Latest Innovation in Pool Screens Unveiled in Recent News

By:Admin

The Hyperpool Screen is designed to effectively remove large particles from drilling fluids, while also ensuring a higher throughput capacity compared to traditional shaker screens. This groundbreaking technology is the result of extensive research and development by Derrick's team of engineers and scientists, who are dedicated to pushing the boundaries of solid control equipment.

With its advanced design and superior performance capabilities, the Hyperpool Screen is expected to deliver significant cost savings for oil and gas companies, as well as improved environmental and safety outcomes. By effectively removing large particles from drilling fluids, the Hyperpool Screen will help to minimize waste and reduce the environmental impact of drilling operations. Additionally, its higher throughput capacity will increase the efficiency of solid control operations, resulting in reduced downtime and improved productivity.

In addition to its technical advancements, the Hyperpool Screen is also built to withstand the most demanding drilling conditions. Its durable construction and high-quality materials ensure long-lasting performance in harsh environments, making it a reliable and cost-effective solution for oil and gas operators around the world.

Derrick Corporation has a long history of innovation and industry leadership, with a strong reputation for delivering cutting-edge solutions to the oil and gas sector. The company's commitment to excellence and continuous improvement is evident in its extensive portfolio of products and technologies, which are trusted by some of the world's largest and most respected oil and gas companies.

With over 70 years of experience in the industry, Derrick Corporation has established itself as a trusted partner for solid control equipment and services. The company's global footprint and comprehensive network of sales and service centers ensure that customers receive the support they need, wherever they are located.

The introduction of the Hyperpool Screen further solidifies Derrick's position as a leader in solid control technology, and demonstrates the company's ongoing commitment to driving innovation and progress in the oil and gas industry. By leveraging its extensive expertise and technical capabilities, Derrick Corporation continues to set new standards for performance and reliability in solid control operations.

The Hyperpool Screen is set to be a game-changer in the oil and gas industry, offering unmatched performance and reliability for solid control operations. Derrick Corporation's latest innovation is a testament to its dedication to excellence and its relentless pursuit of technological advancement. As the industry continues to evolve, Derrick Corporation remains at the forefront, providing innovative solutions to meet the changing needs of its customers.

In conclusion, Derrick Corporation's introduction of the Hyperpool Screen marks a significant milestone in the evolution of solid control technology. With its advanced design, superior performance capabilities, and proven reliability, the Hyperpool Screen is poised to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to lead the way in innovation and progress, the company's latest innovation reaffirms its position as a trusted and forward-thinking partner for oil and gas operators worldwide.

Company News & Blog

Efficient and Powerful Submersible Slurry Pump- A Game-Changer in Pumping Solutions

Title: Groundbreaking Submersible Slurry Pump Revolutionizes Industrial Dredging OperationsIntroduction:Innovative engineering company {} has recently unveiled a game-changing advancement in the field of industrial pumping with their revolutionary Submersible Slurry Pump. This cutting-edge technology is poised to transform dredging operations across a broad range of industries, from mining and construction to oil and gas. With its unparalleled efficiency and durability, this pump is set to streamline operations, minimize downtime, and significantly enhance productivity.Section 1: The Submersible Slurry Pump's Unmatched PerformanceThe Submersible Slurry Pump developed by {} stands out among its competitors due to its outstanding performance capabilities. Its design enables it to handle high-viscosity, abrasive, and corrosive materials, ensuring reliable pumping operations in the harshest environments. The pump's highly efficient motor delivers improved energy consumption, reducing costs and contributing to a greener future.Section 2: Features and TechnologyThe Submersible Slurry Pump is equipped with state-of-the-art features that revolutionize the pumping industry. Its robust construction, built with high-quality materials, ensures long service life even under demanding conditions. The pump's innovative impeller design enables it to handle larger solids with ease, preventing clogging and reducing maintenance needs.One of the most impressive features of this groundbreaking pump is its dynamic sealing system. The advanced sealing technology allows the pump to operate in submerged conditions, preventing leakage and avoiding costly damage. This feature alone sets it apart from traditional slurry pumps, making it an indispensable tool in challenging pumping applications.Section 3: Versatility and ApplicationsThe versatility of the Submersible Slurry Pump opens up a wide range of applications across diverse industries. In mining operations, it effectively manages slurry transportation, improving efficiency and reducing operational costs. For the construction industry, this pump proves invaluable for excavation and dewatering processes, ensuring uninterrupted workflow and increased project timelines.Furthermore, in the oil and gas sector, the Submersible Slurry Pump proves to be a game-changer. It efficiently handles drilling mud, mitigating risks associated with fluid transportation and minimizing environmental impacts. Its versatile design also enables it to excel in wastewater treatment and power plant applications, positioning itself as an essential tool for achieving sustainable and efficient operations.Section 4: The Future of PumpingWith the introduction of the Submersible Slurry Pump, {} has set a new standard for industrial pumping technology. The future of pumping operations now lies in the hands of this groundbreaking innovation. By combining efficiency, durability, and versatility, this pump delivers exceptional performance across a plethora of industries, transforming the way we approach pumping applications.The Submersible Slurry Pump developed by {} is not only a marvel of engineering but also a testament to the company's commitment to providing cutting-edge solutions for the most challenging projects. Their dedication to research and development has yielded a remarkable product that empowers industries worldwide.Conclusion:With its unmatched performance, innovative features, and a wide range of applications, the Submersible Slurry Pump represents a groundbreaking advancement in industrial pumping technology. {}'s commitment to revolutionizing the industry ensures that projects involving slurry pumping operations can now be completed more efficiently, cost-effectively, and sustainably. As the future of pumping takes shape, this remarkable pump positions itself as an indispensable tool for industries seeking enhanced productivity and environmental responsibility.

