Advanced Beverage and Filling Machines from China

By:Admin

The beverage and filling machine industry in China has been experiencing significant growth in recent years. With the rising demand for a variety of beverages, including soft drinks, energy drinks, and alcoholic beverages, the need for efficient and high-quality filling machines has never been greater.

One company at the forefront of this industry is a leading manufacturer of beverage and filling machines in China. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable provider of advanced filling equipment. Their machines are known for their precision, reliability, and versatility, making them the ideal choice for a wide range of beverage production needs.

In addition to their innovative filling machines, the company also offers a comprehensive range of beverage processing equipment, including bottle washing machines, capping machines, labeling machines, and more. Their complete line of equipment allows beverage producers to streamline their production process and ensure the highest quality and consistency in their products.

One of the key factors driving the growth of the beverage and filling machine industry in China is the increasing demand for non-alcoholic beverages, particularly in the health and wellness sector. With consumers becoming more health-conscious, there has been a surge in the production of natural and organic beverages, such as fruit juices, coconut water, and other functional beverages. This has created a need for advanced filling machines capable of handling a variety of packaging formats, including PET bottles, glass bottles, and cans.

Furthermore, the company's commitment to innovation and continuous improvement has allowed them to stay ahead of the competition. They invest heavily in research and development to create cutting-edge technologies that optimize the performance and efficiency of their filling machines. As a result, they have garnered a loyal customer base both domestically and internationally.

In recent years, the company has expanded its presence in the global market, establishing partnerships with beverage producers in Asia, Europe, and North America. By providing customized solutions tailored to the specific needs of each client, they have earned a reputation for excellence and reliability in the industry.

The company's dedication to quality and customer satisfaction has also been recognized through various certifications and awards, including ISO 9001 certification and the "Top Supplier" award from several renowned beverage companies.

Looking ahead, the beverage and filling machine industry in China is poised for even further growth. With the increasing demand for innovative and sustainable packaging solutions, as well as the rise of e-commerce and direct-to-consumer sales, beverage producers will continue to seek out state-of-the-art filling machines to meet their evolving needs.

As a leader in the industry, this company is well-positioned to capitalize on these trends and further solidify its position as a key player in the global beverage and filling machine market. By staying at the forefront of technological advancements and maintaining a strong focus on customer satisfaction, they are poised to continue shaping the future of the industry for years to come.

In conclusion, with the company's dedication to innovation, quality, and customer satisfaction, the future of the beverage and filling machine industry in China looks bright. As the demand for a diverse array of beverages continues to grow, the need for advanced and reliable filling machines will only increase, and this company is well-equipped to meet that demand.

