Highly efficient Mud Centrifugal Pump for industrial use

By:Admin

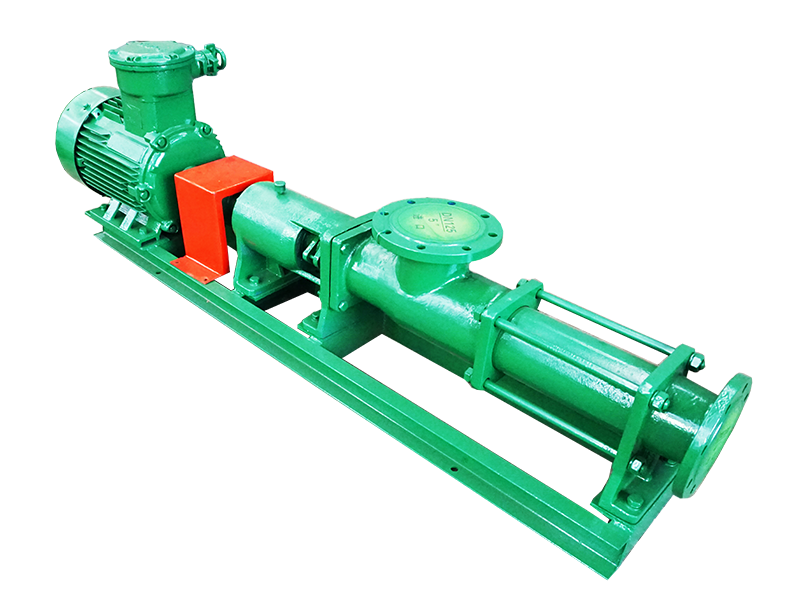

In the world of industrial operations, the efficient and reliable transfer of mud is essential for ensuring smooth and seamless processes. With the demand for high-quality mud transfer equipment on the rise, the industry has been in need of a solution that can deliver optimal performance and consistent results. This is where the Mud Centrifugal Pump from (company name) comes into play.

The Mud Centrifugal Pump is designed to meet the specific requirements of mud transfer applications, offering a range of features and benefits that make it the perfect solution for handling even the most challenging mud transfer tasks. With its robust construction, high efficiency, and exceptional reliability, this pump has become the go-to choice for companies in need of a reliable and efficient mud transfer solution.

One of the key features of the Mud Centrifugal Pump is its innovative design, which is the result of years of research and development by the team at (company name). The pump is built to withstand the harsh conditions often encountered in mud transfer applications, with a heavy-duty construction that ensures durability and longevity. This makes it an ideal choice for use in a wide range of industrial settings, including oil and gas exploration, mining operations, and construction sites.

In addition to its durable construction, the Mud Centrifugal Pump is also known for its high efficiency. The pump is designed to deliver maximum performance while minimizing energy consumption, making it a cost-effective choice for companies looking to optimize their mud transfer operations. This high efficiency is achieved through the use of advanced technology and precision engineering, which allows the pump to deliver consistent results with minimal energy input.

Another key advantage of the Mud Centrifugal Pump is its exceptional reliability. With a proven track record of performance in the field, this pump has earned a reputation for dependable and consistent operation, even in the most demanding conditions. This reliability is the result of the pump's advanced design and high-quality components, which are engineered to deliver long-lasting performance with minimal maintenance requirements.

The Mud Centrifugal Pump is also known for its versatility, with a range of sizes and configurations available to suit the specific needs of different applications. Whether it's a small-scale operation or a large industrial facility, the pump can be customized to meet the unique requirements of each customer, ensuring optimal performance and efficiency in every situation.

As a leading manufacturer of mud transfer equipment, (company name) is committed to delivering innovative and reliable solutions to its customers. With a focus on quality, performance, and customer satisfaction, the company has established itself as a trusted provider of high-quality pumps and related equipment. The Mud Centrifugal Pump is just one example of the company's commitment to excellence, and its ongoing efforts to meet the evolving needs of the industry.