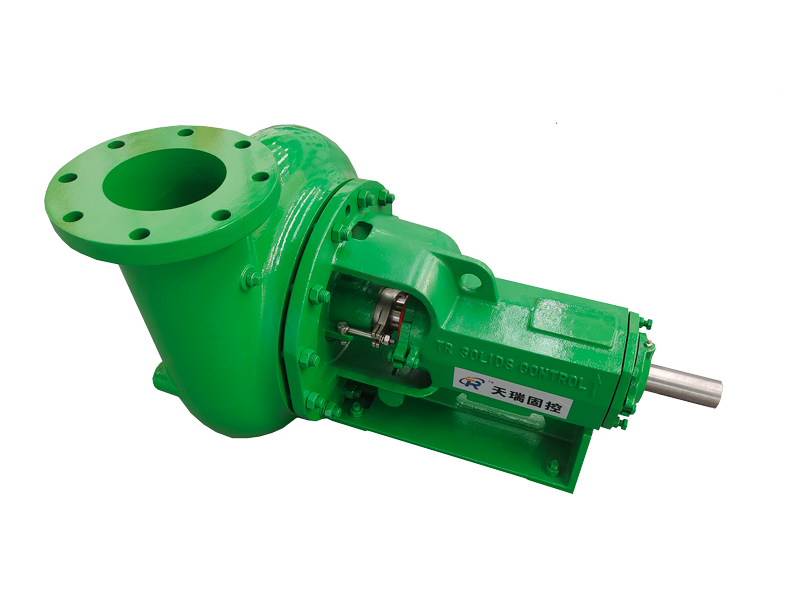

Powerful Mission and Magnum Pumps: A Closer Look at China's Latest Advancements

In recent news, China Mission Pump and Mission Magnum Pump have been making waves in the industry. These two pump manufacturers have been producing high-quality products that are known for their reliability, durability, and performance.China Mission Pump and Mission Magnum Pump are both subsidiaries of a larger company that has been in the pump-manufacturing business for over 20 years. They utilize cutting-edge technology and innovative design concepts in order to create pumps that are both efficient and effective.One of the main advantages of these two brands is that they offer a wide range of pumps for various applications. Whether you need a pump for agriculture, irrigation, mining, construction, or any other industrial purpose, there is a China Mission or Mission Magnum pump that will suit your needs.One of the key features of these pumps is their durability. Many of them are made with high-quality materials, such as cast iron, stainless steel, and other alloys, which makes them able to withstand even the harshest of conditions. They are also designed to be low maintenance, which makes them ideal for clients who want a product that will last for many years without requiring frequent repairs.Another advantage of these pumps is their high-performance levels. They are engineered to provide maximum efficiency and output, which means that they can handle large volumes of liquids, gases, and other fluids with ease. This makes them perfect for applications that require quick and efficient pumping, such as in mining, construction, or industrial processes.In addition to their high-performance levels, these pumps are also designed with user-friendliness in mind. Many models come equipped with features such as automatic controls, easy-to-use interfaces, and clear instructions, making them easy to operate even for those unfamiliar with the technology.More than just high-quality pumps, China Mission and Mission Magnum also provide exceptional customer service. They have a team of knowledgeable technicians and engineers who are available to provide support and guidance to clients who need it. This level of service ensures that clients can make the most out of their pumps, and that any concerns or issues can be resolved quickly and efficiently.In conclusion, China Mission Pump and Mission Magnum Pump are two of the most trusted pump brands on the market today. With their reputation for reliability, durability, and performance, they are the go-to choice for clients who demand only the best. Their wide range of products, high-tech features, and exceptional customer service make them an ideal choice for any industrial setting, from mining and construction to agriculture and irrigation.