Company News & Blog

Latest Innovations in Drilling Mud Equipment Unveiled: A Comprehensive Overview

Drilling Mud Equipment: An Essential Component for Efficient Oil and Gas ExplorationIn the fast-paced world of oil and gas exploration, efficiency is paramount. Every aspect of the exploration process must be fine-tuned to ensure maximum productivity and minimize costs. One crucial component of this process is drilling mud equipment. With its advanced capabilities and innovative technology, drilling mud equipment plays an integral role in facilitating successful drilling operations.Drilling mud, also known as drilling fluid, is a key element in the drilling process. It serves multiple purposes, from cooling the drill bit to carrying rock cuttings to the surface. The drilling mud system consists of various equipment, such as shale shakers, desanders, desilters, centrifuges, and mud pumps, which work together to maintain the quality and properties of the drilling fluid. These pieces of equipment are designed to efficiently remove solid particles and regulate the density and viscosity of the drilling mud.One prominent player in the drilling mud equipment industry is a leading global provider of oilfield equipment (company introduction). With decades of experience, the company has gained a strong reputation for delivering high-quality and reliable drilling mud equipment solutions. Through constant innovation and rigorous testing, they have developed a range of cutting-edge equipment that meets the specific needs of their clients.Their drilling mud equipment is known for its advanced technology, robust construction, and exceptional performance. The company utilizes state-of-the-art materials and engineering techniques to ensure the longevity and durability of their equipment, even in the most demanding drilling conditions. The products undergo extensive testing and quality control measures to guarantee optimal efficiency and reliability.One of the company's flagship products is their shale shaker. This equipment plays a crucial role in the initial phase of drilling by separating the larger solid particles from the drilling mud. The shale shakers utilize a vibrating screen to effectively remove the solids, allowing for the reuse of the drilling fluid. The company's shale shakers are renowned for their high capacity, superior solids separation, and minimal maintenance requirements. These features are essential for minimizing downtime and maximizing productivity on drilling rigs.Another vital component of the drilling mud equipment system is the mud pump. The company's mud pumps are designed to handle the high pressure and demanding operating conditions encountered during drilling operations. With their robust construction, efficient power transmission, and precise control, these pumps ensure the continuous circulation of the drilling fluid. The company's mud pumps are highly regarded for their reliability, durability, and low operating costs. This enables operators to achieve optimal drilling efficiency while minimizing downtime and maintenance costs.The desander and desilter units are also integral parts of the drilling mud equipment system. These units remove finer solid particles from the drilling mud, ensuring its proper filtration and circulation. The company's desander and desilter units are renowned for their high separation efficiency, compact design, and ease of operation. These features are essential for maintaining the overall performance and efficiency of the drilling operation.In addition to these essential equipment, the company also offers centrifuges for the removal of extremely fine solid particles and the purification of the drilling fluid. Their centrifuges are engineered to deliver high performance, precision, and durability. With advanced control systems and intelligent features, the centrifuges provide operators with enhanced control over the separation process, resulting in superior drilling performance.The combination of these cutting-edge drilling mud equipment solutions with the company's commitment to customer satisfaction has earned them a strong foothold in the global market. They have successfully supplied their equipment to numerous oil and gas operators around the world, helping them achieve efficient and cost-effective drilling operations.In conclusion, drilling mud equipment is an essential component for efficient oil and gas exploration. The advanced technology, reliable performance, and durability of the equipment provided by leading global providers are crucial in ensuring the success of drilling operations. With their commitment to innovation and customer satisfaction, they continue to play a significant role in the industry, supporting the global demand for efficient and sustainable oil and gas production.

