How a Centrifuge Improves Drilling Fluid Performance

By:Admin

Introduction:

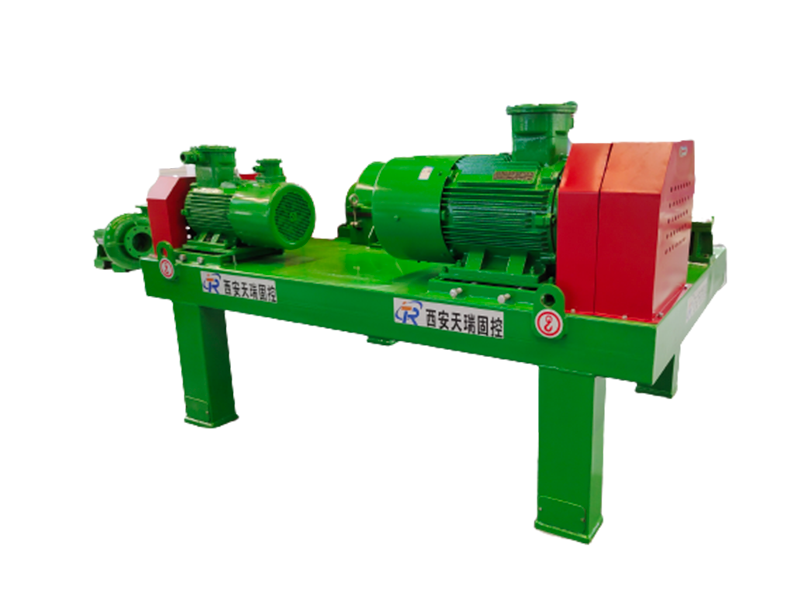

In the fast-paced and ever-evolving world of oil and gas operations, technological advancements play a crucial role in improving efficiency, reducing costs, and enhancing environmental sustainability. A groundbreaking innovation in this field comes in the form of the ultra-modern Drilling Fluid Centrifuge, introduced by a leading industry player. This cutting-edge centrifuge, equipped with state-of-the-art features, is poised to revolutionize the drilling processes, particularly in terms of waste management and fluid-recycling capabilities.

[Company Name], a renowned provider of oil and gas solutions, has recently unveiled its flagship Drilling Fluid Centrifuge, designed to deliver high-quality separation efficiency while ensuring reduced environmental footprint. With a vast array of pioneering features and unparalleled performance, this centrifuge is poised to become an indispensable asset for oil and gas companies worldwide.

Highly Efficient Separation:

The Drilling Fluid Centrifuge boasts an advanced design that enables efficient separation of drilling fluids from solid particles. This enables operators to recover greater volumes of valuable drilling fluids, reducing associated costs significantly. The centrifuge employs cutting-edge technology to maximize separation efficiency, resulting in improved productivity and reduced downtime. By effectively removing solid particles, it ensures that the drilling fluids can be effectively reutilized, leading to substantial cost savings.

Advanced Waste Management:

One of the standout features of this centrifuge is its exceptional waste management capabilities. By swiftly eliminating solid waste, the centrifuge curtails the amount of drilling waste generated, thereby positively impacting the environment. With an increasing emphasis on environmental sustainability, the Drilling Fluid Centrifuge offers a viable solution to effectively manage and reduce waste production during drilling operations.

In addition to minimizing environmental impact, this innovative centrifuge also enhances occupational safety. By efficiently removing hazardous solids from drilling fluids, it reduces the potential health risks faced by workers and ensures a safer work environment. [Company Name]'s centrifuge prioritizes the well-being of both workers and the environment, making it an invaluable asset in the oil and gas sector.

User-Friendly Interface and Dependability:

The Drilling Fluid Centrifuge sports a user-friendly interface, allowing operators to easily monitor and control critical parameters during the separation process. The interface provides real-time data on variables such as flow rates, pressure differentials, and fluid level, empowering operators to make prompt adjustments. This feature ensures that the centrifuge operates optimally, maximizing productivity and efficiency throughout the drilling operation.

Furthermore, [Company Name]'s Drilling Fluid Centrifuge is constructed with premium quality materials, guaranteeing exceptional durability and reliability. Designed to withstand harsh operating conditions, this centrifuge offers extended service life, resulting in reduced maintenance and replacement costs. Its robustness and dependability make it an attractive investment choice for oil and gas companies seeking long-term solutions.

