High Quality Industrial Centrifuges - Everything You Need to Know

By:Admin

Decanter Centrifuges are a vital component in the process of separating various liquids and solids from each other. They are commonly used in industries such as wastewater treatment, oil and gas, food and beverage, and chemical processes. The main function of a Decanter Centrifuge is to separate solid materials from liquids through the principles of sedimentation and centrifugal force. This makes them an essential tool in ensuring the efficient and cost-effective processing of a wide range of substances.

The Decanter Centrifuges offered by {company} are equipped with state-of-the-art features that set them apart from other products in the market. One of the key advantages of {company}'s Decanter Centrifuges is their ability to handle a wide range of materials with varying viscosities, densities, and concentrations. This versatility makes them highly adaptable to the diverse needs of different industries, providing a robust solution for various separation challenges.

In addition, {company}'s Decanter Centrifuges are designed to deliver optimal performance while minimizing energy consumption and operational costs. This is achieved through the integration of advanced control systems and precision engineering, which ensure that the centrifuges operate at peak efficiency at all times. As a result, businesses can expect to see a notable improvement in their bottom line as a direct result of implementing {company}'s Decanter Centrifuges into their operations.

Furthermore, the Decanter Centrifuges offered by {company} are built to withstand the rigors of continuous operation in demanding industrial environments. This is made possible by the utilization of high-quality materials and components, as well as rigorous quality control measures that guarantee the reliability and durability of the centrifuges. As a result, businesses can have confidence in the longevity and performance of {company}'s Decanter Centrifuges, knowing that they are built to last.

It is also worth noting that {company} offers comprehensive support and maintenance services for its Decanter Centrifuges, ensuring that customers can maximize the uptime and effectiveness of their equipment. This includes expert installation, training, and ongoing technical assistance, all of which are designed to help businesses get the most out of their investment in {company}'s cutting-edge separation technology.

Overall, the introduction of Decanter Centrifuges to {company}'s product range represents a significant advancement in the field of separation technology. With their exceptional performance, efficiency, and reliability, these centrifuges are set to make a tangible impact on a wide range of industries, providing a powerful solution for the challenges associated with liquid-solid separation.

For businesses looking to enhance their separation processes and improve their overall operational efficiency, {company}'s Decanter Centrifuges are a compelling choice that offers tangible benefits. With their proven track record of excellence and innovation, {company} has once again demonstrated its position as a leader in the field of separation technology, setting the standard for excellence in this critical area of industrial processing.

