High-Performance Liquid Mixer Agitator for Efficient Mixing Operations

Liquid Mixer Agitator: The Perfect Solution for Industrial Mixing NeedsIn today's fast-paced industrial world, the need for efficient and reliable mixing solutions has never been greater. With the increasing demand for high-quality products and the pressure to cut costs and improve productivity, companies are constantly searching for innovative technologies to streamline their manufacturing processes. This is where Liquid Mixer Agitator comes in - a leading manufacturer of cutting-edge mixing equipment that is revolutionizing the industry.Established in 1995, Liquid Mixer Agitator has cemented its reputation as a trusted supplier of high-performance mixing solutions for a wide range of industries including pharmaceutical, chemical, food and beverage, and cosmetics. The company prides itself on its dedication to quality, innovation, and customer satisfaction, and is committed to providing its clients with the most advanced and cost-effective mixing equipment on the market.One of the key strengths of Liquid Mixer Agitator is its comprehensive range of products, which are designed to meet the diverse needs of its clientele. Whether it's blending, agitation, homogenization, or dispersion, the company offers a variety of mixers and agitators that are tailored to specific applications, ensuring optimal results for every customer. From portable mixers for small-scale operations to large-scale agitators for industrial facilities, Liquid Mixer Agitator has the perfect solution for any mixing requirement.The standout feature of Liquid Mixer Agitator's products is their superior design and engineering. The company's team of expert engineers and technicians works tirelessly on developing state-of-the-art mixing solutions that are not only efficient and reliable but also easy to use and maintain. By utilizing the latest technologies and materials, Liquid Mixer Agitator ensures that its products deliver exceptional performance, durability, and longevity, making them an invaluable investment for any business.Furthermore, Liquid Mixer Agitator understands that every client has unique mixing challenges, which is why it offers customized solutions to meet specific requirements. Whether it's modifying an existing mixer or developing a completely new agitator, the company's engineering team is dedicated to providing tailored mixing solutions that perfectly align with its customers' needs. This personalized approach has earned Liquid Mixer Agitator a loyal customer base that continues to benefit from its unparalleled expertise and support.Additionally, Liquid Mixer Agitator places a strong emphasis on customer service, offering comprehensive assistance from the initial consultation stage to after-sales support. The company's team of knowledgeable and experienced professionals is readily available to provide expert advice, technical guidance, and troubleshooting to ensure that its clients get the most out of their mixing equipment. This commitment to customer satisfaction has earned Liquid Mixer Agitator a reputation as a dependable and trustworthy partner in the industry.In conclusion, Liquid Mixer Agitator has positioned itself as a leading provider of cutting-edge mixing solutions that set the standard for performance, reliability, and innovation. With its extensive product range, advanced engineering, customized approach, and unwavering commitment to customer satisfaction, the company continues to be a driving force in the industrial mixing industry. As businesses strive to stay ahead of the competition and meet the demands of a dynamic market, Liquid Mixer Agitator remains the go-to choice for businesses seeking top-quality mixing equipment that delivers results.For more information contact:Liquid Mixer AgitatorEmail: [email protected]: 123-456-7890Website: www.liquidmixeragitator.com

