareness and regulatory scrutiny, [Company] is well-positioned to play a significant role in driving positive change and promoting the adoption of responsible and eco-friendly practices in industrial operations.In conclusion, [Company] is a leading supplier of decanter centrifuges and drilling sludge dewatering equipment in China, offering advanced and customized solutions for chemical wastewater and drilling sludge management. With a strong focus on quality, reliability, and technical support, the company is well-equipped to meet the evolving needs of industries and contribute to a more sustainable and environmentally responsible future.

Effective Mud Dewatering Centrifuge for Efficient Waste Management

Mud dewatering centrifuge, an essential piece of equipment for various industries such as mining, oil and gas, and wastewater treatment, plays a crucial role in separating solids from liquids. The process of dewatering mud is essential for reducing waste and increasing the efficiency of operations. With the advancements in technology, the demand for high-quality mud dewatering centrifuges has increased significantly.One company that has been at the forefront of providing top-notch mud dewatering centrifuges is {Company Name}. With years of experience and a strong commitment to quality and innovation, {Company Name} has established itself as a leading provider of centrifuge solutions for a wide range of industries around the world.Established in {year}, {Company Name} has grown to become a trusted name in the field of centrifuge technology. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and equipment, allowing them to produce high-performance mud dewatering centrifuges that meet the highest industry standards.{Company Name} takes pride in its team of skilled engineers and technicians who are dedicated to designing and manufacturing centrifuges that deliver outstanding performance and reliability. The company's commitment to research and development has led to the creation of innovative centrifuge solutions that are tailor-made to meet the specific needs of their customers.The mud dewatering centrifuge offered by {Company Name} is designed to handle a wide range of mud types and viscosities, making it suitable for various applications. The centrifuge is capable of efficiently separating solids from liquids, thereby reducing waste and ensuring that the discharged water meets environmental regulations.{Company Name} understands the importance of providing comprehensive support to its customers, which is why they offer a range of services including installation, maintenance, and technical support. The company's team of experts works closely with customers to ensure that the centrifuge solutions meet their unique requirements and provide maximum value.One of the key advantages of the mud dewatering centrifuge offered by {Company Name} is its high level of automation and efficiency. The centrifuge is equipped with advanced controls and monitoring systems that allow for precise control of the dewatering process, resulting in reduced operating costs and increased productivity.Furthermore, {Company Name} is committed to sustainability and environmental responsibility. The mud dewatering centrifuge is designed to minimize the environmental impact of operations by effectively managing waste and reducing the discharge of harmful contaminants into the environment.In conclusion, {Company Name} has established itself as a leading provider of high-quality mud dewatering centrifuges, thanks to its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, the company continues to push the boundaries of centrifuge technology, providing solutions that meet the evolving needs of industries around the world. Whether it's mining, oil and gas, or wastewater treatment, {Company Name} is a trusted partner for companies looking to enhance their dewatering processes and reduce their environmental footprint.

A Guide to Vacuum Pumps and Diaphragm Pumps in China

China-based company, specializing in the production of vacuum pumps and diaphragm pumps, has recently announced the launch of their latest series of innovative and high-performance pumps. With a strong dedication to research and development, the company has established a reputation for delivering top-quality pumping solutions to a wide range of industries, including pharmaceutical, chemical, food and beverage, and more.The new series of vacuum pumps and diaphragm pumps are designed to meet the evolving needs of industrial applications, offering enhanced efficiency, reliability, and performance. These pumps are suitable for a variety of tasks, such as degassing, filtration, distillation, and solvent evaporation, making them an essential component of many production processes.The vacuum pumps are built with advanced technology to provide a high level of vacuum, ensuring optimal performance in the removal of gases and vapors from a sealed space. These pumps are able to operate at low noise levels and are equipped with a stable pumping speed, resulting in consistent and reliable performance. Additionally, the diaphragm pumps feature a robust design and are ideal for applications that require a pulsation-free flow and the ability to handle corrosive and aggressive gases and vapors.The company's commitment to quality and innovation is reflected in the rigorous testing and inspection processes that each pump undergoes before being released to the market. This dedication to quality control ensures that customers receive pumps that are not only technologically advanced, but also reliable and durable.In addition to the new series of pumps, the company also offers a comprehensive range of accessories and spare parts, as well as expert technical support and maintenance services. This holistic approach to customer service ensures that clients have access to everything they need to optimize the performance and longevity of their pumping systems.The company's success can be attributed to its strong emphasis on research and development. By continuously investing in cutting-edge technologies and exploring new materials and manufacturing processes, the company has been able to stay ahead of the curve in the pumping industry. Furthermore, the company's team of experienced engineers and technicians are passionate about pushing the boundaries of pump design and performance, resulting in products that are at the forefront of innovation.With a global presence, the company is well-positioned to provide pumping solutions to customers around the world. Whether it's a small-scale operation or a large industrial plant, the company has the expertise and resources to deliver tailor-made pumping systems that address the unique requirements of each client.As the demand for efficient and reliable pumping solutions continues to grow, the company remains dedicated to pushing the boundaries of pump technology. With a focus on innovation, quality, and customer satisfaction, the company is poised to maintain its position as a leading provider of vacuum pumps and diaphragm pumps in the global market.In conclusion, the latest series of vacuum pumps and diaphragm pumps from the China-based company offers a glimpse into the future of pumping technology. With a strong emphasis on innovation and quality, these pumps are set to deliver exceptional performance and reliability across a wide range of industrial applications. As the company continues to evolve and expand its product offerings, it is clear that they are poised to remain at the forefront of the pumping industry for years to come.