Company News & Blog

Revolutionary Solution: Discover the Power of a High-performance Mud Mixer

Title: Innovative Mud Mixing Solution Optimizes Drilling Efficiency in the Oil and Gas IndustryIntroduction:In the oil and gas industry, the efficient extraction of resources relies heavily on advanced technology and equipment. A key component crucial to drilling operations is the mud mixer, a device that blends drilling fluids or mud to maintain stability and enhance performance during drilling processes. Addressing the increasing demand for improved efficiency and performance, a leading engineering company has introduced their cutting-edge Jet Mud Mixer system, revolutionizing the field of drilling and excavation.Body:1. Understanding the Importance of Mud Mixing: The drilling process generates enormous amounts of heat and pressure, demanding fluids that effectively cool, lubricate, and stabilize the drill bit. Mud mixing systems play a critical role by preparing drilling fluids that are essential for successful drilling operations. The fluids facilitate removing cuttings from the wellbore, preventing formation damage, controlling well pressure, and stabilizing the excavation.2. Introducing the Innovative Jet Mud Mixer System: Recognizing the need for a high-performance and efficient mud mixing solution, [Company Name] has developed the Jet Mud Mixer system. This technology combines precise engineering and state-of-the-art design, enabling drilling companies to achieve unparalleled performance in their operations. By integrating advanced processes and materials, this mud mixer surpasses industry standards, providing enhanced drilling efficiency and cost-effectiveness.3. Cutting-edge Features and Functionality: The Jet Mud Mixer system boasts several innovative features that set it apart from existing mud mixing solutions: a. Superior Mixing Performance: [Company Name]'s technology combines robust jet nozzles with a high-power discharge pump, ensuring thorough blending of drilling fluids at optimum consistency and density. b. Versatility and Scalability: The Jet Mud Mixer system is designed to accommodate a wide range of drilling environments, from small-scale onshore projects to large offshore rigs, providing adaptability and scalability for various drilling operations. c. Precision Controls: Equipped with user-friendly controls, drilling operators can easily configure the desired mud consistency, density, and flow rates, improving overall operational control and efficiency. d. Enhanced Safety Measures: Complying with stringent safety regulations, this cutting-edge system incorporates safety features such as emergency stop mechanisms, leakage protection, and excess pressure triggers, ensuring the well-being of personnel and the environment.4. Optimizing Drilling Efficiency and Cost-effectiveness: The Jet Mud Mixer system offers significant advantages to drilling companies seeking to enhance their operational efficiency and reduce costs: a. Increased Drilling Rates: With precise control of drilling mud density and composition, the Jet Mud Mixer system enables faster drilling rates, reducing overall drilling time and costs. b. Reduced Waste and Environmental Impact: By systematically and accurately managing the drilling fluids, this advanced mixing solution minimizes waste and environmental impact, promoting sustainability within the industry. c. Lower Maintenance and Downtime: The robust construction and durability of the Jet Mud Mixer system ensure minimal maintenance requirements. Consequently, downtime caused by equipment breakdowns is significantly reduced, optimizing overall drilling productivity. d. Enhanced Operator Safety: Incorporating safety mechanisms and protocols, the system prioritizes operator safety during mud mixing operations, minimizing accidents and injuries.Conclusion:The introduction of the Jet Mud Mixer system by [Company Name] marks a significant advancement in drilling technology within the oil and gas industry. With its cutting-edge features, precision controls, and focus on efficiency, this innovative mud mixing solution enhances drilling rates, reduces environmental impact, and improves overall operational cost-effectiveness. Embarking on a journey towards a more sustainable and efficient future, [Company Name] is revolutionizing the drilling industry, setting new benchmarks for performance and safety.