How to Manage Waste Effectively: Tips and Strategies

Waste management is a critical issue that affects every community around the world. Whether it's household waste, industrial waste, or hazardous waste, the responsible and efficient handling of waste is essential for a healthy and sustainable environment. That's where our company comes in.As a leading waste management firm, we are dedicated to providing innovative and environmentally responsible waste management solutions. With years of experience in the industry, we have developed a comprehensive range of services to meet the diverse needs of our clients, including waste collection, recycling, landfill management, and hazardous waste disposal.Our team of dedicated professionals is committed to delivering top-quality waste management services that not only meet but exceed industry standards. We strive to continuously improve our operations and implement the latest technologies and best practices to ensure that our clients receive the most efficient and cost-effective waste management solutions.In line with our commitment to environmental sustainability, we have invested in state-of-the-art recycling facilities and waste-to-energy plants. These facilities are equipped with advanced processes and technologies to sort, separate, and process various types of recyclable materials, as well as convert non-recyclable waste into renewable energy sources.Furthermore, we place a strong emphasis on education and community engagement. We believe that effective waste management begins with raising awareness and educating individuals and businesses about the importance of responsible waste disposal and recycling. To this end, we regularly conduct outreach programs, workshops, and seminars to promote sustainable waste management practices.Our company is also dedicated to fostering strong partnerships with local communities, municipalities, and businesses. By working closely with these stakeholders, we are able to develop tailored waste management solutions that are tailored to the specific needs and challenges of each community.In recent news, our company has made significant strides in expanding its waste management services to new regions. We have recently secured several contracts to provide waste collection and recycling services for municipalities and businesses in [new regions]. This expansion not only allows us to serve a larger client base but also demonstrates our ongoing commitment to promoting environmental sustainability and providing high-quality waste management solutions.In addition, our company has been actively involved in researching and implementing innovative waste management technologies to improve the efficiency and sustainability of our operations. We have recently invested in cutting-edge waste sorting and processing equipment to enhance our recycling capabilities, as well as explored new methods for converting organic waste into valuable resources such as compost and biofuels.Furthermore, we have been recognized for our efforts in promoting environmental responsibility and sustainability. Our company recently received [industry award] for our outstanding contributions to sustainable waste management practices and our ongoing commitment to minimizing environmental impact.Looking ahead, our company is poised to continue leading the way in innovative and sustainable waste management solutions. We remain dedicated to staying at the forefront of the industry by investing in advanced technologies, fostering strong partnerships, and continuously improving our operations to meet the evolving needs of our clients and the environment.In conclusion, our company is committed to providing top-quality waste management solutions that prioritize environmental sustainability, efficiency, and community engagement. Our recent expansion and ongoing efforts to implement innovative technologies and best practices reinforce our dedication to being a leader in the waste management industry. We look forward to continuing to serve our clients and communities with the highest standards of waste management excellence.

