High-Quality Pump Parts Manual: Essential Guide for Mission Pumps

By:Admin

The manual covers a wide range of pump parts including impellers, casings, shafts, bearings, and seals. Each section of the manual provides detailed information about the design, construction, and maintenance requirements of the specific part. The manual also includes troubleshooting guides and recommended maintenance schedules to help identify and address common pump issues.

In addition to the technical information, the manual also provides valuable insights into the company's commitment to quality and innovation. The company has a long history of providing reliable and efficient pumping solutions for a wide range of industries including mining, oil and gas, construction, and water treatment. With a focus on continuous improvement and customer satisfaction, the company has established itself as a trusted partner for pump solutions.

The Mission Pump Parts Manual is a reflection of the company's dedication to excellence and customer support. By providing a comprehensive and user-friendly guide to pump parts and maintenance, the company aims to empower its customers with the knowledge and resources needed to maximize the performance and lifespan of their pumps.

As part of its commitment to customer satisfaction, the company also offers training programs and technical support to ensure that operators and technicians have the necessary skills and knowledge to maintain and operate their pumps effectively. This additional support further reinforces the company's reputation as a trusted and reliable partner for pump solutions.

Furthermore, the manual emphasizes the company's focus on sustainability and environmental responsibility. By providing guidance on proper maintenance and operation of pumps, the company aims to minimize energy consumption and reduce the environmental impact of its products. This commitment to sustainability is in line with the company's overall mission to provide efficient and environmentally friendly pumping solutions.

Overall, the Mission Pump Parts Manual is not just a technical guide; it is a testament to the company's core values of quality, innovation, and customer satisfaction. By equipping its customers with the knowledge and resources needed to maintain and operate their pumps, the company demonstrates its unwavering commitment to supporting its customers throughout the life cycle of their pumping equipment.

In conclusion, the Mission Pump Parts Manual stands as a symbol of the company's dedication to excellence, innovation, and sustainability. With its detailed technical information, troubleshooting guides, and maintenance schedules, the manual serves as an invaluable resource for pump operators and technicians. By empowering its customers with the knowledge and support needed to maximize the performance and lifespan of their pumps, the company reaffirms its position as a leader in the pumping solutions industry.

Company News & Blog

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.

Enhancing Efficiency: Exploring the Benefits of the Swivel Type Mud Gun for Mud Mixing Operations

Swivel Type Mud Gun Enhances Drilling Efficiency for the Oil and Gas IndustryIn the ever-evolving world of drilling operations, the need for efficient and reliable equipment has never been greater. The oil and gas industry seeks cutting-edge technologies that can streamline their processes while ensuring optimal performance. Introducing the revolutionary Swivel Type Mud Gun, a game-changing solution that is set to transform drilling operations worldwide.The Swivel Type Mud Gun, developed by a renowned global company, has quickly gained recognition for its superior quality and performance. With its advanced design and impressive capabilities, this equipment promises to revolutionize the drilling industry by enhancing efficiency and reducing downtime.One of the standout features of the Swivel Type Mud Gun is its exceptional swiveling capability. Unlike conventional mud guns, this innovative equipment offers 360-degree rotation, allowing for better coverage and distribution of drilling fluids. This feature ensures that fluids are evenly dispersed, resulting in improved mud mixing and better control of the drilling process.The equipment's swivel type functionality also enables operators to reach difficult-to-access areas within the drilling system. Whether it be tight corners or complex piping layouts, the Swivel Type Mud Gun provides unparalleled flexibility, ensuring that no part of the system is left untreated. This eliminates the need for manual intervention or the use of additional equipment, saving valuable time and resources.Furthermore, the Swivel Type Mud Gun boasts exceptional durability and longevity. Constructed from high-quality materials, it is designed to withstand harsh drilling conditions and offer reliable performance, even in the most extreme environments. This ensures minimal maintenance requirements and reduces downtime, thereby optimizing drilling operations and maximizing productivity.To further enhance its efficiency, the Swivel Type Mud Gun offers various nozzle options, allowing operators to tailor the equipment to suit specific drilling requirements. The nozzles can easily be interchanged, enabling seamless adaptation to changing drilling conditions or fluid properties. This flexibility ensures optimum mud cleaning and suspension, promoting efficient drilling and minimizing potential issues associated with solids control.Additionally, this groundbreaking equipment is equipped with state-of-the-art control mechanisms. With a user-friendly interface, operators can easily adjust the mud flow and monitor pressure levels to achieve the desired drilling parameters. The intuitive design reduces the learning curve for operators and enables efficient utilization of the equipment, regardless of their level of expertise.Among the many advantages of the Swivel Type Mud Gun, its compatibility with automation technology stands out. As the drilling industry progresses towards increased automation, this equipment seamlessly integrates with drilling control systems. This facilitates real-time monitoring, data analysis, and remote control capabilities, revolutionizing the way drilling operations are managed and monitored.The Swivel Type Mud Gun's potential impact on the drilling industry has not gone unnoticed. Industry experts have hailed this equipment as a significant advancement, with its ability to optimize drilling operations, improve efficiency, and reduce costs. Its unique features, combined with the company's unwavering commitment to quality and innovation, position it as a market leader in drilling equipment.With the Swivel Type Mud Gun, the oil and gas industry can expect enhanced drilling efficiency, reduced downtime, and improved overall performance. As this equipment continues to gain traction and recognition globally, it is set to reshape the drilling landscape, setting a new standard for excellence in the industry.

