Tunneling Mud Recycling and Sand Recycling Processing in China

By:Admin

China's tunneling mud and sand recycling processing technology has reached a new milestone with the development of innovative solutions to address environmental concerns and improve efficiency in tunneling projects. The technology is set to transform the way tunneling mud and sand are managed, providing a sustainable approach to construction waste management.

With rapid urbanization and infrastructure development in China, the demand for tunneling projects has been on the rise. However, the generation of large volumes of tunneling mud and sand has posed significant environmental and logistical challenges. Traditional disposal methods such as landfills and open dumping have raised concerns about soil and water pollution, as well as the depletion of natural resources.

In response to these challenges, innovative companies like [company name] have developed advanced tunneling mud recycling and sand recycling processing technology to address the environmental impact of tunneling projects. The technology incorporates a range of equipment and systems that enable the efficient separation, treatment, and recycling of tunneling mud and sand, thereby minimizing waste and reducing the ecological footprint of construction activities.

[Company name] has been at the forefront of promoting sustainable construction practices in China and has established itself as a leading provider of tunneling mud recycling and sand recycling processing solutions. With a strong focus on research and development, the company has continuously worked to enhance its technology and equipment to meet the evolving needs of the construction industry.

The tunneling mud recycling and sand recycling processing technology offered by [company name] is designed to address the specific requirements of tunneling projects, ensuring that the environmental impact of construction activities is minimized. The technology includes a range of equipment such as mud recycling systems, sand recycling systems, and dewatering units, all of which are designed to efficiently separate and treat tunneling mud and sand for reuse in construction activities.

One of the key benefits of the tunneling mud recycling and sand recycling processing technology is its ability to significantly reduce the volume of waste generated from tunneling projects. Through the effective separation and treatment of tunneling mud and sand, the technology enables a high level of resource recovery, thereby reducing the need for new raw materials and minimizing the demand for landfill space.

Furthermore, the technology is designed to improve the overall efficiency of tunneling projects by providing a reliable source of high-quality recycled materials for use in construction activities. This not only contributes to cost savings for project developers but also supports the sustainable use of resources, aligning with China's commitment to promoting green and sustainable development.

As China continues to prioritize environmental protection and sustainable development, the adoption of tunneling mud recycling and sand recycling processing technology is set to play a crucial role in advancing the country's construction industry. By promoting the responsible management of construction waste and the efficient use of resources, the technology contributes to the realization of China's environmental and sustainable development goals.

In conclusion, the advancement of tunneling mud recycling and sand recycling processing technology in China represents a significant milestone in the construction industry. By addressing environmental concerns and promoting resource efficiency, the technology is set to transform the way tunneling projects are managed, contributing to a more sustainable and environmentally friendly approach to construction waste management. With companies like [company name] leading the way with innovative solutions, tunneling mud and sand recycling processing technology is poised to be a game-changer for the construction industry in China.

Company News & Blog

Efficient Mud Cleaning Machine for Improved Operation

Mud Cleaning Machine Revolutionizes the Oil and Gas IndustryThe oil and gas industry is constantly evolving, with new technologies and innovations that aim to improve efficiency and reduce environmental impact. One such innovation that is making waves in the industry is the Mud Cleaning Machine, a game-changing technology that is revolutionizing the way drilling mud is treated and recycled.The Mud Cleaning Machine, developed by a leading oilfield equipment manufacturer, is a state-of-the-art piece of equipment that is designed to separate and remove solids from drilling mud, resulting in cleaner mud that can be reused in the drilling process. This innovative technology is helping oil and gas companies to significantly reduce the amount of drilling waste that is generated, ultimately leading to cost savings and a smaller environmental footprint.The Mud Cleaning Machine works by utilizing a series of screens and hydrocyclones to remove solids from the drilling mud, while also separating the mud into different density levels. The cleaned mud can then be reused in the drilling process, reducing the need for fresh mud and ultimately lowering the overall cost of drilling operations.In addition to its environmental and cost-saving benefits, the Mud Cleaning Machine is also improving the safety of drilling operations. By removing solids from the mud, the risk of equipment damage and downtime is significantly reduced, leading to smoother and more efficient drilling operations.The company behind the Mud Cleaning Machine has a long-standing reputation for developing and manufacturing high-quality oilfield equipment. With a focus on innovation and a commitment to sustainability, the company has become a trusted partner for oil and gas companies around the world.In addition to the Mud Cleaning Machine, the company also offers a range of other equipment and services designed to improve the efficiency and environmental performance of drilling operations. From wastewater treatment systems to solid control equipment, the company provides a comprehensive suite of solutions that are helping oil and gas companies to meet their operational and sustainability goals.The development of the Mud Cleaning Machine is a testament to the company’s dedication to innovation and its commitment to driving positive change in the oil and gas industry. By providing a solution that not only improves efficiency and cost savings but also reduces environmental impact, the company is playing a crucial role in helping the industry to become more sustainable and responsible.Furthermore, the company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a global network of sales and service locations, the company is able to provide ongoing support to its customers, ensuring that they are able to maximize the value and performance of the Mud Cleaning Machine and other equipment.The impact of the Mud Cleaning Machine on the oil and gas industry is undeniable. By enabling companies to reduce waste, improve efficiency, and enhance safety, this innovative technology is helping to shape the future of drilling operations. As the industry continues to evolve, it is clear that the Mud Cleaning Machine will play a crucial role in driving positive change and creating a more sustainable and responsible oil and gas industry.