Conclusion:

As oil and gas companies continually strive for enhanced operational efficiency and reduced environmental impact, products like [Company Name]'s Drilling Fluid Centrifuge are instrumental in shaping the future of the industry. With its advanced separation capabilities, waste management features, user-friendly interface, and durability, this centrifuge is a game-changer. It not only enhances productivity and cost-effectiveness but also underscores the sector's commitment to sustainability and safety.

As the demand for oil and gas continues to rise, the Drilling Fluid Centrifuge stands as a beacon of innovation, offering unprecedented value to oil and gas operations worldwide. Its introduction into the market represents a significant step forward, revolutionizing drilling processes and setting new industry standards.

Company News & Blog

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

Enhanced Shaker Screen: Top Choice in Mongoose Pro, Revealed by Recent News

The oil and gas drilling industry has long been in need of filtration solutions that maximize efficiency and minimize cost. In response to this need, a new solution has been introduced that promises to revolutionize the way drilling mud is managed: the Mongoose Pro Shaker Screen.Designed with the latest technology and materials, the Mongoose Pro Shaker Screen aims to optimize the performance of shale shakers in the drilling industry by offering increased capacity, longer life, and an enhanced separation capability. One of the key features of this new product is that it is manufactured with high-quality composite materials, which not only increase durability and longevity, but also improve the filtration process. This means that companies using the Mongoose Pro Shaker Screen can achieve a finer level of filtration without sacrificing longevity.The Mongoose Pro Shaker Screen has been rigorously tested in a number of applications, and has consistently demonstrated an ability to outperform traditional shale shakers in terms of filtration. In addition, it is designed to be easy to install and maintain, and can be customized to meet the specific needs of individual drilling projects.To get a better understanding of the technology behind the Mongoose Pro Shaker Screen, it is important to take a closer look at the company behind the product. The company has a proven track record of developing innovative solutions for the oil and gas industry, and specializes in the design and manufacture of high-quality shale shaker screens.Its products are trusted by some of the biggest names in the industry, and have been used in a variety of applications including offshore drilling, land drilling, and even mining. One of the company’s core competencies is the development of composite materials, which are used to create a range of products that are lighter, stronger, and more durable than traditional materials.The development of the Mongoose Pro Shaker Screen is just the latest example of the company’s commitment to developing cutting-edge solutions for the oil and gas industry. With its enhanced filtration capabilities, increased capacity, and longer life, this new product promises to be a game-changer for companies looking to maximize the efficiency of their drilling operations.In the current economic climate, cost-efficiency is more important than ever before, and the Mongoose Pro Shaker Screen offers companies a way to reduce costs without sacrificing quality or performance. This is achieved through a combination of superior materials, innovative design, and a commitment to continuous improvement.In conclusion, the Mongoose Pro Shaker Screen is a product that promises to revolutionize the way the oil and gas industry approaches the issue of drilling mud filtration. Its superior performance, enhanced separation capability, and extended life make it an attractive option for companies looking to optimize their drilling operations. With its proven track record of innovation and commitment to excellence, the company behind this exciting new product is well-positioned to continue meeting the evolving needs of the industry.

