Top-quality Centrifuge and Solid Control Equipment in China

By:Admin

In recent years, China's centrifuge and solid control equipment industry has seen rapid growth and development, with a growing number of companies entering the market and offering innovative solutions to meet the increasing demand for high-quality equipment.

One such company making waves in the industry is {}, a leading manufacturer of centrifuge and solid control equipment in China. With over a decade of experience in the industry, {} has established itself as a reliable and innovative provider of a wide range of products and solutions for various applications in the oil and gas, mining, and environmental industries.

The company's success can be attributed to its commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and technicians, {} continually invests in research and development to improve its product offerings and stay ahead of the competition. This dedication to innovation has allowed the company to introduce cutting-edge technologies and solutions that have set new benchmarks in the industry.

One of the key products offered by {} is its range of centrifuges, which are designed to effectively separate solids from liquids in a wide range of applications. These centrifuges are known for their high efficiency, reliability, and low maintenance requirements, making them the preferred choice for many companies operating in challenging environments.

In addition to centrifuges, {} also offers a comprehensive range of solid control equipment, including shale shakers, mud cleaners, and decanter centrifuges. These products are designed to help companies efficiently manage drilling waste and ensure the smooth operation of drilling processes, leading to improved productivity and cost savings.

Another factor that sets {} apart from its competitors is its dedication to meeting and exceeding customer expectations. The company works closely with its clients to understand their specific requirements and develop tailor-made solutions that address their unique challenges. With a focus on customer satisfaction, {} has built strong and long-lasting relationships with a diverse portfolio of clients, including major oil and gas companies, mining companies, and environmental organizations.

As a testament to its commitment to quality and customer satisfaction, {} has obtained various industry certifications, including ISO 9001 and API Q1, which demonstrate the company's adherence to the highest standards of quality and reliability. These certifications also give customers peace of mind knowing that they are partnering with a reputable and trustworthy supplier.

Looking ahead, {} is poised for further growth and expansion as it continues to invest in research and development, expand its product offerings, and explore new markets. The company's strategic vision and strong leadership position it well for future success in the competitive centrifuge and solid control equipment industry.

In conclusion, {} has emerged as a leading player in China's centrifuge and solid control equipment industry, thanks to its commitment to quality, innovation, and customer satisfaction. With a proven track record of delivering cutting-edge products and solutions, {} is well-positioned for further growth and success in the years to come.

Company News & Blog

Efficient and Reliable Drilling Machines: Unveiling the Power of Drilling

[Company Name] Introduces Advanced Drilling Machine for Enhanced Drilling Operations[date][city, state] - In a bid to revolutionize drilling operations globally, [Company Name], a leader in the manufacturing of cutting-edge industrial machinery, announced the release of their latest drilling machine. The new technology promises to revolutionize the drilling industry by providing enhanced efficiency, versatility, and precision.Designed for both industrial and residential applications, the new drilling machine boasts state-of-the-art features that push the boundaries of current drilling capabilities. With its advanced technology and innovative design, [Company Name] aims to meet the growing demand for more efficient and productive drilling operations worldwide.The key feature of the new drilling machine is its advanced drilling technology, which allows for deeper and more precise drilling. Equipped with a powerful motor and specialized drill bits, this machine can effortlessly penetrate various materials, including concrete, metal, and wood. Its high torque capabilities ensure smooth operation even in the toughest drilling conditions.Additionally, the drilling machine incorporates intelligent automation features that increase operator safety and streamline operations. The inclusion of an automatic feed system ensures consistent drilling depth, negating the need for manual adjustments. This feature not only reduces operator workload but also minimizes drilling errors, resulting in better quality and reliable drilling outputs.Furthermore, the drilling machine offers exceptional versatility with its adjustable speed settings. Whether drilling delicate materials that require slow drilling or tackling heavy-duty tasks that demand high-speed drilling, this machine can cater to different drilling needs. This adaptability ensures that operators can achieve optimal results regardless of the drilling requirements, making it an ideal choice for various industries.In line with [Company Name]'s commitment to sustainability, the drilling machine incorporates eco-friendly features. With energy-efficient motors, reduced noise emissions, and ergonomic design, the machine helps minimize environmental impact while providing a comfortable working environment for operators. By prioritizing sustainability, [Company Name] aims to contribute to a greener future for the drilling industry.To ensure the seamless integration of the drilling machine into various drilling processes, [Company Name] provides comprehensive technical support and maintenance services. Their team of experienced engineers and technicians is readily available to assist clients with installation, training, and troubleshooting. This dedication to excellent customer service reinforces [Company Name]'s commitment to delivering not just top-notch products but also complete customer satisfaction."We are thrilled to introduce our latest drilling machine to the market," said [Spokesperson Name], a representative from [Company Name]. "We believe that this technology will revolutionize the way drilling operations are conducted, offering unparalleled efficiency and precision. We are confident that our clients will greatly benefit from this breakthrough in drilling technology."With its cutting-edge features, versatility, and dedication to sustainability, [Company Name]'s new drilling machine is set to make waves in the drilling industry. As the demand for more efficient drilling practices grows, this technology could pave the way for enhanced productivity and cost savings while reducing environmental impact. [Company Name] continues to drive innovation, setting its sights on transforming the drilling landscape on a global scale.Contact:[Company Name][Contact Person][Phone number][Email address][Website URL]

