Waste Oil Refining and Oil Refining Plant in China

By:Admin

The company has been dedicated to developing advanced techniques for the collection, transportation, and refining of waste oil. By using state-of-the-art equipment and a team of skilled professionals, they have been able to streamline the entire process, reducing waste and maximizing the recovery of usable materials. This not only benefits the environment by reducing the amount of waste oil that ends up in landfills and waterways but also provides a sustainable source of valuable resources.

The waste oil refining plant utilizes a variety of refining techniques to transform waste oil into valuable products such as base oil, diesel, and asphalt. Through a combination of distillation, hydrotreating, and other refining processes, the company is able to produce high-quality products that meet rigorous industry standards. This has not only helped to reduce reliance on virgin oil sources but has also provided a cost-effective and environmentally friendly alternative to traditional oil refining methods.

In addition to their cutting-edge refining processes, China Waste Oil Refining and Oil Refining Plant has also implemented stringent quality control measures to ensure that their products meet the highest standards. By conducting thorough testing and analysis at every stage of the refining process, they are able to guarantee the purity and performance of their products. This has earned them a stellar reputation in the industry and has helped them secure partnerships with a wide range of clients, including automotive companies, lubricant manufacturers, and government agencies.

Furthermore, the company has also invested heavily in research and development to continuously improve their refining processes and develop new applications for their products. By staying ahead of the curve, they have been able to expand their product offerings and stay competitive in a rapidly evolving market. This commitment to innovation has solidified their position as a leader in the waste oil recycling industry and has paved the way for a more sustainable future.

Despite their success, China Waste Oil Refining and Oil Refining Plant remains committed to their core values of environmental responsibility and sustainability. They adhere to strict environmental regulations and prioritize the minimization of their carbon footprint. Through the responsible management of waste oil and the production of eco-friendly products, they continue to make a positive impact on the environment and contribute to the global effort to reduce reliance on finite resources.

In conclusion, China Waste Oil Refining and Oil Refining Plant has established itself as a trailblazer in the waste oil recycling industry. Through their commitment to innovation, quality, and sustainability, they have managed to transform waste oil into valuable resources while minimizing environmental impact. Their state-of-the-art plant and advanced refining processes have set a new standard for the industry and have positioned them as a trusted partner for companies seeking sustainable solutions. As they continue to expand and evolve, they are poised to make an even greater impact and play a key role in shaping the future of waste oil management.

Company News & Blog

Highly-Durable Mud Gun Nozzle Provides Effective Solutions for Industrial Operations

Mud Gun Nozzle, a vital component in the oil and gas industry, plays a crucial role in the drilling process. The mud gun nozzle is used to spray drilling mud, a mixture of water, clay, and other chemicals, into the drilling well to lubricate the drill bit, carry rock cuttings to the surface, and maintain pressure in the well. It is an essential tool for optimizing the drilling process and ensuring the success of oil and gas extraction operations.In this context, one company, which is a leading manufacturer of drilling equipment and tools, has recently launched its latest mud gun nozzle, designed to enhance drilling efficiency and reliability. With over 20 years of experience in the industry, the company has become a trusted name in providing high-quality products and innovative solutions for oil and gas exploration and production.The new mud gun nozzle features a cutting-edge design that offers improved performance and durability. Its advanced nozzle configuration allows for better spray coverage and distribution of drilling mud, resulting in more efficient drilling operations. The material used in the construction of the nozzle is highly resistant to corrosion and abrasion, ensuring long-lasting performance even in the harshest drilling environments.Furthermore, the company's mud gun nozzle is engineered to provide easy maintenance and servicing, reducing downtime and operational costs for drilling companies. The design incorporates quick-connect fittings and accessible components, allowing for effortless disassembly and reassembly when necessary. This user-friendly approach reflects the company's commitment to delivering practical and reliable solutions to its customers.In addition to the superior design and functionality, the mud gun nozzle is also backed by the company's renowned technical support and customer service. The company's team of experienced engineers and technicians are available to provide assistance with installation, maintenance, and troubleshooting, ensuring that customers can maximize the performance of the mud gun nozzle and their overall drilling operations.As part of its dedication to quality and customer satisfaction, the company conducts rigorous testing and quality assurance procedures to ensure that its mud gun nozzles meet the highest standards of performance and reliability. This attention to detail and commitment to excellence have earned the company the trust and loyalty of numerous drilling companies around the world.The launch of the new mud gun nozzle represents the company's ongoing efforts to innovate and improve its product offerings to meet the evolving needs of the oil and gas industry. By leveraging its expertise and technical capabilities, the company aims to continue playing a significant role in advancing drilling technologies and supporting the exploration and production activities of its customers.In conclusion, the introduction of the new mud gun nozzle by the company signifies a significant development in the realm of drilling equipment and tools for the oil and gas industry. With its advanced design, exceptional performance, and unwavering commitment to customer support, the company continues to solidify its position as a leading provider of reliable and innovative solutions for drilling operations. As the industry continues to evolve, the company remains poised to meet the challenges and demands of the future, driven by its dedication to excellence and customer satisfaction.