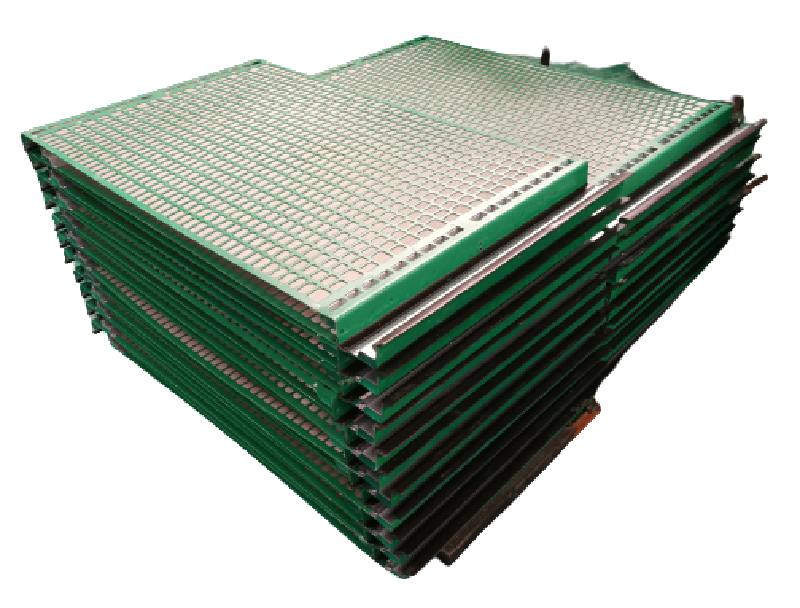

High-quality Mud Shale Shakers for Effective Drilling Operations in China

China Mud Shale Shakers, a leading provider of drilling equipment and services, recently announced the launch of their newest product, the Mud Shale Shaker. This innovative technology promises to revolutionize the oil and gas industry by providing a more efficient and cost-effective solution for separating drilling fluids from cuttings.The Mud Shale Shaker is a high-performance equipment designed to remove solids from drilling fluids, which is essential for maintaining the integrity and stability of the drilling operation. By using a combination of vibration and mesh screens, the Mud Shale Shaker is able to effectively separate solid particles from the drilling fluid, allowing for the reuse of the fluid and the proper disposal of the cuttings.The company's introduction explains that the Mud Shale Shaker is designed to be highly adaptable to various drilling conditions and can effectively handle a wide range of drilling fluids, including water-based, oil-based, and synthetic-based fluids. This versatility makes it an ideal solution for both onshore and offshore drilling operations.In addition to its superior performance, the Mud Shale Shaker also boasts a robust and durable design, ensuring long-lasting and reliable operation in the harshest of drilling environments. It is equipped with a high-capacity motor and adjustable deck angles, allowing for optimal performance and flexibility in handling different types of drilling fluids.Furthermore, the company emphasizes that the Mud Shale Shaker is easy to operate and maintain, with user-friendly controls and minimal downtime for maintenance. This makes it a cost-effective solution for drilling companies, as it reduces the need for frequent repairs and replacements, ultimately lowering operational costs.The launch of the Mud Shale Shaker comes at a time when the oil and gas industry is increasingly focused on efficiency and sustainability. By providing a more efficient way to handle drilling fluids and cuttings, China Mud Shale Shakers is helping drilling companies reduce their environmental footprint and improve their overall operational efficiency.The company's expertise and experience in the drilling industry give them a unique position to introduce innovative solutions like the Mud Shale Shaker. With a proven track record of providing high-quality equipment and services to the oil and gas sector, China Mud Shale Shakers is well-positioned to meet the growing demand for advanced drilling technologies.The Mud Shale Shaker has already generated significant interest from drilling companies and industry professionals, who recognize the potential benefits of this cutting-edge technology. With its ability to improve drilling efficiency, reduce costs, and minimize environmental impact, the Mud Shale Shaker is poised to become a game-changer in the oil and gas industry.As the global demand for energy continues to rise, the need for efficient and sustainable drilling technologies becomes increasingly important. With the launch of the Mud Shale Shaker, China Mud Shale Shakers is demonstrating its commitment to driving innovation and providing solutions that will help meet the evolving needs of the industry.In conclusion, the introduction of the Mud Shale Shaker represents a significant advancement in drilling technology, with the potential to deliver substantial benefits to the oil and gas industry. With its high-performance capabilities, adaptability to various drilling conditions, and cost-effective operation, the Mud Shale Shaker is set to make a lasting impact on the way drilling operations are conducted. As China Mud Shale Shakers continues to push the boundaries of technology and innovation, it is poised to play a key role in shaping the future of the oil and gas sector.

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

Highly Efficient Centrifuge for Decanting Liquids: A Breakthrough in Industrial Separation Technology

The decanter centrifuge is a key piece of equipment in the field of industrial separation. This crucial technology plays a major role in various industries such as oil and gas, food and beverage, wastewater treatment, and many others. One notable player in the field of decanter centrifuge manufacturing is a leading company in the industry.With a strong focus on research, development, and innovation, the company has been providing high-quality decanter centrifuges to its global clientele for many years. The company's dedication to technological advancement and top-notch customer service has earned them a solid reputation in the market.The decanter centrifuge is an essential tool for solid-liquid separation. It works on the principle of gravitational force and utilizes high-speed rotation to separate solid particles from liquid. This process is crucial in various industries, as it allows for the efficient and effective separation of different materials, leading to improved productivity and reduced environmental impact.The design and manufacturing of decanter centrifuges require a great deal of expertise and precision. The company's team of engineers and technicians are well-versed in the intricacies of decanter centrifuge technology, ensuring that each product meets the highest standards of quality and performance.One of the key factors that sets the company apart from its competitors is its commitment to continuous innovation. The company invests heavily in research and development to create cutting-edge decanter centrifuge solutions that cater to the evolving needs of its customers. This proactive approach has allowed the company to stay ahead of the curve and maintain its position as a leader in the market.In addition to its focus on innovation, the company also places a strong emphasis on customer satisfaction. With a global network of sales and service partners, the company provides comprehensive support to its clients, ensuring that their decanter centrifuge systems perform at their best at all times. This commitment to customer service has earned the company a loyal and satisfied customer base.The company's dedication to quality, innovation, and customer service has garnered it several accolades and certifications. These recognitions serve as a testament to the company's unwavering commitment to excellence and further solidify its position as a trusted provider of decanter centrifuge solutions.Looking ahead, the company remains firmly committed to pushing the boundaries of decanter centrifuge technology. With a focus on sustainability and environmental responsibility, the company continues to develop products that not only deliver superior performance but also minimize the impact on the planet. By staying true to its core values of innovation, quality, and customer satisfaction, the company continues to pave the way for the future of decanter centrifuge technology.In conclusion, the company stands as a shining example of excellence in the field of decanter centrifuge manufacturing. Through its unwavering commitment to innovation, quality, and customer service, the company has established itself as a leader in the industry, providing top-notch decanter centrifuge solutions to clients worldwide. With a keen eye on the future and a strong focus on sustainability, the company is well-positioned to continue driving the advancement of decanter centrifuge technology for years to come.