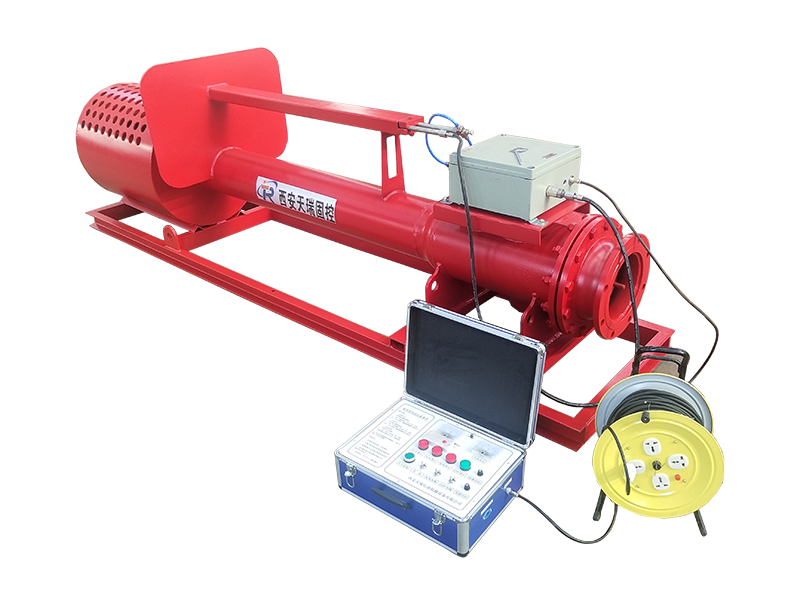

Effective Mud Gas Separator Design for Oil and Gas Operations

Mud Gas Separator Design Innovations by Leading CompanyIn the oil and gas industry, the need to effectively separate gas from drilling fluid has led to the development of advanced technologies such as the Mud Gas Separator (MGS). One of the leading companies in this field, with a proven track record of innovation and excellence, is {}. Their latest MGS design is set to revolutionize the industry by offering improved performance and efficiency.Established in {}, {} has been at the forefront of developing cutting-edge solutions for the oil and gas sector. With a team of highly skilled engineers and researchers, the company has consistently delivered state-of-the-art equipment that meets the evolving needs of the industry. The company's commitment to quality, safety, and environmental protection has earned them a stellar reputation as a trusted partner for oil and gas companies around the world.The latest Mud Gas Separator design by {} is the result of years of research and development. This innovative technology is designed to effectively separate and vent gas from drilling fluid, ensuring the safety of personnel and equipment on drilling rigs. The new design incorporates advanced features that enhance performance and reliability, making it an invaluable tool for oil and gas operations.One of the key features of the new Mud Gas Separator design is its enhanced gas-liquid separation efficiency. Thanks to innovative engineering and advanced materials, the MGS is capable of effectively capturing and removing gas from drilling fluid, even in high-pressure and high-temperature environments. This not only improves safety on drilling rigs but also minimizes the risk of equipment damage and downtime.Furthermore, the new MGS design also incorporates a compact and lightweight construction, making it easier to transport and install on drilling rigs. This innovative approach to design and engineering reflects {}'s commitment to practicality and ease of use, ensuring that their products meet the needs of their clients in the field.In addition to its performance and portability, the new Mud Gas Separator design by {} also integrates advanced safety features. These include robust gas venting systems and fail-safe mechanisms, which are essential for ensuring the wellbeing of personnel and the protection of the environment during drilling operations.{}'s Mud Gas Separator design is also designed to be user-friendly, with intuitive controls and maintenance features that make it easier for operators to monitor and service the equipment. This focus on usability and accessibility is a testament to {}'s customer-centric approach, ensuring that their products are not only technologically advanced but also practical and easy to operate.With the launch of their latest Mud Gas Separator design, {} reinforces their position as a leading innovator in the oil and gas industry. This new technology is set to raise the bar for gas-liquid separation on drilling rigs, offering unparalleled performance, reliability, and safety. As the industry continues to evolve, {} remains dedicated to developing solutions that address the challenges of today and anticipate the needs of tomorrow. Their commitment to excellence and innovation is evident in every aspect of their business, making them a trusted partner for oil and gas companies worldwide.

Discover the Environmental Impact of Drilling Waste