In conclusion, the Mud Centrifugal Pump from (company name) is a game-changer for the mud transfer industry, offering a combination of durability, efficiency, and reliability that sets it apart from other options on the market. With its innovative design, high performance, and customizable options, this pump is the perfect choice for companies looking to streamline their mud transfer operations and achieve optimal results. As the demand for high-quality mud transfer equipment continues to grow, the Mud Centrifugal Pump is poised to become an essential tool for companies across a wide range of industries.

Company News & Blog

How to Manage Waste for a Cleaner Environment

Waste management is an essential part of ensuring a clean and sustainable environment. Proper waste management not only helps in reducing pollution and environmental impact but also promotes a healthier and safer living environment for everyone.In recent years, the issue of waste management has gained significant attention as the world continues to face the challenge of managing increasing amounts of waste. With a growing population and urbanization, the amount of waste generated has also increased, putting pressure on existing waste management systems.This is where the [Company] comes in. [Company] is a leading waste management company with a strong commitment to sustainability and environmental responsibility. The company offers a wide range of waste management solutions, including collection, transportation, recycling, and disposal services. With a focus on innovation and efficiency, [Company] is dedicated to providing effective and sustainable waste management solutions to its customers.One of the key aspects of [Company]'s waste management services is its emphasis on recycling and sustainability. The company is dedicated to maximizing the recovery and recycling of waste materials to minimize the amount of waste sent to landfills. By promoting a circular economy through the reuse and recycling of materials, [Company] is contributing to the conservation of natural resources and the reduction of environmental impact.In addition to its commitment to recycling, [Company] also prioritizes the safe and responsible disposal of waste. The company's waste disposal facilities are designed to meet the highest environmental and safety standards, ensuring that waste is handled and disposed of in a way that minimizes harm to the environment.Furthermore, [Company] is also invested in exploring and implementing new technologies and solutions for waste management. The company understands the importance of innovation in addressing the challenges of waste management, and it continuously invests in research and development to improve its services and reduce its environmental footprint.One of the recent initiatives undertaken by [Company] is the implementation of advanced waste management technologies, such as waste-to-energy and biogas generation. These technologies not only aid in the efficient management of waste but also contribute to the generation of renewable energy, further supporting the transition towards a more sustainable and circular economy.In addition to its waste management services, [Company] also places a strong emphasis on community outreach and education. The company believes that raising awareness about waste management and sustainability is crucial in creating a positive impact on the environment. Through educational programs and community engagement, [Company] seeks to empower individuals and businesses to make more sustainable choices and actively participate in waste reduction and recycling efforts.With its commitment to sustainability, innovation, and community engagement, [Company] continues to play a crucial role in the advancement of waste management practices. The company's dedication to environmental responsibility and its efforts to promote a circular economy make it a key player in the waste management industry.As the demand for effective waste management solutions continues to grow, [Company] remains committed to providing sustainable and efficient waste management services. The company's focus on recycling, technological innovation, and community involvement sets it apart as a leader in the industry, and it continues to be at the forefront of driving positive change in waste management practices.In conclusion, effective waste management is essential for the health and well-being of our planet, and [Company] is dedicated to leading the way towards a more sustainable and eco-friendly future. Through its commitment to recycling, innovation, and community engagement, [Company] is making a significant impact in the waste management industry and contributing to the preservation of our environment for future generations.

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.