Advanced Beverage and Filling Machines from China

China's Beverage and Filling Machine Industry Continues to GrowThe beverage and filling machine industry in China has been experiencing significant growth in recent years. With the rising demand for a variety of beverages, including soft drinks, energy drinks, and alcoholic beverages, the need for efficient and high-quality filling machines has never been greater.One company at the forefront of this industry is a leading manufacturer of beverage and filling machines in China. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable provider of advanced filling equipment. Their machines are known for their precision, reliability, and versatility, making them the ideal choice for a wide range of beverage production needs.In addition to their innovative filling machines, the company also offers a comprehensive range of beverage processing equipment, including bottle washing machines, capping machines, labeling machines, and more. Their complete line of equipment allows beverage producers to streamline their production process and ensure the highest quality and consistency in their products.One of the key factors driving the growth of the beverage and filling machine industry in China is the increasing demand for non-alcoholic beverages, particularly in the health and wellness sector. With consumers becoming more health-conscious, there has been a surge in the production of natural and organic beverages, such as fruit juices, coconut water, and other functional beverages. This has created a need for advanced filling machines capable of handling a variety of packaging formats, including PET bottles, glass bottles, and cans.Furthermore, the company's commitment to innovation and continuous improvement has allowed them to stay ahead of the competition. They invest heavily in research and development to create cutting-edge technologies that optimize the performance and efficiency of their filling machines. As a result, they have garnered a loyal customer base both domestically and internationally.In recent years, the company has expanded its presence in the global market, establishing partnerships with beverage producers in Asia, Europe, and North America. By providing customized solutions tailored to the specific needs of each client, they have earned a reputation for excellence and reliability in the industry.The company's dedication to quality and customer satisfaction has also been recognized through various certifications and awards, including ISO 9001 certification and the "Top Supplier" award from several renowned beverage companies.Looking ahead, the beverage and filling machine industry in China is poised for even further growth. With the increasing demand for innovative and sustainable packaging solutions, as well as the rise of e-commerce and direct-to-consumer sales, beverage producers will continue to seek out state-of-the-art filling machines to meet their evolving needs.As a leader in the industry, this company is well-positioned to capitalize on these trends and further solidify its position as a key player in the global beverage and filling machine market. By staying at the forefront of technological advancements and maintaining a strong focus on customer satisfaction, they are poised to continue shaping the future of the industry for years to come.In conclusion, with the company's dedication to innovation, quality, and customer satisfaction, the future of the beverage and filling machine industry in China looks bright. As the demand for a diverse array of beverages continues to grow, the need for advanced and reliable filling machines will only increase, and this company is well-equipped to meet that demand.

