New Mixing Hopper Technology: A Game Changer in Industrial Processing

By:Admin

With the increasing demand for efficient and effective mixing technology in industrial applications, the introduction of the Venturi Mixing Hopper has been a game-changer in the industry. This innovative solution has been designed to revolutionize the way materials are mixed, offering a more effective and efficient approach to industrial mixing.

The Venturi Mixing Hopper, developed by a leading company in the field of industrial equipment manufacturing, has been gaining widespread attention for its ability to significantly improve mixing processes in various industries. This cutting-edge technology has been designed to provide a solution to the challenges faced by industries when it comes to mixing materials effectively and efficiently.

The company behind the Venturi Mixing Hopper is known for its commitment to innovation and excellence in the field of industrial equipment manufacturing. With a proven track record of delivering high-quality solutions to industries around the world, the company has built a reputation for pushing the boundaries of what is possible in industrial technology.

The Venturi Mixing Hopper is a testament to the company's dedication to innovation and its ability to develop solutions that meet the ever-evolving needs of industries. By combining cutting-edge technology with practical industrial applications, the company has been able to create a product that is not only effective but also efficient and reliable.

One of the key features of the Venturi Mixing Hopper is its ability to achieve thorough and uniform mixing of materials, regardless of their properties or characteristics. This has been a significant challenge for industries that rely on effective mixing processes to ensure the quality and consistency of their products. The Venturi Mixing Hopper has been able to address this challenge by utilizing advanced technology that is capable of achieving optimal mixing results.

In addition to its exceptional mixing capabilities, the Venturi Mixing Hopper also offers a range of other benefits that make it a valuable investment for industries. Its compact design and user-friendly interface make it easy to operate and maintain, while its robust construction ensures durability and longevity. Furthermore, the Venturi Mixing Hopper is designed to be adaptable to various industrial settings, making it a versatile and flexible solution for different applications.

The introduction of the Venturi Mixing Hopper has been met with a positive response from industries that have been struggling with outdated and inefficient mixing technologies. The significant improvements in mixing efficiency and quality that the Venturi Mixing Hopper offers have been a game-changer for these industries, allowing them to optimize their processes and achieve better results.

The company behind the Venturi Mixing Hopper has been actively promoting the benefits and advantages of this innovative solution, working closely with industries to demonstrate its capabilities and potential impact. Through various demonstrations and case studies, the company has been able to showcase the significant improvements that the Venturi Mixing Hopper can bring to industrial mixing processes.

Moving forward, the company is committed to further developing and enhancing the capabilities of the Venturi Mixing Hopper, as well as exploring new opportunities for its application in different industries. By continuing to innovate and push the boundaries of industrial mixing technology, the company aims to further solidify the position of the Venturi Mixing Hopper as a leading solution for efficient and effective mixing in industrial applications.

In conclusion, the introduction of the Venturi Mixing Hopper has been a significant development in the field of industrial mixing technology. With its exceptional capabilities and numerous benefits, this innovative solution has already made a substantial impact on industries that rely on efficient and effective mixing processes. As the company behind the Venturi Mixing Hopper continues to drive innovation and excellence in industrial equipment manufacturing, the future looks promising for the continued success and evolution of this groundbreaking technology.