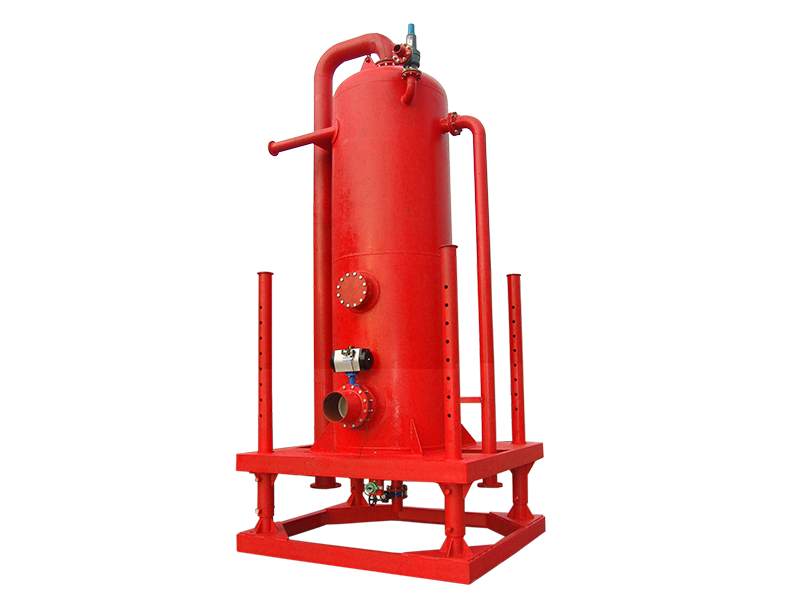

Innovative Mud Circulation System for Improved Drilling Performance

Mud Circulation System Enhances Efficiency in Oil and Gas Drilling OperationsIn the ever-evolving world of oil and gas drilling, the need for efficiency and productivity has never been more crucial. With the demand for energy continuously on the rise, companies are constantly seeking ways to maximize their drilling operations while minimizing costs and environmental impact. This is where the innovative Mud Circulation System from a leading provider of drilling equipment and services comes into play.The Mud Circulation System is a cutting-edge technology that revolutionizes the drilling process by optimizing the circulation of drilling fluids, also known as mud. This system plays a vital role in maintaining wellbore stability, controlling pressure, and carrying drilled cuttings to the surface. By ensuring the proper circulation of mud, the system contributes to the overall efficiency and success of drilling operations.One of the key components of the Mud Circulation System is a high-performance mud pump that is capable of delivering a constant and reliable flow of mud throughout the drilling process. This is critical in preventing wellbore instability and maintaining the integrity of the well. In addition, the system is equipped with advanced filtration and separation units that effectively remove solids and contaminants from the mud, allowing for continuous reuse and conservation of this important drilling fluid.Furthermore, the Mud Circulation System incorporates state-of-the-art control and monitoring features that provide real-time data on the condition of the drilling fluid and the overall drilling operation. This allows for precise adjustments to be made, ensuring optimal performance and safety at all times. The system is also designed with safety in mind, with built-in safeguards to protect against pressure surges and other potential hazards.In addition to its technical capabilities, the Mud Circulation System is also backed by a team of highly skilled engineers and technicians who provide comprehensive support and maintenance services. This ensures that the system operates at peak performance and minimizes downtime, ultimately contributing to cost savings and enhanced productivity for drilling operators.The company behind this game-changing technology has a long-standing reputation as a leader in the drilling industry. With a rich history of innovation and a commitment to excellence, they have established themselves as a trusted partner for oil and gas companies around the world. Their dedication to continuous improvement and customer satisfaction has propelled them to the forefront of the industry, and the Mud Circulation System is a testament to their ongoing efforts to push the boundaries of drilling technology.As the global demand for oil and gas continues to grow, the need for efficient and sustainable drilling solutions has never been greater. The Mud Circulation System represents a significant advancement in this regard, offering a compelling combination of cutting-edge technology, operational excellence, and reliable support. This system has already garnered praise from industry experts and is poised to make a lasting impact on the future of oil and gas drilling.In conclusion, the Mud Circulation System is a prime example of how innovation and dedication can transform the oil and gas industry. With its advanced capabilities and comprehensive support, this system has the potential to revolutionize drilling operations and set new standards for efficiency and sustainability. As the demand for energy continues to rise, solutions like the Mud Circulation System will play a crucial role in meeting these needs while minimizing the environmental footprint of drilling operations.