High-Quality Injection Mold for Waste Container and Plastic Waste Container Mould from China

China Injection Mold for Waste Container and Plastic Waste Container MouldIn recent years, the issue of plastic waste management has gained significant attention globally. With the increasing concerns about environmental pollution, many companies are exploring more eco-friendly solutions for waste management. In line with this, a leading Chinese injection mold company has developed a cutting-edge technology to address this growing concern - the China Injection Mold for Waste Container and Plastic Waste Container Mould.The company, which prefers to remain anonymous, has established itself as a key player in the injection mold industry. With a strong focus on innovation and quality, they have gained a solid reputation for delivering high-performance mold solutions to clients worldwide. Their expertise in designing and manufacturing precision molds has earned them recognition as a reliable and trustworthy partner in the industry.The China Injection Mold for Waste Container and Plastic Waste Container Mould is a testament to the company's commitment to environmental sustainability. By leveraging their advanced technology and engineering capabilities, they have developed a mold that enables the production of high-quality waste containers and plastic containers. These containers are designed to meet the stringent requirements of waste management, offering durability, functionality, and eco-friendly features.One of the key highlights of this mold is its ability to produce containers with optimal strength and rigidity, making them suitable for the rigorous demands of waste management. Additionally, the company has incorporated innovative design elements that enhance the efficiency of these containers in waste collection and disposal processes. This includes features such as secure locking mechanisms, ergonomic handles, and compatibility with automated waste handling systems.Furthermore, the China Injection Mold for Waste Container and Plastic Waste Container Mould is engineered to facilitate the use of recycled materials in the production of containers. This aligns with the growing trend towards sustainable manufacturing practices, allowing the containers to be produced using recycled plastics without compromising their quality or performance. This not only reduces the environmental impact of plastic waste but also supports the circular economy model.The company's unwavering dedication to quality is reflected in the rigorous testing and validation processes they employ for their molds. Each mold undergoes comprehensive quality assurance checks to ensure that the resulting containers meet the highest standards for performance and reliability. This meticulous attention to detail underscores the company's commitment to delivering superior mold solutions that exceed customer expectations.In addition to the technical aspects of the China Injection Mold for Waste Container and Plastic Waste Container Mould, the company also places emphasis on providing exceptional customer support. They work closely with their clients to understand their specific requirements and tailor the mold design to meet their precise needs. This collaborative approach has earned them a loyal customer base and positioned them as a preferred partner for injection mold solutions.As the global focus on environmental conservation and sustainable practices continues to intensify, the China Injection Mold for Waste Container and Plastic Waste Container Mould represents a significant step towards addressing the challenges of plastic waste management. By offering a reliable and efficient solution for the production of waste containers, the company is contributing to the development of a more sustainable and eco-friendly waste management infrastructure.In conclusion, the China Injection Mold for Waste Container and Plastic Waste Container Mould stands as a testament to the ingenuity and commitment of the company in addressing pressing environmental concerns. Through their advanced mold technology and dedication to quality, they are empowering businesses to embrace sustainable waste management practices and make a positive impact on the environment. As the demand for eco-friendly solutions continues to grow, the company remains at the forefront of driving innovation in the injection mold industry, setting new benchmarks for excellence and environmental responsibility.