Company News & Blog

Quality Engine Parts for Machinery: A Complete Guide

China Machinery Parts and Engine Parts has been a leading provider of high-quality machinery and engine parts for a wide range of industries. The company has built a strong reputation for delivering precision-engineered parts that meet the strictest quality standards. With a focus on innovation and continuous improvement, China Machinery Parts and Engine Parts has positioned itself as a trusted partner for businesses seeking reliable and durable parts for their machinery and engines.The company specializes in producing a wide variety of machinery and engine parts, including but not limited to, pistons, cylinders, valves, gaskets, seals, and bearings. With an extensive product range, China Machinery Parts and Engine Parts is able to serve diverse industries such as automotive, construction, agriculture, and marine.One of the key factors that sets China Machinery Parts and Engine Parts apart from its competitors is its commitment to quality. The company has invested in state-of-the-art manufacturing facilities and employs a team of highly skilled engineers and technicians who ensure that every part meets the highest standards of precision and reliability. By leveraging advanced technologies and stringent quality control processes, China Machinery Parts and Engine Parts has been able to consistently deliver parts that exceed customer expectations.In addition to its dedication to quality, China Machinery Parts and Engine Parts also places a strong emphasis on innovation. The company continuously invests in research and development to stay ahead of industry trends and develop cutting-edge solutions for its customers. This commitment to innovation has enabled China Machinery Parts and Engine Parts to introduce new and improved parts that enhance the performance and longevity of machinery and engines.Furthermore, China Machinery Parts and Engine Parts has built a robust global supply chain that enables it to efficiently distribute its products to customers around the world. By partnering with reliable logistics providers, the company ensures that its parts are delivered on time and in pristine condition, no matter where its customers are located.Despite the challenges posed by the global pandemic, China Machinery Parts and Engine Parts has remained steadfast in its commitment to supporting its customers. The company has implemented rigorous safety protocols in its facilities to protect its employees and maintain uninterrupted production. Additionally, China Machinery Parts and Engine Parts has worked closely with its supply chain partners to mitigate potential disruptions and ensure the continued availability of its parts.Looking ahead, China Machinery Parts and Engine Parts is poised for continued growth and success. The company remains dedicated to providing exceptional parts and service to its customers, while also exploring new opportunities for expansion and diversification. With its unwavering focus on quality, innovation, and customer satisfaction, China Machinery Parts and Engine Parts is well-positioned to cement its position as a leader in the global machinery and engine parts industry.In conclusion, China Machinery Parts and Engine Parts has established itself as a world-class provider of high-quality machinery and engine parts. With a steadfast commitment to quality, innovation, and customer satisfaction, the company has earned the trust and loyalty of businesses across diverse industries. As it continues to grow and expand its presence in the global market, China Machinery Parts and Engine Parts is poised to remain a top choice for businesses seeking reliable and durable parts for their machinery and engines.

High-Quality Drilling Rig Parts and Drawworks in China

China has long been a leader in the oil and gas industry, and their advancements in drilling rig technology have been at the forefront of this. With a commitment to innovation and quality, Chinese companies continue to provide essential parts and equipment for drilling operations around the world.One such company is {}, a leading provider of drilling rig parts and equipment. With a focus on research and development, they have become known for their high-quality products that meet the demands of the industry. From drill drawworks to drilling rig components, {} has established itself as a reliable supplier for companies looking to enhance their drilling operations.In recent years, the demand for drilling rig parts and equipment has continued to grow as the global energy market expands. This has led to increased competition among suppliers, but {} has been able to distinguish itself through its dedication to quality and customer service.One of the key products that {} offers is their drill drawworks. This essential component of a drilling rig is responsible for raising and lowering the drill string, making it a vital part of the overall operation. With a focus on durability and efficiency, {}'s drill drawworks have become a popular choice for companies looking to maximize their drilling capabilities.In addition to drill drawworks, {} also provides a wide range of other drilling rig parts, including mud pumps, top drives, and more. Their comprehensive selection of products makes them a one-stop shop for companies in need of reliable equipment for their drilling operations.One of the major advantages of working with {} is their commitment to customization. They understand that every drilling operation is unique, and they are able to tailor their products to fit the specific needs of their customers. This flexibility has made them a preferred supplier for drilling companies around the world.In addition to their product offerings, {} also provides comprehensive support and services for their customers. This includes technical assistance, maintenance and repair services, and training programs for operators. This commitment to customer satisfaction sets {} apart from other suppliers and has helped them build long-lasting relationships with their clients.With an eye towards the future, {} continues to invest in research and development to further enhance their products and services. They understand the importance of staying ahead of the curve in an ever-evolving industry, and they are dedicated to maintaining their position as a leading supplier of drilling rig parts and equipment.As the global demand for energy continues to rise, the importance of reliable drilling operations has never been greater. Companies like {} play a critical role in supporting these operations by providing high-quality parts and equipment that are essential for success. With their commitment to innovation and customer satisfaction, {} is well-positioned to continue leading the way in the drilling rig industry for years to come.