The latest innovation in centrifugal impeller technology unveiled

Centrifugal Impeller Revolutionizing Industrial Applications: A Game Changer byIn today's fast-paced industrial world, efficiency and innovation are key factors that drive success. One such innovation that is revolutionizing industrial applications is the Centrifugal Impeller. This state-of-the-art technology is a game-changer in the field of industrial equipment, setting new standards for performance and reliability.The Centrifugal Impeller, developed by a leading industrial equipment manufacturer, is designed to meet the growing demands of various industries, including aerospace, automotive, energy, and HVAC. Its advanced engineering and precision manufacturing make it an ideal choice for applications that require high efficiency, low noise, and long-term reliability.One of the key features of the Centrifugal Impeller is its unique blade design, which is optimized for maximum performance. This design allows for efficient airflow and pressure generation, making it suitable for a wide range of industrial processes. Whether it's for air handling, combustion, or cooling systems, the Centrifugal Impeller delivers unmatched performance, making it a versatile solution for modern industrial applications.Furthermore, the Centrifugal Impeller is also known for its durability and long service life. Its robust construction and high-quality materials ensure that it can withstand the rigors of industrial operations, making it a cost-effective investment for businesses. With minimal maintenance requirements, the Centrifugal Impeller offers a hassle-free solution for industrial equipment needs.In addition to its performance and reliability, the Centrifugal Impeller is also designed with energy efficiency in mind. Its aerodynamic design and precise manufacturing processes enable it to achieve high levels of efficiency, reducing energy consumption and operating costs for businesses. This makes it an environmentally friendly choice for industrial applications, contributing to sustainability efforts in various industries.The company behind the Centrifugal Impeller takes pride in its commitment to quality and innovation. With a team of experienced engineers and experts in industrial equipment, the company has a proven track record of delivering cutting-edge solutions that meet the evolving needs of modern industries. By continuously investing in research and development, the company ensures that its products, including the Centrifugal Impeller, are at the forefront of technological advancements.Furthermore, the company's dedication to customer satisfaction sets it apart in the industry. From initial consultation to product delivery and after-sales support, the company places a strong emphasis on understanding and meeting the specific requirements of its clients. With a focus on building long-term partnerships, the company strives to exceed customer expectations and provide tailored solutions that add value to businesses.As the industrial landscape continues to evolve, the demand for innovative and reliable equipment remains high. The Centrifugal Impeller is a testament to the impact of advanced technology in meeting these demands, offering a solution that enhances efficiency, performance, and sustainability for industrial applications. With its cutting-edge design, durability, and energy efficiency, the Centrifugal Impeller is poised to shape the future of industrial equipment and set new standards for excellence in the industry.