Effective Mud Cleaners for Efficient Solid Control in Drilling Operations

Mud Cleaners: The Revolutionary Solution for Efficient Solids ControlIn the oil and gas drilling industry, the efficient management of drilling fluid, also known as mud, is crucial for successful and safe operations. Solids control equipment plays a vital role in this process, and one company has been leading the way in providing innovative solutions for the industry. With a history of expertise and dedication to excellence, {company name} has become a trusted name in the field of solids control equipment, particularly with their revolutionary Mud Cleaners.{company name} was founded with the vision of providing high-quality, reliable, and efficient equipment for the oil and gas industry. With over 20 years of experience, the company has continuously strived to innovate and improve their products to meet the evolving needs of their customers. Their commitment to research and development has led to the creation of cutting-edge solutions that have transformed the way solids control is approached in drilling operations.One of {company name}'s flagship products is their Mud Cleaner, a vital piece of equipment that plays a crucial role in the solids control process. Mud Cleaners are designed to remove solids and other impurities from the drilling fluid, ensuring that it remains in optimal condition for the drilling process. This not only helps to improve drilling efficiency but also extends the lifespan of the drilling equipment, ultimately leading to cost savings for the operator.The Mud Cleaner works by combining a hydrocyclone system with a shale shaker, providing a multi-stage separation process that effectively removes both large and small particles from the drilling fluid. This results in cleaner, high-quality mud that enhances drilling performance and reduces the environmental impact of the operation. Additionally, {company name}'s Mud Cleaners are designed to be robust, durable, and easy to maintain, ensuring that they can withstand the harsh conditions of drilling operations while requiring minimal upkeep.The benefits of using {company name}'s Mud Cleaners are numerous. By effectively removing solids from the drilling fluid, operators can minimize the risk of equipment damage, improve drilling efficiency, and reduce the overall cost of the operation. Furthermore, the cleaner mud produced by the Mud Cleaner helps to reduce waste and environmental impact, aligning with the industry's growing emphasis on sustainability and responsible practices.{company name} has built a strong reputation for providing exceptional customer support and service, further enhancing the value of their Mud Cleaners. With a global network of service centers and technical experts, the company ensures that their customers receive the assistance they need to optimize the performance of their equipment. This commitment to customer satisfaction has solidified {company name}'s position as a trusted partner for drilling operations around the world.As the oil and gas industry continues to evolve, the demand for efficient and sustainable drilling solutions will only continue to grow. {company name}'s Mud Cleaners stand at the forefront of this evolution, offering a reliable and innovative solution for solids control that is essential for the success of modern drilling operations. With a track record of excellence and a deep understanding of the industry's needs, {company name} remains a driving force in the field of solids control equipment, and their Mud Cleaners are a testament to their commitment to advancing the industry.

Enhancing HDD Mud Pump Efficiency: Introducing a High-performance Mud Mixing Pump