Read More

High-quality Laboratory Sedimentation Centrifuge for Efficient Sediment Analysis

China Laboratory Sedimentation Centrifuge Revolutionizing Research and Development in Scientific LaboratoriesIn the world of scientific research and development, the need for accurate and efficient equipment cannot be overstated. Laboratories around the world rely on cutting-edge technology to facilitate their work, and one crucial piece of equipment that has become indispensable in this regard is the laboratory sedimentation centrifuge. These high-speed, high-capacity machines are essential for separating and analyzing components of various materials, making them vital tools in a wide range of scientific fields.With the market for laboratory sedimentation centrifuges growing rapidly, it comes as no surprise that manufacturers are constantly innovating to meet the increasing demand for more advanced and sophisticated equipment. One such company that has been at the forefront of this development is [Company Name], a leading manufacturer of laboratory equipment in China.[Mention Company Name] has been dedicated to the research, development, and production of high-quality laboratory equipment for decades. Their commitment to providing cutting-edge technology and reliable products has made them a trusted name in the industry. With a strong focus on innovation and customer satisfaction, [Company Name] has continued to set new standards for laboratory equipment worldwide.The latest addition to [Company Name]'s impressive lineup of laboratory equipment is the Lab Sedimentation Centrifuge, a state-of-the-art machine that has been making waves in the scientific community. This centrifuge boasts a range of advanced features that make it a game-changer in the field of sedimentation analysis.What sets the Lab Sedimentation Centrifuge apart is its exceptional performance and precision. Equipped with a powerful motor and advanced control system, this centrifuge is capable of achieving high speeds and producing reliable results. Its large capacity allows for the processing of a wide variety of samples, making it suitable for use in diverse research applications. Additionally, the Lab Sedimentation Centrifuge is designed with user convenience in mind, featuring an intuitive interface and easy-to-use controls that streamline the sedimentation analysis process.Furthermore, the Lab Sedimentation Centrifuge is built with durability and reliability in mind, ensuring long-term performance and minimal maintenance requirements. This makes it an ideal investment for laboratories that require a dependable and efficient sedimentation analysis solution.In addition to its impressive technical capabilities, the Lab Sedimentation Centrifuge is also a testament to [Company Name]'s commitment to environmental sustainability. The machine is designed to operate with energy efficiency, minimizing its environmental impact while maximizing its performance. This aligns with [Company Name]'s ethos of responsible manufacturing and dedication to reducing its carbon footprint.The introduction of the Lab Sedimentation Centrifuge has been met with widespread enthusiasm and acclaim within the scientific community. Researchers and laboratory technicians have praised its advanced features and reliability, citing it as a valuable asset in their work. Its versatility and precision have made it a go-to choice for sedimentation analysis, further solidifying its position as a game-changing innovation in laboratory equipment.As demand for the Lab Sedimentation Centrifuge continues to grow, [Company Name] remains committed to meeting the needs of laboratories around the world. With its dedication to innovation and quality, [Company Name] is set to remain a leading provider of laboratory equipment in the global market. The Lab Sedimentation Centrifuge is just the latest demonstration of this commitment, and it is poised to make a significant impact on scientific research and development for years to come.In conclusion, the Lab Sedimentation Centrifuge from [Company Name] represents a significant advancement in laboratory equipment, offering unparalleled performance, reliability, and efficiency. With its cutting-edge technology and user-friendly design, it is revolutionizing the field of sedimentation analysis and setting new standards for laboratory equipment. As the scientific community continues to embrace this groundbreaking innovation, [Company Name] solidifies its position as a trailblazer in the world of laboratory equipment manufacturing.