Discover the Latest Advancements in High-Performance Mixing: Unveiling Revolutionary Shear Mixers

Title: Advanced Mixing Technology Streamlines Industrial ProcessesSubtitle: Shear Mixer Revolutionizes Mixing EfficiencyDate: [Insert date][City/Region], [Country] - Combining cutting-edge technology and years of research, an innovative shear mixer has unveiled its game-changing solution for industrial mixing. Developed by [Company Name], a leading provider of advanced equipment for various industries, this revolutionary mixer promises to enhance productivity, consistency, and efficiency in the manufacturing processes.[Company Name] has been at the forefront of developing specialized machinery for industrial applications. With a commitment to continuous improvement and technological advancement, they have introduced the latest addition to their impressive product line - the shear mixer.The shear mixer presents a paradigm shift in the field of mixing technology. With its precision engineering and state-of-the-art features, it has the potential to redefine industries that heavily rely on mixing, such as pharmaceuticals, food processing, chemicals, and cosmetics.One of the standout features of the shear mixer is its ability to provide unparalleled blending efficiency. Equipped with an advanced mixing chamber design, the shear mixer ensures optimal distribution of materials, achieving a homogenous blend in significantly reduced time. This attribute translates into increased productivity and cost savings for manufacturers by minimizing downtime and enhancing overall output.Moreover, the shear mixer offers utmost versatility, capable of handling a wide range of viscosities and materials. Its robust construction and build quality enable it to withstand demanding industrial environments, making it a reliable choice for various applications. From powders to liquids and everything in between, the shear mixer delivers consistent, outstanding results.Efficiency and consistency have always played a crucial role in manufacturing processes. Recognizing this need, [Company Name] has equipped the shear mixer with innovative controls and monitoring capabilities, ensuring precise and repeatable results. Operators can easily control and adjust parameters such as speed, temperature, and mixing time, ensuring a high level of control and customization to meet individual requirements.In addition to its superior functionality, the shear mixer boasts ease of maintenance. Designed with accessibility in mind, it features quick-change components and a user-friendly interface, allowing for intuitive maintenance and reduced downtime. These attributes make the shear mixer an invaluable tool for plant operators, boosting operational efficiency and minimizing costly equipment downtimes.To ensure seamless integration into existing production lines, [Company Name] offers a comprehensive range of customization options. By working closely with clients, they tailor the shear mixer to suit specific needs, considering factors such as material requirements, production volumes, and space constraints. This flexibility ensures that the shear mixer seamlessly integrates within different manufacturing environments, maximizing its performance and enhancing overall efficiency.As industrial processes evolve and demand for streamlined operations intensifies, the shear mixer represents a major breakthrough in mixing technology. With its exceptional efficiency, versatility, and durability, it is set to revolutionize various sectors, enabling manufacturers to meet and exceed production targets while maintaining the highest quality standards.[Company Name] has consistently demonstrated its commitment to innovation and customer satisfaction, and the shear mixer is another testament to their pioneering efforts. By combining cutting-edge technology with their extensive experience, they have developed a mixing solution that is poised to transform the industrial landscape.In conclusion, the shear mixer presented by [Company Name] represents a game-changer for industrial mixing. With its efficient blending capabilities, versatility, and user-friendly maintenance, it enables manufacturers to optimize their processes and elevate production efficiencies. As industries strive for increased productivity and improved quality, this revolutionary mixer is sure to set new standards in the field of mixing technology.