Discover the Benefits of Utilizing a High-Quality Drilling Mud Desilter

Drilling Mud Desilter – The Solution to Efficient Drilling OperationsDrilling operations in the oil and gas industry involve various stages and processes to ensure the successful extraction of hydrocarbons. One such stage is drilling mud cleaning, which is vital to ensure the effectiveness of the drilling process. Drilling mud, a mixture of fluids, solids, and chemicals, is used to lubricate and cool the drill bit, as well as to transport the drilled cuttings to the surface. Over time, the drilling mud becomes contaminated with solids and other impurities, which can cause operational problems, impede drilling efficiency, and could even lead to equipment failure. To address these concerns, companies are turning to Drilling Mud Desilters.Drilling Mud Desilters are equipment designed to remove impurities from drilling mud, leaving behind a clean and reusable liquid. The process involves separating solids from liquids, ensuring that only the necessary components remain, and the contaminants are removed. This process prevents operational problems during drilling operations, improves drilling efficiency, and increases the lifespan of the equipment used.One company leading the charge in producing efficient Drilling Mud Desilters is a pioneer in engineering solutions. With over ten years of industry experience in providing drilling equipment and services, their commitment to excellence is evident in their outstanding product design and reliable customer service. The company has designed a range of Desilters, each tailored to solve specific customer challenges, and with the capacity to handle a wide range of drilling mud.Some of the benefits of using the Drilling Mud Desilter include improved efficiency, reduced downtime, reduced operating costs and increased lifespan for drilling equipment. This equipment is also critical in mitigating environmental challenges, limiting pollution, and ensuring a healthy, safe working environment for the workforce.The company has established a reputation for providing top-quality products and services, and this is no different for their line of Drilling Mud Desilters. The equipment is designed for durability, reliability, and efficiency while remaining affordable and eco-friendly. The equipment is made from high-quality materials that are built to withstand the harsh conditions of drilling operations, ensuring a long lifespan with minimal maintenance.This company's Drilling Mud Desilter is also user-friendly, easy to operate, and provides quick results. Their products are built with state-of-the-art technology, designed to meet the needs and demands of today's drilling industry. Additionally, the company provides exceptional customer support, ensuring that any concerns are addressed promptly and satisfactorily.In conclusion, Drilling Mud Desilters are essential equipment that no drilling operation can function without. They are imperative in ensuring operational cost saving, improved efficiency, and a sustainable solution to drilling-related environmental challenges. Thus, investing in reliable, durable, and cost-effective Drilling Mud Desilters, such as those offered by this company, can set the pace for continued success in drilling operations.

Discover the Advantages of Ceramic Liner and Zirconia Cylinder Liners in China

Title: China's Ceramic Liner and Zirconia Cylinder Liners Boost Efficiency and Durability in ManufacturingIntroduction:In recent years, China has witnessed a rapid growth in advanced manufacturing technologies. As a part of this dynamic sector, China's Ceramic Liner and Zirconia Cylinder Liner industry have emerged as indispensable components in various industrial applications. Their superior attributes, including high wear resistance, exceptional mechanical strength, and improved performance, have revolutionized manufacturing processes across industries.Unveiling the China Ceramic Liner and Zirconia Cylinder Liners:China's Ceramic Liner and Zirconia Cylinder Liners have garnered significant attention due to their unique properties. These liners exhibit exceptional thermal stability, resistance to corrosive environments, and reduced friction, making them highly sought-after in machinery manufacturing, mining, petrochemical refining, and other vital industrial sectors.Ceramic Liner: A Game-Changer in Industrial ManufacturingThe Ceramic Liner industry in China has experienced substantial growth owing to its numerous advantages over traditional liner materials. These liners, often made from alumina ceramics, exhibit outstanding hardness and high-temperature resistance, making them ideal for applications in demanding environments. Moreover, Ceramic Liners possess exceptional wear resistance, ensuring extended durability and reduced maintenance costs.One of the key merits of Ceramic Liners is their ability to effectively minimize friction, resulting in reduced energy consumption and enhanced operational efficiency. Manufacturers across various sectors have embraced these liners, witnessing improvements in equipment longevity and decreased system downtime.Leading the Zirconia Cylinder Liner Innovations:China's Zirconia Cylinder Liner industry has emerged as an integral part of the automotive and machinery manufacturing sectors. Zirconia Cylinder Liners, made from advanced zirconium oxide ceramics, have revolutionized engine efficiency and durability. These liners exhibit reduced friction, outstanding thermal insulation properties, and exceptional resistance to wear, corrosion, and thermal shock.Automobile manufacturers worldwide have recognized the significance of Zirconia Cylinder Liners in improving fuel efficiency and reducing emissions. As a result, China has become a major supplier of Zirconia Cylinder Liners, catering to the global automotive industry's increasing demand.Surpassing Industry Standards:China's Ceramic Liner and Zirconia Cylinder Liner manufacturers have continuously focused on surpassing industry standards. By leveraging advanced manufacturing techniques, stringent quality control procedures, and cutting-edge technologies, these manufacturers have developed innovative solutions to meet diverse customer requirements.In addition to their high-performance characteristics, China's Ceramic Liner and Zirconia Cylinder Liner manufacturers prioritize the delivery of customized products to suit various industrial needs. By collaborating with research institutions, they constantly strive for improvements in materials science and engineering, resulting in enhanced product durability and reliability.Global Impact and Future Prospects:China's Ceramic Liner and Zirconia Cylinder Liner industry have achieved global recognition and are experiencing substantial growth in international markets. The exceptional quality, cost-effectiveness, and adaptability of these liners have made China a world leader in this sector.Furthermore, with the ongoing advancements in additive manufacturing, China aims to revolutionize the production process of Ceramic Liners and Zirconia Cylinder Liners. Novel manufacturing techniques, such as 3D printing, are expected to further enhance the versatility, efficiency, and affordability of these liners, cementing China's dominance in the global market.Conclusion:China's Ceramic Liner and Zirconia Cylinder Liner industry have fueled advancements in manufacturing processes, optimizing efficiency and durability across various sectors. The exceptional attributes of these liners, including wear resistance, thermal stability, and reduced friction, have propelled their adoption in machinery manufacturing, refining, and automotive sectors worldwide. China's commitment to innovation, stringent quality control, and customized solutions ensure that its Ceramic Liners and Zirconia Cylinder Liners continue to remain at the forefront of global manufacturing technologies.