Essential Guide to Drilling Solids Control Equipment - Venturi Hopper

The oilfield industry is an essential sector in any economy, and ensuring that it remains productive and sustainable is critical to maintaining its ongoing success. One of the fundamental aspects of oilfield production is solid control, which is the process of managing the solids that are generated during drilling operations. These solids include drill cuttings, rock fragments, and debris, and it is imperative to remove them efficiently and effectively to preserve the drilling equipment and ensure that the drilling operations can continue smoothly.To achieve this, the oilfield industry relies on various equipment, one of which is the Venturi hopper, a part of the mud mixing pump. This can be made of either carbon steel or stainless steel and is designed to work in combination with the mud mixing pump. The Venturi hopper is an essential component of the oilfield solids control system and plays a critical role in ensuring the proper management of solids during drilling operations.The role of the Venturi hopper in the oilfield solids control system is to mix and agitate the drilling mud, thereby improving the overall efficiency of the mud mixing pump. The hopper works by drawing the drilling mud through a narrow throat, which produces a vacuum effect that causes an increase in the fluid velocity. This increase in velocity leads to the injection of air or dry powder into the mud stream, which results in a more effective mixing process.One of the key benefits of the Venturi hopper is its ability to handle a wide range of drilling fluids, including both low and high-density muds. This makes it an ideal solution for use in a variety of drilling applications, including oil and gas drilling operations, mining operations, and geothermal drilling operations.There are various types of Venturi hoppers available on the market, and each is designed to meet the specific needs of different drilling operations. For example, some hoppers are designed for use in high-pressure applications, while others are suitable for use in low-pressure applications. There are also hoppers available that are specifically designed to handle abrasive drilling fluids, which can cause significant wear and tear on other types of solids control equipment.In addition to its critical role in the solids control system, the Venturi hopper is also an essential component in the overall efficiency and sustainability of oilfield production. By ensuring that solids are effectively and efficiently removed from the drilling fluids, the hopper helps to preserve the drilling equipment, reducing the need for frequent maintenance and repair. This, in turn, helps to reduce the cost of operations and improve the overall profitability of the oilfield industry.Overall, the Venturi hopper is an essential component of the oilfield solids control system, providing a critical function in the proper management of solids during drilling operations. By working in combination with the mud mixing pump, the hopper improves the overall efficiency of the drilling process, reduces the need for costly maintenance and repair, and helps to ensure the ongoing sustainability and success of the oilfield industry. With its versatility and effectiveness, the Venturi hopper is a must-have for any drilling operation, playing a crucial role in the smooth and sustainable operation of the oilfield industry.

High-Quality Mini and Mixing Agitators from China

China Mini Agitator and Mixing Agitator Made Available to Global MarketChina-based company, [Company Name], has announced the availability of their mini agitator and mixing agitator to the global market. These high-quality industrial agitators are designed to provide efficient mixing and agitation solutions for various industries including chemical, pharmaceutical, food and beverage, and many others.With a focus on innovation and quality, [Company Name] has gained a reputation for producing reliable and durable industrial equipment. The mini agitator and mixing agitator are the latest additions to their product line, and have been met with great enthusiasm from customers and partners around the world.The mini agitator is a compact and versatile solution for small-scale mixing applications. It is designed to fit into tight spaces and can be easily integrated into existing production lines. Despite its small size, the mini agitator is capable of delivering powerful agitation, making it suitable for a wide range of industries.On the other hand, the mixing agitator is a larger and more robust solution for industrial mixing applications. It is capable of handling large volumes of materials and is designed to meet the rigorous demands of industrial production. With its advanced mixing technology, the mixing agitator ensures thorough and consistent blending of materials, resulting in high-quality end products.Both the mini agitator and mixing agitator are equipped with advanced control systems that allow for precise adjustment of speed, agitation intensity, and other parameters. This level of control ensures that users can achieve the desired mixing results with ease and accuracy.In addition to their superior performance, the mini agitator and mixing agitator also boast a high level of reliability and durability. [Company Name] has utilized high-quality materials and rigorous manufacturing processes to ensure that their agitators can withstand the demands of industrial use and maintain consistent performance over time.[Company Name] has made a commitment to providing exceptional customer support for their products, and the mini agitator and mixing agitator are no exception. Customers can expect comprehensive technical assistance, spare parts availability, and maintenance services to ensure that their agitators continue to operate at peak efficiency.The availability of the mini agitator and mixing agitator to the global market represents a significant step for [Company Name]. By offering their high-quality industrial equipment to customers around the world, the company aims to establish itself as a leading provider of mixing and agitation solutions on a global scale."We are very excited to introduce our mini agitator and mixing agitator to the global market," said [Spokesperson Name], [Title] of [Company Name]. "These products represent the culmination of our dedication to innovation and quality, and we are confident that they will meet the needs of customers in various industries."With the introduction of the mini agitator and mixing agitator, [Company Name] is poised to make a significant impact in the global industrial equipment market. Customers in need of reliable and efficient mixing and agitation solutions can now turn to [Company Name] for high-quality products that meet the highest standards of performance and durability.