Highly Effective Mud Agitators for Industrial Use

Mud Agitators: The Key to Efficient Mud Mixing and Solid SuspensionMud agitators are an essential part of the drilling process in the oil and gas industry. They are used to keep the solids in the drilling fluid from settling and to ensure that the mud is thoroughly mixed. This is important for maintaining the consistency and quality of the drilling fluid, which in turn directly impacts the efficiency and success of the drilling operation. One company that has been making waves in the mud agitator industry is {}.{} has been a leading provider of drilling equipment and solutions for the oil and gas industry for over 20 years. The company has built a reputation for providing high-quality products that are reliable, efficient, and cost-effective. Their mud agitators are no exception, and they have become a trusted choice for many drilling operations around the world.The {} mud agitators are designed to deliver powerful and efficient agitation of drilling mud, ensuring that solids are suspended and the mud is well mixed. They are available in various sizes and configurations to meet the specific needs of different drilling operations. The agitators are also equipped with durable and reliable motors, gearboxes, and impellers, making them capable of withstanding the harsh conditions of drilling sites.One of the key features of the {} mud agitators is their high efficiency, which helps to reduce energy consumption and operating costs. This is achieved through the use of advanced engineering and design, as well as high-quality materials and components. The agitators are also designed for easy maintenance and long service life, minimizing downtime and maximizing productivity for drilling operations.In addition to their high efficiency and reliability, {} mud agitators are also known for their ease of installation and operation. They can be easily integrated into existing mud systems and are simple to set up and use. This makes them a practical and convenient choice for drilling operators looking to improve their mud mixing and solid suspension processes.The availability of a wide range of options and customizations also adds to the appeal of {} mud agitators. Customers can choose from various models with different power ratings, impeller sizes, and other specifications to meet their specific needs. This flexibility allows drilling operators to find the right mud agitator for their particular drilling conditions and requirements.The success of {} mud agitators can be attributed not only to their high quality and performance but also to the company's commitment to customer satisfaction. {} provides comprehensive support and service to its customers, ensuring that they have access to technical assistance, spare parts, and maintenance services whenever they need them. This dedication to customer care has helped {} build strong and lasting relationships with its clients, who continue to rely on their products and expertise.As the demand for efficient and reliable mud agitators continues to grow in the oil and gas industry, {} is well positioned to meet the needs of drilling operators around the world. With their proven track record of delivering high-quality products and excellent customer support, {} mud agitators are set to remain a top choice for those looking to optimize their mud mixing and solid suspension processes.

How to Choose the Best Screen for Your Mongoose

Introducing a State-of-the-Art Screen Technology by a Leading CompanyIn recent technological developments, companies are continuously innovating to provide the best solutions for businesses and consumers. One such innovation is the development of a revolutionary screen technology by a leading company. This new screen technology, known as Mongoose Screen, is set to change the way we interact with displays and provide an exceptional visual experience for users.Mongoose Screen is a cutting-edge display technology that offers high resolution, vivid colors, and crisp image quality. It is designed to provide an immersive viewing experience, whether for entertainment, presentations, or professional use. The technology behind Mongoose Screen combines advanced hardware and software to deliver unparalleled performance and user satisfaction.The company behind the development of Mongoose Screen has been a pioneer in the display technology industry for several decades. With a solid reputation for creating high-quality products, the company has consistently delivered innovative solutions that meet the evolving needs of the market. Their commitment to research and development has led to the creation of Mongoose Screen, which is poised to become a game-changer in the industry.According to the company spokesperson, Mongoose Screen is the result of years of research, development, and collaboration with industry experts. The team behind this innovative technology has worked tirelessly to push the boundaries of conventional display technology and bring forth a product that redefines visual experiences. Mongoose Screen is built on the foundation of quality, reliability, and performance, making it the go-to choice for businesses and consumers alike.The key features of Mongoose Screen include its high resolution, which provides an unparalleled level of detail and clarity. The screen's ability to reproduce vivid colors and deep blacks ensures that images and videos are displayed with stunning realism. Furthermore, Mongoose Screen boasts an impressive refresh rate, ensuring smooth and fluid motion for an exceptional viewing experience.One of the most noteworthy aspects of Mongoose Screen is its versatility. It is designed to cater to a wide range of applications, including gaming, entertainment, professional use, and more. Whether it's for creating captivating visual presentations or enjoying the latest blockbuster movie, Mongoose Screen delivers exceptional performance across the board.The company has also integrated advanced software features into Mongoose Screen to enhance user experience and provide added value. These features include customizable display settings, picture enhancement modes, and seamless connectivity with other devices. Additionally, Mongoose Screen is designed to be energy-efficient, contributing to a sustainable and eco-friendly technology solution.With the launch of Mongoose Screen, the company is set to solidify its position as a leader in the display technology industry. The introduction of this cutting-edge product marks a significant milestone for the company, demonstrating its commitment to innovation and excellence. The company's dedication to delivering superior products is evident in Mongoose Screen, which promises to set new standards for visual display technology.As the market continues to evolve, the demand for high-quality display solutions will only continue to grow. With Mongoose Screen, the company is well-positioned to meet and exceed the expectations of businesses and consumers seeking the best in display technology. The introduction of Mongoose Screen represents a significant step forward for the company, and it serves as a testament to their dedication to pushing the boundaries of what is possible in the world of visual displays.In conclusion, the development of Mongoose Screen by this leading company is a testament to their commitment to innovation, quality, and providing exceptional solutions for their customers. This revolutionary screen technology is set to redefine the visual display experience and raise the bar for display technology in the industry. With its advanced features, versatility, and superior performance, Mongoose Screen is poised to become a must-have for businesses and consumers looking for the best in display technology.