Drilling Waste, a leading provider of waste management solutions in the oil and gas industry, has revolutionized the way that drilling waste is managed and disposed of. With a focus on sustainability and environmental responsibility, they have developed innovative technologies and processes to minimize the environmental impact of drilling waste while also maximizing the recovery of valuable resources.The oil and gas industry generates large quantities of drilling waste, including cuttings, muds, and fluids, as a byproduct of drilling operations. Historically, this waste has been a significant environmental concern, as it can contain potentially harmful substances such as heavy metals, hydrocarbons, and other contaminants. In addition, the disposal of drilling waste has also been a significant cost for oil and gas companies, as traditional methods of disposal, such as landfills and injection wells, are expensive and can have negative environmental consequences.Drilling Waste has developed a range of solutions to address these challenges, including advanced filtration and separation technologies, as well as thermal treatment processes, to effectively and efficiently manage and dispose of drilling waste. Their proprietary technologies enable the recovery of valuable resources from drilling waste, such as oil and water, while also ensuring that the remaining waste is safely and responsibly disposed of.One of the key technologies that Drilling Waste has developed is a thermal treatment process that can effectively treat and convert drilling waste into a reusable material. This process involves heating the waste to high temperatures in a controlled environment, which allows for the separation of valuable substances, such as oil and water, from the waste. The remaining solid material is then processed to meet environmental and regulatory standards for disposal, minimizing the environmental impact of the waste.In addition to their advanced treatment technologies, Drilling Waste also offers comprehensive waste management services to their clients, including waste characterization, transportation, and regulatory compliance. By providing a full suite of waste management solutions, they enable their clients to effectively and responsibly manage their drilling waste, while also minimizing costs and environmental impact.Drilling Waste's commitment to sustainability and environmental responsibility is evident in their approach to waste management. They work closely with their clients to develop tailored solutions that meet their specific needs and operational requirements, while also ensuring the highest standards of environmental compliance.Their expertise in waste management and their dedication to innovation have made them a trusted partner for some of the world's leading oil and gas companies. With a proven track record of delivering cost-effective and sustainable waste management solutions, they have earned a reputation as a leader in the industry.In conclusion, Drilling Waste is at the forefront of revolutionizing the way that drilling waste is managed and disposed of in the oil and gas industry. Their innovative technologies and commitment to sustainability enable their clients to effectively and responsibly manage their drilling waste, while also minimizing costs and environmental impact. As the demand for sustainable waste management solutions continues to grow, Drilling Waste is well-positioned to lead the industry in providing innovative and effective solutions for the oil and gas industry.