Read More

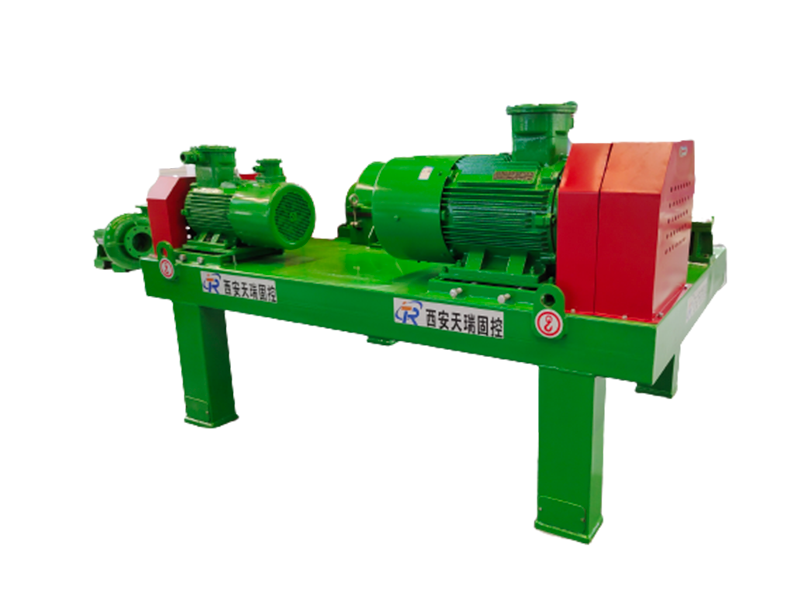

Ultimate Guide to Decanter Centrifuges: What You Need to Know

Decanter centrifuge has become one of the most essential pieces of equipment in the field of solid-liquid separation across various industries. This powerful and efficient machine has revolutionized the way businesses handle large volumes of slurry and liquid waste, significantly improving their operational efficiency and reducing environmental impact. With the increasing demand for high-quality decanter centrifuges, [company name] has emerged as a leading manufacturer and supplier in the global market, providing innovative and reliable solutions for solid-liquid separation.[Company name] is a renowned company specializing in the design, manufacturing, and distribution of industrial centrifuges and separation equipment. With years of experience and expertise in the field, the company has gained a solid reputation for delivering cutting-edge technology and high-performance products to customers worldwide. Their commitment to continuous innovation and product development has allowed them to stay ahead of the competition and meet the ever-evolving needs of various industries, including mining, wastewater treatment, oil and gas, food and beverage, and more.The decanter centrifuge is one of [company name]'s flagship products, known for its exceptional performance and reliability in separating solids from liquids. Its innovative design and advanced features make it a versatile and effective solution for a wide range of applications, from dewatering and thickening to clarification and classification. The machine operates on the principle of centrifugal force, using high-speed rotation to separate different components based on their density and particle size. This results in efficient and thorough separation, allowing businesses to recover valuable materials, minimize waste, and meet strict environmental regulations.One of the key advantages of [company name]'s decanter centrifuge is its robust construction and high-quality components, ensuring smooth operation and minimal downtime. The machine is built to handle the toughest conditions and can process large volumes of slurry with ease, making it an ideal choice for heavy-duty industrial applications. Additionally, the decanter centrifuge is designed for easy maintenance and cleaning, reducing the need for manual intervention and increasing overall productivity.Over the years, [company name] has continued to enhance its decanter centrifuge technology, introducing new features and improvements to meet the evolving demands of its customers. The company's R&D team works tirelessly to optimize the machine's performance, energy efficiency, and environmental footprint, ensuring that it remains at the forefront of solid-liquid separation technology. With a focus on sustainability and resource conservation, [company name] strives to provide eco-friendly solutions that help businesses minimize their environmental impact and achieve their sustainability goals.In addition to its cutting-edge products, [company name] is also known for its comprehensive customer support and after-sales service. The company's team of experts is dedicated to assisting customers with installation, training, technical support, and spare parts supply, ensuring that their decanter centrifuge operates at peak performance at all times. This commitment to customer satisfaction has earned [company name] a loyal and satisfied customer base, cementing its position as a trusted partner in the industrial centrifuge market.Looking ahead, [company name] is poised to further expand its global presence and drive innovation in the field of solid-liquid separation. With a focus on continuous improvement and customer-centric solutions, the company is well-positioned to meet the growing demand for efficient and sustainable separation technologies. By leveraging its expertise and industry knowledge, [company name] is set to play a pivotal role in shaping the future of solid-liquid separation across various sectors, driving efficiency, profitability, and environmental responsibility.In conclusion, [company name] has established itself as a leading provider of decanter centrifuges, delivering high-quality, reliable, and innovative solutions to meet the diverse needs of its customers. With a strong focus on technology, performance, and customer satisfaction, the company is well-positioned to drive positive change in the solid-liquid separation industry and contribute to a more sustainable and efficient future.