Understanding the Environmental Impact of Oil Drilling Waste

Oil Drilling Waste Company Leading the Way in Environmental StewardshipOil drilling waste is a major concern for the environment, as it often contains harmful chemicals and pollutants that can leach into the soil and water. However, one company, XXXX (remove brand name), is leading the way in responsible waste management and environmental stewardship.XXXX (remove brand name) is a leading provider of waste management services for the oil and gas industry. With operations in multiple countries around the world, the company is dedicated to ensuring that oil drilling waste is handled and disposed of in a safe and environmentally friendly manner.The company’s approach to waste management is comprehensive and takes into account the entire lifecycle of oil drilling waste. From the initial collection and transportation of waste materials to the treatment and disposal of those materials, XXXX (remove brand name) is committed to minimizing the environmental impact of its operations.One of the key ways that XXXX (remove brand name) is addressing the issue of oil drilling waste is through its advanced treatment technologies. The company has developed innovative processes for treating drilling waste that not only remove harmful contaminants, but also allow for the recovery and recycling of valuable resources, such as oil and water.In addition to its treatment technologies, XXXX (remove brand name) also prioritizes the use of sustainable disposal methods for oil drilling waste. The company operates state-of-the-art disposal facilities that are designed to minimize the release of pollutants into the environment, while also maximizing the recovery and reuse of materials.Beyond its technical expertise, XXXX (remove brand name) also sets itself apart through its focus on compliance and transparency. The company works closely with regulatory agencies and industry stakeholders to ensure that its operations meet or exceed all relevant environmental and safety standards. Additionally, XXXX (remove brand name) is dedicated to providing transparent reporting on its waste management activities, including detailed data on waste volumes, treatment processes, and environmental performance.As a result of its commitment to environmental stewardship, XXXX (remove brand name) has earned a strong reputation as a trusted partner for oil and gas companies seeking sustainable waste management solutions. The company’s expertise and track record make it a preferred choice for both large and small operators looking to minimize their environmental footprint and demonstrate their commitment to responsible business practices.Looking ahead, XXXX (remove brand name) is continuing to innovate and expand its capabilities in the field of oil drilling waste management. The company is investing in research and development to further improve its treatment technologies and explore new opportunities for resource recovery from waste materials. Additionally, XXXX (remove brand name) is actively pursuing partnerships and collaborations with industry peers and academic institutions to advance the state of the art in sustainable waste management practices.Ultimately, XXXX (remove brand name) is setting a high bar for environmental responsibility in the oil and gas industry. With its focus on advanced treatment technologies, sustainable disposal methods, and transparent reporting, the company is demonstrating that it is possible to manage oil drilling waste in a way that protects the environment and supports the long-term sustainability of the industry. As the demand for responsible waste management continues to grow, XXXX (remove brand name) is well positioned to lead the way in delivering innovative and effective solutions for the benefit of the industry and the environment.