Ultimate Guide to Decanter Centrifuge Diagrams

Decanter Centrifuge Diagram and its Application in Various IndustriesA decanter centrifuge is a versatile piece of equipment that is used in a wide range of industries for liquid-solid separation. The diagram of a decanter centrifuge shows the various components and their functions in the separation process. With its efficient and effective design, decanter centrifuges have become essential in industries such as wastewater treatment, oil and gas, food and beverage, pharmaceuticals, and many more.A typical decanter centrifuge consists of a rotating bowl, screw conveyor, and drive system. The bowl rotates at high speeds, creating centrifugal force that causes the solids to settle at the bowl wall while the liquid phases out through the conveyor. The diagram illustrates how the conveyor then moves the separated solids to one end of the centrifuge while the liquid is discharged from the other end.One of the leading manufacturers of decanter centrifuges has been {Company Name}. With years of experience and expertise in the industry, they have been providing high-quality and reliable decanter centrifuges for various applications. Their decanter centrifuge diagram showcases the innovative design and technology that sets their products apart from the competition.The diagram also illustrates the versatility of decanter centrifuges in various industries. In wastewater treatment, decanter centrifuges are crucial for separating sludge from water, allowing for the efficient and cost-effective treatment of wastewater. In the oil and gas industry, decanter centrifuges are used for the separation of oil, water, and solids in drilling muds and produced water. The diagram also demonstrates how decanter centrifuges are utilized in the food and beverage industry for the clarification of liquids and separation of solids from slurries.Moreover, in the pharmaceutical industry, decanter centrifuges play a vital role in the separation and purification of active ingredients, as well as the recovery of solvents and the processing of biological products. The diagram further highlights the use of decanter centrifuges in the mining and mineral processing industry for dewatering and tailings management, as well as in the chemical industry for the separation of liquid-liquid and liquid-solid mixtures.As a leading manufacturer in the industry, {Company Name} has continuously strived to innovate and improve their decanter centrifuges to meet the evolving needs of various industries. Their dedication to research and development is evident in the design and features outlined in the decanter centrifuge diagram. With a focus on efficiency, reliability, and ease of maintenance, their decanter centrifuges have become the preferred choice for many companies around the world.In addition to providing high-quality equipment, {Company Name} also offers comprehensive support and services to ensure the smooth operation of their decanter centrifuges. Their team of experts is available to provide technical assistance, maintenance, and training to their customers, ensuring the optimal performance of their decanter centrifuges.In conclusion, the decanter centrifuge diagram provides a comprehensive overview of the technology and applications of this essential piece of equipment. With {Company Name} at the forefront of innovation, the diagram showcases the advanced features and capabilities of their decanter centrifuges. As industries continue to evolve, the versatility and efficiency of decanter centrifuges will remain crucial in a wide range of applications, making them indispensable for various separation processes.