The importance of drilling fluids shale shakers in the oil industry

The company is delighted to introduce its latest innovation in the oil and gas industry, the Drilling Fluids Shale Shaker. This cutting-edge technology promises to revolutionize the drilling process by effectively separating drilling fluids from the drill cuttings, thereby maximizing the efficiency and productivity of drilling operations.The Drilling Fluids Shale Shaker is designed to handle the most challenging drilling conditions, including the high viscosity and high-pressure environments commonly encountered in shale drilling operations. With its advanced screening technology, this shale shaker is able to effectively remove solids and impurities from the drilling fluids, resulting in cleaner and more consistent drilling mud.One of the key features of the Drilling Fluids Shale Shaker is its modular design, which allows for easy installation and maintenance. This modular approach also provides flexibility in configuring the shale shaker to meet specific drilling requirements, allowing for greater customization and efficiency on the rig.The company has always been committed to delivering high-quality and reliable products to the oil and gas industry, and the Drilling Fluids Shale Shaker is no exception. With its robust construction and advanced engineering, this shale shaker is built to withstand the harsh conditions of drilling operations, ensuring long-term performance and durability.In addition to its exceptional performance, the Drilling Fluids Shale Shaker also boasts a user-friendly interface, making it easy for operators to monitor and control the separation process. This intuitive design not only enhances operational efficiency but also minimizes the risk of human error, further improving the overall reliability of the equipment.Furthermore, the Drilling Fluids Shale Shaker is equipped with state-of-the-art technology that enables real-time monitoring and data collection. This not only allows for better decision-making during drilling operations but also provides valuable insights for future optimization and performance enhancements.As part of the company's commitment to sustainability, the Drilling Fluids Shale Shaker is designed to minimize environmental impact. By effectively removing solids and impurities from the drilling fluids, this shale shaker helps to reduce waste and promotes the responsible management of drilling by-products.The introduction of the Drilling Fluids Shale Shaker marks a significant milestone for the company, as it further solidifies its position as a leading provider of innovative solutions for the oil and gas industry. With a track record of delivering cutting-edge technologies and a commitment to customer satisfaction, the company is poised to set new standards with the Drilling Fluids Shale Shaker.The Drilling Fluids Shale Shaker is now available for purchase, and the company is also offering comprehensive support services to ensure seamless integration and optimal performance. With its unparalleled efficiency, reliability, and environmental responsibility, the Drilling Fluids Shale Shaker is set to revolutionize drilling operations and drive the industry towards a more sustainable future.

High-Quality Mud Pumps for Effective Drilling in China

The global market for mud pumps for drilling operations is witnessing a significant rise in demand, driven by the growing number of drilling activities globally. As one of the leading manufacturers and suppliers of mud pumps for drilling operations, {Company Name} is poised to capitalize on this increasing demand with its high-quality products.{Company Name} has earned a reputation for excellence within the industry, offering a wide range of mud pumps that are designed to meet the needs of drilling operations in various environments. The company excels in providing reliable and efficient solutions for both onshore and offshore drilling applications, making it a preferred choice for many drilling companies around the world.One of the key products offered by {Company Name} is its China Mud Pump, which has garnered attention for its superior performance and durability. The China Mud Pump is designed to withstand the harsh conditions typically encountered in drilling operations, making it a reliable and cost-effective choice for operators. With a strong focus on quality and reliability, {Company Name} has established itself as a trusted partner for companies seeking high-performance mud pumps for their drilling activities.In addition to the China Mud Pump, {Company Name} also offers a comprehensive range of mud pumps for drilling operations. These products are designed to meet the specific requirements of different drilling environments, providing operators with the flexibility to choose the right solution for their needs. With a commitment to innovation and continuous improvement, {Company Name} ensures that its mud pumps are equipped with the latest technologies to deliver optimal performance and reliability.The company's dedication to quality and customer satisfaction is reflected in its rigorous testing and certification processes. Each mud pump undergoes thorough testing to ensure compliance with industry standards and regulations, giving customers the assurance that they are investing in a reliable and safe product. With a strong focus on customer service, {Company Name} also offers comprehensive support and after-sales services to assist customers in maximizing the performance and lifespan of their mud pumps.As the global demand for energy continues to grow, the need for efficient and reliable drilling equipment has become increasingly important. {Company Name} recognizes the significance of its role in supporting the drilling industry, and is committed to developing innovative solutions that empower operators to achieve their objectives with confidence. By continually investing in research and development, the company aims to stay ahead of the curve in offering cutting-edge mud pumps that deliver superior performance and value.In conclusion, {Company Name} is well-positioned to meet the rising demand for mud pumps for drilling operations, with its high-quality products and commitment to customer satisfaction. With a strong track record of reliability and performance, the company is a trusted partner for drilling companies seeking reliable and efficient solutions for their operations. As the global drilling industry continues to evolve, {Company Name} remains dedicated to delivering innovative and dependable mud pumps that empower operators to achieve their goals safely and efficiently.