Essential Software Solutions and Technology Advancements for Effective Exploration Decision-Making

Exploring for minerals and metals is a complex, costly and time-consuming process. However, technology advancements have significantly changed the exploration industry over the past decade by providing innovative solutions that enhance exploration efficiencies. From remote sensing to geophysical surveys, cutting-edge technologies have emerged to increase accuracy and reduce the risks associated with mineral exploration. One aspect of exploration that has benefited from advances in technology is drill cuttings management.Drill cuttings management is a critical aspect of any mining exploration program. It involves collecting and analyzing the rock fragments or cuttings produced during drilling operations. These cuttings can be analyzed to provide essential geological information such as the mineralogy, rock type, and structure of the underlying deposit. Information from drill cuttings is used by geologists and mining engineers to make informed decisions regarding the next drilling location, prioritize targets, and guide further exploration.In the past, the process of managing drill cuttings was time-consuming and human-intensive, which resulted in delays in decision-making and high exploration costs. Nowadays, however, due to advances in digital technologies, the process has become more efficient and cost-effective.One of the leading solutions to drill cuttings management is remote sensing, which relies on the use of unmanned aerial vehicles (UAVs) to capture high-resolution images of the drilled area. The images are then analyzed using machine learning algorithms, which can accurately identify and interpret geological features, automate data processing, and improve the accuracy of the exploration data.Another technology that has transformed drill cuttings management is the use of real-time data analytics. Instead of waiting for samples to be analyzed in a laboratory, real-time data analytics can provide information on the properties of the material being drilled. This technology has the potential to be a game-changer in the exploration industry, improving the efficiency of the exploration program by providing instant feedback to exploration teams while drilling is still in progress.The use of mobile apps is another technology that has revolutionized the management of drill cuttings. Exploration teams can use mobile apps to collect data, input geological information, and track drilling progress. The apps can also be used to upload and analyze the data, which provides an interactive platform for the exploration team to collaborate. The use of mobile apps promotes critical decision-making in real-time, thus reducing the risks associated with mineral exploration.In conclusion, the exploration industry has benefited greatly from technological advancements in drill cuttings management. The use of UAVs, real-time data analytics, mobile apps and machine learning algorithms offer a more efficient and cost-effective approach to exploration. As the exploration industry continues to evolve, it is expected that we will see further advances in drill cuttings management, which will continue to drive efficiencies in the exploration process.