Drilling Fluids Technology Training Course | Learn Online or In-Person at International Locations

and Training, Drilling Fluids Technology, Mobility Oil & Gas, online training, international training locations.Drilling Fluids Technology: Learn from the Best with Mobility Oil & GasDrilling fluids technology is a crucial aspect of any well drilling process. Whether it's a land-based or offshore drilling project, the right drilling fluid equipment and expertise are necessary for a successful outcome. This is where Mobility Oil & Gas comes in. The company provides comprehensive drilling fluids technology training courses both online and in-person.Mobility Oil & Gas is a leading provider of drilling fluids technology training courses in a variety of drilling-related areas. The company has several years of experience delivering cutting-edge drilling solutions for clients in the oil and gas industry. They have a team of highly trained professionals dedicated to providing industry-leading training and support to drilling professionals around the world.The drilling fluids technology training courses offered by Mobility Oil & Gas cover a wide range of topics, from basic to advanced. The company's instructors are experienced professionals with years of experience in their respective fields. They provide practical insights into the latest industry trends, equipment, and techniques. The courses are designed to meet the needs of professionals at all levels of expertise, from beginner to advanced.Mobility Oil & Gas provides its drilling fluids technology training courses both online and in-person. The online courses are a convenient option for busy professionals who may not be able to attend in-person training. The company employs cutting-edge technology to deliver its online courses in an interactive and engaging manner. Students can learn at their own pace and from the comfort of their homes or offices.In-person training courses are available at several international locations. Mobility Oil & Gas operates in many countries around the world, providing easy access to their training courses. The company has invested heavily in state-of-the-art training facilities that provide a hands-on approach to learning. Students get the opportunity to work with the latest drilling fluid equipment and techniques, ensuring that they are adequately prepared for real-world scenarios.The drilling fluids technology training courses provided by Mobility Oil & Gas are designed to meet the needs of companies of all sizes. Companies can choose to train their entire staff or select individuals they want to develop. The company provides customized training solutions tailored to the needs of each company. This ensures that companies get the maximum return on their investment in training.The drilling fluids technology training courses provided by Mobility Oil & Gas cover a range of topics, including the basics of drilling fluids, advanced drilling fluid equipment and techniques, and best practices for managing drilling fluids. The courses emphasize safety and environmental responsibility and aim at reducing the risks associated with drilling operations. The courses are designed to meet the needs of a diverse range of stakeholders, including drilling engineers, drilling supervisors, drilling fluids engineers, and other personnel involved in drilling operations.In conclusion, drilling fluids technology training is essential to the success of any drilling project. Mobility Oil & Gas provides industry-leading training courses designed to equip drilling professionals with the latest drilling fluid equipment and techniques. The company's courses are available both online and in-person and cover a range of topics. Companies of all sizes can benefit from Mobility Oil & Gas's customized training solutions, ensuring that their staff is adequately prepared for the challenges of drilling operations.

China Solid Liquid Separator and 3-Phase Separation Filter in the Spotlight: Exploring Advanced Separation Technology

China Solid Liquid Separator and 3-Phase Separation Filter Improves Wastewater Treatment EfficiencyChina's industrial sector has been continuously growing rapidly, and so does the volume of industrial wastewater discharged. This situation poses severe environmental concerns, as untreated wastewater can be a major pollutant to the environment, affecting the local ecosystem and public health. The Chinese government acknowledges this problem and endeavors to tackle it by implementing stricter regulations on wastewater discharge and encouraging wastewater treatment innovation. In light of these developments, China Solid Liquid Separator and 3-Phase Separation Filter have emerged as a promising solution for wastewater treatment efficiency. These two technologies are designed to remove contaminants and impurities from wastewater, providing high-quality treated wastewater that is safe for discharge. Solid Liquid Separator is a simple and effective mechanical device that separates solid particles from the liquid mixture. The technology works by using a rotating drum that filters the wastewater and separates the solids, allowing the clean liquid to pass through. This process is advantageous because it does not require chemicals or electricity for operation, making it a cost-efficient and eco-friendly solution. Solid Liquid Separator is particularly helpful for wastewater treatment in the food and beverage processing industry, where the wastewater contains high solid content.3-Phase Separation Filter, on the other hand, is a more advanced technology that separates the wastewater into three phases: solid, liquid, and oil. This technology is ideal for wastewater treatment in industries such as petroleum, textile, and chemicals, where the wastewater contains high amounts of oil and solid particles. 3-Phase Separation Filter uses a centrifugal force to separate the different phases and has a higher efficiency in removing impurities compared to other separation methods. The integration of Solid Liquid Separator and 3-Phase Separation Filter provides a comprehensive solution for wastewater treatment, ensuring that the wastewater is free from solid particles, oil, and other contaminants. This integration improves the efficiency of the wastewater treatment process, reducing the amount of time and energy required for treatment. Moreover, the treated wastewater can be recycled and reused for various purposes, reducing water consumption.One prominent provider of Solid Liquid Separator and 3-Phase Separation Filter in China is a leading wastewater treatment equipment manufacturer that has extensive experience in the industry. The company has a team of experts that designs and develops innovative technologies for wastewater treatment, focusing on providing sustainable and cost-effective solutions. The company's Solid Liquid Separator and 3-Phase Separation Filter have been tested and proven effective in various industries, garnering positive feedback from satisfied customers.In an interview with the company's CEO, he emphasized the importance of wastewater treatment in China and how these technologies can help address the issue. He said, "We recognize the urgency of improving the wastewater treatment efficiency in China, and we are committed to providing our customers with the best solutions to address this issue. Our Solid Liquid Separator and 3-Phase Separation Filter not only remove impurities and contaminants effectively, but also promote sustainability and cost-efficiency in the wastewater treatment process."Overall, the integration of Solid Liquid Separator and 3-Phase Separation Filter presents a promising solution for wastewater treatment in China. These two technologies can improve the efficiency and sustainability of the wastewater treatment process while reducing the environmental impact of industrial wastewater. With the support of market leaders like the aforementioned equipment manufacturer providing innovative solutions, the goal of achieving a cleaner environment through wastewater treatment can be close at hand.

