- Efficient shale shaker screens for improved performance in oil and gas industry

By:Admin

With a commitment to delivering high-quality products and unparalleled customer service, Screen Shale Shaker has established itself as a trusted name in the realm of solids control equipment. The company's extensive experience and expertise in the field have enabled them to develop industry-leading solutions that cater to the evolving needs of drilling professionals.

The SS5000 Shale Shaker is a testament to Screen Shale Shaker's relentless pursuit of excellence. Equipped with a robust vibrating motor and a precisely engineered screen panel, this state-of-the-art shale shaker is designed to effectively separate solids from drilling fluid, ensuring optimal performance and cost-efficiency. The shaker's high G-force and large screening area contribute to its exceptional capacity to handle a wide range of drilling conditions, making it a valuable asset for any drilling operation.

In addition to its superior performance capabilities, the SS5000 Shale Shaker is also lauded for its user-friendly design and ease of maintenance. The shaker's streamlined construction and intuitive controls make it simple to operate, while its durable components and minimal parts requirement contribute to reduced downtime and overall operating costs. Furthermore, Screen Shale Shaker's dedicated technical support team is readily available to provide assistance and ensure that the equipment performs at its peak potential.

Screen Shale Shaker's commitment to innovation and customer satisfaction extends beyond the SS5000 Shale Shaker, encompassing a comprehensive range of solids control solutions. From shale shakers and mud cleaners to centrifuges and agitators, the company offers a diverse portfolio of equipment designed to optimize drilling performance and minimize environmental impact. Moreover, Screen Shale Shaker provides customized solutions tailored to specific operational requirements, demonstrating a deep understanding of the unique challenges faced by drilling professionals.

As a testament to its unwavering dedication to excellence, Screen Shale Shaker has cultivated strong partnerships with industry leaders and earned a reputation for delivering unparalleled value to its customers. The company's proven track record of success and innovation has positioned it as a go-to provider for high-quality solids control equipment, and its continued commitment to pushing the boundaries of technology ensures that it remains at the forefront of the industry.

Looking ahead, Screen Shale Shaker is poised to continue its trajectory of success, driven by a steadfast commitment to advancing the efficiency and effectiveness of solids control solutions. With the introduction of the SS5000 Shale Shaker, the company has raised the bar for performance and reliability, setting a new standard for excellence in the field. As the industry evolves and new challenges emerge, Screen Shale Shaker stands ready to lead the way with its unwavering dedication to innovation and customer satisfaction.

Company News & Blog

Ultimate Guide to Drilling Fluid Mud: What You Need to Know

Drilling Fluid Mud has been an integral part of the oil and gas industry for decades. It is used to lubricate drill bits, remove cuttings from the wellbore, and maintain pressure and stability during drilling operations. One industry leader in the production of drilling fluid mud is {Company Name}.{Company Name} has been in the business of providing high-quality drilling fluid mud and other related products for over 30 years. Their commitment to innovation and customer satisfaction has made them a trusted partner for many major oil and gas companies around the world.The key to {Company Name}'s success is their dedication to research and development. They invest heavily in state-of-the-art laboratories and testing facilities to ensure that their products meet the highest industry standards. As a result, their drilling fluid mud is known for its superior performance and reliability in even the most challenging drilling environments.In addition to their cutting-edge technology, {Company Name} places a strong emphasis on environmental responsibility. They constantly strive to develop products that minimize their impact on the environment, and they work closely with regulatory agencies to ensure that their operations are in compliance with all relevant laws and regulations.One of the company's most recent achievements is the development of a new line of drilling fluid mud that is specifically designed for use in deepwater drilling operations. This product has been rigorously tested and has already received positive feedback from industry experts. Its unique formulation allows it to maintain stability and performance even at extreme depths, making it an invaluable tool for companies involved in deepwater drilling projects.In addition to their commitment to quality and innovation, {Company Name} is also known for their outstanding customer service. Their experienced team of engineers and technicians are always available to provide technical support and assistance to their clients. Whether it's recommending the right product for a specific application or troubleshooting a problem on-site, {Company Name} is dedicated to helping their customers achieve success in their drilling operations.Furthermore, {Company Name} has a global presence, with distribution and support centers located in key regions around the world. This ensures that their customers have access to their products and services wherever they may be operating. Whether it's a remote drilling site in the middle of the ocean or a major production facility on land, {Company Name} is there to support their customers every step of the way.In conclusion, {Company Name} is a leading provider of drilling fluid mud and related products, with a proven track record of quality, innovation, and customer service. Their commitment to excellence and dedication to environmental responsibility make them a trusted partner for oil and gas companies around the world. With a strong focus on research and development, as well as a global presence, {Company Name} is well-positioned to continue meeting the needs of the industry for years to come.