Efficient Vertical Cutting Dryer for Improved Solids Control

The revolutionary Vertical Cutting Dryer, developed by a leading provider of drilling waste management solutions, is set to transform the oil and gas industry. This innovative technology is designed to efficiently remove drilled solids from drilling fluids, providing significant cost savings and environmental benefits for companies operating in the sector.The Vertical Cutting Dryer is a key component of the company's comprehensive range of drilling waste management equipment, which is used to separate and recover valuable drilling fluids from solid waste materials. The dryer is capable of processing large volumes of drilled solids, effectively reducing waste volumes and minimizing environmental impact.Designed with a vertical configuration, the cutting dryer utilizes centrifugal force to remove excess liquid from drill cuttings, resulting in drier cuttings and improved overall drilling fluid recovery. The machine's advanced design also reduces the need for dilution and disposal of drilling fluids, leading to substantial cost savings for operators.In addition to its cost-saving benefits, the Vertical Cutting Dryer is also an environmentally friendly solution for managing drilling waste. By effectively separating solids from liquids, the dryer helps to minimize the volume of waste material that requires disposal, reducing the overall environmental footprint of drilling operations.The company behind the Vertical Cutting Dryer is a global leader in providing innovative and sustainable solutions for managing drilling waste. With a strong focus on research and development, the company has continuously pushed the boundaries of technological innovation in the oil and gas industry, delivering products that optimize operational efficiency while reducing environmental impact.The company's extensive experience and expertise in the field of drilling waste management have positioned it as a trusted partner for oil and gas companies seeking sustainable and cost-effective solutions. By offering a comprehensive range of equipment and services, including the Vertical Cutting Dryer, the company helps its clients meet and exceed regulatory requirements while enhancing their overall operational performance.The Vertical Cutting Dryer has already garnered attention from industry experts and operators, who recognize its potential to revolutionize drilling waste management processes. By incorporating this cutting-edge technology into their operations, companies can expect to see improved efficiency, reduced costs, and enhanced environmental stewardship.In a statement, a spokesperson for the company commented, "We are thrilled to introduce the Vertical Cutting Dryer to the market. This innovative technology represents a significant leap forward in the field of drilling waste management, and we believe it will deliver substantial benefits to our clients. By offering a more efficient and sustainable solution for processing drilling waste, we are proud to support our customers in their efforts to operate responsibly and profitably."As the oil and gas industry continues to prioritize sustainability and operational efficiency, the Vertical Cutting Dryer is poised to become an indispensable tool for companies seeking to optimize their drilling waste management processes. With its advanced technology and proven performance, this innovative equipment is set to make a lasting impact on the sector, delivering tangible benefits for both companies and the environment.

Balancing Budget and Quality for Maximum Effectiveness in Horizontal Directional Drilling Projects

China Drilling Desilter and Drilling Machine: Leaders in the Horizontal Directional Drilling IndustryFounded in China, China Drilling Desilter and Drilling Machine are leaders in the horizontal directional drilling industry, manufacturing and selling some of the best HDD (Horizontal Directional Drilling) machines and drilling mud solids control systems on the market. Their reputation for quality and innovation in the industry is second to none, leading to the company becoming one of the fastest-growing enterprises in the field of no-dig technology.The company has state-of-the-art manufacturing facilities with cutting-edge technology such as EDM (Electrical Discharge Machining) and CNC Lathe, enabling them to produce quality HDD machines that meet the needs of their clients. Their workforce consists of well-trained experts in no-dig technology, with years of experience in the industry, ensuring that the end products they produce perfectly meet their customers' needs.One of the prominent HDD machines they manufacture is the Vermeer NAVIGATOR line. The Vermeer NAVIGATOR line of HDD machines is ideal for installing gas, electric, water, telecommunication, or soil remediation lines without excavation or trenching. It is a reliable and robust HDD machine that can undertake demanding projects, such as large-scale infrastructure projects, including laying utility pipes or performing soil remediation.Another HDD machine manufactured by China Drilling Desilter and Drilling Machine is the Drillto HDD machine. The company's multi-faceted manufacturing facility can produce this machine, allowing them to address the needs of their diverse range of customers. These two HDD machines have an excellent reputation in the industry, delivering high-quality work output and lasting performance.The company also produces drilling mud solids control systems that enable their clients to efficiently handle and filter drilling mud. These mud systems work by removing solids from the drilling mud while returning clean fluid back to the drilling process. GN solids control is an example of a drilling mud processing supplier that China Drilling Desilter and Drilling Machine has partnered with, providing their clients with efficient and reliable mud processing systems.When it comes to an HDD project, ensuring that you have a balance between budget and quality is an essential consideration. Therefore, it is crucial to use world-renowned drilling machines such as those produced by China Drilling Desilter and Drilling Machine. When combined with efficient mud processing systems from reputed companies like GN solids control, you can achieve maximum project effectiveness.The reputation China Drilling Desilter and Drilling Machine have built over the years is a testament to the quality and reliability of their products. The company operates with purpose, committed to ensuring their customers' needs are met by delivering high-quality products that meet industry standards.In conclusion, China Drilling Desilter and Drilling Machine stand out among the industry's brightest stars, providing high-quality HDD machines and drilling mud solids control systems. Considering their reputation for delivering quality products, their commitment to improving their products as per industry standards, there's no doubt that they are one of the most reputable companies in the industry.