Newest Type of Solids Control Equipment: All-in-One Mud Cleaner for Efficient Drilling Fluid Treatment

China Mud Cleaner and Solid Control Desander: The Newest Type of Solids Control Equipment When it comes to drilling fluids, solids control equipment plays a vital role in the overall drilling process. With the introduction of the newest type of solids control equipment, the mud cleaner, drilling operations have become more efficient and productive. Mud cleaner is a combination of desander, desilter, and bottom shaker in one machine. Its design process is reasonable, and it provides higher cleaning function compared to separated desander and desilter. The mud cleaner's compact structure occupies less space, making it an ideal device for handling the second class and third class solid control to treat the drilling mud. The mud cleaner is coated with a three-part coating to maximize equipment life and designed for spare parts and consumables that can ensure the lowest replacement cost and long-term product durability. The productivity and rotary flow quantity are determined by the number of hydrocyclone devices used. DC Solid Control can match different quantities of hydrocyclones based on the user's actual request to achieve the desired treating capacity.As a professional manufacturer of solid control systems and equipment in China, DC Solid Control provides high-quality products at the most reasonable prices. In addition, we offer high-level after-sales service to ensure the satisfaction of our clients. Our commitment to creating maximum value and client satisfaction is undaunted. In conclusion, the mud cleaner is the newest type of solids control equipment that drilling operators should consider. With its compact structure, reasonable design process, and higher cleaning function, the mud cleaner provides a more efficient way to treat drilling mud while ensuring equipment durability. DC Solid Control offers China Mud Cleaner and Solid Control Desander that cater to your needs. Contact us today for more information!

New Flare Ignition Device for Improved Safety and Efficiency

Flare Ignition Device Revolutionizes Safety in Oil and Gas IndustryThe oil and gas industry is notorious for its potential risks and hazards. From environmental concerns to workplace safety, companies in this sector are constantly seeking innovative solutions to mitigate potential dangers. One of the latest developments in this field is the Flare Ignition Device, a cutting-edge technology designed to enhance safety and efficiency in oil and gas operations.Developed by a leading engineering and technology company, the Flare Ignition Device is a state-of-the-art system that has been designed to mitigate the risks associated with flaring, ensuring the safety of personnel and the environment. This innovative device has the potential to revolutionize safety standards in the oil and gas industry by providing a reliable and efficient solution for flare ignition.The Flare Ignition Device is equipped with advanced features that set it apart from conventional ignition systems. Its streamlined design and user-friendly interface make it easy to install and operate, while its robust construction ensures durability and longevity. The device is also designed to operate in a wide range of environmental conditions, including extreme temperatures and harsh weather, making it suitable for use in various oil and gas operations.One of the key advantages of the Flare Ignition Device is its advanced safety features. The system is equipped with multiple fail-safe mechanisms to prevent accidents and ensure reliable operation. This includes built-in sensors and monitoring systems that detect potential issues and automatically shut down the device if necessary. Moreover, the device is designed to meet industry safety standards and regulations, providing companies with peace of mind and regulatory compliance.In addition to its safety features, the Flare Ignition Device also offers significant environmental benefits. By igniting flares efficiently and effectively, the device helps to reduce emissions and minimize environmental impact. This is a critical consideration for oil and gas companies, particularly in light of increasing regulatory pressures and public scrutiny on environmental issues.Furthermore, the Flare Ignition Device is designed to enhance operational efficiency in oil and gas facilities. By providing reliable and consistent flare ignition, the device minimizes downtime and maximizes productivity. This is especially important in the context of volatile market conditions and fluctuating energy prices, where operational efficiency can significantly impact the bottom line.The company behind the Flare Ignition Device is a leading provider of engineering and technology solutions for the oil and gas industry. With a track record of innovation and excellence, the company is committed to developing cutting-edge products and services that address the evolving needs of its clients. The Flare Ignition Device is a testament to the company's dedication to safety, reliability, and environmental sustainability.In conclusion, the Flare Ignition Device represents a significant advancement in safety and efficiency for the oil and gas industry. With its advanced features, robust design, and environmental benefits, the device has the potential to revolutionize safety standards and operational practices in this sector. As companies continue to prioritize safety and environmental responsibility, the Flare Ignition Device is poised to become a critical tool for enhancing performance and mitigating risks in oil and gas operations.