Understanding the Importance of Drilling Rig Mud Tank Systems

XYZ Drilling Rig Mud Tank System: A Reliable Solution for Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological innovations and advancements. One such innovation that has revolutionized the industry is the drilling rig mud tank system, which plays a crucial role in the drilling process. XYZ Corporation, a leading provider of drilling equipment and solutions, has developed a state-of-the-art mud tank system that has been widely acclaimed for its efficiency and reliability.XYZ Corporation is a global leader in providing drilling solutions to the oil and gas industry. With a strong focus on research and development, the company has been at the forefront of introducing cutting-edge technologies and systems that have helped in enhancing the efficiency and safety of drilling operations. The drilling rig mud tank system is one such example of the company's commitment to innovation and excellence.The mud tank system is an integral part of the drilling process, as it is responsible for the proper management and treatment of drilling fluids. This is crucial for maintaining the stability of the wellbore, controlling pressure, and carrying rock cuttings to the surface. The XYZ mud tank system is designed to effectively handle these tasks, ensuring that the drilling operations are conducted smoothly and efficiently.One of the key features of the XYZ mud tank system is its modular design, which allows for easy customization and adaptation to different drilling environments and requirements. The system can be easily configured to accommodate different volumes of drilling fluids, and its compact design enables it to be easily transported and installed at the drilling site. This flexibility and scalability make the XYZ mud tank system a preferred choice for drilling operators around the world.The mud tank system also incorporates advanced technologies for the treatment and recycling of drilling fluids, minimizing waste and reducing environmental impact. This is in line with XYZ Corporation's commitment to sustainable and eco-friendly drilling practices. The system is equipped with high-performance shakers, centrifuges, and other equipment for efficient solids control and waste management.In addition to its technical capabilities, the XYZ mud tank system is built to withstand the demanding conditions of drilling operations. It is constructed from high-quality materials and undergoes rigorous testing to ensure its durability and reliability. This ensures that the system can perform effectively in the challenging environments commonly encountered in the oil and gas industry.The XYZ mud tank system has gained widespread recognition for its performance and reliability. It has been deployed in numerous drilling projects around the world, where it has consistently delivered excellent results. The system has proven its ability to enhance drilling efficiency, reduce downtime, and minimize operational costs, making it a valuable asset for drilling operators.With its innovative design, advanced technologies, and proven performance, the XYZ mud tank system has set new standards for mud tank systems in the oil and gas industry. It has established itself as a reliable and efficient solution for the challenges faced in drilling operations, and has earned the trust of drilling operators globally.In conclusion, the XYZ drilling rig mud tank system is a testament to XYZ Corporation's commitment to excellence and innovation in the oil and gas industry. Its advanced design, robust construction, and superior performance make it a preferred choice for drilling operators seeking reliable and efficient solutions for their drilling operations. As the industry continues to evolve, the XYZ mud tank system is poised to play a pivotal role in shaping the future of drilling practices. With its proven track record and continuing advancements, XYZ Corporation remains at the forefront of providing cutting-edge solutions for the oil and gas industry's evolving needs.