High-Quality Centrifuges for Laboratory and Medical Use, Hand-Operated Options Available

China-based company [Company Name] has recently introduced a new line of centrifuge products, including a high-speed centrifuge and a hand-operated centrifuge, aimed at serving the needs of various industries, including medical, research, and industrial settings.The high-speed centrifuge is designed to provide efficient and reliable separation of substances, such as blood, urine, and other biological samples. With its advanced technology, the high-speed centrifuge is able to rapidly spin samples at high speeds, resulting in quick and precise separation of components. This is particularly beneficial in medical laboratories and research facilities where time is crucial and accurate results are paramount.On the other hand, the hand-operated centrifuge is a portable and versatile solution for smaller-scale separation tasks. This compact device is designed for situations where access to a power source is limited or when a smaller volume of samples needs to be processed. It can be used in various settings, such as field research, remote clinics, and educational laboratories.[Company Name] has a long history of developing and manufacturing high-quality centrifuge equipment for various applications. With a focus on technological innovation and product excellence, the company has established itself as a trusted supplier of centrifuge solutions in the global market.The company's commitment to quality and performance is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. Each centrifuge product undergoes comprehensive testing and inspection to ensure it meets the highest standards of reliability and efficiency.In addition to its technical expertise, [Company Name] also prides itself on providing exceptional customer service and support. The company's dedicated team of professionals is well-equipped to offer personalized advice and assistance to customers, helping them select the most suitable centrifuge solution for their specific needs.The introduction of the new high-speed and hand-operated centrifuge products further demonstrates [Company Name]'s dedication to meeting the evolving needs of its customers. By continuously expanding its product range and incorporating the latest technological advancements, the company aims to remain at the forefront of the centrifuge industry.The global demand for centrifuge equipment continues to grow, driven by increasing applications in the fields of healthcare, biotechnology, and research. [Company Name] is well-positioned to capitalize on this trend through its innovative product offerings and commitment to customer satisfaction.While the high-speed centrifuge is designed for high-throughput laboratories and facilities with demanding separation requirements, the hand-operated centrifuge is expected to appeal to customers seeking a portable and cost-effective solution for smaller-scale applications. Both products are expected to contribute to [Company Name]'s continued success in the centrifuge market.As [Company Name] looks to the future, it remains steadfast in its commitment to innovation, quality, and customer satisfaction. With its new line of centrifuge products, the company is poised to make a significant impact in the global market and solidify its reputation as a leading provider of centrifuge solutions.