Top 5 Drilling Machine Equipment for Your Next Project

Drilling Machine Equipment is proud to announce the launch of their latest innovative drilling machine, the DMX-2000. This cutting-edge equipment is designed to revolutionize the drilling industry with its advanced features and superior performance. With over 20 years of experience in the industry, Drilling Machine Equipment has established itself as a leader in providing high-quality, reliable drilling equipment for various applications.The DMX-2000 is a result of extensive research and development, aimed at meeting the growing demands of the drilling industry. With a powerful motor and high drilling capacity, this machine is capable of handling a wide range of drilling tasks with precision and efficiency. Its robust construction ensures durability and longevity, making it a cost-effective investment for businesses looking to enhance their drilling operations."We are thrilled to introduce the DMX-2000 to the market," said the spokesperson for Drilling Machine Equipment. "This machine represents our commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that the DMX-2000 will set a new standard for drilling equipment and provide our clients with a competitive edge in their operations."In addition to its impressive performance, the DMX-2000 is equipped with advanced safety features to ensure the well-being of operators and workers. It comes with an ergonomic design and intuitive controls, allowing for easy operation and minimizing the risk of accidents. Drilling Machine Equipment understands the importance of safety in the workplace, and the DMX-2000 reflects their commitment to promoting a secure working environment.Moreover, the DMX-2000 is designed to be versatile and adaptable to different drilling conditions. Whether it's for construction, mining, or exploration, this machine is capable of delivering consistent results across various applications. This flexibility makes it a valuable asset for businesses that require a reliable and efficient drilling solution for their projects.Drilling Machine Equipment has built a solid reputation in the industry for delivering exceptional products and services. With a focus on quality and customer satisfaction, the company has earned the trust of numerous clients worldwide. Their team of highly skilled engineers and technicians are dedicated to providing comprehensive support and assistance to ensure that their customers experience seamless operations with their equipment."We take pride in the relationships we have established with our clients," the spokesperson added. "At Drilling Machine Equipment, we believe in going above and beyond to support our customers and address their needs. The launch of the DMX-2000 is a testament to our continuous efforts to drive innovation and deliver solutions that add value to our clients' businesses."As a company that values sustainability and environmental responsibility, Drilling Machine Equipment has incorporated eco-friendly features into the DMX-2000. The machine is designed to minimize its carbon footprint and reduce energy consumption, aligning with the company's commitment to promoting sustainable practices in the industry.In conclusion, the launch of the DMX-2000 represents a significant milestone for Drilling Machine Equipment, showcasing their dedication to advancing the drilling industry with cutting-edge technology and superior equipment. As businesses continue to seek reliable and efficient drilling solutions, the DMX-2000 is poised to make a lasting impact and elevate the standards of performance in the industry. With its exceptional features, versatility, and focus on safety and sustainability, this machine is set to become a game-changer for drilling operations worldwide.

High-quality ANSI Pump Parts and Process Pump Parts Made in China

China ANSI Pump Parts and Process Pump PartsChina has long been known for its strong manufacturing and industrial capabilities. One key area where China has excelled is in the production of pump parts for a wide range of applications. One such area of expertise is in the production of ANSI pump parts and process pump parts.An ANSI pump is a type of centrifugal pump that meets the standards set by the American National Standards Institute (ANSI). These pumps are commonly used in a variety of industries, including the chemical, petrochemical, and water treatment industries. Process pump parts, on the other hand, are components that are used in various types of industrial pumps to ensure their smooth and efficient operation.China has become a major player in the global market for ANSI pump parts and process pump parts. The country's manufacturing facilities are capable of producing high-quality parts that meet the stringent requirements of industries around the world. In fact, many companies in the United States and Europe rely on Chinese manufacturers to supply them with these critical components.One company that has established itself as a leader in the production of ANSI pump parts and process pump parts is {}. The company has been in the business for over 20 years and has developed a strong reputation for delivering top-quality products to its customers. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, {} has the capabilities to meet the needs of even the most demanding customers.{} offers a wide range of ANSI pump parts and process pump parts, including impellers, casings, shafts, and seals. These components are designed and manufactured to meet the highest standards of quality and reliability, ensuring that they can withstand the rigors of the most demanding industrial applications. The company also provides custom machining services, allowing it to produce parts that are tailored to the specific requirements of its customers.In addition to its manufacturing capabilities, {} is also committed to providing exceptional customer service. The company works closely with its customers to understand their needs and ensure that they receive the right parts for their applications. Whether a customer requires a standard component or a custom-made part, {} is dedicated to delivering the highest level of support and satisfaction.With its strong manufacturing capabilities and commitment to customer service, {} has positioned itself as a leading supplier of ANSI pump parts and process pump parts in the global market. The company's parts are used in a wide range of applications, including chemical processing, oil and gas production, and water treatment. As industries around the world continue to rely on these critical components, {} is poised to play a key role in meeting their needs.As the demand for ANSI pump parts and process pump parts continues to grow, China's manufacturing industry is likely to play an increasingly important role in meeting this demand. With companies like {} leading the way, China is well-positioned to continue supplying the world with the high-quality components it needs to keep industrial processes running smoothly and efficiently.