Title: Mud Mixing Pump: The Game-Changer in Horizontal Directional Drilling Mud SystemsIntroduction:Horizontal directional drilling (HDD) has emerged as a key technique for the installation of underground utilities, minimizing disruptions to the surrounding environment. However, HDD projects require a well-designed mud recycling system to efficiently manage drilling fluids. In this regard, the mud mixing pump acts as a supercharging pump, revolutionizing the HDD mud pump system.Compact and Convenient:The HDD mud recycling system is typically a compact unit that is incredibly convenient for transportation. The integrated design allows for easy movement and ensures efficiency while relocating from one drilling site to another. Such systems are in high demand as they offer enhanced flexibility and versatility to HDD contractors.Role of Mud Mixing Pump:The mud mixing pump plays a crucial role in the HDD mud pump system. Acting as a supercharging pump, it enhances the performance and efficiency of the whole operation. By mixing the drilling fluids with precision, it ensures optimal mud viscosity, density, and stability, thereby improving the overall drilling process.Efficient Drilling Fluid Mixing:With the integration of a mud mixing pump, HDD contractors can experience efficient drilling fluid mixing like never before. This equipment utilizes advanced technology to combine the different materials, chemicals, and additives required in drilling fluids. The precise and rapid mixing capability guarantees a consistent mud mixture, enabling contractors to maintain stability throughout the drilling process.Enhanced Mud Recycling:The mud mixing pump significantly contributes to enhancing the mud recycling process in HDD projects. By efficiently incorporating various additives, it ensures that the recovered drilling fluids are of excellent quality and can be reused effectively. This not only reduces operational costs but also minimizes the environmental impact of HDD activities.Supreme Performance and Reliability:The selection of a reliable and high-performance mud mixing pump is crucial for the success of an HDD project. Manufacturers like {Mud Cleaner Drilling} are renowned for their cutting-edge technology and innovative solutions in this field. With expertise in designing and manufacturing mud mixing pumps, they offer top-of-the-line equipment that meets the diverse requirements of HDD contractors.Customized Solutions:With a focus on customer satisfaction, companies specializing in mud mixing pumps provide tailored solutions to meet specific project needs. These solutions encompass a range of features, such as automated controls, user-friendly interfaces, and robust components, to ensure smooth operations and maximum efficiency during HDD projects.Industry Impact:The integration of the mud mixing pump into the HDD mud system has had a profound impact on the industry. By enhancing the mud recycling process and improving drilling fluid properties, it has significantly increased drilling speed, reduced downtime, and minimized waste. This cutting-edge equipment has revolutionized the efficiency and environmental sustainability of HDD projects worldwide.Conclusion:The mud mixing pump has emerged as a game-changer in the HDD industry, acting as a supercharging pump for the mud pump system. With its efficient drilling fluid mixing capabilities and potential for customization, this equipment has transformed the way HDD projects are executed. With technological advancements and the expertise of companies like {Mud Cleaner Drilling}, the future of HDD looks promising, ensuring improved performance, reduced costs, and greater environmental preservation.

Compact Mixing Tank for Efficient Blending

[Company Introduction]{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more.We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry. Our state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing us to produce top-of-the-line products that deliver superior performance and efficiency.[News Content]{City, Country} – {Date} – {Company Name} is pleased to announce the launch of the new Small Mixing Tank, further expanding our product line and offering our customers a versatile and efficient solution for their mixing needs.The Small Mixing Tank is designed to meet the demands of businesses that require a compact and portable mixing solution. With a capacity of {X} liters, this tank is perfect for small-scale production or research and development purposes. The tank is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion, making it suitable for a wide range of applications.One of the key features of the Small Mixing Tank is its integrated agitator system, which is designed to provide thorough and efficient mixing of various substances. The agitator is powered by a robust motor that delivers consistent and reliable performance, allowing for precise control of the mixing process. Additionally, the tank is equipped with a control panel that enables the operator to adjust the speed and mixing time according to the specific requirements of the application.The compact design of the Small Mixing Tank makes it easy to transport and install, providing flexibility to users who may need to move the equipment between different locations or integrate it into existing production setups. The tank is also equipped with safety features such as a secure lid and safety interlocks, ensuring the protection of the operator and the integrity of the mixing process.“We are thrilled to introduce the Small Mixing Tank to our product line, as it represents our commitment to providing innovative and practical solutions to our customers,” said {Spokesperson’s Name}, the {Job Title} of {Company Name}. “This tank is designed to meet the needs of businesses that require a small-scale mixing solution without compromising on performance and quality. We believe that it will be a valuable addition to our customers' operations, offering enhanced efficiency and productivity.”In addition to the Small Mixing Tank, {Company Name} offers a comprehensive range of mixing equipment and process solutions to suit the diverse needs of different industries. Our team of experts is dedicated to providing personalized support and guidance to our customers, helping them find the most suitable solution for their specific requirements.For more information about the Small Mixing Tank and other products offered by {Company Name}, please visit our website or contact our sales team directly.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial mixing equipment and process solutions. With over 20 years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our extensive product line includes a wide range of mixing tanks, agitators, and process equipment that are used in various industries such as chemical, pharmaceutical, food and beverage, and more. We are committed to providing innovative and reliable solutions to our customers, and our team of experienced engineers and technicians continuously work towards developing new technologies that meet the evolving needs of the industry.