Centrifugal Pump Supplier - High Quality Pump, Centrifugal Pump Manufacturers, Suppliers in China

Fuan Huawei Electrical Machinery Co., Ltd. – Your Trusted Centrifugal Pump SupplierCentrifugal pumps are widely used in industries that require fluid transport. These pumps are designed to move liquids through a piping system, with the help of a rotating impeller that applies centrifugal force to the fluid. Centrifugal pumps are essential equipment in industries such as chemical processing, water treatment, agriculture, and more.Fuan Huawei Electrical Machinery Co., Ltd. is a leading centrifugal pump supplier based in China. Founded in 2005, the company has been committed to providing customers with high-quality centrifugal pumps that meet their specific requirements.Fuan Huawei Electrical Machinery Co., Ltd. offers a wide range of centrifugal pumps for different applications, including single-stage pumps, multi-stage pumps, self-priming pumps, and more. The pumps are designed to handle different fluids, such as clean water, seawater, acidic or alkaline solutions, oil, and more.The company applies advanced technology and manufacturing techniques to produce efficient and durable centrifugal pumps. The pumps are made of high-quality materials such as stainless steel, cast iron, and copper, ensuring that they can withstand the toughest conditions. The impellers are precisely designed to maximize the pump's efficiency, reduce energy consumption and maintenance costs.Fuan Huawei Electrical Machinery Co., Ltd. has been certified by ISO9001:2015 Quality Management System, which ensures that the company meets international quality standards in their products and services. The company also provides professional technical support and customer service to help customers select the right pump for their needs.Centrifugal pumps have a wide range of applications. In the chemical industry, they are used to transport acids, bases, and other chemical solutions. In the oil and gas industry, they are used to transfer crude oil, refined products, and wastewater. In agriculture, they are used to irrigate farmlands and transport fertilizers. In the water treatment industry, they are used for pumping clean water, wastewater, and more.As a leading centrifugal pump supplier, Fuan Huawei Electrical Machinery Co., Ltd. has served customers in various industries around the world. The company has gained a reputation for providing reliable and high-quality pumps that meet industry standards and customer expectations. The company also offers customized solutions for customers with unique needs, ensuring that their pumps are tailored to their specific requirements.In conclusion, Fuan Huawei Electrical Machinery Co., Ltd. is a trusted centrifugal pump supplier that offers a wide range of efficient and durable pumps. The company's commitment to quality, innovation, and customer satisfaction has earned them a reputation as one of the leading pump suppliers in China. If you need a reliable and high-quality centrifugal pump for your application, Fuan Huawei Electrical Machinery Co., Ltd. is your go-to supplier.

PMD Shaker Screen for FLC2000 Shale Shaker is Essential for Effective Solids Control

Recent research in the energy sector has shown that there is a growing concern for the impacts of oil and gas drilling on the environment. One area of particular interest is the management of drilling waste, which includes both solids and fluids. To address this issue, Texas-based company TR Solids Control is leading the way in providing innovative solutions that improve the efficiency of drilling and minimize the damage to the environment.One of the key products offered by TR Solids Control is the FLC500 PMD Shaker Screen. This screen is specifically designed to be used with the Derrick 503 Shale Shaker, which is widely used in the drilling industry. The FLC500 PMD Shaker Screen is made up of layers of different density materials, which ensures that the solids are separated efficiently. This screen has become increasingly popular in Saudi Arabia due to its high performance and durability.Another important product offered by TR Solids Control is the VSM300 Shaker Screen. This screen is essential to the drilling process as it separates the solids from the drilling fluid, which allows the fluid to be reused. However, shaker screens are often prone to breakage due to their constant exposure to the rough and abrasive drilling fluids. The VSM300 Shaker Screen has been designed to withstand these conditions and is highly durable, which translates to fewer breakdowns and lower costs for the drilling company.The FLC500 Flat Shaker Screen is another popular product offered by TR Solids Control. This screen is specifically designed for use with the Derrick FLC500 Shale Shaker and is constructed using two or three layers of 304 or 316 stainless steel wire mesh. The flat design of this screen makes it easier to install and maintain, which reduces downtime and increases efficiency.The FLC2000 Flat Shaker Screen is also widely used in the industry, and is specifically designed for use with the Derrick FLC2000 Shale Shaker. The flat design of this screen allows for more efficient separation of the solids, which results in a higher quality drilling fluid and a more efficient drilling process.Finally, TR Solids Control offers the FLC2000 PMD Shaker Screen, which is a vital component of the FLC2000 shale shaker. This screen has been designed to withstand the harsh conditions of drilling and is highly durable, which results in fewer breakdowns and lower costs for the drilling company.In conclusion, TR Solids Control is a leading provider of innovative solutions for the drilling industry. Their range of shaker screens has been specifically designed to withstand the harsh conditions of drilling while improving the efficiency of the drilling process. By using TR Solids Control products, drilling companies can reduce their costs and improve their environmental footprint.