Discover the Versatility of Flat Shaker Screens for Effective Solid Separation

FLC 500 Flat Shaker Screen: Revolutionizing the Drilling IndustryThe drilling industry is constantly evolving, with new technologies and equipment constantly emerging to improve efficiency and operational capabilities. One such innovation making waves in the sector is the FLC 500 Flat Shaker Screen, a groundbreaking solution developed by a prominent industry player.Designed to enhance the performance and productivity of drilling operations, the FLC 500 Flat Shaker Screen is revolutionizing the way drilling companies approach their work. With its advanced features and engineering excellence, this game-changing technology has gained significant recognition within the industry.The FLC 500 Flat Shaker Screen is the result of extensive research and development by a leading drilling equipment manufacturer. Leveraging their rich experience and expertise, the company identified a need for an improved shaker screen solution to overcome the challenges faced by drilling companies.One of the key features that sets the FLC 500 Flat Shaker Screen apart from its competitors is its flat design. This innovative construction ensures optimal solids control, allowing for more efficient separation of drilling fluids and solids during the drilling process. The flat screen surface provides a larger area for fluid dewatering, maximizing the screen's capacity and performance.Additionally, the FLC 500 Flat Shaker Screen boasts enhanced durability and longevity. Crafted using high-quality materials and state-of-the-art manufacturing techniques, this robust solution withstands the harsh operating conditions typically encountered in drilling operations. Its extended lifespan not only reduces operational downtime but also significantly lowers maintenance and replacement costs.Furthermore, the FLC 500 Flat Shaker Screen offers exceptional versatility. Compatible with various drilling equipment, it seamlessly integrates with existing systems, ensuring a hassle-free installation process. Its adaptability empowers drilling companies to upgrade their equipment without requiring substantial modifications, thereby improving operational efficiency and saving valuable time.The company behind this breakthrough innovation is known for its commitment to delivering superior technology with a focus on customer satisfaction. With a relentless dedication to research and development, combined with a customer-centric approach, they have earned a reputation as a trusted and reliable partner in the drilling industry.The FLC 500 Flat Shaker Screen is just one example of the company's commitment to innovation. Their extensive product portfolio includes a range of drilling equipment tailored to meet the unique needs and challenges of the industry. From screens to pumps, they offer comprehensive solutions that cater to diverse drilling requirements.In addition to their cutting-edge technology, the company places great emphasis on customer support and service. Their team of highly skilled professionals provides industry-leading technical assistance and on-site support to ensure seamless integration and optimal performance of their equipment. This dedication to customer satisfaction has positioned them as a preferred supplier amongst drilling companies worldwide.The introduction of the FLC 500 Flat Shaker Screen marks a significant milestone in the drilling industry. With its flat design, enhanced durability, and unmatched versatility, it is transforming the way drilling operations are conducted. As companies continue to prioritize efficiency and productivity, this revolutionary technology is set to play a pivotal role in shaping the future of the drilling industry.

Highly Efficient Mud Tank Drilling: Unveiling the Latest Techniques and Advancements

Mud Tank Drilling Expands its Reach in the Oil and Gas IndustryLeading Provider of Cutting Edge Drilling Solutions Continues to Revolutionize the Sector(Global) - Mud Tank Drilling, an innovative drilling solutions provider, is making waves in the oil and gas industry with its groundbreaking technologies and commitment to excellence. With a diverse range of services and state-of-the-art equipment, the company has established itself as a leading name in the drilling sector.Headquartered in [location], Mud Tank Drilling has been at the forefront of the industry for over [number of] years. The company's extensive portfolio of drilling solutions includes advanced mud tanks, solids control equipment, and advanced drilling fluids. These cutting-edge technologies have revolutionized drilling operations, offering clients increased efficiency, productivity, and cost-effectiveness.Mud Tank Drilling's success can be attributed to its unwavering commitment to research and development. The company continuously invests in state-of-the-art technologies and innovative solutions to offer its clients the most advanced drilling equipment on the market. By staying ahead of industry trends and anticipating future needs, Mud Tank Drilling ensures that its clients have access to the most efficient and reliable drilling solutions available.One of the key factors that sets Mud Tank Drilling apart is its team of highly skilled engineers and technicians. Committed to providing unparalleled customer service, these experts work closely with clients to understand their specific requirements and develop tailored drilling solutions to meet their needs. With a wealth of experience and expertise, Mud Tank Drilling's team is equipped to handle any drilling challenge, from complex offshore projects to onshore drilling operations.In addition to its comprehensive range of equipment and services, Mud Tank Drilling emphasizes safety and environmental sustainability. The company adheres to rigorous safety standards and implements strict safety protocols to protect its employees and ensure accident-free operations. Furthermore, it is dedicated to minimizing its environmental impact by employing eco-friendly practices and investing in technologies that reduce greenhouse gas emissions.Over the years, Mud Tank Drilling has completed numerous projects of varying scales and complexities across the globe. From remote and challenging terrains to offshore installations, the company has consistently delivered successful drilling solutions to its clients. The ability to adapt and thrive in diverse operating environments has earned Mud Tank Drilling a stellar reputation in the oil and gas industry.Looking towards the future, Mud Tank Drilling has ambitious expansion plans. The company aims to strengthen its presence in existing markets while exploring new opportunities globally. By broadening its global footprint, Mud Tank Drilling is poised to provide its cutting-edge drilling solutions to an even wider range of clients, cementing its position as a leader in the industry.In conclusion, Mud Tank Drilling has established itself as a frontrunner in the oil and gas industry by offering revolutionary drilling solutions. With a diverse range of services, state-of-the-art equipment, and a commitment to excellence, the company continues to drive innovation within the sector. As Mud Tank Drilling expands its global reach, it is well-positioned to meet the evolving needs of its clients and shape the future of drilling in the oil and gas industry.