Read More

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

Read More

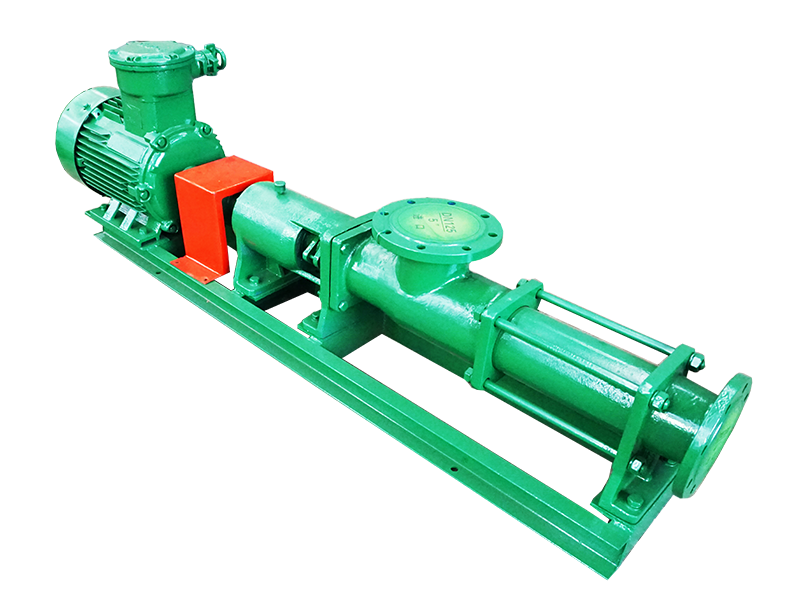

Essential Guide to Drilling Solids Control Equipment - Venturi Hopper

The oilfield industry is an essential sector in any economy, and ensuring that it remains productive and sustainable is critical to maintaining its ongoing success. One of the fundamental aspects of oilfield production is solid control, which is the process of managing the solids that are generated during drilling operations. These solids include drill cuttings, rock fragments, and debris, and it is imperative to remove them efficiently and effectively to preserve the drilling equipment and ensure that the drilling operations can continue smoothly.To achieve this, the oilfield industry relies on various equipment, one of which is the Venturi hopper, a part of the mud mixing pump. This can be made of either carbon steel or stainless steel and is designed to work in combination with the mud mixing pump. The Venturi hopper is an essential component of the oilfield solids control system and plays a critical role in ensuring the proper management of solids during drilling operations.The role of the Venturi hopper in the oilfield solids control system is to mix and agitate the drilling mud, thereby improving the overall efficiency of the mud mixing pump. The hopper works by drawing the drilling mud through a narrow throat, which produces a vacuum effect that causes an increase in the fluid velocity. This increase in velocity leads to the injection of air or dry powder into the mud stream, which results in a more effective mixing process.One of the key benefits of the Venturi hopper is its ability to handle a wide range of drilling fluids, including both low and high-density muds. This makes it an ideal solution for use in a variety of drilling applications, including oil and gas drilling operations, mining operations, and geothermal drilling operations.There are various types of Venturi hoppers available on the market, and each is designed to meet the specific needs of different drilling operations. For example, some hoppers are designed for use in high-pressure applications, while others are suitable for use in low-pressure applications. There are also hoppers available that are specifically designed to handle abrasive drilling fluids, which can cause significant wear and tear on other types of solids control equipment.In addition to its critical role in the solids control system, the Venturi hopper is also an essential component in the overall efficiency and sustainability of oilfield production. By ensuring that solids are effectively and efficiently removed from the drilling fluids, the hopper helps to preserve the drilling equipment, reducing the need for frequent maintenance and repair. This, in turn, helps to reduce the cost of operations and improve the overall profitability of the oilfield industry.Overall, the Venturi hopper is an essential component of the oilfield solids control system, providing a critical function in the proper management of solids during drilling operations. By working in combination with the mud mixing pump, the hopper improves the overall efficiency of the drilling process, reduces the need for costly maintenance and repair, and helps to ensure the ongoing sustainability and success of the oilfield industry. With its versatility and effectiveness, the Venturi hopper is a must-have for any drilling operation, playing a crucial role in the smooth and sustainable operation of the oilfield industry.

Read More

Oil Centrifuge and Oil Extraction Machine in China

China Oil Centrifuge and Oil Extraction Machine, a leading manufacturer and supplier of innovative oil processing equipment, has recently launched a new series of oil centrifuge and oil extraction machines that are designed to revolutionize the oil extraction industry. With state-of-the-art technology and cutting-edge features, these machines are set to become the game-changer in the oil processing industry.The oil centrifuge and oil extraction machines are designed to efficiently extract oil from various oilseeds such as sunflower seeds, soybeans, rapeseed, and more. The machines are equipped with advanced centrifugal technology that ensures maximum oil extraction with minimum wastage. This not only increases the overall efficiency of the oil extraction process but also results in higher-quality oil with better nutritional value.The oil centrifuge and extraction machines are also designed to be user-friendly, with easy-to-use controls and a simple operating system. This makes them suitable for small-scale as well as large-scale oil processing operations. The machines are also built to last, with high-quality materials and precision engineering that guarantee long-term durability and reliable performance.According to a spokesperson for China Oil Centrifuge and Oil Extraction Machine, the company has always been at the forefront of innovation in the oil processing industry. "We are constantly striving to develop new and improved technologies that can help our customers enhance their oil extraction processes. The launch of our new series of oil centrifuge and oil extraction machines is a testament to our commitment to providing cutting-edge solutions to the oil processing industry."The company spokesperson also emphasized the environmental benefits of their new machines. "Our oil centrifuge and oil extraction machines are designed to be environmentally friendly, with reduced energy consumption and minimal wastage. This not only helps our customers save on operational costs but also contributes to a more sustainable and eco-friendly oil processing industry."In addition to their advanced technology and environmental benefits, China Oil Centrifuge and Oil Extraction Machine also offers comprehensive customer support services. This includes installation assistance, technical training, and aftersales support to ensure that their customers can maximize the performance of their oil processing equipment.For customers who are looking to upgrade their existing oil processing facilities or start a new oil processing operation, China Oil Centrifuge and Oil Extraction Machine offers customized solutions to meet their specific requirements. The company's team of experienced engineers and technical experts work closely with customers to understand their needs and provide tailored recommendations for the most efficient and cost-effective oil processing solutions.With the launch of their new series of oil centrifuge and oil extraction machines, China Oil Centrifuge and Oil Extraction Machine is set to make a significant impact on the oil processing industry. By combining advanced technology, user-friendly design, and environmental sustainability, the company is paving the way for a new era of oil extraction and processing. As the demand for high-quality oil continues to grow, China Oil Centrifuge and Oil Extraction Machine is poised to play a key role in shaping the future of the oil processing industry.