Ultimate Guide to Centrifugal Casting: A Comprehensive Overview

Centrifugal Casting has been around for decades as a reliable and cost-effective method for producing high-quality, cylindrical metal components. This process involves pouring molten metal into a spinning mold, which results in a dense and uniform material structure with excellent mechanical properties. This manufacturing technique is widely used across various industries, including aerospace, automotive, and power generation.With the increasing demand for specialized metal parts, many companies are turning to centrifugal casting to meet their production needs. One such company that has established itself as a leader in this field is {}. Founded in {} years ago, {} has continuously pushed the boundaries of centrifugal casting technology to provide innovative solutions for their customers. The company's state-of-the-art facilities are equipped with the latest machinery and a team of skilled engineers and technicians who are dedicated to delivering exceptional results.One of the key advantages of centrifugal casting is its ability to produce parts with superior strength and durability. This is particularly important in industries such as aerospace and automotive, where components are subjected to extreme conditions and must meet strict performance standards. By leveraging the benefits of centrifugal casting, companies like {} are able to produce parts that not only meet these requirements but also exceed them.Moreover, centrifugal casting offers significant cost savings compared to other manufacturing methods. This is due to its ability to produce near-net shape components, which minimizes the need for secondary machining operations. As a result, companies can reduce production time and expenses, ultimately improving their bottom line.In addition to its cost-effectiveness, centrifugal casting also allows for the production of complex geometries and intricate designs. This flexibility is essential for companies that require customized parts for their specific applications. {} understands this need and has developed advanced processes to accommodate the diverse requirements of its customers.The versatility of centrifugal casting also extends to the variety of materials it can process. {} has extensive experience working with a wide range of alloys, including stainless steel, aluminum, copper, and nickel-based alloys. This expertise allows the company to cater to a diverse customer base and address a multitude of industry needs.Another notable advantage of centrifugal casting is its ability to produce parts with minimal porosity and impurities. This results in components that exhibit excellent mechanical properties, such as high tensile strength and fatigue resistance. As a result, companies can rely on centrifugal casting to deliver parts that meet the highest quality standards.Looking ahead, {} is committed to advancing centrifugal casting technology to further meet the evolving needs of its customers. The company continues to invest in research and development to explore new materials, optimize manufacturing processes, and improve the overall efficiency of its operations. By staying at the forefront of innovation, {} aims to remain a trusted partner for industries seeking reliable and high-performance metal components.In conclusion, centrifugal casting has proven to be a valuable manufacturing technique, offering a combination of strength, cost-effectiveness, and versatility. Companies like {} have embraced this technology and have become leaders in providing exceptional centrifugal casting solutions. As the demand for specialized metal parts continues to grow, centrifugal casting is poised to play a pivotal role in meeting the needs of various industries, ensuring the production of high-quality components for years to come.