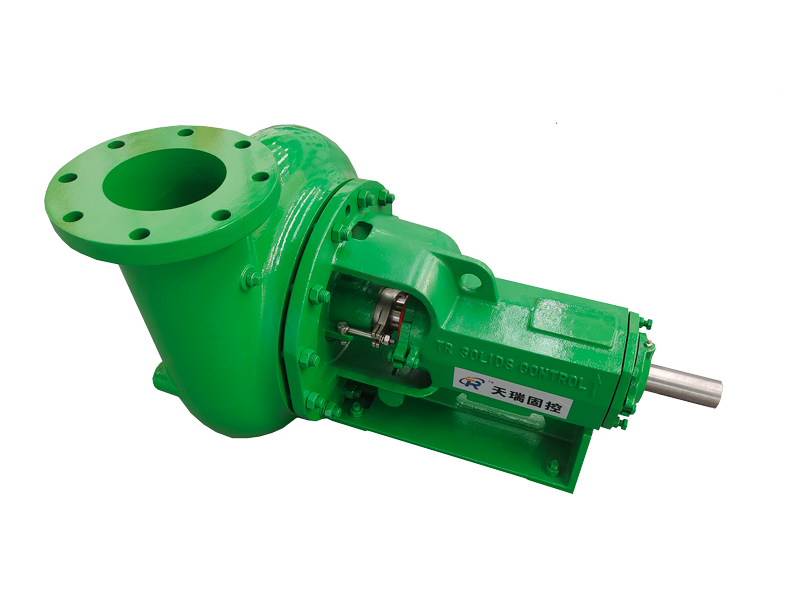

Centrifugal Pump Supplier - High Quality Pump, Centrifugal Pump Manufacturers, Suppliers in China