Understanding the Function of a Centrifugal Pump for Moving Liquids and Gases

Title: Understanding Centrifugal Pump Parts: A Comprehensive GuideIntroductionCentrifugal pumps are an essential device for moving liquids and gases in various industries. These pumps consist of several crucial components that work together to efficiently transfer fluids. In this blog post, we will explore the key parts of a centrifugal pump and their functions. By understanding these components, we can gain insights into pump operation and ensure optimal performance. Let's dive in!1. Impeller: The Heart of a Centrifugal PumpThe impeller is arguably the most critical component of a centrifugal pump. It is a wheel-like structure with curved vanes that rotate to create a centrifugal force. As fluid enters the pump, the impeller imparts kinetic energy and increases the fluid's velocity. The vanes play a vital role as they guide the fluid towards the pump's outlet. Impellers can come in various designs, including closed, open, semi-open, and recessed.2. Pump Casing: Protecting and Directing Fluid FlowEnveloping the impeller, the pump casing serves as a protective enclosure for other components. It also crucially controls the flow direction and ensures that the velocity imparted by the impeller is effectively converted into pressure energy. The casing generally has a circular design and can be made from different materials like cast iron, stainless steel, or even plastic, depending on the application.3. Volute: Efficiently Converting Kinetic EnergyWithin the pump casing, you will often find a volute, a curved chamber that efficiently converts kinetic energy into pressure energy. This component helps in minimizing energy losses and achieving a more uniform flow pattern. Volute casings offer advantages such as reduced vibration and noise, making them a popular choice for centrifugal pumps.4. Shaft: Connecting the Power Source to the ImpellerThe shaft is a crucial element that connects the pump's impeller to the power source, often an electric motor or an engine. While rotating, the shaft allows the impeller to move fluid through the pump. It must be appropriately designed to withstand high speeds and loads. Materials like stainless steel, alloy steel, or carbon steel are commonly used to ensure strength and durability.5. Bearings: Supporting the Rotating ShaftTo reduce friction and support the rotating shaft, bearings are installed inside the pump. These components help maintain the alignment between the shaft and the impeller, ensuring smooth operation. Bearings can be either grease-lubricated or oil-lubricated, depending on the pump's requirements. Proper maintenance and regular lubrication are necessary to ensure their longevity and prevent premature wear.6. Mechanical Seal: Preventing LeakageTo prevent fluid leakage from the pump, a mechanical seal is employed where the shaft extends through the pump casing. This seal creates a barrier between the rotating shaft and the stationary casing, effectively sealing the pump chamber. The mechanical seal comprises various components like rotating and stationary faces, secondary seals, and a gland to hold everything in place. Proper selection and maintenance of mechanical seals are crucial for ensuring leak-free pump operation.In conclusion, understanding the key parts of a centrifugal pump is essential for optimal performance and efficient fluid transfer. The impeller, pump casing, volute, shaft, bearings, and mechanical seal are all critical components that play significant roles in the pump's operation. By choosing high-quality pump parts and maintaining them effectively, one can ensure reliable performance and prolonged lifespan. Keywords: centrifugal pump parts, impeller, pump casing, volute, shaft, bearings, mechanical seal, fluid transfer, optimal performance