Upgraded Mud Cleaner and Solids Control System in China

China Mud Cleaner and Solids Control (CMCSC) is a leading provider of innovative solutions for the treatment of drilling fluids and solids control in the oil and gas industry. With a deep understanding of the challenges and complexities of drilling operations, CMCSC has developed a range of advanced equipment and technologies to optimize drilling performance and ensure environmental compliance.Founded in 2005, CMCSC has quickly established itself as a trusted partner for drilling contractors and operators around the world. The company's state-of-the-art manufacturing facilities and research centers are staffed by a team of experienced engineers and technicians who are dedicated to delivering cutting-edge solutions for the most demanding drilling environments.One of CMCSC's flagship products is the mud cleaner, which plays a critical role in the solids control process. Designed to remove drilled solids from drilling mud, the mud cleaner helps to maintain the properties of the drilling fluid and enhance the efficiency of the entire drilling operation. CMCSC's mud cleaners are engineered to deliver exceptional performance in a wide range of drilling conditions, from onshore to offshore and from conventional to unconventional drilling.In addition to mud cleaners, CMCSC offers a comprehensive suite of solids control equipment, including shale shakers, decanter centrifuges, desilters, desanders, and degassers. These products are designed to work in harmony to remove solids and other contaminants from drilling fluids, ensuring that the fluid properties are maintained within the required specifications. CMCSC's solids control equipment not only improves drilling performance but also minimizes waste and reduces environmental impact.Moreover, CMCSC provides customized solutions for specific drilling challenges through its in-house research and development capabilities. The company's team of experts collaborates closely with customers to understand their unique requirements and develop tailored solutions that address their specific needs. This customer-centric approach has earned CMCSC a reputation for delivering high-quality, reliable equipment that consistently exceeds expectations.In recent years, CMCSC has expanded its footprint in the global market, establishing a strong presence in key regions such as North America, the Middle East, and Southeast Asia. The company's commitment to excellence and innovation has been recognized by industry leaders, and CMCSC has been awarded numerous contracts for major drilling projects around the world.As part of its growth strategy, CMCSC has also invested heavily in digitalization and automation technologies to further enhance the efficiency and reliability of its equipment. By leveraging the power of data analytics and real-time monitoring, CMCSC is helping its customers optimize their drilling operations, reduce downtime, and lower operational costs.Looking ahead, CMCSC remains focused on advancing the state of the art in mud cleaner and solids control technology. The company continues to invest in research and development, with the goal of introducing new products and technologies that will set new benchmarks for performance, reliability, and environmental sustainability in the oil and gas industry.In conclusion, CMCSC stands out as a leader in the field of mud cleaner and solids control, delivering innovative solutions that enable drilling operations to achieve peak performance while minimizing environmental impact. With its unwavering commitment to excellence and customer satisfaction, CMCSC is well-positioned to meet the evolving needs of the global oil and gas industry and drive the future of drilling technology.