Highly-Durable Mud Gun Nozzle Provides Effective Solutions for Industrial Operations

Mud Gun Nozzle, a vital component in the oil and gas industry, plays a crucial role in the drilling process. The mud gun nozzle is used to spray drilling mud, a mixture of water, clay, and other chemicals, into the drilling well to lubricate the drill bit, carry rock cuttings to the surface, and maintain pressure in the well. It is an essential tool for optimizing the drilling process and ensuring the success of oil and gas extraction operations.In this context, one company, which is a leading manufacturer of drilling equipment and tools, has recently launched its latest mud gun nozzle, designed to enhance drilling efficiency and reliability. With over 20 years of experience in the industry, the company has become a trusted name in providing high-quality products and innovative solutions for oil and gas exploration and production.The new mud gun nozzle features a cutting-edge design that offers improved performance and durability. Its advanced nozzle configuration allows for better spray coverage and distribution of drilling mud, resulting in more efficient drilling operations. The material used in the construction of the nozzle is highly resistant to corrosion and abrasion, ensuring long-lasting performance even in the harshest drilling environments.Furthermore, the company's mud gun nozzle is engineered to provide easy maintenance and servicing, reducing downtime and operational costs for drilling companies. The design incorporates quick-connect fittings and accessible components, allowing for effortless disassembly and reassembly when necessary. This user-friendly approach reflects the company's commitment to delivering practical and reliable solutions to its customers.In addition to the superior design and functionality, the mud gun nozzle is also backed by the company's renowned technical support and customer service. The company's team of experienced engineers and technicians are available to provide assistance with installation, maintenance, and troubleshooting, ensuring that customers can maximize the performance of the mud gun nozzle and their overall drilling operations.As part of its dedication to quality and customer satisfaction, the company conducts rigorous testing and quality assurance procedures to ensure that its mud gun nozzles meet the highest standards of performance and reliability. This attention to detail and commitment to excellence have earned the company the trust and loyalty of numerous drilling companies around the world.The launch of the new mud gun nozzle represents the company's ongoing efforts to innovate and improve its product offerings to meet the evolving needs of the oil and gas industry. By leveraging its expertise and technical capabilities, the company aims to continue playing a significant role in advancing drilling technologies and supporting the exploration and production activities of its customers.In conclusion, the introduction of the new mud gun nozzle by the company signifies a significant development in the realm of drilling equipment and tools for the oil and gas industry. With its advanced design, exceptional performance, and unwavering commitment to customer support, the company continues to solidify its position as a leading provider of reliable and innovative solutions for drilling operations. As the industry continues to evolve, the company remains poised to meet the challenges and demands of the future, driven by its dedication to excellence and customer satisfaction.