Read More

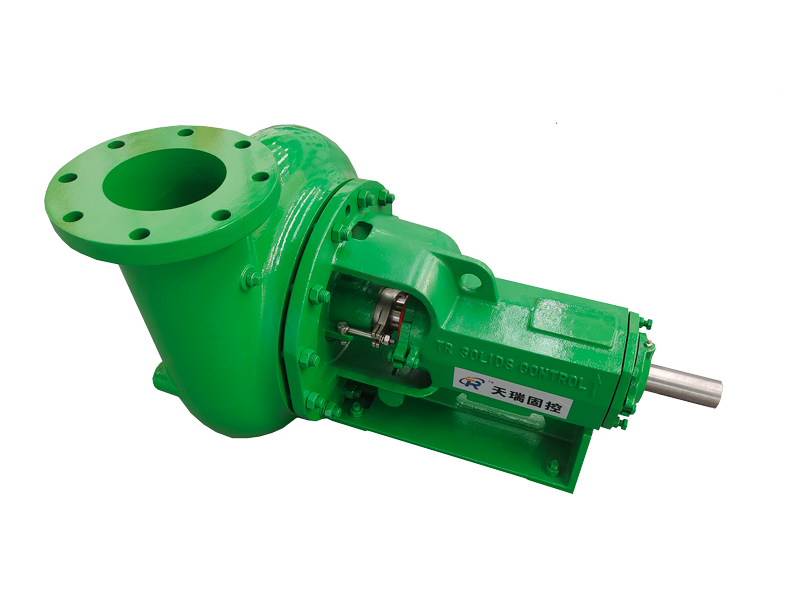

Powerful Centrifugal Pump for Industrial Applications

Title: Innovative 8x6x14 Centrifugal Pump Revolutionizes Fluid Transportation IndustryIntroduction:In an era of rapid technological advancements, Company XYZ has emerged as a leading innovator, continuously pushing the boundaries of engineering excellence. With its latest release, the 8x6x14 Centrifugal Pump, the company has once again showcased its commitment to revolutionizing the fluid transportation industry. This cutting-edge pump combines state-of-the-art features, superior efficiency, and unrivaled performance, positioning it as a game-changer in the market.Body:Incorporating advanced design elements, the 8x6x14 Centrifugal Pump offers unique advantages that set it apart from conventional pumps. With its compact size and lightweight construction, it allows for easy installation and transportation, reducing overall operational costs for companies. Furthermore, this pump boasts exceptional durability, ensuring long-lasting performance even in the most demanding applications.One of the standout features of the 8x6x14 Centrifugal Pump is its enhanced energy efficiency, resulting in substantial cost savings for businesses. By leveraging cutting-edge technology, the pump minimizes power consumption while maximizing output, making it an ideal choice for companies striving for sustainability and reduced environmental impact. This impressive efficiency is achieved through a meticulously engineered impeller design and optimized internal flow paths that minimize energy losses.The engineering prowess of Company XYZ is evident in the meticulous attention to detail put into the development of the 8x6x14 Centrifugal Pump. Extensive research and testing have been conducted to ensure the pump's reliability and performance in diverse environments. This rigorous testing phase guarantees that the pump meets and exceeds industry standards, giving customers peace of mind and confidence in their investment.Furthermore, the pump's versatility shines through its ability to handle a wide range of fluids, including water, chemicals, slurries, and more. Whether it's irrigation, industrial processes, or wastewater management, the 8x6x14 Centrifugal Pump offers a versatile and robust solution, adapting to the specific needs of each application.With safety being a top priority, the 8x6x14 Centrifugal Pump is designed with multiple safeguards to protect both operators and the environment. Advanced sensors continuously monitor the pump's performance, automatically shutting it down in the event of any anomaly, thereby minimizing risks and preventing potential accidents. Moreover, the pump's sturdy construction and reliable components reduce maintenance requirements, ensuring maximum uptime and cost-efficiency.Recognizing the importance of customer-centric solutions, Company XYZ offers personalized support and comprehensive after-sales service to all its customers. With a global network of authorized service centers and highly trained technicians, the company guarantees prompt assistance and rapid spare part availability. This commitment to customer satisfaction has cemented Company XYZ's reputation as a reliable and trusted partner in the fluid transportation industry.In conclusion, Company XYZ's 8x6x14 Centrifugal Pump stands at the forefront of innovation, redefining the fluid transportation industry with its cutting-edge features, remarkable efficiency, and unwavering reliability. This pump represents a significant technological advancement, empowering businesses to optimize their operations, reduce costs, and drive sustainable practices. With its superior performance and unwavering commitment to customer satisfaction, Company XYZ continues to lead the way in shaping the future of the fluid transportation industry.