High-Quality Pump Parts Manual: Essential Guide for Mission Pumps

Mission Pump Parts Manual is a comprehensive guide that provides a detailed breakdown of the different pump parts, their functionalities, and maintenance procedures. This manual is an essential tool for pump operators and maintenance technicians to ensure the efficient and safe operation of the pumps.The manual covers a wide range of pump parts including impellers, casings, shafts, bearings, and seals. Each section of the manual provides detailed information about the design, construction, and maintenance requirements of the specific part. The manual also includes troubleshooting guides and recommended maintenance schedules to help identify and address common pump issues.In addition to the technical information, the manual also provides valuable insights into the company's commitment to quality and innovation. The company has a long history of providing reliable and efficient pumping solutions for a wide range of industries including mining, oil and gas, construction, and water treatment. With a focus on continuous improvement and customer satisfaction, the company has established itself as a trusted partner for pump solutions.The Mission Pump Parts Manual is a reflection of the company's dedication to excellence and customer support. By providing a comprehensive and user-friendly guide to pump parts and maintenance, the company aims to empower its customers with the knowledge and resources needed to maximize the performance and lifespan of their pumps.As part of its commitment to customer satisfaction, the company also offers training programs and technical support to ensure that operators and technicians have the necessary skills and knowledge to maintain and operate their pumps effectively. This additional support further reinforces the company's reputation as a trusted and reliable partner for pump solutions.Furthermore, the manual emphasizes the company's focus on sustainability and environmental responsibility. By providing guidance on proper maintenance and operation of pumps, the company aims to minimize energy consumption and reduce the environmental impact of its products. This commitment to sustainability is in line with the company's overall mission to provide efficient and environmentally friendly pumping solutions.Overall, the Mission Pump Parts Manual is not just a technical guide; it is a testament to the company's core values of quality, innovation, and customer satisfaction. By equipping its customers with the knowledge and resources needed to maintain and operate their pumps, the company demonstrates its unwavering commitment to supporting its customers throughout the life cycle of their pumping equipment.In conclusion, the Mission Pump Parts Manual stands as a symbol of the company's dedication to excellence, innovation, and sustainability. With its detailed technical information, troubleshooting guides, and maintenance schedules, the manual serves as an invaluable resource for pump operators and technicians. By empowering its customers with the knowledge and support needed to maximize the performance and lifespan of their pumps, the company reaffirms its position as a leader in the pumping solutions industry.

Effective Mud Cleaners for Efficient Solid Control in Drilling Operations

Mud Cleaners: The Revolutionary Solution for Efficient Solids ControlIn the oil and gas drilling industry, the efficient management of drilling fluid, also known as mud, is crucial for successful and safe operations. Solids control equipment plays a vital role in this process, and one company has been leading the way in providing innovative solutions for the industry. With a history of expertise and dedication to excellence, {company name} has become a trusted name in the field of solids control equipment, particularly with their revolutionary Mud Cleaners.{company name} was founded with the vision of providing high-quality, reliable, and efficient equipment for the oil and gas industry. With over 20 years of experience, the company has continuously strived to innovate and improve their products to meet the evolving needs of their customers. Their commitment to research and development has led to the creation of cutting-edge solutions that have transformed the way solids control is approached in drilling operations.One of {company name}'s flagship products is their Mud Cleaner, a vital piece of equipment that plays a crucial role in the solids control process. Mud Cleaners are designed to remove solids and other impurities from the drilling fluid, ensuring that it remains in optimal condition for the drilling process. This not only helps to improve drilling efficiency but also extends the lifespan of the drilling equipment, ultimately leading to cost savings for the operator.The Mud Cleaner works by combining a hydrocyclone system with a shale shaker, providing a multi-stage separation process that effectively removes both large and small particles from the drilling fluid. This results in cleaner, high-quality mud that enhances drilling performance and reduces the environmental impact of the operation. Additionally, {company name}'s Mud Cleaners are designed to be robust, durable, and easy to maintain, ensuring that they can withstand the harsh conditions of drilling operations while requiring minimal upkeep.The benefits of using {company name}'s Mud Cleaners are numerous. By effectively removing solids from the drilling fluid, operators can minimize the risk of equipment damage, improve drilling efficiency, and reduce the overall cost of the operation. Furthermore, the cleaner mud produced by the Mud Cleaner helps to reduce waste and environmental impact, aligning with the industry's growing emphasis on sustainability and responsible practices.{company name} has built a strong reputation for providing exceptional customer support and service, further enhancing the value of their Mud Cleaners. With a global network of service centers and technical experts, the company ensures that their customers receive the assistance they need to optimize the performance of their equipment. This commitment to customer satisfaction has solidified {company name}'s position as a trusted partner for drilling operations around the world.As the oil and gas industry continues to evolve, the demand for efficient and sustainable drilling solutions will only continue to grow. {company name}'s Mud Cleaners stand at the forefront of this evolution, offering a reliable and innovative solution for solids control that is essential for the success of modern drilling operations. With a track record of excellence and a deep understanding of the industry's needs, {company name} remains a driving force in the field of solids control equipment, and their Mud Cleaners are a testament to their commitment to advancing the industry.