High-Efficiency Sludge Agitator for Effective Waste Management

Sludge Agitator Improves Waste Treatment Efficiency and Environmental SustainabilityIn response to the growing demand for effective waste treatment solutions, the renowned company {} has recently unveiled its latest innovation – the Sludge Agitator. This state-of-the-art equipment is designed to significantly enhance the efficiency of waste treatment processes, ultimately contributing to a more sustainable and environmentally-friendly approach to waste management.The Sludge Agitator, a revolutionary solution developed by {}, is set to revolutionize the way in which sludge is treated in industrial and municipal wastewater treatment facilities. By effectively mixing and agitating the sludge, this equipment offers an efficient and cost-effective method for optimizing the treatment process, ultimately leading to improved overall performance.The primary function of the Sludge Agitator is to prevent the settling of solids within the sludge, which can lead to uneven treatment and reduced efficiency. By constantly agitating the sludge, this innovative equipment ensures that the solids remain in suspension, allowing for better treatment and separation of the waste materials.One of the key features of the Sludge Agitator is its versatility and adaptability to different types of waste treatment systems. Whether it is used in activated sludge processes, anaerobic digesters, or other treatment facilities, this equipment is designed to seamlessly integrate into existing infrastructure, providing a seamless and efficient solution for optimizing waste treatment operations.Furthermore, the Sludge Agitator is equipped with advanced control and monitoring capabilities, allowing operators to easily adjust the agitation intensity and duration to suit specific treatment requirements. This level of control not only enhances the overall performance of the equipment but also ensures that the treatment process is optimized for maximum efficiency and effectiveness.In addition to its technical capabilities, the Sludge Agitator also offers notable benefits in terms of environmental sustainability. By improving the overall efficiency of waste treatment processes, this equipment can help reduce the environmental impact of industrial and municipal operations, leading to lower energy consumption, reduced waste generation, and ultimately, a more sustainable approach to waste management.The introduction of the Sludge Agitator is a testament to {}'s commitment to developing innovative solutions that address the evolving needs of the waste treatment industry. With a proven track record of delivering high-quality and reliable equipment, the company continues to spearhead advancements in waste management technology, setting new standards for efficiency, reliability, and sustainability.As a leading provider of waste treatment solutions, {} is dedicated to supporting its customers in achieving their environmental and operational goals. The introduction of the Sludge Agitator represents yet another milestone in the company's ongoing efforts to drive positive change in the waste treatment industry, offering a tangible solution for improving efficiency and sustainability in waste management operations.In conclusion, the launch of the Sludge Agitator marks a significant advancement in waste treatment technology, offering a comprehensive solution for enhancing the efficiency and sustainability of waste treatment processes. With its cutting-edge design, advanced capabilities, and environmental benefits, this equipment is poised to make a transformative impact on the waste management industry, setting new standards for operational excellence and environmental responsibility. As the demand for more sustainable waste treatment solutions continues to grow, the Sludge Agitator stands out as a compelling and effective option for organizations looking to optimize their waste treatment operations and minimize their environmental footprint.