Fuan Huawei Electrical Machinery Co., Ltd. – Your Trusted Centrifugal Pump SupplierCentrifugal pumps are widely used in industries that require fluid transport. These pumps are designed to move liquids through a piping system, with the help of a rotating impeller that applies centrifugal force to the fluid. Centrifugal pumps are essential equipment in industries such as chemical processing, water treatment, agriculture, and more.Fuan Huawei Electrical Machinery Co., Ltd. is a leading centrifugal pump supplier based in China. Founded in 2005, the company has been committed to providing customers with high-quality centrifugal pumps that meet their specific requirements.Fuan Huawei Electrical Machinery Co., Ltd. offers a wide range of centrifugal pumps for different applications, including single-stage pumps, multi-stage pumps, self-priming pumps, and more. The pumps are designed to handle different fluids, such as clean water, seawater, acidic or alkaline solutions, oil, and more.The company applies advanced technology and manufacturing techniques to produce efficient and durable centrifugal pumps. The pumps are made of high-quality materials such as stainless steel, cast iron, and copper, ensuring that they can withstand the toughest conditions. The impellers are precisely designed to maximize the pump's efficiency, reduce energy consumption and maintenance costs.Fuan Huawei Electrical Machinery Co., Ltd. has been certified by ISO9001:2015 Quality Management System, which ensures that the company meets international quality standards in their products and services. The company also provides professional technical support and customer service to help customers select the right pump for their needs.Centrifugal pumps have a wide range of applications. In the chemical industry, they are used to transport acids, bases, and other chemical solutions. In the oil and gas industry, they are used to transfer crude oil, refined products, and wastewater. In agriculture, they are used to irrigate farmlands and transport fertilizers. In the water treatment industry, they are used for pumping clean water, wastewater, and more.As a leading centrifugal pump supplier, Fuan Huawei Electrical Machinery Co., Ltd. has served customers in various industries around the world. The company has gained a reputation for providing reliable and high-quality pumps that meet industry standards and customer expectations. The company also offers customized solutions for customers with unique needs, ensuring that their pumps are tailored to their specific requirements.In conclusion, Fuan Huawei Electrical Machinery Co., Ltd. is a trusted centrifugal pump supplier that offers a wide range of efficient and durable pumps. The company's commitment to quality, innovation, and customer satisfaction has earned them a reputation as one of the leading pump suppliers in China. If you need a reliable and high-quality centrifugal pump for your application, Fuan Huawei Electrical Machinery Co., Ltd. is your go-to supplier.

How Desander Cyclones are Helping to Improve Industrial Processes

Desander Cyclone Technology Revolutionizes Extraction Process, Setting New Industry StandardsIn the world of oil and gas extraction, the efficiency and effectiveness of the extraction process are vital to the success of any operation. The use of cutting-edge technology has revolutionized the industry, and the introduction of the Desander Cyclone has set new standards for the extraction process.The Desander Cyclone is a crucial component in the extraction process, as it is designed to remove sand and other solids from the drilling fluid. This innovative technology has been developed by a leading company in the oil and gas industry, which has been at the forefront of technological advancements in the field.The company behind the Desander Cyclone has a proven track record of providing top-of-the-line equipment and technology to the oil and gas industry. With a strong focus on research and development, the company has consistently delivered groundbreaking solutions that have transformed the way extraction operations are conducted.The Desander Cyclone is a prime example of the company's commitment to innovation. This cutting-edge technology is designed to efficiently separate sand and other solids from the drilling fluid, ensuring that the extraction process runs smoothly and effectively. The Desander Cyclone has been lauded for its ability to improve the overall efficiency of extraction operations, leading to cost savings and increased productivity.One of the key features of the Desander Cyclone is its high-performance capabilities. The technology is able to handle high volumes of drilling fluid and effectively remove a wide range of solids, including sand, in a reliable and consistent manner. This has proven to be a game-changer for extraction operations, as it minimizes downtime and maximizes the overall productivity of the operation.Another noteworthy aspect of the Desander Cyclone is its robust and durable design. Built to withstand the harsh conditions of oil and gas extraction sites, the technology is engineered to deliver optimal performance in even the most challenging environments. This longevity and reliability make the Desander Cyclone a sound investment for extraction companies looking to enhance their operations.Furthermore, the Desander Cyclone has been designed with ease of use in mind. The technology is user-friendly and can be easily integrated into existing extraction operations, minimizing the need for extensive training or reconfiguration. This seamless integration has made the Desander Cyclone a popular choice among extraction companies looking to upgrade their equipment and improve their overall efficiency.The introduction of the Desander Cyclone has been met with widespread acclaim within the oil and gas industry. Extraction companies have been quick to recognize the significant benefits that this innovative technology offers, and many have already integrated the Desander Cyclone into their operations. The positive feedback from these companies is a testament to the impact that the Desander Cyclone has had on extraction processes.As a result of the success of the Desander Cyclone, the company behind this groundbreaking technology has solidified its position as a leader in the oil and gas industry. Its commitment to continuous improvement and innovation has set new standards for extraction operations, and the Desander Cyclone is a clear example of the company's dedication to providing cutting-edge solutions to its clients.Looking ahead, it is clear that the Desander Cyclone will continue to play a pivotal role in shaping the future of oil and gas extraction. As the demand for energy continues to rise, the need for efficient and effective extraction processes will only grow, and the Desander Cyclone is well-positioned to meet these evolving demands.In conclusion, the introduction of the Desander Cyclone has brought about a significant shift in the oil and gas extraction industry. Its exceptional performance, durability, and ease of use have made it a standout technology that has set new standards for extraction operations. As the industry continues to evolve, the Desander Cyclone will undoubtedly remain at the forefront, driving efficiency and productivity for extraction companies around the world.