Understanding the Function of a Centrifugal Pump for Moving Liquids and Gases

Title: Understanding Centrifugal Pump Parts: A Comprehensive GuideIntroductionCentrifugal pumps are an essential device for moving liquids and gases in various industries. These pumps consist of several crucial components that work together to efficiently transfer fluids. In this blog post, we will explore the key parts of a centrifugal pump and their functions. By understanding these components, we can gain insights into pump operation and ensure optimal performance. Let's dive in!1. Impeller: The Heart of a Centrifugal PumpThe impeller is arguably the most critical component of a centrifugal pump. It is a wheel-like structure with curved vanes that rotate to create a centrifugal force. As fluid enters the pump, the impeller imparts kinetic energy and increases the fluid's velocity. The vanes play a vital role as they guide the fluid towards the pump's outlet. Impellers can come in various designs, including closed, open, semi-open, and recessed.2. Pump Casing: Protecting and Directing Fluid FlowEnveloping the impeller, the pump casing serves as a protective enclosure for other components. It also crucially controls the flow direction and ensures that the velocity imparted by the impeller is effectively converted into pressure energy. The casing generally has a circular design and can be made from different materials like cast iron, stainless steel, or even plastic, depending on the application.3. Volute: Efficiently Converting Kinetic EnergyWithin the pump casing, you will often find a volute, a curved chamber that efficiently converts kinetic energy into pressure energy. This component helps in minimizing energy losses and achieving a more uniform flow pattern. Volute casings offer advantages such as reduced vibration and noise, making them a popular choice for centrifugal pumps.4. Shaft: Connecting the Power Source to the ImpellerThe shaft is a crucial element that connects the pump's impeller to the power source, often an electric motor or an engine. While rotating, the shaft allows the impeller to move fluid through the pump. It must be appropriately designed to withstand high speeds and loads. Materials like stainless steel, alloy steel, or carbon steel are commonly used to ensure strength and durability.5. Bearings: Supporting the Rotating ShaftTo reduce friction and support the rotating shaft, bearings are installed inside the pump. These components help maintain the alignment between the shaft and the impeller, ensuring smooth operation. Bearings can be either grease-lubricated or oil-lubricated, depending on the pump's requirements. Proper maintenance and regular lubrication are necessary to ensure their longevity and prevent premature wear.6. Mechanical Seal: Preventing LeakageTo prevent fluid leakage from the pump, a mechanical seal is employed where the shaft extends through the pump casing. This seal creates a barrier between the rotating shaft and the stationary casing, effectively sealing the pump chamber. The mechanical seal comprises various components like rotating and stationary faces, secondary seals, and a gland to hold everything in place. Proper selection and maintenance of mechanical seals are crucial for ensuring leak-free pump operation.In conclusion, understanding the key parts of a centrifugal pump is essential for optimal performance and efficient fluid transfer. The impeller, pump casing, volute, shaft, bearings, and mechanical seal are all critical components that play significant roles in the pump's operation. By choosing high-quality pump parts and maintaining them effectively, one can ensure reliable performance and prolonged lifespan. Keywords: centrifugal pump parts, impeller, pump casing, volute, shaft, bearings, mechanical seal, fluid transfer, optimal performance