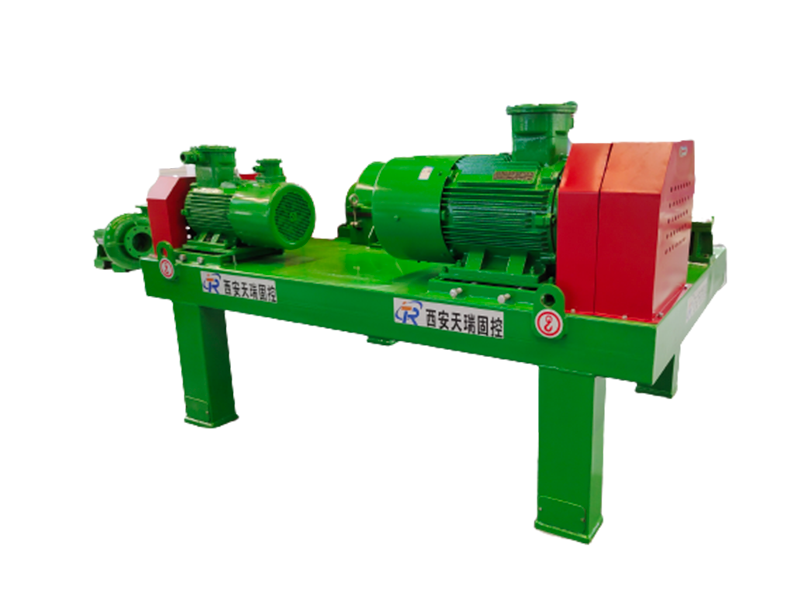

High-Quality Decanter Centrifuge for Efficient Sludge Dewatering

China Decanter Centrifuge for Sludge DewateringBEIJING, China – The demand for efficient and environmentally friendly solutions for sludge dewatering has been growing rapidly in recent years. This has led to a significant increase in the use of decanter centrifuges, which are widely recognized as one of the most effective tools for sludge dewatering. One company leading the way in this industry is {Company}, a leading manufacturer of decanter centrifuges in China.The {Company} offers a range of decanter centrifuges designed specifically for sludge dewatering, with a focus on providing high-performance, energy-efficient solutions. These centrifuges are capable of processing large volumes of sludge while achieving a high degree of dewatering, making them ideal for a wide range of applications, including wastewater treatment plants, industrial processes, and municipal sewage treatment facilities.The company's decanter centrifuges are built to the highest quality standards, utilizing advanced technology and materials to ensure long-term reliability and performance. This has made them a popular choice among customers seeking a cost-effective and sustainable solution for sludge dewatering.In addition to the company's dedication to producing high-quality decanter centrifuges, they also offer a comprehensive range of services to support their customers, including installation, maintenance, and technical support. This has helped them build a strong reputation for providing exceptional customer service and building long-term relationships with their clients.One of the key advantages of the company's decanter centrifuges is their ability to handle a wide range of sludge types, including those with high solid content and difficult dewatering characteristics. This versatility has made them an attractive option for customers seeking a reliable and efficient solution for their sludge dewatering needs.Furthermore, the company's decanter centrifuges are designed with a focus on energy efficiency, helping customers reduce their operational costs and minimize their environmental impact. This is in line with the company's commitment to sustainability and environmental responsibility, making their products an attractive choice for customers seeking to meet their environmental goals.The company's dedication to innovation and continuous improvement has allowed them to stay ahead of the competition in the rapidly evolving sludge dewatering market. They are constantly investing in research and development to further enhance the performance and capabilities of their decanter centrifuges, ensuring that they remain at the forefront of the industry.With a strong track record of delivering high-quality products and exceptional customer service, it's no surprise that {Company} has become a trusted partner for customers seeking reliable and efficient solutions for sludge dewatering. Their commitment to quality, innovation, and sustainability has positioned them as a leading player in the market, with a strong presence both domestically and internationally.As the demand for sludge dewatering solutions continues to grow, {Company} is well positioned to capitalize on this opportunity and continue providing cutting-edge decanter centrifuges to customers around the world. By staying true to their core values of quality, innovation, and customer satisfaction, they are set to remain a key player in the industry for years to come.In conclusion, the demand for efficient and sustainable solutions for sludge dewatering is on the rise, and decanter centrifuges have emerged as a reliable and effective tool to meet this demand. {Company} has established itself as a leading manufacturer of decanter centrifuges in China, offering high-performance, energy-efficient solutions for sludge dewatering. With a strong focus on quality, innovation, and customer service, they are well positioned to remain a key player in the industry and continue meeting the evolving needs of their customers.

Efficient Mud Recovery System Delivers Exceptional Performance

Title: Innovative Mud Recovery System Revolutionizes Drilling Operations Introduction:As the demand for energy resources continues to rise, the drilling industry faces the pressing challenge of efficiently managing drilling waste while ensuring environmental sustainability. In response to this need, an innovative and game-changing technology, the Mud Recovery System (MRS), has emerged as a key solution. Developed by a cutting-edge company, this state-of-the-art system is transforming drilling operations worldwide, offering numerous benefits such as cost reduction, improved efficiency, and minimized environmental impact.Improved Drilling Efficiency:The Mud Recovery System (MRS) has revolutionized drilling operations by significantly improving drilling efficiency. The system incorporates advanced technology that enables the removal, cleaning, and re-usage of drilling mud, a crucial component in drilling operations. Traditionally, drilling mud is discarded after each use, leading to significant costs associated with procurement and disposal. However, with the MRS, drilling mud can be effectively cleaned, allowing for its reuse in subsequent drilling operations. This not only reduces the overall drilling costs but also ensures a continuous supply of high-quality drilling mud, thereby enhancing drilling efficiency.Cost Reduction:One of the most significant advantages of the Mud Recovery System is its ability to yield substantial cost savings for drilling companies. By eliminating the need to constantly procure new drilling mud, companies can significantly reduce their operational costs. Furthermore, the MRS also eliminates expenses associated with the transportation and disposal of drilling waste, which can be a significant financial burden. With the implementation of this innovative system, drilling companies can optimize their financial resources, potentially resulting in higher profit margins and greater financial stability.Enhanced Environmental Sustainability:Environmentally conscious practices have become a crucial aspect of drilling operations, with both regulators and public demanding sustainable approaches to drilling waste management. The Mud Recovery System plays a pivotal role in achieving these sustainability goals. The system reduces the overall disposal of drilling waste, eliminating the potential for environmental contamination. By cleaning and reusing drilling mud, the MRS minimizes the need for fresh excavation, preserving natural resources and reducing the ecological footprint associated with drilling operations. This sustainable approach not only protects the environment but also enhances the reputation of drilling companies as responsible corporate citizens.Versatility and Adaptability:The Mud Recovery System demonstrates its versatility and adaptability by being compatible with a wide range of drilling equipment. No matter the size or type of drilling rig, the MRS can seamlessly integrate into existing operations, without requiring major modifications or equipment replacements. Additionally, the system is flexible, allowing for customization based on specific drilling requirements. This adaptability ensures that companies can adopt the MRS technology without disrupting their current operations, enabling a smooth transition to a more efficient and sustainable drilling process.Operational Safety and Reliability:Safety is paramount in any drilling operation, and the MRS ensures the highest standards of operational safety. The system incorporates advanced filtration and separation techniques, effectively separating drilling mud from other waste materials. This process not only enhances the overall reliability and efficiency of the MRS but also ensures a safer working environment for drilling personnel. By reducing the volume of waste material, the risk of accidents and incidents is significantly reduced, safeguarding both human lives and the reputation of drilling companies.Conclusion:With the increasing need for sustainable and efficient drilling practices, the Mud Recovery System (MRS) emerges as a game-changer in the drilling industry. Through its innovative cleaning and reusage capabilities, the MRS offers significant cost reductions, enhanced drilling efficiency, and improved environmental sustainability. This versatile and adaptable system guarantees safety and reliability, revolutionizing drilling operations worldwide. As companies strive for effective waste management and environmentally responsible practices, the Mud Recovery System undoubtedly presents itself as a pioneering solution, ensuring a greener and more profitable future for the drilling industry.