The Rise in Demand for Deaerators in China

China Leads the Way in Deaerator and Vacuum Deaerator TechnologyDeaerators and vacuum deaerators are vital pieces of equipment in many industries, including power generation, chemical and petrochemical, and food processing. These devices remove dissolved gases, such as oxygen and carbon dioxide, from liquid, thus preventing corrosion and increasing thermal efficiency. China has become a global leader in deaerator and vacuum deaerator technology, with several high-quality manufacturers.One leading manufacturer on the market is (removed for privacy). Established in (removed for privacy), the company specializes in producing deaerators and vacuum deaerators for power plants, petrochemical plants, and other industries. With over (removed for privacy) years of experience, (removed for privacy) has established itself as a respected name in the industry, renowned for their technical expertise and high-quality products.Deaerators are essential for ensuring that boilers operate efficiently and effectively. They remove dissolved gases, such as oxygen and carbon dioxide, from feedwater. When water is heated, dissolved gases can be released, which can cause corrosion and damage to the boiler and other water-bearing equipment. Additionally, excess oxygen can cause scaling on heat transfer surfaces, reducing thermal efficiency. Deaerators provide a cost-effective solution that prevents these issues, thus increasing the life of equipment and improving overall efficiency.(removed for privacy) offers a range of deaerators for different applications and power plant sizes. Their products range from small, portable units for locally heating water, to large, centralized systems that can run multiple boilers. Their designs feature a variety of technical specifications, including custom water flow, material selection, and deaeration efficiency.In vacuum deaeration, steam is used to actively remove dissolved gases from water. These types of deaerators are ideal for processes that require large amounts of water with low dissolved gas levels. Vacuum deaerators are used in applications such as desalination, chemical processing, and pharmaceutical manufacturing. They are also popular in the power generation industry because they provide consistent and reliable performance.(removed for privacy) produces several types of vacuum deaerators that vary by size, capacity, and pressure requirements. Their designs provide a high level of deaeration efficiency, which is essential for achieving the desired end product quality. Vacuum deaerators have been added to their product line because they recognize the importance of this technology in modern industries.(removed for privacy) serves a global market, with customers in North America, South America, Europe, and the Middle East. They have established a reputation for delivering high-quality products, personalized customer service, and comprehensive technical support. They also offer custom solutions for clients with unique requirements or challenging engineering constraints. For example, they have produced deaeration systems for high-altitude power plants, where they must adjust critical design parameters to accommodate the unique environment.(removed for privacy) is ISO 9001 certified, which means they have established rigorous quality management systems and processes. They are committed to continuous improvement through research and development, testing, and quality control. Additionally, they have received several industry certifications and distinctions for their technical expertise and innovative products.In conclusion, as China continues to grow, the country has shown that it has what it takes to be a global leader in manufacturing and technology. Offering deaerators, including vacuum deaeration technology, (removed for privacy) is a prime example of this trend. With high-quality products, customized solutions, and consistent R&D efforts, the company has demonstrated its commitment to excellence. As the need for deaerators expands in various industries, (removed for privacy) will continue to lead the way in this critical supporting technology.