Essential Software Solutions and Technology Advancements for Effective Exploration Decision-Making

Exploring for minerals and metals is a complex, costly and time-consuming process. However, technology advancements have significantly changed the exploration industry over the past decade by providing innovative solutions that enhance exploration efficiencies. From remote sensing to geophysical surveys, cutting-edge technologies have emerged to increase accuracy and reduce the risks associated with mineral exploration. One aspect of exploration that has benefited from advances in technology is drill cuttings management.Drill cuttings management is a critical aspect of any mining exploration program. It involves collecting and analyzing the rock fragments or cuttings produced during drilling operations. These cuttings can be analyzed to provide essential geological information such as the mineralogy, rock type, and structure of the underlying deposit. Information from drill cuttings is used by geologists and mining engineers to make informed decisions regarding the next drilling location, prioritize targets, and guide further exploration.In the past, the process of managing drill cuttings was time-consuming and human-intensive, which resulted in delays in decision-making and high exploration costs. Nowadays, however, due to advances in digital technologies, the process has become more efficient and cost-effective.One of the leading solutions to drill cuttings management is remote sensing, which relies on the use of unmanned aerial vehicles (UAVs) to capture high-resolution images of the drilled area. The images are then analyzed using machine learning algorithms, which can accurately identify and interpret geological features, automate data processing, and improve the accuracy of the exploration data.Another technology that has transformed drill cuttings management is the use of real-time data analytics. Instead of waiting for samples to be analyzed in a laboratory, real-time data analytics can provide information on the properties of the material being drilled. This technology has the potential to be a game-changer in the exploration industry, improving the efficiency of the exploration program by providing instant feedback to exploration teams while drilling is still in progress.The use of mobile apps is another technology that has revolutionized the management of drill cuttings. Exploration teams can use mobile apps to collect data, input geological information, and track drilling progress. The apps can also be used to upload and analyze the data, which provides an interactive platform for the exploration team to collaborate. The use of mobile apps promotes critical decision-making in real-time, thus reducing the risks associated with mineral exploration.In conclusion, the exploration industry has benefited greatly from technological advancements in drill cuttings management. The use of UAVs, real-time data analytics, mobile apps and machine learning algorithms offer a more efficient and cost-effective approach to exploration. As the exploration industry continues to evolve, it is expected that we will see further advances in drill cuttings management, which will continue to drive efficiencies in the exploration process.

Quality Sand Investment Casting and Coated Sand Investment Castings in China

China Sand Investment Casting and Coated Sand Investment Castings have become increasingly popular in the manufacturing industry due to their superior quality and cost-effectiveness. With the rise of demand for precision-engineered components in various industries, the investment casting process has become an integral part of the production of high-quality and complex parts.Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating a wax pattern that is coated with a ceramic material. This pattern is then melted, leaving a hollow ceramic shell that is filled with molten metal to create the final part. This process allows for the production of parts with intricate shapes, thin walls, and fine details, making it a preferred method for the production of components in industries such as aerospace, automotive, and marine.China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise in the production of high-quality precision components. With state-of-the-art facilities and a highly skilled workforce, they are able to meet the most demanding requirements of their customers, providing cost-effective solutions for complex and critical components.The investment casting process offers numerous benefits, including the ability to produce parts with tight tolerances, excellent surface finish, and complex geometry. This makes it a preferred choice for manufacturers looking to produce high-performance components that meet stringent quality standards.China Sand Investment Casting and Coated Sand Investment Castings specialize in the production of a wide range of components, including turbine blades, impellers, and other complex parts used in the aerospace and automotive industries. Their expertise in producing components with high temperature and corrosion resistance makes them a trusted partner for manufacturers requiring precision-engineered parts for critical applications.In addition to traditional investment casting, China Sand Investment Casting and Coated Sand Investment Castings also offer coated sand investment casting, a process that involves coating sand with a refractory material to create a mold for casting. This process is particularly suitable for the production of large and heavy parts, offering cost-effective solutions for manufacturers looking to produce components with complex shapes and structures.The company's commitment to quality and innovation has made them a preferred choice for manufacturers looking for reliable and cost-effective investment casting solutions. With a strong focus on research and development, they continue to invest in new technologies and processes to ensure that they are at the forefront of the industry, offering their customers the best possible solutions for their production needs.With a global presence and a strong reputation for quality and reliability, China Sand Investment Casting and Coated Sand Investment Castings are well-positioned to meet the growing demand for precision-engineered components in various industries. Their commitment to excellence and customer satisfaction has made them a trusted partner for manufacturers worldwide, providing them with the high-quality components they need to stay competitive in today's market.In conclusion, China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise to meet the most demanding requirements of their customers. With a strong focus on quality, innovation, and customer satisfaction, they are well-positioned to continue their success and remain a preferred partner for manufacturers looking for cost-effective and reliable solutions for their production needs.