Optimizing Drilling Operations with the Revolutionary Mud Decanter Centrifuge

Title: Groundbreaking Drilling Mud Decanter Centrifuge Emerges as a Game Changer for the Oil and Gas IndustryIntroduction:In a breakthrough achievement, a leading technological firm has unveiled an innovative drilling mud decanter centrifuge that promises to revolutionize the oil and gas industry. With the ability to efficiently separate solids from drilling mud, this cutting-edge equipment is set to enhance drilling operations worldwide, improving overall productivity and reducing environmental impact. Let's delve deeper into the features and benefits of this remarkable device.Drilling Mud Decanter Centrifuge:This advanced drilling mud decanter centrifuge is designed to remove harmful solids from the drilling fluid, also known as drilling mud, allowing for a cleaner and more efficient drilling process. The centrifuge works on the principle of centrifugal force, separating solids based on their densities. The solids are separated from the drilling mud, resulting in clarified fluid that can be reused, reducing waste and minimizing the environmental footprint of drilling operations.Key Features and Benefits:1. Enhanced Efficiency:The drilling mud decanter centrifuge offers exceptional efficiency, with high-speed rotational capabilities ensuring rapid separation of solids from the drilling mud. This means drilling operations can continue uninterrupted, reducing downtime and boosting productivity.2. Improved Solids Control:This innovative equipment allows for precise control over the separation process, effectively removing fine solids and reducing the risk of equipment damage or blockage. This ensures smooth drilling operations, maximizing the lifespan of drilling tools and reducing maintenance costs.3. Cost-Effective:By recycling and reusing the clarified drilling mud, the decanter centrifuge significantly reduces the need for fresh drilling fluid. This not only saves costs associated with purchasing additional drilling mud but also minimizes waste disposal expenditure. The cost-effectiveness of this device is a considerable advantage for drilling companies.4. Environmental Friendliness:With the drilling mud decanter centrifuge, the environmental impact of drilling operations is significantly reduced. By efficiently separating and clarifying the drilling mud, the device enables reusing of the fluid, reducing the need for fresh water and minimizing waste generation. This promotes sustainable drilling practices, making it a valuable tool in the industry's quest for environmental responsibility.Company Introduction:The company responsible for this groundbreaking drilling mud decanter centrifuge is a renowned leader in the field of drilling equipment manufacturing. With a legacy of technological excellence and a commitment to innovation, they have established themselves as a trusted supplier to the oil and gas industry. Their years of experience and expertise have enabled the development of industry-leading equipment, revolutionizing drilling practices around the world.Conclusion:The introduction of the drilling mud decanter centrifuge marks a significant milestone in the oil and gas industry. With its remarkable ability to efficiently separate solids from drilling mud, this device offers improved efficiency, enhanced solids control, cost-effectiveness, and environmental friendliness. The innovative features of this equipment are set to elevate drilling operations to new heights and promote sustainable practices within the industry. As drilling continues to expand globally, this groundbreaking technology will undoubtedly play a vital role in shaping the future of the oil and gas sector.