Innovative Mud Gun Drilling Technology Makes Waves in the Industry

Mud Gun Drilling Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, and the latest innovation to make waves in the sector is mud gun drilling. This cutting-edge technology has the potential to revolutionize the way drilling operations are carried out, offering a more efficient and cost-effective solution for extracting oil and gas reserves.Mud gun drilling is a sophisticated drilling technique that uses high-pressure mud to break through rock formations and create a path for extracting oil and gas. This method is not only faster and more efficient than traditional drilling techniques, but it also enables operators to access previously unreachable reserves, making it a game-changer for the industry.One company that has been leading the way in developing and implementing mud gun drilling technology is {}. Founded in [], the company has quickly established itself as a pioneer in the field of oil and gas exploration and production. With a strong focus on research and development, they have successfully developed innovative drilling technologies that have set new industry standards.The primary benefit of mud gun drilling is its ability to significantly reduce drilling time and costs. Traditional drilling methods can be time-consuming and costly, requiring multiple operations to create a wellbore. Mud gun drilling, on the other hand, can complete the drilling process in a fraction of the time, saving both time and money for operators.In addition to its cost-efficiency, mud gun drilling also offers improved wellbore stability and reduced environmental impact. The high-pressure mud used in the process helps to stabilize the wellbore and reduce the risk of collapse, enhancing safety for both workers and the environment. Furthermore, this method also minimizes the amount of waste generated during drilling operations, making it a more sustainable option for oil and gas exploration.The success of mud gun drilling has not gone unnoticed, and the industry has begun to recognize its potential. With its proven track record of delivering successful drilling operations, {} has gained a reputation as a trusted provider of mud gun drilling services. Their cutting-edge technology and innovative approach have helped to position them as a go-to partner for operators looking to optimize their drilling operations.In addition to providing mud gun drilling services, {} also offers comprehensive training and support for operators looking to adopt this innovative technology. Their team of experts has extensive experience in mud gun drilling and is committed to sharing their knowledge and expertise with others in the industry. By offering training programs and ongoing support, they are helping to drive the adoption of mud gun drilling technology across the oil and gas sector.Looking ahead, the future of mud gun drilling looks promising, with the potential to transform the way oil and gas reserves are extracted. As the industry continues to evolve, the demand for more efficient and sustainable drilling technologies will only continue to grow, making mud gun drilling an essential tool for operators looking to stay competitive in the market.With its proven track record of success and commitment to innovation, {} is well-positioned to lead the way in the adoption of mud gun drilling technology. As the industry looks to optimize its operations and reduce costs, this cutting-edge technology has the potential to drive significant advancements in oil and gas exploration and production.

Reverse Osmosis Alkaline Water Filter with Storage Tank and Fittings

Reverse Osmosis Alkaline Water Filter - The Perfect Solution to Your Drinking Water WoesClean drinking water is an essential commodity for any household. The quality of water has a direct impact on our health, and with the ever-increasing levels of pollution, it has become essential to ensure that the water we drink is of the highest quality.One of the best ways to ensure that you have clean and healthy drinking water is by using a reverse osmosis water filter. Reverse osmosis removes impurities from water by pushing it through a semi-permeable membrane, leaving behind only pure and clean water.If you are looking for a high-quality reverse osmosis water filter, look no further than the Reverse Osmosis Alkaline Water Filter. This filter system comes complete with a standard gallon storage tank and all the necessary fittings and installation kits.The system also features a special color-coded 1/4 tubing system, making it easy to install and use. The Reverse Osmosis Alkaline Water Filter also adds minerals to the water, making it alkaline and more beneficial for your health.The filter system is also equipped with an antioxidant system that helps balance out the pH levels in the water, giving you clean and healthy drinking water that tastes great.At the Chinese ultraviolet water treatment equipment manufacturer, we are dedicated to providing high-quality water treatment solutions to our customers. Our reverse osmosis water filter comes equipped with a one stage RO water treatment system, ensuring that your drinking water is of the highest quality.We also offer a range of other water treatment solutions, including ultra-filtration systems, to meet your specific needs. Our experienced team is dedicated to providing you with the best possible solutions for your drinking water needs.In conclusion, if you are looking for clean and healthy drinking water, the Reverse Osmosis Alkaline Water Filter is the perfect solution. At the Chinese ultraviolet water treatment equipment manufacturer, we are dedicated to providing you with high-quality water treatment solutions that meet your specific needs. Contact us today to learn more about our range of products and services!