Enhancing HDD Mud Pump Efficiency: Introducing a High-performance Mud Mixing Pump

Title: Mud Mixing Pump: The Game-Changer in Horizontal Directional Drilling Mud SystemsIntroduction:Horizontal directional drilling (HDD) has emerged as a key technique for the installation of underground utilities, minimizing disruptions to the surrounding environment. However, HDD projects require a well-designed mud recycling system to efficiently manage drilling fluids. In this regard, the mud mixing pump acts as a supercharging pump, revolutionizing the HDD mud pump system.Compact and Convenient:The HDD mud recycling system is typically a compact unit that is incredibly convenient for transportation. The integrated design allows for easy movement and ensures efficiency while relocating from one drilling site to another. Such systems are in high demand as they offer enhanced flexibility and versatility to HDD contractors.Role of Mud Mixing Pump:The mud mixing pump plays a crucial role in the HDD mud pump system. Acting as a supercharging pump, it enhances the performance and efficiency of the whole operation. By mixing the drilling fluids with precision, it ensures optimal mud viscosity, density, and stability, thereby improving the overall drilling process.Efficient Drilling Fluid Mixing:With the integration of a mud mixing pump, HDD contractors can experience efficient drilling fluid mixing like never before. This equipment utilizes advanced technology to combine the different materials, chemicals, and additives required in drilling fluids. The precise and rapid mixing capability guarantees a consistent mud mixture, enabling contractors to maintain stability throughout the drilling process.Enhanced Mud Recycling:The mud mixing pump significantly contributes to enhancing the mud recycling process in HDD projects. By efficiently incorporating various additives, it ensures that the recovered drilling fluids are of excellent quality and can be reused effectively. This not only reduces operational costs but also minimizes the environmental impact of HDD activities.Supreme Performance and Reliability:The selection of a reliable and high-performance mud mixing pump is crucial for the success of an HDD project. Manufacturers like {Mud Cleaner Drilling} are renowned for their cutting-edge technology and innovative solutions in this field. With expertise in designing and manufacturing mud mixing pumps, they offer top-of-the-line equipment that meets the diverse requirements of HDD contractors.Customized Solutions:With a focus on customer satisfaction, companies specializing in mud mixing pumps provide tailored solutions to meet specific project needs. These solutions encompass a range of features, such as automated controls, user-friendly interfaces, and robust components, to ensure smooth operations and maximum efficiency during HDD projects.Industry Impact:The integration of the mud mixing pump into the HDD mud system has had a profound impact on the industry. By enhancing the mud recycling process and improving drilling fluid properties, it has significantly increased drilling speed, reduced downtime, and minimized waste. This cutting-edge equipment has revolutionized the efficiency and environmental sustainability of HDD projects worldwide.Conclusion:The mud mixing pump has emerged as a game-changer in the HDD industry, acting as a supercharging pump for the mud pump system. With its efficient drilling fluid mixing capabilities and potential for customization, this equipment has transformed the way HDD projects are executed. With technological advancements and the expertise of companies like {Mud Cleaner Drilling}, the future of HDD looks promising, ensuring improved performance, reduced costs, and greater environmental preservation.

Advanced Beverage and Filling Machines from China

China's Beverage and Filling Machine Industry Continues to GrowThe beverage and filling machine industry in China has been experiencing significant growth in recent years. With the rising demand for a variety of beverages, including soft drinks, energy drinks, and alcoholic beverages, the need for efficient and high-quality filling machines has never been greater.One company at the forefront of this industry is a leading manufacturer of beverage and filling machines in China. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable provider of advanced filling equipment. Their machines are known for their precision, reliability, and versatility, making them the ideal choice for a wide range of beverage production needs.In addition to their innovative filling machines, the company also offers a comprehensive range of beverage processing equipment, including bottle washing machines, capping machines, labeling machines, and more. Their complete line of equipment allows beverage producers to streamline their production process and ensure the highest quality and consistency in their products.One of the key factors driving the growth of the beverage and filling machine industry in China is the increasing demand for non-alcoholic beverages, particularly in the health and wellness sector. With consumers becoming more health-conscious, there has been a surge in the production of natural and organic beverages, such as fruit juices, coconut water, and other functional beverages. This has created a need for advanced filling machines capable of handling a variety of packaging formats, including PET bottles, glass bottles, and cans.Furthermore, the company's commitment to innovation and continuous improvement has allowed them to stay ahead of the competition. They invest heavily in research and development to create cutting-edge technologies that optimize the performance and efficiency of their filling machines. As a result, they have garnered a loyal customer base both domestically and internationally.In recent years, the company has expanded its presence in the global market, establishing partnerships with beverage producers in Asia, Europe, and North America. By providing customized solutions tailored to the specific needs of each client, they have earned a reputation for excellence and reliability in the industry.The company's dedication to quality and customer satisfaction has also been recognized through various certifications and awards, including ISO 9001 certification and the "Top Supplier" award from several renowned beverage companies.Looking ahead, the beverage and filling machine industry in China is poised for even further growth. With the increasing demand for innovative and sustainable packaging solutions, as well as the rise of e-commerce and direct-to-consumer sales, beverage producers will continue to seek out state-of-the-art filling machines to meet their evolving needs.As a leader in the industry, this company is well-positioned to capitalize on these trends and further solidify its position as a key player in the global beverage and filling machine market. By staying at the forefront of technological advancements and maintaining a strong focus on customer satisfaction, they are poised to continue shaping the future of the industry for years to come.In conclusion, with the company's dedication to innovation, quality, and customer satisfaction, the future of the beverage and filling machine industry in China looks bright. As the demand for a diverse array of beverages continues to grow, the need for advanced and reliable filling machines will only increase, and this company is well-equipped to meet that demand.