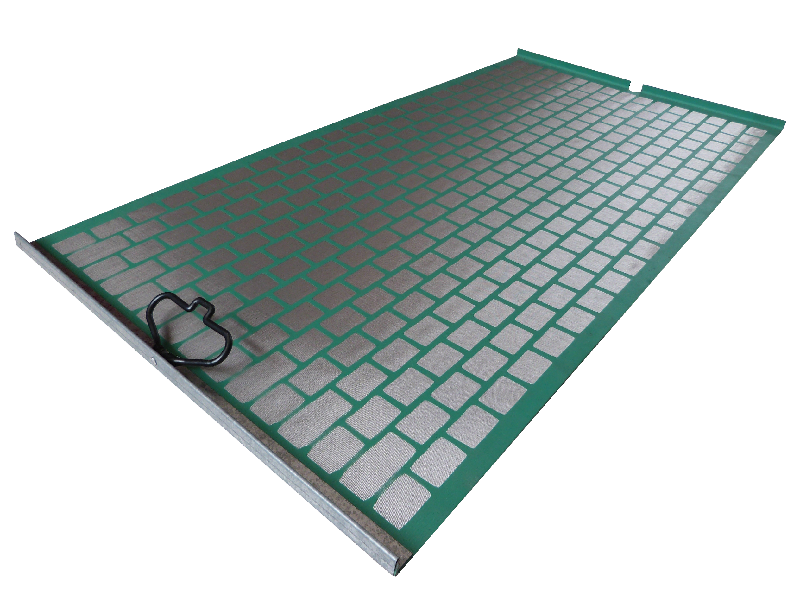

Discover the Versatility of Flat Shaker Screens for Effective Solid Separation

FLC 500 Flat Shaker Screen: Revolutionizing the Drilling IndustryThe drilling industry is constantly evolving, with new technologies and equipment constantly emerging to improve efficiency and operational capabilities. One such innovation making waves in the sector is the FLC 500 Flat Shaker Screen, a groundbreaking solution developed by a prominent industry player.Designed to enhance the performance and productivity of drilling operations, the FLC 500 Flat Shaker Screen is revolutionizing the way drilling companies approach their work. With its advanced features and engineering excellence, this game-changing technology has gained significant recognition within the industry.The FLC 500 Flat Shaker Screen is the result of extensive research and development by a leading drilling equipment manufacturer. Leveraging their rich experience and expertise, the company identified a need for an improved shaker screen solution to overcome the challenges faced by drilling companies.One of the key features that sets the FLC 500 Flat Shaker Screen apart from its competitors is its flat design. This innovative construction ensures optimal solids control, allowing for more efficient separation of drilling fluids and solids during the drilling process. The flat screen surface provides a larger area for fluid dewatering, maximizing the screen's capacity and performance.Additionally, the FLC 500 Flat Shaker Screen boasts enhanced durability and longevity. Crafted using high-quality materials and state-of-the-art manufacturing techniques, this robust solution withstands the harsh operating conditions typically encountered in drilling operations. Its extended lifespan not only reduces operational downtime but also significantly lowers maintenance and replacement costs.Furthermore, the FLC 500 Flat Shaker Screen offers exceptional versatility. Compatible with various drilling equipment, it seamlessly integrates with existing systems, ensuring a hassle-free installation process. Its adaptability empowers drilling companies to upgrade their equipment without requiring substantial modifications, thereby improving operational efficiency and saving valuable time.The company behind this breakthrough innovation is known for its commitment to delivering superior technology with a focus on customer satisfaction. With a relentless dedication to research and development, combined with a customer-centric approach, they have earned a reputation as a trusted and reliable partner in the drilling industry.The FLC 500 Flat Shaker Screen is just one example of the company's commitment to innovation. Their extensive product portfolio includes a range of drilling equipment tailored to meet the unique needs and challenges of the industry. From screens to pumps, they offer comprehensive solutions that cater to diverse drilling requirements.In addition to their cutting-edge technology, the company places great emphasis on customer support and service. Their team of highly skilled professionals provides industry-leading technical assistance and on-site support to ensure seamless integration and optimal performance of their equipment. This dedication to customer satisfaction has positioned them as a preferred supplier amongst drilling companies worldwide.The introduction of the FLC 500 Flat Shaker Screen marks a significant milestone in the drilling industry. With its flat design, enhanced durability, and unmatched versatility, it is transforming the way drilling operations are conducted. As companies continue to prioritize efficiency and productivity, this revolutionary technology is set to play a pivotal role in shaping the future of the drilling industry.

Hydrocyclone Desander Manufacturer for Drilling Mud Fluids - Buy Quality Solids Control Desander from China Supplier

The China Desander is an important component in the drilling industry. It is primarily used to remove solid particles, sand, and mud from drilling fluids. This is crucial because these particles can cause a number of problems in the drilling process, such as clogging of equipment and decreased efficiency.One of the most popular types of desanders is the Hydrocyclone Desander. This device works by creating a spinning motion that separates the solid particles from the fluid. The solids are then expelled out of the bottom while the clean fluid is discharged out of the top. This method is highly effective and efficient, making the Hydrocyclone Desander a preferred choice among many drilling companies.One of the leading manufacturers of Hydrocyclone Desanders is GN Solids Control. This China-based company offers high-quality desanders and other equipment for the drilling industry. GN Solids Control has a reputation for producing durable and reliable equipment that can withstand the harsh conditions of drilling.The GN mud desander is a popular product offered by the company. This particular desander is known for its good cones and efficient performance. It is designed to be used in conjunction with other equipment, such as shale shakers and mud cleaners, to provide a complete solids control system for drilling operations.For companies in need of a solids control drilling mud fluids desander, GN Solids Control is a reliable and trustworthy supplier. Their years of experience in the industry and commitment to quality make them a top choice for many drilling companies around the world.In conclusion, the China Desander and Hydrocyclone Desander play an important role in the drilling industry. They are essential for removing solid particles and maintaining the efficiency of drilling equipment. GN Solids Control is a leading supplier of high-quality desanders and other equipment, making them a top choice for companies in need of solids control solutions. With their commitment to quality and customer satisfaction, GN Solids Control is sure to continue to be a top player in the drilling industry for years to come.