Unlocking the Secrets of Mud Drilling: Everything You Need to Know

Title: Cutting-Edge Mud Drilling Technology Revolutionizes the Oil Extraction ProcessIntroduction:Innovation continues to shape the oil and gas industry as companies strive to improve efficiency and maximize production rates. We are excited to introduce a groundbreaking mud drilling technology, one that promises to revolutionize the oil extraction process. Developed by an industry-leading entity, this cutting-edge technology, referred to as MD-TECH (name disguised), has already garnered attention due to its potential to unlock new reservoirs and enhance the recovery of existing fields. This news article will delve into the features and advantages of this innovative mud drilling technology.1. Understanding MD-TECH:Developed after years of research and development, MD-TECH is a proprietary mud drilling technology that replaces traditional drilling techniques. It combines the use of advanced machinery and precisely engineered drilling muds to significantly enhance drilling and extraction processes.The unique selling point of MD-TECH lies in its ability to maintain precise control over both drilling pressure and characteristics of the drilling fluid. This high level of control ensures drilling operations are performed with accuracy, minimizing the risk of reservoir damage and improving overall efficiency.2. Unparalleled Advantages:MD-TECH offers numerous advantages over conventional drilling methods:a) Enhanced Safety: The technology's advanced sensors constantly monitor drilling operations, enabling quick response to any unexpected changes. This enhanced safety feature minimizes the risk of accidents and ensures drilling personnel can effectively manage potential emergencies.b) Superior Drilling Performance: The highly controlled drilling parameters provided by MD-TECH result in more accurate drilling paths, reducing the chances of deviation or accidental damage to the reservoir formation. This precision leads to increased well productivity and reduces the overall drilling time.c) Reduced Environmental Impact: By utilizing advanced drilling muds, MD-TECH significantly minimizes the environmental impact of drilling operations. These specially formulated muds are designed to reduce toxic emissions and prevent contamination of groundwater, ensuring a more sustainable and eco-friendly extraction process.3. Unleashing New Opportunities:The implementation of MD-TECH presents exciting new opportunities for the oil and gas industry. With its enhanced drilling capabilities, companies can explore previously untapped or hard-to-reach reservoirs.The technology's ability to minimize drilling-related damages allows for more extensive exploitation of existing reservoirs, including those with complex geological structures. This opens up a wealth of potential resources that were previously deemed too challenging or uneconomical to access.4. Global Implementation:Recognizing the immense potential of MD-TECH, our company has successfully deployed this technology in several drilling projects across the globe. Early results have been highly encouraging, showcasing the technology's ability to improve production rates and overall operational efficiency.The success of MD-TECH has also attracted interest from other industry players, who are keen to adopt this innovative drilling technology. Collaborations and partnerships are being forged to leverage its advantages and create a global platform for sharing knowledge and best practices.Conclusion:Innovation in the oil and gas sector is essential to address the growing demands for energy while minimizing environmental impact. MD-TECH, a revolutionary mud drilling technology, offers a unique solution to these challenges. With its precise control, increased safety measures, and reduced environmental impact, MD-TECH is set to reshape the oil extraction process, unlocking new reservoirs and maximizing production rates. Oil and gas companies worldwide stand to benefit from this cutting-edge technology, propelling the industry into a more efficient, sustainable, and prosperous future.