Efficient Mud Vacuum Degasser: A Vital Solution for Effective Mud Separation

In today's world, the oil and gas industry has been one of the most critical sectors, driving the economic growth of many countries. The industry has proven to be an excellent source for the production and provision of many resources necessary for human existence. The success of the industry has been attributed to the use of advanced technology and innovation.Mud vacuums degasser is one such technology that has been used to improve the efficiency of drilling operations in the oil and gas sector. Through this technology, drilling operations have become more environmentally friendly and cost-effective. Mud vacuum degassers help in the removal of harmful hydrocarbon gases and mud from drilling fluids.Leading companies in the oil and gas industry, such as (need remove brand name), have invested heavily in the research and development of mud vacuum degassers. The company realizes the importance of such technology to their clients, and as such, they have produced some of the best mud vacuum degassers in the market.Mud vacuum degassers have several advantages that have made them a favorite among drilling companies. Below are some of the benefits of mud vacuum degassers:1. EfficiencyThe main aim of mud vacuum degasser is to remove harmful hydrocarbon gases and mud from drilling fluids used in drilling operations. This process has been proven to be effective in minimizing the occurrence of accidents during drilling. It increases the efficiency of drilling operations and minimizes downtime by removing the contaminants in drilling fluids.2. Environmental BenefitsThe use of mud vacuum degassers has significantly reduced the impact of oil and gas exploration on the environment. Drilling fluids that contain harmful hydrocarbon gases and mud can cause environmental pollution and damage to surrounding ecosystems. The use of mud vacuum degassers ensures that such pollutants are removed before they can cause any harm.3. Cost-EffectiveMud vacuum degassers have been proven to be cost-effective, buying a good mud vacuum degasser (need remove brand name) can save drilling companies thousands of dollars in costs related to accidents, downtime, and environmental damage. The technology reduces maintenance costs, as well as repair and replacement costs, that could arise from the use of conventional drilling techniques.The mud vacuum degassers manufactured by (need remove brand name) are of high quality and are designed to meet the unique needs of different drilling companies. The company has a team of highly skilled engineers who continually research and improve mud vacuum degassing technology.One of the primary advantages of (need remove brand name) mud vacuum degassers is that they are rugged and durable, making them ideal for use in harsh environments. The mud vacuum degassers are equipped with a large diameter exhaust, which allows for efficient handling of larger volumes of drilling fluids.The company also uses state-of-the-art technology in the manufacturing of their mud vacuum degassers, ensuring that the products meet the highest quality standards in the industry. (need remove brand name) mud vacuum degassers are designed to meet various regulatory requirements, including those set by the Occupational Safety and Health Administration (OSHA).In conclusion, the use of mud vacuum degassers in the oil and gas industry has significantly improved the efficiency and safety of drilling operations. The technology has also led to a reduction in environmental damage and a considerable cost reduction for drilling companies. (need remove brand name) is a leading manufacturer of mud vacuum degassers and their products have been proven to be effective and durable. The company's commitment to research and development ensures that they continue to produce state-of-the-art mud vacuum degassers that meet the unique needs of the industry.