Innovative Mud Mixing Hopper Venturi for Efficient Operations

Mud Mixing Hopper Venturi for Efficient and High-Quality Mud MixingIn the world of drilling operations, the need for efficient and high-quality mud mixing is crucial for successful and smooth operations. One of the key components in this process is the Mud Mixing Hopper Venturi, a vital tool that ensures the proper mixing of drilling fluids and additives. With its advanced design and innovative technology, the Mud Mixing Hopper Venturi from [Company Name] is setting new standards in the industry.[Company Name] is a leading manufacturer and supplier of oilfield equipment and tools, specializing in providing top-notch solutions for drilling operations. With a strong focus on innovation and quality, [Company Name] has become a trusted name in the industry, serving customers worldwide with cutting-edge products and excellent customer service.The Mud Mixing Hopper Venturi from [Company Name] is designed to deliver exceptional performance and efficiency in mud mixing processes. Its unique venturi design creates a vacuum effect, allowing for the quick and thorough mixing of drilling fluids and additives. This results in a consistent and homogeneous mud mixture, essential for optimal drilling performance.One of the key features of the Mud Mixing Hopper Venturi is its versatility. It can be used with a wide range of drilling fluids and additives, making it suitable for various drilling applications. Whether it's for onshore or offshore drilling, the Mud Mixing Hopper Venturi from [Company Name] provides a reliable solution for achieving consistent and high-quality mud mixing.Moreover, the Mud Mixing Hopper Venturi is built with durability in mind. Constructed from high-quality materials and engineered to withstand harsh drilling conditions, it is designed to provide long-term and reliable performance. This ensures that drilling operations can continue smoothly without any disruptions due to equipment failure.In addition to its exceptional performance, the Mud Mixing Hopper Venturi also offers ease of use and maintenance. Its user-friendly design and simple operation make it convenient for drilling crews to handle, reducing the risk of human error and increasing operational efficiency. Furthermore, it requires minimal maintenance, saving both time and costs for drilling operators.The Mud Mixing Hopper Venturi from [Company Name] is backed by a team of experts who are dedicated to providing excellent support and service to customers. With their in-depth knowledge and experience in drilling operations, they are equipped to offer technical assistance, training, and troubleshooting, ensuring that customers get the most out of their equipment.As a testimony to its quality and reliability, the Mud Mixing Hopper Venturi from [Company Name] has received positive feedback from customers around the world. Its proven performance and efficiency have made it a preferred choice for drilling operations in various countries, further solidifying [Company Name]'s reputation as a leading provider of top-quality oilfield equipment.With its commitment to innovation and excellence, [Company Name] continues to lead the way in delivering advanced solutions for the oil and gas industry. The Mud Mixing Hopper Venturi stands as a testament to [Company Name]'s dedication to providing reliable, efficient, and high-quality equipment for drilling operations.In conclusion, the Mud Mixing Hopper Venturi from [Company Name] is a game-changer in the world of mud mixing for drilling operations. Offering exceptional performance, durability, and ease of use, it has become a go-to solution for achieving consistent and high-quality mud mixing. With [Company Name]'s unwavering commitment to innovation and customer satisfaction, the Mud Mixing Hopper Venturi is set to continue making a significant impact in the oil and gas industry.

Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge: Key Equipment for Waste Water Treatment