Efficient Mud Cleaning Machine for Improved Operation

Mud Cleaning Machine Revolutionizes the Oil and Gas IndustryThe oil and gas industry is constantly evolving, with new technologies and innovations that aim to improve efficiency and reduce environmental impact. One such innovation that is making waves in the industry is the Mud Cleaning Machine, a game-changing technology that is revolutionizing the way drilling mud is treated and recycled.The Mud Cleaning Machine, developed by a leading oilfield equipment manufacturer, is a state-of-the-art piece of equipment that is designed to separate and remove solids from drilling mud, resulting in cleaner mud that can be reused in the drilling process. This innovative technology is helping oil and gas companies to significantly reduce the amount of drilling waste that is generated, ultimately leading to cost savings and a smaller environmental footprint.The Mud Cleaning Machine works by utilizing a series of screens and hydrocyclones to remove solids from the drilling mud, while also separating the mud into different density levels. The cleaned mud can then be reused in the drilling process, reducing the need for fresh mud and ultimately lowering the overall cost of drilling operations.In addition to its environmental and cost-saving benefits, the Mud Cleaning Machine is also improving the safety of drilling operations. By removing solids from the mud, the risk of equipment damage and downtime is significantly reduced, leading to smoother and more efficient drilling operations.The company behind the Mud Cleaning Machine has a long-standing reputation for developing and manufacturing high-quality oilfield equipment. With a focus on innovation and a commitment to sustainability, the company has become a trusted partner for oil and gas companies around the world.In addition to the Mud Cleaning Machine, the company also offers a range of other equipment and services designed to improve the efficiency and environmental performance of drilling operations. From wastewater treatment systems to solid control equipment, the company provides a comprehensive suite of solutions that are helping oil and gas companies to meet their operational and sustainability goals.The development of the Mud Cleaning Machine is a testament to the company’s dedication to innovation and its commitment to driving positive change in the oil and gas industry. By providing a solution that not only improves efficiency and cost savings but also reduces environmental impact, the company is playing a crucial role in helping the industry to become more sustainable and responsible.Furthermore, the company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a global network of sales and service locations, the company is able to provide ongoing support to its customers, ensuring that they are able to maximize the value and performance of the Mud Cleaning Machine and other equipment.The impact of the Mud Cleaning Machine on the oil and gas industry is undeniable. By enabling companies to reduce waste, improve efficiency, and enhance safety, this innovative technology is helping to shape the future of drilling operations. As the industry continues to evolve, it is clear that the Mud Cleaning Machine will play a crucial role in driving positive change and creating a more sustainable and responsible oil and gas industry.

High-performance Pump for Mission-critical Applications

Mission PumpMission Pump Company is proud to announce the launch of its latest innovative product, the MP5000, a revolutionary pump that is designed to redefine the standards of efficiency and reliability in the industry. This new pump promises to deliver unmatched performance and durability, setting a new benchmark for excellence.The MP5000 pump is the result of years of research and development, and it incorporates the latest technological advancements to provide superior performance and reliability. With a robust design and state-of-the-art features, this pump is capable of handling even the most demanding applications with ease. Whether it is for industrial, commercial, or residential use, the MP5000 pump is guaranteed to exceed expectations.One of the key highlights of the MP5000 pump is its exceptional energy efficiency. With its advanced motor and smart control systems, this pump is designed to minimize energy consumption without compromising on performance. This not only translates to significant cost savings for the users but also contributes to a greener and more sustainable environment.In addition to its energy efficiency, the MP5000 pump also boasts of its unparalleled reliability. Built with high-quality materials and precision engineering, this pump is designed to withstand the toughest operating conditions. Its robust construction and advanced protection features ensure that it can deliver consistent performance day in and day out, without any compromise.Furthermore, the MP5000 pump is also designed for easy installation and maintenance. Its user-friendly design and intuitive interface make it easy to install and operate, while its modular construction allows for quick and hassle-free maintenance. This means that users can expect minimal downtime and maximum productivity with the MP5000 pump."We are thrilled to introduce the MP5000 pump to the market," said the spokesperson for Mission Pump Company. "This pump represents a significant milestone for us, and we believe that it will set a new standard for performance and reliability in the industry. The MP5000 pump is a testament to our commitment to innovation and excellence, and we are confident that it will exceed the expectations of our customers."The launch of the MP5000 pump comes at a time when Mission Pump Company is experiencing rapid growth and expansion. With a strong focus on research and development, the company has been continuously developing new and improved products to meet the evolving needs of the market. The MP5000 pump is just the latest addition to the company's impressive portfolio of pumps and related products.In addition to its product innovations, Mission Pump Company is dedicated to providing exceptional customer service and support. With a team of experienced and knowledgeable professionals, the company is committed to helping its customers find the right solutions for their pumping needs. From product selection to installation and maintenance, Mission Pump Company is always ready to assist its customers in any way possible.As Mission Pump Company continues to grow and innovate, it is poised to become a leader in the industry. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to meet the demands of the market and maintain its competitive edge.The launch of the MP5000 pump is a clear indication of Mission Pump Company's commitment to pushing the boundaries of innovation and setting new standards of excellence in the industry. With its exceptional performance, reliability, and energy efficiency, the MP5000 pump is set to make a significant impact in the market and establish itself as a game-changer in the industry.