High-efficiency Drilling Mud Solid Control System for China and Drilling Rig

China’s Drilling Mud Solid Control System and Solid Control System for Drilling Rig are at the forefront of cutting-edge technology in the oil and gas industry, providing innovative solutions for the management and treatment of drilling waste. With a proven track record of excellence, these systems have set a new standard for efficiency and environmental responsibility in the field of drilling operations.The Drilling Mud Solid Control System is designed to effectively remove solid particles from drilling fluids, ensuring the smooth and efficient progress of drilling operations. By utilizing high-performance equipment such as shale shakers, desanders, desilters, and decanting centrifuges, this system is able to separate and treat drilling waste with unparalleled precision and speed. The result is a significant reduction in waste disposal costs and environmental impact, as well as improved drilling fluid properties that enhance overall drilling efficiency.In addition to the Drilling Mud Solid Control System, the Solid Control System for Drilling Rig is a comprehensive solution that encompasses a wide range of equipment and processes for managing drilling waste on-site. Featuring advanced technologies such as mud cleaners, vacuum degassers, and centrifugal pumps, this system is capable of handling the full spectrum of drilling waste management needs, from initial solids removal to the recycling of drilling fluids. Its modular design and customizable configurations make it adaptable to a variety of drilling conditions and project requirements, ensuring maximum operational flexibility.Behind these industry-leading solutions is a company that has established itself as a premier provider of integrated drilling waste management systems. With a focus on research, development, and innovation, the company has consistently pushed the boundaries of what is possible in the field of solid control and waste management. Its team of experienced engineers and technicians are dedicated to delivering top-quality products and services that meet the evolving needs of the oil and gas industry.Moreover, the company’s commitment to environmental stewardship is evident in its emphasis on sustainable practices and the development of eco-friendly technologies. By prioritizing the efficient use of resources and the minimization of waste, the company is playing a proactive role in promoting responsible and sustainable drilling operations. This dedication to sustainability has earned the company recognition as a leader in the industry and a trusted partner for organizations seeking to enhance their environmental performance.In addition to its technical expertise, the company has also cultivated a reputation for exceptional customer service and support. Its global network of sales and service professionals ensures that customers receive prompt and reliable assistance, whether it’s for equipment installation, maintenance, or troubleshooting. This commitment to customer satisfaction has contributed to the company’s long-standing relationships with clients around the world, who rely on its expertise to optimize their drilling operations.Looking ahead, the company remains dedicated to advancing the state of the art in drilling waste management, as it continues to invest in research and development to bring new and improved solutions to market. By staying at the forefront of technological innovation and industry trends, the company is poised to lead the way in shaping the future of solid control and waste management in the oil and gas industry.As the demand for efficient and environmentally responsible drilling waste management solutions continues to grow, China’s Drilling Mud Solid Control System and Solid Control System for Drilling Rig are well-positioned to meet the evolving needs of the industry. With a proven track record of excellence, a commitment to sustainability, and a focus on customer satisfaction, the company is primed to remain a driving force in advancing the standards of drilling operations worldwide.

- Efficient shale shaker screens for improved performance in oil and gas industry

Screen Shale Shaker, a leading provider of innovative and efficient solids control equipment, has been making waves in the industry with its cutting-edge technology and superior performance. The company has recently introduced its latest model, the SS5000 Shale Shaker, which has been garnering attention for its advanced features and ability to enhance drilling operations.With a commitment to delivering high-quality products and unparalleled customer service, Screen Shale Shaker has established itself as a trusted name in the realm of solids control equipment. The company's extensive experience and expertise in the field have enabled them to develop industry-leading solutions that cater to the evolving needs of drilling professionals.The SS5000 Shale Shaker is a testament to Screen Shale Shaker's relentless pursuit of excellence. Equipped with a robust vibrating motor and a precisely engineered screen panel, this state-of-the-art shale shaker is designed to effectively separate solids from drilling fluid, ensuring optimal performance and cost-efficiency. The shaker's high G-force and large screening area contribute to its exceptional capacity to handle a wide range of drilling conditions, making it a valuable asset for any drilling operation.In addition to its superior performance capabilities, the SS5000 Shale Shaker is also lauded for its user-friendly design and ease of maintenance. The shaker's streamlined construction and intuitive controls make it simple to operate, while its durable components and minimal parts requirement contribute to reduced downtime and overall operating costs. Furthermore, Screen Shale Shaker's dedicated technical support team is readily available to provide assistance and ensure that the equipment performs at its peak potential.Screen Shale Shaker's commitment to innovation and customer satisfaction extends beyond the SS5000 Shale Shaker, encompassing a comprehensive range of solids control solutions. From shale shakers and mud cleaners to centrifuges and agitators, the company offers a diverse portfolio of equipment designed to optimize drilling performance and minimize environmental impact. Moreover, Screen Shale Shaker provides customized solutions tailored to specific operational requirements, demonstrating a deep understanding of the unique challenges faced by drilling professionals.As a testament to its unwavering dedication to excellence, Screen Shale Shaker has cultivated strong partnerships with industry leaders and earned a reputation for delivering unparalleled value to its customers. The company's proven track record of success and innovation has positioned it as a go-to provider for high-quality solids control equipment, and its continued commitment to pushing the boundaries of technology ensures that it remains at the forefront of the industry.Looking ahead, Screen Shale Shaker is poised to continue its trajectory of success, driven by a steadfast commitment to advancing the efficiency and effectiveness of solids control solutions. With the introduction of the SS5000 Shale Shaker, the company has raised the bar for performance and reliability, setting a new standard for excellence in the field. As the industry evolves and new challenges emerge, Screen Shale Shaker stands ready to lead the way with its unwavering dedication to innovation and customer satisfaction.