High-quality Decanter Centrifuge for Sludge Dewatering in China

China Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge have become essential equipment in various industries such as wastewater treatment, food and beverage, pharmaceuticals, and mining, among others. These machines are known for their ability to separate solids from liquids, making them an indispensable tool for many businesses.One of the leading companies in the manufacturing of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is {}. Their dedication to quality and innovation has solidified their position as a top player in the industry. With a strong focus on research and development, they have been able to continuously improve their products, offering their customers cutting-edge solutions for their separation needs.With a wide range of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge models, the company is able to cater to the diverse requirements of different industries. Their equipment is designed to handle various materials, from sewage sludge to industrial wastes, and effectively separate the solid and liquid components. This not only helps in waste reduction but also in the recovery of valuable resources from the process.One of the key features of their Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is their high efficiency and low energy consumption. This not only reduces operational costs for the businesses but also makes the equipment more environmentally friendly. Additionally, the company also offers custom solutions for specific needs, ensuring that their customers get the perfect equipment for their applications.Furthermore, the company also provides excellent after-sales service, including installation, training, maintenance, and spare parts support. This ensures that their customers can maximize the performance and lifespan of their Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge, giving them peace of mind and confidence in their investment.In recent years, the demand for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge has been on the rise, driven by the increasing focus on environmental protection and resource recovery. With stricter regulations on waste disposal and a growing awareness of the importance of sustainability, businesses are turning to equipment like these to optimize their processes and minimize their impact on the environment.The global market for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is projected to continue growing, with a significant impact on industries such as wastewater treatment, food and beverage, and mining, among others. With their advanced technology and high-quality products, {} is well-positioned to capture a substantial share of this market and continue to be a leader in the industry.As businesses continue to prioritize efficiency, sustainability, and responsible waste management, the demand for Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge is only expected to increase. With their proven track record and commitment to excellence, {} is ready to meet this growing demand and help businesses worldwide achieve their separation and dewatering needs.In conclusion, the role of Decanter Centrifuge and Sludge Dewatering Decanter Centrifuge in various industries cannot be overstated. With their ability to effectively separate solids from liquids, these machines have become indispensable for businesses looking to optimize their processes and reduce their environmental footprint. With {}. as a leading manufacturer and provider of these equipment, businesses can look forward to high-quality solutions and excellent support for their separation and dewatering needs.

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

Hand Operated Centrifuge and Drilling Mud Tester in China

China-based company, X, has recently launched a revolutionary hand-operated centrifuge and drilling mud tester, which is set to make a significant impact in the drilling industry. This innovative technology is designed to provide accurate and reliable testing of drilling mud, ensuring the efficiency and safety of drilling operations.The hand-operated centrifuge and drilling mud tester is a portable and easy-to-use device, which can be operated manually without the need for any external power source. This makes it an ideal tool for use in remote locations or in areas where access to electricity is limited.The centrifuge component of the device is capable of separating different components of the drilling mud, such as solid particles and liquids, with great precision. This allows for thorough analysis of the mud, enabling users to identify any potential issues or contamination that may affect the drilling process.Furthermore, the drilling mud tester is equipped with advanced sensors and measurement tools, which provide accurate data on the viscosity, density, and other key properties of the drilling mud. This information is crucial for ensuring the stability and effectiveness of the drilling operation.The hand-operated centrifuge and drilling mud tester is the result of extensive research and development by X, a leading manufacturer of drilling equipment and tools. With a strong focus on innovation and quality, the company has established itself as a trusted provider of cutting-edge solutions for the drilling industry.X has a proven track record of delivering reliable and efficient products to its customers, and the hand-operated centrifuge and drilling mud tester is no exception. The device is built to withstand the harsh conditions of drilling operations, with rugged construction and durable materials that ensure long-lasting performance.Furthermore, X provides comprehensive training and support for its products, ensuring that customers are able to make the most of their investment. The company’s team of technical experts is available to provide guidance on the operation and maintenance of the hand-operated centrifuge and drilling mud tester, as well as any other products in their extensive lineup.In addition to its commitment to quality and customer support, X is also dedicated to the implementation of sustainable and environmentally friendly practices in its operations. The hand-operated centrifuge and drilling mud tester is designed with this in mind, with energy-efficient features and a minimal environmental footprint.As a result of its numerous advantages and benefits, the hand-operated centrifuge and drilling mud tester is expected to be well-received by drilling companies and professionals around the world. Its portability, ease of use, and accurate testing capabilities make it an indispensable tool for ensuring the success of drilling operations.In conclusion, the launch of the hand-operated centrifuge and drilling mud tester by X represents a significant advancement for the drilling industry. With its innovative technology, robust construction, and comprehensive support, this device is set to become a vital asset for drilling companies and professionals seeking to enhance the efficiency and safety of their operations. X continues to demonstrate its commitment to delivering superior solutions for the drilling industry, and the hand-operated centrifuge and drilling mud tester is a prime example of this dedication.