Top Tank Agitator Models and Uses in Industrial Processes

Today, we are excited to introduce a new tank agitator, designed and manufactured by our company. This innovative product is set to revolutionize the industry with its advanced technology and unparalleled efficiency. The tank agitator is an essential tool for mixing and blending various substances in industrial processes, and our new product is poised to set a new standard for performance and reliability.Our company has been a leading provider of industrial equipment and machinery for over 20 years. We have a strong reputation for delivering high-quality products and exceptional customer service. Our team of engineers and designers are constantly working to develop new and improved solutions to meet the evolving needs of our clients. With our state-of-the-art manufacturing facilities and cutting-edge technology, we are able to bring innovative products to the market that offer superior performance and value.The new tank agitator is a testament to our commitment to innovation and excellence. It is equipped with the latest in agitation technology, allowing for precise control and optimal mixing capabilities. The agitator is designed to handle a wide range of viscosities and densities, making it versatile enough for a variety of applications. Whether it's blending liquids, suspending solids, or promoting chemical reactions, our tank agitator delivers consistent and reliable results.One of the key features of our tank agitator is its robust construction and durability. We understand the demanding nature of industrial processes, and our product is built to withstand the toughest operating conditions. With quality materials and solid engineering, our tank agitator is built to last, minimizing downtime and maintenance costs for our customers.In addition to its performance capabilities, our tank agitator is also designed with user convenience in mind. It is easy to install, operate, and maintain, allowing for seamless integration into existing production systems. Our goal is to provide our customers with a hassle-free experience, and our tank agitator is a reflection of that commitment.Furthermore, our company provides comprehensive support and service for all of our products, including the new tank agitator. We offer technical assistance, maintenance, and repair services to ensure that our customers get the most out of their investment. Our team is dedicated to helping our clients achieve their production goals and maximize efficiency with our equipment.As we look to the future, we are confident that our new tank agitator will make a significant impact in the industry. Its advanced technology, reliability, and user-friendly design set it apart from the competition, and we are excited to see the positive results it will bring to our customers. We will continue to innovate and deliver cutting-edge solutions to meet the evolving needs of the industrial sector, and the tank agitator is just the beginning of what's to come.