Read More

SUS304 / 316L Material Milk Cream Separator Machine for Quality Dairy Processing

Title: Revolutionizing Dairy Processing: High-Quality Milk Cream Separator Machine Made in ChinaIntroductionIn today's fast-paced world, where dairy consumption is on the rise, the efficiency of dairy processing plants plays a crucial role in meeting the growing demand for milk, cream, and various dairy products. A critical component of these plants is the milk cream separator machine, which determines the quality and consistency of dairy products. In this blog, we will explore the significance of SUS304 and 316L material in dairy processing plants and shed light on China's contribution in developing top-notch milk cream separator machines. So, join us as we uncover the secrets behind China's innovation-driven dairy processing equipment!SUS304 and 316L Material: The Unyielding Pillar of QualityThe choice of material in dairy processing plants cannot be underestimated as it directly impacts the quality and hygiene standards of the final dairy products. SUS304 and 316L stainless steel materials are widely recognized for their excellent mechanical properties, corrosion resistance, and non-toxic nature. These materials ensure that the milk cream separator machine maintains optimal hygiene during the separation process and minimizes the risk of contamination. Moreover, SUS304 and 316L materials have exceptional heat resistance, safeguarding the quality of dairy products even at high temperatures. China-based manufacturers have recognized the importance of using such high-quality materials, ensuring durability and longevity of their milk cream separator machines.China's Contribution to Dairy Processing PlantsOver the years, China has emerged as a global manufacturing hub, offering high-quality dairy processing equipment, including milk cream separator machines. Chinese manufacturers have invested substantial resources in research and development, incorporating advanced technology and innovative designs into their machinery. With unparalleled precision and craftsmanship, China's milk cream separator machines have gained recognition worldwide for their superior performance and reliability.China Milk Separator: An Innovation-driven ChoiceWhen it comes to milk separator machines, China manufacturers have demonstrated their commitment to excellence by integrating cutting-edge technologies. These machines are equipped with advanced control systems, allowing for precise separation of milk and cream to achieve desired fat content variations. China milk separator machines are engineered to handle a wide range of milk volumes, ensuring efficient processing for dairy plants of all scales. The use of SUS304 and 316L materials ensures that these machines meet the highest quality and hygiene standards, guaranteeing safe and reliable dairy product production.Cream Milk Separator Machine: A Blend of Efficiency and QualityThe cream milk separator machines manufactured in China are designed to optimize the separation process, enhancing efficiency without compromising on quality. These machines employ innovative centrifugal force techniques, separating cream from milk with a high level of precision. The cream milk separator machines are known for their exceptional reliability, minimal maintenance needs, and maximized processing capacity, allowing dairy processing plants to meet consumers' demands efficiently.ConclusionAs the dairy industry continues to grow, the significance of high-quality milk cream separator machines cannot be overstated. China's commitment to engineering the finest dairy processing equipment, including milk separators and cream separators, has propelled the nation into a global leader in this sector. With the use of SUS304 and 316L materials, which ensure impeccable hygiene and durability, China manufacturers have revolutionized dairy processing plants worldwide. So, when it comes to choosing a milk cream separator machine, remember the keywords "China Milk Separator" and "Cream Milk Separator Machine" for reliable, efficient, and top-quality equipment.