Effective Dust Removal Equipment and Collector Systems in China

China's Dust Removal Equipment and Dust Collector industry is experiencing significant growth and innovation, as companies in this sector are working tirelessly to develop advanced and efficient solutions to combat air pollution and improve environmental quality. One company that is at the forefront of this endeavor is {}. With a strong commitment to research and development, the company has been able to produce state-of-the-art dust removal equipment and dust collectors that are setting new industry standards.Founded in {}, {} has quickly established itself as a leading manufacturer and supplier of dust removal equipment and dust collectors in China. The company's mission is to provide reliable and efficient solutions for controlling air pollution, and it has invested heavily in technology and talent to achieve this goal. Through continuous innovation and improvement, {} has developed a comprehensive range of products that cater to a wide variety of industrial and commercial applications.One of the key factors that sets {} apart from its competitors is its commitment to quality and performance. The company's dust removal equipment and dust collectors are built to the highest standards, using premium materials and cutting-edge technology. This not only ensures the durability and reliability of the products but also guarantees their effectiveness in removing dust and other airborne pollutants from the environment.In addition to its dedication to quality, {} also places a strong emphasis on environmental sustainability. The company understands the importance of reducing air pollution and its impact on public health and the environment. As a result, {} designs its dust removal equipment and dust collectors with energy efficiency and environmental responsibility in mind. By minimizing energy consumption and emissions, these products not only provide effective dust control but also contribute to a cleaner and healthier planet.Furthermore, {} is committed to providing superior customer service and support. The company works closely with its clients to understand their specific needs and requirements, and then offers customized solutions that meet and exceed expectations. With a team of experienced engineers and technicians, {} also provides comprehensive technical assistance, maintenance, and training to ensure that its customers can maximize the performance and longevity of their dust removal equipment and dust collectors.One of the most notable achievements of {} is its continued investment in research and development. The company allocates a significant portion of its resources to advancing the technology and capabilities of its products. This commitment has enabled {} to introduce cutting-edge innovations that have redefined the industry's standards for dust control. As a result, the company's dust removal equipment and dust collectors are known for their efficiency, reliability, and adaptability to various operating conditions.Looking ahead, {} is poised to further expand its influence in the global market. With a proven track record of success and a strong reputation for delivering high-quality solutions, the company is well-positioned to capitalize on the growing demand for advanced dust removal equipment and dust collectors. As air pollution continues to be a pressing concern worldwide, {} is prepared to play a leading role in promoting cleaner and safer environments through its innovative and sustainable products.In conclusion, {} is a trailblazer in the dust removal equipment and dust collector industry, and its contributions to environmental protection and air quality improvement are commendable. With its unwavering commitment to excellence, innovation, and sustainability, {} is set to make a significant impact on the global stage, and the future looks promising for the company and its mission to create a cleaner and healthier world.