Mud Tanks on Drilling Rig: Understanding their Importance and Functionality

Title: Mud Tanks on Drilling Rig: Enhancing Efficiency and Environmental ResponsibilityIntroduction:As the demand for oil and gas continues to rise worldwide, drilling companies are constantly seeking innovative solutions to improve efficiency, reduce costs, and minimize their environmental impact. One crucial aspect of the drilling process is the effective management of drilling fluids, or mud. In this article, we will delve into the significance of mud tanks on drilling rigs, exploring how they contribute to fluid management and the operational success of drilling companies. We will also examine the role of a leading drilling equipment provider in delivering advanced mud tank solutions that prioritize efficiency, safety, and environmental responsibility.Efficient Fluid Management:Mud tanks play a pivotal role in the drilling process, providing a centralized location for the storage, circulation, and treatment of drilling mud. These large tanks are integrated into drilling rigs and are carefully designed to meet the specific operational requirements of each drilling project. By efficiently managing the drilling fluid, mud tanks ensure the integrity of the wellbore, lubricate the drilling bit, and carry cuttings to the surface, thereby enhancing the drilling process's overall efficiency.Safety and Environmental Considerations:With increasing environmental consciousness, drilling companies are under pressure to minimize their environmental footprint. Mud tanks aid in this endeavor by effectively separating the drilling mud from the drill cuttings, allowing for proper treatment and disposal of these byproducts. This system ensures compliance with environmental regulations and facilitates responsible waste management.In addition, mud tanks are equipped with advanced safety features to protect workers and prevent accidents. These features include sensors, alarms, and containment measures that detect and mitigate any potential leaks or spills, preserving the wellbeing of the crew and surrounding environment.The Role of [Drilling Equipment Provider]:[Drilling Equipment Provider], a global leader in drilling solutions, has been at the forefront of developing state-of-the-art mud tank systems. Committed to engineering excellence, they continuously improve their products to meet the evolving needs of the industry. By deploying their cutting-edge mud tank technologies, drilling companies can optimize their operations while adhering to stringent safety and environmental standards.[Drilling Equipment Provider] employs a holistic approach, beginning with comprehensive research and development, and continuing through the manufacturing, installation, and ongoing support phases. Their mud tank systems are designed to deliver high-performance capabilities, ensuring efficient separation of liquid and solids, better fluid control, and enhanced drilling mud treatment.Moreover, [Drilling Equipment Provider]'s mud tank solutions incorporate innovative automation and monitoring features that allow for real-time data analysis. This enables drilling companies to optimize their fluid management, detect any potential issues promptly, and make data-driven decisions to ensure continuous operations.Conclusion:Mud tanks constitute a critical element in the drilling process, playing a significant role in enhancing efficiency, safety, and environmental responsibility. By partnering with industry leaders like [Drilling Equipment Provider], drilling companies can gain access to cutting-edge mud tank systems that optimize fluid management and reinforce their commitment to sustainable practices. With the continuous development of advanced technologies, the integration of highly efficient mud tank systems is ushering in a new era of drilling operations that are both productive and environmentally conscious.