How to Manage Waste Effectively: Tips and Strategies

Waste management is a critical issue that affects every community around the world. Whether it's household waste, industrial waste, or hazardous waste, the responsible and efficient handling of waste is essential for a healthy and sustainable environment. That's where our company comes in.As a leading waste management firm, we are dedicated to providing innovative and environmentally responsible waste management solutions. With years of experience in the industry, we have developed a comprehensive range of services to meet the diverse needs of our clients, including waste collection, recycling, landfill management, and hazardous waste disposal.Our team of dedicated professionals is committed to delivering top-quality waste management services that not only meet but exceed industry standards. We strive to continuously improve our operations and implement the latest technologies and best practices to ensure that our clients receive the most efficient and cost-effective waste management solutions.In line with our commitment to environmental sustainability, we have invested in state-of-the-art recycling facilities and waste-to-energy plants. These facilities are equipped with advanced processes and technologies to sort, separate, and process various types of recyclable materials, as well as convert non-recyclable waste into renewable energy sources.Furthermore, we place a strong emphasis on education and community engagement. We believe that effective waste management begins with raising awareness and educating individuals and businesses about the importance of responsible waste disposal and recycling. To this end, we regularly conduct outreach programs, workshops, and seminars to promote sustainable waste management practices.Our company is also dedicated to fostering strong partnerships with local communities, municipalities, and businesses. By working closely with these stakeholders, we are able to develop tailored waste management solutions that are tailored to the specific needs and challenges of each community.In recent news, our company has made significant strides in expanding its waste management services to new regions. We have recently secured several contracts to provide waste collection and recycling services for municipalities and businesses in [new regions]. This expansion not only allows us to serve a larger client base but also demonstrates our ongoing commitment to promoting environmental sustainability and providing high-quality waste management solutions.In addition, our company has been actively involved in researching and implementing innovative waste management technologies to improve the efficiency and sustainability of our operations. We have recently invested in cutting-edge waste sorting and processing equipment to enhance our recycling capabilities, as well as explored new methods for converting organic waste into valuable resources such as compost and biofuels.Furthermore, we have been recognized for our efforts in promoting environmental responsibility and sustainability. Our company recently received [industry award] for our outstanding contributions to sustainable waste management practices and our ongoing commitment to minimizing environmental impact.Looking ahead, our company is poised to continue leading the way in innovative and sustainable waste management solutions. We remain dedicated to staying at the forefront of the industry by investing in advanced technologies, fostering strong partnerships, and continuously improving our operations to meet the evolving needs of our clients and the environment.In conclusion, our company is committed to providing top-quality waste management solutions that prioritize environmental sustainability, efficiency, and community engagement. Our recent expansion and ongoing efforts to implement innovative technologies and best practices reinforce our dedication to being a leader in the waste management industry. We look forward to continuing to serve our clients and communities with the highest standards of waste management excellence.

Innovative Centrifuge Drilling Technology for Efficient and Effective Drilling Operations

Centrifuge Drilling is revolutionizing the oil and gas industry with its cutting-edge technology that allows for more efficient and cost-effective drilling. This innovative company has quickly become a leader in the field, providing solutions that are changing the way companies approach drilling operations.Founded in 2010, Centrifuge Drilling has a mission to improve the efficiency and effectiveness of drilling for oil and gas reserves. The company specializes in the development and manufacturing of advanced drilling equipment, including centrifuges, that are designed to enhance performance and reduce costs for its customers.Centrifuge Drilling's technology is based on the principle of using centrifugal force to separate different components of drilling mud, allowing for better control and management of the drilling process. This results in improved drilling performance, reduced downtime, and ultimately, significant cost savings for operators.One of the key advantages of Centrifuge Drilling's technology is its ability to handle a wide range of drilling conditions, making it suitable for both onshore and offshore operations. Additionally, the company's equipment is designed to be highly adaptable, allowing for easy integration into existing drilling rigs.The company has quickly gained recognition for its innovative approach to drilling, and it has already established a strong track record of success with numerous projects around the world. Centrifuge Drilling's technology has been proven to significantly improve drilling efficiency and reduce operational costs, making it an attractive solution for operators looking to maximize their resources.One of the company's flagship products is its centrifuge system, which has been specifically designed to address the challenges of drilling in complex geological formations. This system can effectively separate solids from drilling mud, allowing for better control of viscosity and density, which in turn leads to improved drilling performance and reduced wear and tear on equipment.In addition to its cutting-edge technology, Centrifuge Drilling also offers comprehensive support services to its customers. The company's team of experts is available to provide technical assistance, training, and maintenance services to ensure the continued success of its technology in the field.Centrifuge Drilling's commitment to innovation and excellence has earned it a reputation as a trusted partner for operators in the oil and gas industry. The company's dedication to providing reliable, cost-effective solutions has helped it build strong relationships with a wide range of clients, from small independent operators to major international companies.Looking ahead, Centrifuge Drilling is focused on continued research and development to further enhance its technology and maintain its position as a leader in the field. The company is also exploring new opportunities to expand its presence in key markets and build on its success in providing innovative solutions for the oil and gas industry.As the demand for efficient and sustainable drilling continues to grow, Centrifuge Drilling is well-positioned to play a key role in shaping the future of the industry. With its proven technology and commitment to excellence, the company is poised to make a lasting impact on the way drilling operations are conducted around the world.