New Mixing Hopper Technology: A Game Changer in Industrial Processing

Venturi Mixing Hopper Revolutionizes Mixing Technology in Industrial ApplicationsWith the increasing demand for efficient and effective mixing technology in industrial applications, the introduction of the Venturi Mixing Hopper has been a game-changer in the industry. This innovative solution has been designed to revolutionize the way materials are mixed, offering a more effective and efficient approach to industrial mixing.The Venturi Mixing Hopper, developed by a leading company in the field of industrial equipment manufacturing, has been gaining widespread attention for its ability to significantly improve mixing processes in various industries. This cutting-edge technology has been designed to provide a solution to the challenges faced by industries when it comes to mixing materials effectively and efficiently.The company behind the Venturi Mixing Hopper is known for its commitment to innovation and excellence in the field of industrial equipment manufacturing. With a proven track record of delivering high-quality solutions to industries around the world, the company has built a reputation for pushing the boundaries of what is possible in industrial technology.The Venturi Mixing Hopper is a testament to the company's dedication to innovation and its ability to develop solutions that meet the ever-evolving needs of industries. By combining cutting-edge technology with practical industrial applications, the company has been able to create a product that is not only effective but also efficient and reliable.One of the key features of the Venturi Mixing Hopper is its ability to achieve thorough and uniform mixing of materials, regardless of their properties or characteristics. This has been a significant challenge for industries that rely on effective mixing processes to ensure the quality and consistency of their products. The Venturi Mixing Hopper has been able to address this challenge by utilizing advanced technology that is capable of achieving optimal mixing results.In addition to its exceptional mixing capabilities, the Venturi Mixing Hopper also offers a range of other benefits that make it a valuable investment for industries. Its compact design and user-friendly interface make it easy to operate and maintain, while its robust construction ensures durability and longevity. Furthermore, the Venturi Mixing Hopper is designed to be adaptable to various industrial settings, making it a versatile and flexible solution for different applications.The introduction of the Venturi Mixing Hopper has been met with a positive response from industries that have been struggling with outdated and inefficient mixing technologies. The significant improvements in mixing efficiency and quality that the Venturi Mixing Hopper offers have been a game-changer for these industries, allowing them to optimize their processes and achieve better results.The company behind the Venturi Mixing Hopper has been actively promoting the benefits and advantages of this innovative solution, working closely with industries to demonstrate its capabilities and potential impact. Through various demonstrations and case studies, the company has been able to showcase the significant improvements that the Venturi Mixing Hopper can bring to industrial mixing processes.Moving forward, the company is committed to further developing and enhancing the capabilities of the Venturi Mixing Hopper, as well as exploring new opportunities for its application in different industries. By continuing to innovate and push the boundaries of industrial mixing technology, the company aims to further solidify the position of the Venturi Mixing Hopper as a leading solution for efficient and effective mixing in industrial applications.In conclusion, the introduction of the Venturi Mixing Hopper has been a significant development in the field of industrial mixing technology. With its exceptional capabilities and numerous benefits, this innovative solution has already made a substantial impact on industries that rely on efficient and effective mixing processes. As the company behind the Venturi Mixing Hopper continues to drive innovation and excellence in industrial equipment manufacturing, the future looks promising for the continued success and evolution of this groundbreaking technology.

Sewage Suction Trucks from China and Japan Available for Sale

China Sewage Suction Truck and Japanese Sewage Truck for SaleIn recent developments in the municipal services industry, there has been an increase in the availability of high-quality sewage suction trucks from both China and Japan. These trucks are designed to efficiently and effectively remove waste from sewage systems, providing a crucial service for municipalities and industrial facilities.One of the leading players in the sewage suction truck market is {}, a China-based company specializing in the production and sale of heavy-duty vehicles. With a strong focus on quality and innovation, {} has established itself as a trusted supplier of sewage suction trucks in the global market.The company's sewage suction trucks are equipped with advanced pumping and suction systems, allowing for the efficient removal of waste from sewage systems. These trucks are built to withstand the rigors of heavy-duty use, making them ideal for demanding applications in municipal and industrial settings. With a commitment to customer satisfaction and continuous improvement, {} strives to provide the most reliable and effective sewage suction trucks on the market.On the other hand, the Japanese sewage truck market has also seen significant growth in recent years. With a reputation for precision engineering and durability, Japanese sewage trucks are highly sought after by municipal authorities and private contractors alike. These trucks are known for their high performance and reliability, making them a popular choice for demanding sewage removal tasks.One of the key players in the Japanese sewage truck market is {}, a renowned manufacturer of heavy-duty vehicles with a strong emphasis on quality and innovation. The company's sewage trucks are designed to meet the highest standards of performance, safety, and environmental sustainability. With a focus on advanced technology and superior engineering, {} has positioned itself as a leading supplier of sewage trucks in the global market.In light of the growing demand for sewage suction trucks, both in China and Japan, {} and {} have announced the availability of their latest models for sale. These trucks are equipped with state-of-the-art features and technologies, designed to provide the most effective and reliable sewage removal solutions.The combination of advanced pumping and suction systems, durable construction, and efficient operation make these sewage suction trucks ideal for a wide range of applications, including municipal waste management, industrial waste removal, and environmental cleanup efforts. With a strong focus on customer satisfaction and product quality, both {} and {} continue to set the standard for excellence in the sewage truck market.Furthermore, the availability of these high-quality sewage suction trucks presents an opportunity for municipalities, industrial facilities, and waste management companies to enhance their capabilities and improve their efficiency in sewage removal operations. By investing in these advanced trucks, organizations can benefit from increased productivity, reduced downtime, and lower maintenance costs, ultimately leading to improved overall performance and service delivery.In conclusion, the availability of China sewage suction trucks and Japanese sewage trucks for sale represents a significant development in the municipal services industry. With a focus on quality, innovation, and customer satisfaction, {} and {} are leading the way in providing the most reliable and effective sewage removal solutions on the market. As demand for sewage suction trucks continues to grow, these companies are poised to play a crucial role in meeting the needs of municipalities, industrial facilities, and waste management companies around the world.