Read More

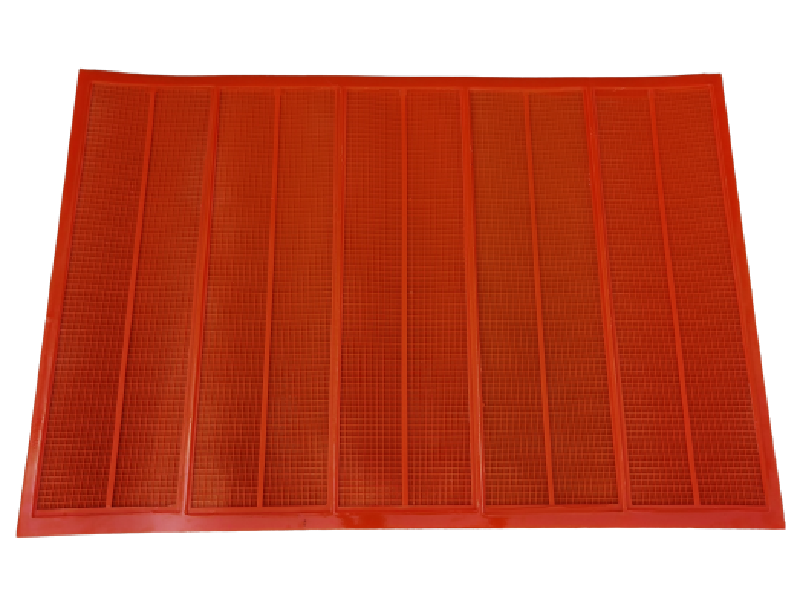

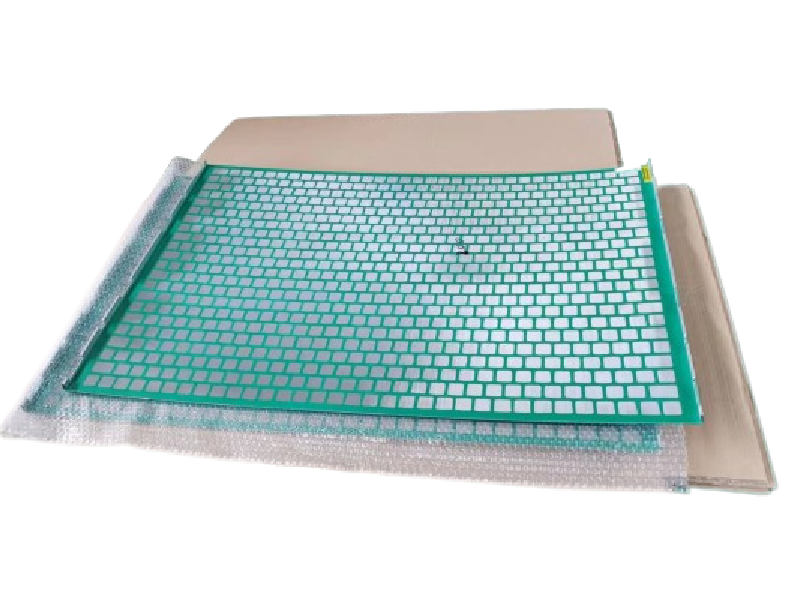

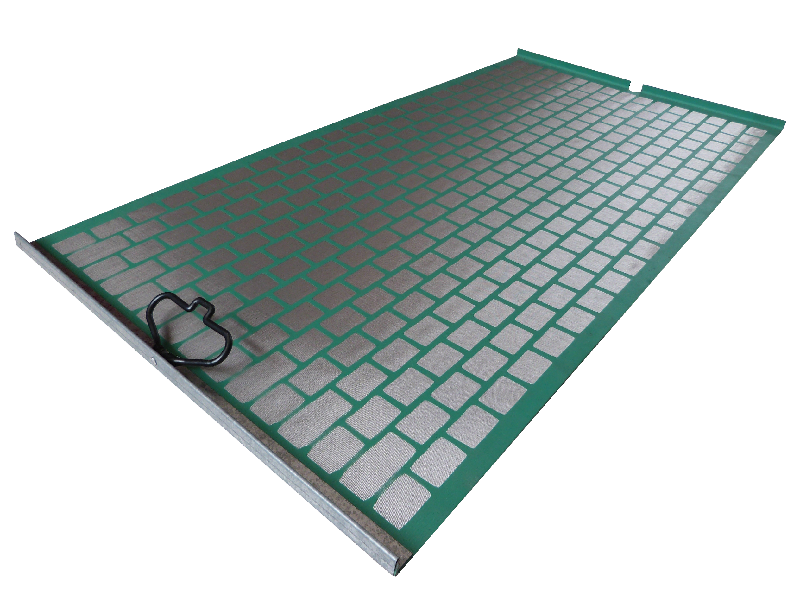

High-performance Shale Shaker for Oil and Gas Industry

Mongoose Pro Shale Shaker Sets the Standard for Efficiency and Reliability in Shale Shaker TechnologyThe demand for shale shaker technology has been steadily rising in the oil and gas industry, and companies are consistently looking for the most efficient and reliable equipment to meet their needs. This is where the Mongoose Pro Shale Shaker comes in, setting the standard for efficiency and reliability in shale shaker technology.The Mongoose Pro Shale Shaker is a product of innovation and expertise, developed by a leading company in the oil and gas industry. With a commitment to providing top-of-the-line equipment, this company has a proven track record of delivering high-quality products that are designed to meet the demands of the ever-evolving industry.This particular shale shaker is built to withstand the harshest drilling conditions, making it the perfect choice for companies looking to maximize their drilling operations. With its advanced design and cutting-edge technology, the Mongoose Pro Shale Shaker is able to effectively separate solids from drilling fluid, resulting in improved efficiency and reduced operating costs.One of the key features of the Mongoose Pro Shale Shaker is its adjustable G-force, allowing for optimal performance in various drilling conditions. This, in combination with its high-capacity composite screen panels, ensures that the shaker is able to handle a wide range of drilling fluids and produce consistently high-quality results.In addition to its impressive performance capabilities, the Mongoose Pro Shale Shaker is also built with ease of use in mind. Its user-friendly interface and simple maintenance requirements make it an ideal choice for companies looking to streamline their operations and maximize productivity.The Mongoose Pro Shale Shaker is also designed with durability in mind, with rugged construction and high-quality materials that are built to last. This ensures that companies can rely on this equipment to perform consistently, even in the most challenging drilling environments.Furthermore, the Mongoose Pro Shale Shaker is backed by a team of experts who are dedicated to providing top-notch service and support to ensure that customers get the most out of their investment. This level of support is a testament to the company's commitment to customer satisfaction and its dedication to delivering reliable equipment that meets the needs of the industry.Overall, the Mongoose Pro Shale Shaker is a game-changer in the world of shale shaker technology, offering unmatched efficiency, reliability, and performance. With its advanced design, user-friendly interface, and durable construction, it is the ideal choice for companies looking to maximize their drilling operations and achieve optimal results.As the demand for shale shaker technology continues to grow, the Mongoose Pro Shale Shaker stands out as a leader in the industry, providing companies with the equipment they need to stay ahead of the curve. With its proven track record of delivering high-quality products and exceptional customer support, this company is setting the standard for excellence in shale shaker technology.

Read More

Boost Efficiency and Performance with a High-Performance Tank Agitator