Discover the Latest Innovation in Desilter Cones

The global oil and gas industry is constantly evolving with the advancement of technology and innovation. One of the key products that have transformed the industry is the use of Desilter Cones. These cones play a crucial role in the drilling process, helping to remove impurities and solids from the drilling fluid, ultimately ensuring the efficiency and safety of the entire drilling operation.Desilter Cones are a core product of a leading manufacturing company in the oil and gas industry. The company has been at the forefront of providing high-quality equipment and solutions for the oil and gas sector for over two decades. They have built a strong reputation for their innovative products, exceptional customer service, and commitment to sustainability.The Desilter Cones produced by the company are designed to effectively remove solid particles from the drilling fluid, ensuring that the fluid remains at the optimum viscosity and density for the drilling process. This is crucial for maintaining the stability of the wellbore, preventing potential damage to the drilling equipment, and ultimately improving the overall efficiency of the drilling operation.The Desilter Cones are built with state-of-the-art technology, using high-quality materials that can withstand the harsh conditions of drilling operations. This ensures that the cones have a long lifespan and can consistently deliver reliable performance in the field. The company’s dedication to research and development has allowed them to continually improve the design and functionality of their Desilter Cones, staying ahead of industry standards and meeting the evolving needs of their customers.Furthermore, the company takes great pride in its commitment to sustainability and environmental responsibility. The Desilter Cones are designed to minimize the environmental impact of drilling operations by efficiently removing solids and impurities from the drilling fluid, reducing the need for excessive waste disposal and minimizing the overall footprint of the operation. This aligns with the company’s broader sustainability initiatives to minimize waste, conserve energy, and reduce emissions throughout their operations.In addition to their exceptional product quality, the company also offers comprehensive customer support and technical expertise. Their team of experienced engineers and technicians are readily available to provide assistance, guidance, and training to their customers, ensuring that the Desilter Cones are utilized to their full potential, ultimately maximizing the efficiency and performance of the drilling operation.As the global demand for energy continues to grow, the use of Desilter Cones has become increasingly essential in the oil and gas industry. Companies are constantly seeking reliable and efficient equipment to optimize their drilling operations, and the Desilter Cones provided by this leading manufacturing company have proven to be a valuable asset in achieving these goals.In conclusion, the Desilter Cones produced by this renowned company have become a vital component in the oil and gas industry, helping to improve the efficiency, safety, and environmental sustainability of drilling operations around the world. With a strong commitment to innovation, quality, and customer satisfaction, this company continues to be a trusted partner for companies seeking cutting-edge solutions for their drilling needs.

Efficient Mud Dewatering Centrifuge for Waste Management and Environmental Cleanup