Durable Urethane Panel for Various Applications - Ultimate Guide

Leading Urethane Panel Manufacturer Introduces TH48-30X.85MT Urethane PanelThe renowned urethane panel manufacturer, known for its commitment to quality and innovation, has introduced their latest product - the TH48-30X.85MT Urethane Panel. This new addition to their extensive range of urethane panels is set to revolutionize the industry with its advanced features and unparalleled performance.The TH48-30X.85MT Urethane Panel is designed to meet the diverse needs of various industries, including mining, construction, and agriculture. The company has leveraged its expertise and state-of-the-art manufacturing facilities to create a product that offers exceptional durability, wear resistance, and impact strength. This makes it an ideal solution for applications that require reliable and long-lasting performance, even in the most demanding environments.One of the key highlights of the TH48-30X.85MT Urethane Panel is its unique formulation, which incorporates high-quality materials to deliver exceptional performance. The company's team of experts has meticulously developed the urethane panel to ensure that it meets the highest industry standards and exceeds customer expectations. Additionally, the panel is engineered to provide superior flexibility and resilience, enabling it to withstand heavy loads and abrasive materials without compromising its integrity.The TH48-30X.85MT Urethane Panel also boasts a specially designed surface that minimizes material buildup and reduces maintenance requirements. This feature is particularly beneficial for industries such as mining and quarrying, where material buildup can hamper equipment performance and lead to costly downtime. By incorporating this innovative design, the company has demonstrated its commitment to providing practical solutions that address the real-world challenges faced by its customers.Moreover, the company's commitment to sustainability is reflected in the TH48-30X.85MT Urethane Panel, which is manufactured using environmentally friendly processes and materials. This aligns with the company's vision of promoting sustainable practices while delivering high-performance products to its customers. By choosing the TH48-30X.85MT Urethane Panel, customers can contribute to their environmental efforts without compromising on quality or performance.In addition to its impressive technical specifications, the TH48-30X.85MT Urethane Panel is backed by the company's renowned customer support and technical assistance. The company's team of experts is dedicated to helping customers choose the right products for their specific applications and providing ongoing support to ensure optimal performance and longevity. This comprehensive approach sets the company apart in the industry and reinforces its position as a trusted partner for businesses around the world.As the company expands its product portfolio with the introduction of the TH48-30X.85MT Urethane Panel, customers can look forward to a wider range of options that cater to their evolving needs. The company's relentless pursuit of innovation and improvement is driven by its dedication to delivering value to its customers and setting new benchmarks in the industry. With their extensive experience and commitment to excellence, customers can trust that the company will continue to lead the way in urethane panel solutions.In conclusion, the introduction of the TH48-30X.85MT Urethane Panel marks a significant milestone for the leading urethane panel manufacturer. With its advanced features, exceptional performance, and commitment to sustainability, the TH48-30X.85MT Urethane Panel is set to redefine industry standards and exceed customer expectations. As the company continues to innovate and expand its product offerings, customers can rely on its expertise and support to drive their success.