Top-rated Drilling Fluids Agitator - Find the Best Quality at An Affordable Price

Drilling Fluids Agitator Revolutionizes Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to improve efficiency and productivity. One such innovation that is making waves in the industry is the drilling fluids agitator developed by a leading company in the sector.The drilling fluids agitator is a crucial tool used in the process of drilling for oil and gas. It plays a vital role in maintaining the proper consistency and viscosity of the drilling fluids, which is essential for the success of drilling operations. The agitator is used to effectively mix the various components of the drilling fluids, ensuring that they are well blended and ready for use in the drilling process.The agitator's design and functionality are what set it apart from traditional agitators used in the industry. It is equipped with state-of-the-art technology that allows for precise control and monitoring of the mixing process. This technology enables operators to adjust the agitator's speed and intensity according to the specific requirements of the drilling fluids, ensuring optimal performance and consistency.Furthermore, the agitator is designed to withstand the harsh and demanding conditions typically encountered in drilling operations. Its robust construction and durable materials ensure that it can operate seamlessly in extreme temperatures and high-pressure environments, providing reliability and longevity for continuous use.The company behind the development of this innovative agitator has a long-standing reputation for delivering high-quality equipment and solutions to the oil and gas industry. With decades of experience and expertise in the field, the company has consistently been at the forefront of technological advancements, driving innovation and pushing the boundaries of what is possible in the industry.Through continuous research and development, the company has been able to stay ahead of the curve, anticipating the needs and challenges of the industry and developing solutions that address them effectively. The drilling fluids agitator is a prime example of the company's commitment to innovation and excellence, setting a new standard for agitators in the oil and gas sector.In addition to its cutting-edge technology, the company also prides itself on its dedication to customer satisfaction and support. It provides comprehensive training and technical assistance to ensure that operators can maximize the potential of the agitator and operate it safely and efficiently. This level of support and service has earned the company a loyal and satisfied customer base, further solidifying its position as a leader in the industry.The impact of the drilling fluids agitator on the oil and gas industry has been significant. Its introduction has led to improvements in drilling operations, resulting in enhanced efficiency, reduced downtime, and ultimately, cost savings for companies. By streamlining the mixing process and ensuring the consistency of drilling fluids, the agitator has contributed to improved overall performance and productivity in drilling operations.Looking ahead, the company is committed to furthering the development of innovative solutions for the oil and gas industry. It continues to invest in research and development, exploring new technologies and approaches to address the evolving needs of the industry. With a strong focus on sustainability and environmental responsibility, the company aims to develop solutions that not only improve efficiency but also minimize the impact on the environment.In conclusion, the drilling fluids agitator has proven to be a game-changer in the oil and gas industry, showcasing the impact that advanced technology and innovative solutions can have on the sector. With its state-of-the-art design, robust construction, and unparalleled performance, the agitator has set a new standard for drilling equipment, paving the way for a more efficient and sustainable future in the industry. As the company continues to lead the charge in innovation, it is poised to shape the future of drilling operations with its groundbreaking solutions.