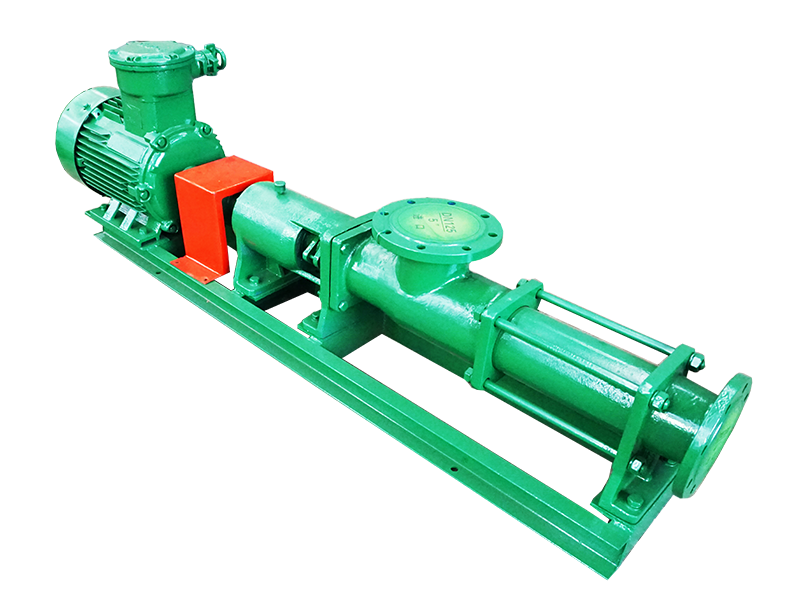

Highly Efficient Screw Pump: A Breakthrough in Pump Technology

Screw Pump Technology Revolutionizes Industrial Fluid HandlingIndustrial fluid handling has always been a critical aspect of various manufacturing processes. Whether it’s transferring chemicals, oil, or wastewater, the efficiency and reliability of the pumping system play a crucial role in maintaining the overall productivity of the operation. In this context, the introduction of the innovative Screw Pump technology by [Company] has revolutionized the way industrial fluids are handled and transferred.[Company] is a leading provider of innovative pumping solutions for a wide range of industrial applications. With a focus on delivering high-performance and reliable products, the company has built a reputation for excellence and innovation in the fluid handling industry. The latest addition to their product line, the Screw Pump, is not only a testament to their commitment to innovation but also a game-changer in the industry.The Screw Pump technology is based on the principle of positive displacement, where the fluid is moved through the pump in a smooth and consistent manner, resulting in stable flow rates and minimal pulsation. This makes it an ideal choice for applications where precision and accuracy are crucial, such as in chemical processing and oil refineries. Furthermore, the design of the Screw Pump allows for handling a wide range of viscosities, from low to high, without sacrificing performance, making it a versatile solution for various industrial fluid handling needs.One of the key features of the Screw Pump is its ability to handle abrasive and shear-sensitive fluids with ease. This is achieved through the use of robust materials and an advanced design that minimizes wear and tear, thus extending the lifespan of the pump and reducing maintenance costs. In addition, the Screw Pump is equipped with a sealing system that effectively prevents leakage, ensuring the safety and reliability of the pumping operation.The efficiency of the Screw Pump is also worth noting, as it can deliver high flow rates with minimal energy consumption. This not only reduces operational costs but also contributes to environmental sustainability by minimizing energy usage and reducing carbon emissions. The compact design of the Screw Pump further adds to its appeal, as it can be easily integrated into existing systems or installed in limited spaces, saving valuable floor space in industrial facilities.With its advanced technology and robust construction, the Screw Pump has quickly gained recognition in the industrial fluid handling market. [Company] has received positive feedback from customers who have implemented the Screw Pump in their operations, citing its reliability, efficiency, and low maintenance requirements as key factors in their satisfaction. The company’s commitment to providing exceptional customer support further enhances the overall experience of integrating the Screw Pump into industrial processes.Looking ahead, [Company] is dedicated to further enhancing the Screw Pump technology, with ongoing research and development efforts aimed at introducing new features and improvements to meet the evolving needs of the industry. As a forward-thinking and customer-focused company, [Company] is dedicated to continuous innovation and excellence in providing pumping solutions that drive the success of industrial operations around the world.In conclusion, the introduction of the Screw Pump by [Company] signifies a new era in industrial fluid handling, offering a combination of efficiency, reliability, and versatility that sets a new standard for pumping technology. With its advanced design and proven performance, the Screw Pump has quickly established itself as a preferred choice for a wide range of industrial applications, reaffirming [Company]’s position as a leader in the fluid handling industry.

Powerful Industrial Pumps Available for Purchase

Local Business, a leading supplier of industrial equipment, has recently announced the availability of a new range of mission magnum pumps for sale. These high-quality pumps are designed to provide efficient and reliable performance in a wide range of industrial applications.Local Business has been a trusted supplier of industrial equipment for many years, serving customers in a variety of industries including oil and gas, mining, construction, and manufacturing. The company has built a strong reputation for delivering high-quality products and exceptional customer service, making them a go-to supplier for businesses looking for reliable industrial equipment.The new range of mission magnum pumps for sale is the latest addition to Local Business's extensive product offering. These pumps are designed to handle the most demanding pumping applications, providing reliable performance and long-lasting durability. Whether for dewatering, solids control, or slurry transfer, these pumps are up to the task.“We are excited to offer our customers access to the new range of mission magnum pumps,” said a representative from Local Business. “These pumps are known for their robust construction and reliable performance, making them an ideal choice for our customers in need of dependable pumping solutions.”The mission magnum pumps for sale from Local Business are available in a variety of configurations to suit different application requirements. Customers can choose from different sizes and specifications to ensure they get the right pump for their specific needs. In addition, Local Business offers expert guidance and support to help customers select the best pump for their application, ensuring they get the most out of their investment.In addition to offering mission magnum pumps for sale, Local Business also provides a range of services to support their customers. This includes pump installation, maintenance, and repair services, as well as technical support and training. The company's team of experienced technicians is on hand to provide support throughout the lifespan of the pumps, ensuring they continue to deliver reliable performance for years to come.“We don't just sell pumps – we provide comprehensive support to ensure our customers get the most out of their investment,” said the representative from Local Business. “Our team is committed to providing the highest level of service and support to our customers, helping them achieve their operational goals.”Customers interested in the mission magnum pumps for sale can get in touch with Local Business to discuss their requirements and receive expert guidance on selecting the right pump for their needs. With a commitment to quality and customer satisfaction, Local Business is the trusted choice for businesses looking for reliable industrial equipment and support.For more information about the mission magnum pumps for sale and the range of industrial equipment and services offered by Local Business, customers are encouraged to visit the company's website or contact their sales team directly. With a strong track record of delivering high-quality products and exceptional service, Local Business is the preferred partner for businesses looking for reliable pumping solutions.