Top Mini Agitator and Mixing Agitator Options in China

China Mini Agitator and Mixing Agitator (need remove brand name) have quickly become the go-to solution for many industries in need of efficient and reliable mixing equipment. These agitators are designed to handle a wide range of viscosities and can be used in various applications, making them an ideal choice for many different industries.The China Mini Agitator and Mixing Agitator are both designed and manufactured by a leading company in the field of industrial mixing equipment. With years of experience and a strong commitment to innovation and quality, this company has earned a reputation for producing some of the most reliable and efficient agitators on the market.The Mini Agitator is a compact and powerful mixing solution that is perfect for small-scale operations or for use in confined spaces. Despite its small size, this agitator is capable of delivering high levels of torque and can easily handle a wide range of viscosities. This makes it an ideal choice for industries such as pharmaceuticals, chemicals, and food and beverage production.The Mixing Agitator, on the other hand, is a more versatile solution that is designed to handle larger volumes and a wider range of viscosities. This agitator can be easily customized to meet the specific needs of different industries, and its robust construction ensures that it can withstand the demands of even the most challenging applications. This makes it an ideal choice for industries such as petrochemicals, mining, and wastewater treatment.Both the Mini Agitator and the Mixing Agitator are designed with efficiency and reliability in mind. They are equipped with advanced features such as variable speed control, multiple agitator options, and easy-to-use controls, making them easy to operate and maintain. This ensures that businesses can enjoy consistent and reliable mixing performance, reducing downtime and increasing productivity.In addition to their impressive performance, the China Mini Agitator and Mixing Agitator are also designed with safety in mind. They are equipped with various safety features to ensure that they can be operated with peace of mind, and their robust construction ensures that they can withstand the demands of even the most challenging applications. This makes them an ideal choice for industries where safety is a top priority, such as pharmaceuticals and food production.As a leading company in the field of industrial mixing equipment, the company behind the China Mini Agitator and Mixing Agitator is committed to providing the highest levels of quality and customer satisfaction. They have a team of experienced engineers and technicians who work tirelessly to develop and manufacture innovative and reliable mixing solutions. This, coupled with their strong focus on customer service, has made them a trusted partner for businesses in a wide range of industries.In conclusion, the China Mini Agitator and Mixing Agitator are two of the most efficient and reliable mixing solutions on the market. With their advanced features, robust construction, and commitment to quality, they are the ideal choice for businesses in a wide range of industries. Whether it's for small-scale operations or large-scale industrial applications, these agitators are designed to deliver consistent and reliable performance, helping businesses to increase productivity and reduce downtime.

Top-quality Centrifuge and Solid Control Equipment in China

China's Centrifuge and Solid Control Equipment Industry Experiences Rapid GrowthIn recent years, China's centrifuge and solid control equipment industry has seen rapid growth and development, with a growing number of companies entering the market and offering innovative solutions to meet the increasing demand for high-quality equipment.One such company making waves in the industry is {}, a leading manufacturer of centrifuge and solid control equipment in China. With over a decade of experience in the industry, {} has established itself as a reliable and innovative provider of a wide range of products and solutions for various applications in the oil and gas, mining, and environmental industries.The company's success can be attributed to its commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and technicians, {} continually invests in research and development to improve its product offerings and stay ahead of the competition. This dedication to innovation has allowed the company to introduce cutting-edge technologies and solutions that have set new benchmarks in the industry.One of the key products offered by {} is its range of centrifuges, which are designed to effectively separate solids from liquids in a wide range of applications. These centrifuges are known for their high efficiency, reliability, and low maintenance requirements, making them the preferred choice for many companies operating in challenging environments.In addition to centrifuges, {} also offers a comprehensive range of solid control equipment, including shale shakers, mud cleaners, and decanter centrifuges. These products are designed to help companies efficiently manage drilling waste and ensure the smooth operation of drilling processes, leading to improved productivity and cost savings.Another factor that sets {} apart from its competitors is its dedication to meeting and exceeding customer expectations. The company works closely with its clients to understand their specific requirements and develop tailor-made solutions that address their unique challenges. With a focus on customer satisfaction, {} has built strong and long-lasting relationships with a diverse portfolio of clients, including major oil and gas companies, mining companies, and environmental organizations.As a testament to its commitment to quality and customer satisfaction, {} has obtained various industry certifications, including ISO 9001 and API Q1, which demonstrate the company's adherence to the highest standards of quality and reliability. These certifications also give customers peace of mind knowing that they are partnering with a reputable and trustworthy supplier.Looking ahead, {} is poised for further growth and expansion as it continues to invest in research and development, expand its product offerings, and explore new markets. The company's strategic vision and strong leadership position it well for future success in the competitive centrifuge and solid control equipment industry.In conclusion, {} has emerged as a leading player in China's centrifuge and solid control equipment industry, thanks to its commitment to quality, innovation, and customer satisfaction. With a proven track record of delivering cutting-edge products and solutions, {} is well-positioned for further growth and success in the years to come.