High-quality Shale Shaker and Drilling Rig for Efficient China Drilling Operations

China Drill Shale Shaker and Drilling RigIn recent news, China has successfully developed and launched a new drill shale shaker and drilling rig, showcasing the country's advancements in drilling technology. This breakthrough in drilling equipment is expected to revolutionize the industry and improve efficiency in oil and gas exploration.The newly developed drill shale shaker and drilling rig are the result of extensive research and development by a leading Chinese company in the drilling equipment manufacturing sector. The company has a long-standing reputation for producing high-quality and innovative drilling equipment, and the latest launch further solidifies its position as a leader in the industry.The drill shale shaker is a vital component in the drilling process, used to separate drilling cuttings from the drilling fluid. This is essential for maintaining the integrity of the drilling fluid and ensuring smooth and efficient drilling operations. The new shale shaker is designed to achieve optimal performance, with enhanced efficiency and durability, making it an ideal choice for demanding drilling environments.In addition to the shale shaker, the company has also introduced a state-of-the-art drilling rig that is designed to work seamlessly with the shale shaker. The drilling rig is equipped with advanced technology and features that enhance its performance and reliability. It is designed to meet the complex and diverse drilling requirements of various geological and environmental conditions, making it a versatile and efficient tool for oil and gas exploration.The successful development of the drill shale shaker and drilling rig represents a significant milestone for the company and the Chinese drilling equipment manufacturing sector as a whole. It demonstrates the country's commitment to innovation and technological advancement in the field of oil and gas exploration.This latest advancement in drilling technology is expected to have a far-reaching impact on the global oil and gas industry. The improved efficiency and performance of the drill shale shaker and drilling rig will not only benefit Chinese oil and gas companies but also international companies operating in the region. The new equipment is poised to increase productivity, reduce costs, and improve safety standards in drilling operations, ultimately driving greater efficiency and profitability for the industry.The company behind the development of the drill shale shaker and drilling rig has a strong track record of delivering cutting-edge drilling equipment to the market. With a focus on innovation and quality, the company has established itself as a trusted and reliable partner for oil and gas companies worldwide. Its commitment to research and development has enabled it to consistently introduce new and improved drilling solutions, contributing to the advancement of the industry.As the demand for oil and gas continues to grow, the development of advanced drilling equipment like the new shale shaker and drilling rig is crucial for meeting the industry's evolving needs and challenges. The Chinese company's commitment to technological innovation and product development is expected to play a key role in shaping the future of the global oil and gas exploration sector.In conclusion, the launch of the new drill shale shaker and drilling rig in China represents a significant step forward for the country's drilling equipment manufacturing sector. The innovative and efficient drilling solutions are set to have a transformative impact on the industry, improving productivity and safety standards for oil and gas exploration operations. As the company continues to lead the way in technological advancement, it is poised to make a lasting impact on the global oil and gas industry.

Top Quality Shale Shakers Available for Sale in China - Find the Best Deals Now

China's Shale Shaker and Shale Shakers for Sale are revolutionizing the oil and gas industry with their innovative technology and high-performance capabilities. These state-of-the-art equipment are designed to efficiently separate drilling cuttings from drilling fluid, providing a crucial step in the process of drilling for oil and gas.One of the leading manufacturers of shale shakers in China, {} has established itself as a trusted provider of high-quality equipment for the oil and gas industry. With a strong focus on research and development, the company has continually advanced the capabilities of their shale shakers, making them some of the most reliable and efficient options on the market.The shale shaker is a critical component in the drilling process. It is responsible for removing large solids from the drilling fluid, which is essential for maintaining the integrity of the fluid and ensuring that it can be reused in the drilling operation. By efficiently separating the solid particles, the shale shaker helps to prolong the life of the drilling equipment and reduce the environmental impact of the drilling operation.In addition to their superior performance, the shale shakers offered by {} are also designed with durability and ease of maintenance in mind. This ensures that they can withstand the harsh conditions of drilling operations and require minimal maintenance to keep them operating at peak efficiency.With a commitment to providing exceptional customer service, {} offers a range of shale shakers for sale to meet the specific needs of their clients. Whether it's a small-scale drilling operation or a large-scale industrial project, the company has a shale shaker solution to suit every requirement.The company's extensive experience in the industry has allowed them to develop a deep understanding of the challenges faced by their clients and the demands of the oil and gas industry as a whole. This has driven their continuous innovation and improvement of their shale shaker technology, ensuring that they remain at the forefront of the industry.In addition to manufacturing shale shakers, {} also provides comprehensive support and technical assistance to their clients. This includes installation, training, and ongoing maintenance services, all aimed at ensuring that their clients are able to maximize the performance and lifespan of their equipment.By combining cutting-edge technology with a customer-centric approach, {} has solidified its position as a leading provider of shale shakers in China and beyond. With a commitment to quality, reliability, and innovation, the company continues to play a crucial role in the success of oil and gas drilling operations around the world.As the demand for oil and gas continues to grow, the need for efficient and reliable drilling equipment becomes increasingly important. {}'s shale shakers are playing a vital role in meeting this demand, providing a crucial piece of equipment that is essential for the success of drilling operations.Overall, {}'s dedication to excellence and innovation has positioned them as a key player in the oil and gas industry, and their shale shakers continue to set the standard for performance and reliability. With a focus on meeting the specific needs of their clients and a commitment to advancing the capabilities of their equipment, the company is poised to continue making a significant impact on the industry for years to come.