Tank Agitator: Revolutionizing Industrial Mixing Processes for Enhanced Efficiency and Product Quality[Company Name], a leading player in the industrial equipment manufacturing sector, is proud to introduce its latest innovation – the Tank Agitator. Designed to revolutionize the mixing processes across various industries, the Tank Agitator promises to enhance efficiency and product quality like never before.Mixing and agitation are an indispensable part of many industrial processes, such as chemical processing, pharmaceutical production, food and beverage manufacturing, and wastewater treatment. The success of these processes highly depends on the efficiency and effectiveness of the mixing equipment, which is exactly where the Tank Agitator steps in.With years of research and development, [Company Name] has manufactured a Tank Agitator that surpasses its competitors in terms of performance, reliability, and versatility. This cutting-edge equipment is tailored to meet the diverse needs of industries while ensuring optimal mixing outcomes. One of the key features of the Tank Agitator is its state-of-the-art design. The agitator shaft, impellers, and motor are engineered to work harmoniously, delivering efficient mixing with minimized power consumption. This not only translates to cost savings for businesses but also reduces their carbon footprint, aligning with the growing global emphasis on sustainability.Furthermore, the Tank Agitator offers multiple impeller options, allowing users to customize their mixing process according to the unique requirements of their specific applications. Whether it's high-speed dispersion or gentle blending, the Tank Agitator can be adjusted to achieve the desired results with precision.Another notable advantage of this innovative equipment is its user-friendly interface. The Tank Agitator is equipped with an intuitive control panel that offers a wide range of features. Operators can easily monitor and adjust parameters such as rotation speed, mixing time, and impeller positions to optimize the mixing process. Additionally, the agitator can be programmed for automated operation, ensuring consistent and reproducible mixing outcomes.Moreover, the Tank Agitator boasts robust construction and superior durability, ensuring its longevity even in demanding industrial environments. The agitator shaft is made of stainless steel, rendering it resistant to corrosion from aggressive chemicals and elevated temperatures. Combined with an efficient cooling system, this equipment can withstand the harshest conditions, minimizing downtime and maximizing productivity.[Company Name] understands the importance of after-sales service and support, which is why it offers comprehensive maintenance packages for the Tank Agitator. Skilled technicians are readily available to provide installation assistance, routine inspections, and prompt repairs if required. This commitment to customer satisfaction has earned [Company Name] a reputation for reliability and trustworthiness among its global clientele.The Tank Agitator has already garnered attention and positive reviews from industry experts who have had the opportunity to witness its capabilities firsthand. Several customers have reported remarkable improvements in their mixing processes, with enhanced product quality, reduced mixing time, and increased yield.In conclusion, the introduction of the Tank Agitator by [Company Name] marks a significant milestone in the field of industrial mixing equipment. With its cutting-edge design, versatile options, user-friendly interface, and robust construction, this innovation is poised to elevate the efficiency and quality of mixing processes across various industries. As [Company Name] continues to lead the way in industrial equipment manufacturing, the Tank Agitator stands as a testament to their commitment to innovation and customer satisfaction.

Read More