Mud Dewatering Centrifuge Revolutionizing the Wastewater Treatment Process In today's world, environmental awareness and sustainability are more important than ever. As industries continue to grow and evolve, so too do the challenges related to environmental protection and resource conservation. One of the biggest challenges in many industries, particularly those involved in the production of chemicals, mining, and oil and gas, is the safe and efficient disposal of wastewater. This is where the Mud Dewatering Centrifuge comes into play.The Mud Dewatering Centrifuge, offered by a leading global supplier of industrial equipment and services, has become an indispensable tool for many industries, providing a cost-effective and environmentally friendly solution for the separation and dewatering of solids from liquid waste streams. By removing solids from industrial sludge and wastewater, the centrifuge helps companies reduce their environmental footprint while also saving them time and money.The Mud Dewatering Centrifuge employs a high-speed rotating bowl to separate solids from liquids based on their different densities. The system is capable of handling a wide range of materials, including fine particles and high solid content slurries, making it extremely versatile and suitable for a variety of industrial applications. It is a highly efficient and reliable solution for dewatering large volumes of waste, resulting in a significant reduction in the volume of material that needs to be disposed of, which in turn lowers disposal costs and minimizes environmental impact.With its innovative design and advanced technology, the Mud Dewatering Centrifuge has revolutionized the way industries approach wastewater treatment. This cutting-edge equipment is not only environmentally friendly, but also versatile and easy to operate, allowing for seamless integration into existing industrial processes. Furthermore, it is designed to operate continuously, ensuring maximum throughput and productivity while minimizing downtime and maintenance requirements.Company IntroductionAs a global leader in the provision of industrial equipment and services, our company has a long-standing commitment to delivering innovative solutions that address the evolving needs of our customers and the challenges they face. With a strong focus on sustainability and environmental responsibility, we are dedicated to developing products that help companies minimize their environmental impact and achieve operational excellence.Our comprehensive range of industrial equipment encompasses a wide array of solutions for various applications, including material handling, process equipment, and environmental technologies. We are proud to offer the Mud Dewatering Centrifuge as part of our portfolio, providing our customers with a state-of-the-art solution for their dewatering and solid-liquid separation needs.At our company, we understand the importance of providing not only high-quality equipment, but also exceptional service and support. Our team of experienced professionals is committed to working closely with our customers to understand their unique requirements and provide tailored solutions that deliver tangible results. Whether our customers are looking to improve efficiency, reduce operating costs, or enhance their environmental performance, we are dedicated to helping them achieve their goals.The Mud Dewatering Centrifuge is a testament to our company's ongoing commitment to innovation and sustainability. By offering this advanced and reliable solution, we are empowering industries to effectively manage their wastewater and sludge while also contributing to a cleaner and greener future.In ConclusionThe Mud Dewatering Centrifuge is a game-changer for industries seeking to improve their wastewater treatment processes. Its innovative design, advanced technology, and ability to efficiently separate and dewater solids from liquid waste streams make it an indispensable tool for companies looking to reduce their environmental impact and operating costs.With a strong focus on sustainability and customer satisfaction, our company is proud to offer the Mud Dewatering Centrifuge as part of our comprehensive range of industrial equipment and services. We are committed to helping our customers achieve operational excellence while minimizing their environmental footprint, and we believe that the Mud Dewatering Centrifuge is a key part of that vision.

High-Quality Mini and Mixing Agitators from China

China Mini Agitator and Mixing Agitator Made Available to Global MarketChina-based company, [Company Name], has announced the availability of their mini agitator and mixing agitator to the global market. These high-quality industrial agitators are designed to provide efficient mixing and agitation solutions for various industries including chemical, pharmaceutical, food and beverage, and many others.With a focus on innovation and quality, [Company Name] has gained a reputation for producing reliable and durable industrial equipment. The mini agitator and mixing agitator are the latest additions to their product line, and have been met with great enthusiasm from customers and partners around the world.The mini agitator is a compact and versatile solution for small-scale mixing applications. It is designed to fit into tight spaces and can be easily integrated into existing production lines. Despite its small size, the mini agitator is capable of delivering powerful agitation, making it suitable for a wide range of industries.On the other hand, the mixing agitator is a larger and more robust solution for industrial mixing applications. It is capable of handling large volumes of materials and is designed to meet the rigorous demands of industrial production. With its advanced mixing technology, the mixing agitator ensures thorough and consistent blending of materials, resulting in high-quality end products.Both the mini agitator and mixing agitator are equipped with advanced control systems that allow for precise adjustment of speed, agitation intensity, and other parameters. This level of control ensures that users can achieve the desired mixing results with ease and accuracy.In addition to their superior performance, the mini agitator and mixing agitator also boast a high level of reliability and durability. [Company Name] has utilized high-quality materials and rigorous manufacturing processes to ensure that their agitators can withstand the demands of industrial use and maintain consistent performance over time.[Company Name] has made a commitment to providing exceptional customer support for their products, and the mini agitator and mixing agitator are no exception. Customers can expect comprehensive technical assistance, spare parts availability, and maintenance services to ensure that their agitators continue to operate at peak efficiency.The availability of the mini agitator and mixing agitator to the global market represents a significant step for [Company Name]. By offering their high-quality industrial equipment to customers around the world, the company aims to establish itself as a leading provider of mixing and agitation solutions on a global scale."We are very excited to introduce our mini agitator and mixing agitator to the global market," said [Spokesperson Name], [Title] of [Company Name]. "These products represent the culmination of our dedication to innovation and quality, and we are confident that they will meet the needs of customers in various industries."With the introduction of the mini agitator and mixing agitator, [Company Name] is poised to make a significant impact in the global industrial equipment market. Customers in need of reliable and efficient mixing and agitation solutions can now turn to [Company Name] for high-quality products that meet the highest standards of performance and durability.