Drilling Fluids Technology Training Course | Learn Online or In-Person at International Locations

and Training, Drilling Fluids Technology, Mobility Oil & Gas, online training, international training locations.Drilling Fluids Technology: Learn from the Best with Mobility Oil & GasDrilling fluids technology is a crucial aspect of any well drilling process. Whether it's a land-based or offshore drilling project, the right drilling fluid equipment and expertise are necessary for a successful outcome. This is where Mobility Oil & Gas comes in. The company provides comprehensive drilling fluids technology training courses both online and in-person.Mobility Oil & Gas is a leading provider of drilling fluids technology training courses in a variety of drilling-related areas. The company has several years of experience delivering cutting-edge drilling solutions for clients in the oil and gas industry. They have a team of highly trained professionals dedicated to providing industry-leading training and support to drilling professionals around the world.The drilling fluids technology training courses offered by Mobility Oil & Gas cover a wide range of topics, from basic to advanced. The company's instructors are experienced professionals with years of experience in their respective fields. They provide practical insights into the latest industry trends, equipment, and techniques. The courses are designed to meet the needs of professionals at all levels of expertise, from beginner to advanced.Mobility Oil & Gas provides its drilling fluids technology training courses both online and in-person. The online courses are a convenient option for busy professionals who may not be able to attend in-person training. The company employs cutting-edge technology to deliver its online courses in an interactive and engaging manner. Students can learn at their own pace and from the comfort of their homes or offices.In-person training courses are available at several international locations. Mobility Oil & Gas operates in many countries around the world, providing easy access to their training courses. The company has invested heavily in state-of-the-art training facilities that provide a hands-on approach to learning. Students get the opportunity to work with the latest drilling fluid equipment and techniques, ensuring that they are adequately prepared for real-world scenarios.The drilling fluids technology training courses provided by Mobility Oil & Gas are designed to meet the needs of companies of all sizes. Companies can choose to train their entire staff or select individuals they want to develop. The company provides customized training solutions tailored to the needs of each company. This ensures that companies get the maximum return on their investment in training.The drilling fluids technology training courses provided by Mobility Oil & Gas cover a range of topics, including the basics of drilling fluids, advanced drilling fluid equipment and techniques, and best practices for managing drilling fluids. The courses emphasize safety and environmental responsibility and aim at reducing the risks associated with drilling operations. The courses are designed to meet the needs of a diverse range of stakeholders, including drilling engineers, drilling supervisors, drilling fluids engineers, and other personnel involved in drilling operations.In conclusion, drilling fluids technology training is essential to the success of any drilling project. Mobility Oil & Gas provides industry-leading training courses designed to equip drilling professionals with the latest drilling fluid equipment and techniques. The company's courses are available both online and in-person and cover a range of topics. Companies of all sizes can benefit from Mobility Oil & Gas's customized training solutions, ensuring that their staff is adequately prepared for the challenges of drilling operations.