China Municipal Sewage Decanter Centrifuge and Sewage Decanter CentrifugeIn recent years, China has been making significant strides in improving its environmental protection efforts, with a focus on reducing pollution and promoting sustainable development. One key area of focus has been the treatment of municipal sewage, which has led to the development of innovative technologies such as the Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge.The Municipal Sewage Decanter Centrifuge, developed by a leading Chinese company, is a cutting-edge technology designed to efficiently separate solids from liquids in municipal sewage treatment plants. This innovative equipment utilizes high-speed centrifugal force to separate and dewater solid materials, resulting in clean, treated water that can be safely discharged back into the environment.The Sewage Decanter Centrifuge, on the other hand, is specifically designed for use in industrial sewage treatment processes. This advanced technology is capable of effectively separating various types of industrial sludge from wastewater, ensuring that the treated water meets environmental standards before being released into water bodies or reused in industrial processes.Both the Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge have been widely adopted by municipal and industrial sewage treatment facilities across China due to their high efficiency, low energy consumption, and minimal environmental impact. These state-of-the-art technologies have played a crucial role in improving the overall quality of water treatment processes, contributing to a cleaner and healthier environment for communities and industries.Company Introduction{Company Name}, the developer and manufacturer of the Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge, is a leading Chinese company specializing in the design and production of environmental protection equipment. With a strong focus on research and development, the company has continuously invested in innovative technologies to address the growing environmental challenges facing China and the world.Established in 2005, {Company Name} has quickly emerged as a key player in the environmental protection industry, offering a wide range of solutions for water and wastewater treatment, air pollution control, and solid waste management. The company's commitment to technological innovation and product quality has earned it a solid reputation both domestically and internationally.One of the company's core strengths lies in its state-of-the-art manufacturing facilities, which are equipped with advanced production lines and quality control systems to ensure the highest standards of product performance and reliability. In addition, {Company Name} has a dedicated team of experts in research, engineering, and project management, who work closely with customers to design and implement tailored solutions to meet their specific environmental protection needs.{Company Name} places a strong emphasis on sustainable development and corporate social responsibility, striving to contribute to a greener and more sustainable future for all. Through continuous improvement and innovation, the company is committed to delivering cutting-edge technologies and superior services that not only meet the needs of its customers but also contribute to the global effort in environmental protection.In conclusion, the Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge developed by {Company Name} represent significant advancements in the field of sewage treatment technology. As China continues to prioritize environmental protection and sustainable development, these innovative solutions have proven to be instrumental in achieving cleaner and safer water treatment processes. With the ongoing commitment and dedication of companies like {Company Name}, China is well-positioned to further improve its environmental protection efforts and set an example for the world.

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.

High-performance Mixing Tank with Agitator for Efficient Mixing

The company is a renowned manufacturer of industrial mixing equipment that is used in a wide range of industries including chemical, pharmaceutical, food and beverage, and cosmetics among others. Their products are known for their high quality, efficiency, and reliability, making them the top choice for businesses looking for innovative mixing solutions.One of their flagship products is the Mixing Tank with Agitator, which has gained a reputation for its exceptional performance and versatility. This mixing tank is designed to handle a variety of mixing applications including blending, dispersion, and homogenization. It is equipped with a powerful agitator that ensures thorough mixing and uniform distribution of materials, resulting in high-quality end products.The Mixing Tank with Agitator is available in different sizes and configurations to meet the specific needs of different industries. It is constructed using high-grade materials such as stainless steel, making it durable and resistant to corrosion. The tank is also designed with safety features and easy-to-use controls, ensuring the convenience and protection of operators.The agitator system of the mixing tank is a key component that sets it apart from other similar products in the market. It is engineered to deliver high levels of agitation, allowing for efficient mixing of even the most challenging materials. The agitator is also designed to minimize energy consumption while maximizing the effectiveness of the mixing process.One of the main advantages of the Mixing Tank with Agitator is its ability to improve the overall efficiency of manufacturing processes. By ensuring proper mixing and blending of materials, it helps businesses achieve higher product quality and consistency, leading to increased customer satisfaction. It also helps in reducing production time and costs, ultimately boosting the bottom line of businesses.Another noteworthy feature of the Mixing Tank with Agitator is its ease of maintenance. The design of the tank and agitator system allows for easy access for cleaning and maintenance, reducing downtime and prolonging the lifespan of the equipment. This contributes to the overall cost-effectiveness of the product, making it a valuable investment for businesses.In addition to the Mixing Tank with Agitator, the company also offers comprehensive customer support and after-sales service. Their team of technical experts is readily available to provide assistance with installation, training, troubleshooting, and spare parts supply. This ensures that customers can maximize the benefits of their mixing equipment and minimize any disruptions to their operations.The company takes pride in its commitment to innovation and continuous improvement. They are constantly researching and developing new technologies to enhance their products and stay ahead of industry trends. With a strong focus on customer satisfaction and technical excellence, they have established themselves as a trusted partner for businesses seeking reliable mixing solutions.Overall, the Mixing Tank with Agitator from {} represents a top-tier mixing solution for a wide range of industries. Its exceptional performance, durability, and user-friendly design make it a valuable asset for businesses looking to optimize their mixing processes. With the backing of a reputable manufacturer and dedicated customer support, businesses can trust in the reliability and effectiveness of this mixing tank for their operations.