New Mixing Hopper Technology: A Game Changer in Industrial Processing

Venturi Mixing Hopper Revolutionizes Mixing Technology in Industrial ApplicationsWith the increasing demand for efficient and effective mixing technology in industrial applications, the introduction of the Venturi Mixing Hopper has been a game-changer in the industry. This innovative solution has been designed to revolutionize the way materials are mixed, offering a more effective and efficient approach to industrial mixing.The Venturi Mixing Hopper, developed by a leading company in the field of industrial equipment manufacturing, has been gaining widespread attention for its ability to significantly improve mixing processes in various industries. This cutting-edge technology has been designed to provide a solution to the challenges faced by industries when it comes to mixing materials effectively and efficiently.The company behind the Venturi Mixing Hopper is known for its commitment to innovation and excellence in the field of industrial equipment manufacturing. With a proven track record of delivering high-quality solutions to industries around the world, the company has built a reputation for pushing the boundaries of what is possible in industrial technology.The Venturi Mixing Hopper is a testament to the company's dedication to innovation and its ability to develop solutions that meet the ever-evolving needs of industries. By combining cutting-edge technology with practical industrial applications, the company has been able to create a product that is not only effective but also efficient and reliable.One of the key features of the Venturi Mixing Hopper is its ability to achieve thorough and uniform mixing of materials, regardless of their properties or characteristics. This has been a significant challenge for industries that rely on effective mixing processes to ensure the quality and consistency of their products. The Venturi Mixing Hopper has been able to address this challenge by utilizing advanced technology that is capable of achieving optimal mixing results.In addition to its exceptional mixing capabilities, the Venturi Mixing Hopper also offers a range of other benefits that make it a valuable investment for industries. Its compact design and user-friendly interface make it easy to operate and maintain, while its robust construction ensures durability and longevity. Furthermore, the Venturi Mixing Hopper is designed to be adaptable to various industrial settings, making it a versatile and flexible solution for different applications.The introduction of the Venturi Mixing Hopper has been met with a positive response from industries that have been struggling with outdated and inefficient mixing technologies. The significant improvements in mixing efficiency and quality that the Venturi Mixing Hopper offers have been a game-changer for these industries, allowing them to optimize their processes and achieve better results.The company behind the Venturi Mixing Hopper has been actively promoting the benefits and advantages of this innovative solution, working closely with industries to demonstrate its capabilities and potential impact. Through various demonstrations and case studies, the company has been able to showcase the significant improvements that the Venturi Mixing Hopper can bring to industrial mixing processes.Moving forward, the company is committed to further developing and enhancing the capabilities of the Venturi Mixing Hopper, as well as exploring new opportunities for its application in different industries. By continuing to innovate and push the boundaries of industrial mixing technology, the company aims to further solidify the position of the Venturi Mixing Hopper as a leading solution for efficient and effective mixing in industrial applications.In conclusion, the introduction of the Venturi Mixing Hopper has been a significant development in the field of industrial mixing technology. With its exceptional capabilities and numerous benefits, this innovative solution has already made a substantial impact on industries that rely on efficient and effective mixing processes. As the company behind the Venturi Mixing Hopper continues to drive innovation and excellence in industrial equipment manufacturing, the future looks promising for the continued success and evolution of this groundbreaking technology.