Powerful Hydraulic Pump for Mission Sandmaster

Mission Sandmaster Pump is a revolutionary product that has gained immense popularity in the industry for its innovative features and exceptional performance. This state-of-the-art pump is designed to meet the increasing demand for efficient and reliable pumping solutions in the oil and gas sector. Mission Sandmaster Pump is manufactured by a leading company in the industry, which has a long-standing reputation for delivering high-quality and advanced products.The company responsible for manufacturing Mission Sandmaster Pump is committed to providing innovative solutions to the oil and gas industry. With a strong focus on research and development, the company has been able to create cutting-edge products that meet the evolving needs of the industry. The company is known for its extensive expertise in engineering, manufacturing, and servicing a wide range of pumping solutions, and it has set new standards for reliability and performance in the industry.Mission Sandmaster Pump is designed to handle the toughest pumping challenges in the oil and gas sector. It is specifically engineered to efficiently handle abrasive and corrosive fluids, making it the ideal solution for demanding applications. The pump is capable of handling high viscosity fluids and solid-laden slurries, ensuring consistent and reliable performance in the most challenging environments. Its robust construction and advanced design make it a versatile and reliable choice for a wide range of pumping applications.One of the key features of Mission Sandmaster Pump is its cutting-edge technology, which sets it apart from traditional pumping solutions. The pump is equipped with a high-efficiency impeller and casing design, which minimizes wear and maximizes uptime. This innovative design ensures that the pump can maintain peak performance even in the harshest operating conditions, reducing downtime and maintenance costs for operators. Additionally, the pump is designed to be easily customizable to meet specific application requirements, providing operators with a flexible and reliable solution for their pumping needs.In addition to its advanced technology, Mission Sandmaster Pump is also known for its exceptional reliability and durability. The pump is built to withstand the most demanding operating conditions, providing operators with a long-lasting and cost-effective pumping solution. Its rugged construction and high-quality materials ensure that the pump can withstand the wear and tear of continuous operation, delivering reliable performance over an extended service life. This unparalleled durability makes Mission Sandmaster Pump a preferred choice for operators looking for a dependable and low-maintenance pumping solution.Furthermore, Mission Sandmaster Pump is supported by a comprehensive service network provided by the manufacturing company, ensuring that operators receive the support they need to maximize the performance and lifespan of their pumps. The company has a team of highly skilled technicians and engineers who are dedicated to providing exceptional service and support for Mission Sandmaster Pump. From installation and commissioning to maintenance and repair, the company's service network is committed to delivering unmatched support to operators, ensuring that their pumping systems operate at their best at all times.In conclusion, Mission Sandmaster Pump is a game-changing product that has redefined pumping solutions in the oil and gas industry. Its advanced technology, exceptional reliability, and comprehensive service network make it a superior choice for operators looking for efficient and dependable pumping solutions. Supported by a leading company with a proven track record in the industry, Mission Sandmaster Pump is set to continue its success and establish itself as the go-to pumping solution for the most demanding applications in the oil and gas sector.

World-leading Manufacturer Provides Workover Drilling Rig Mud System for China Drilling Company

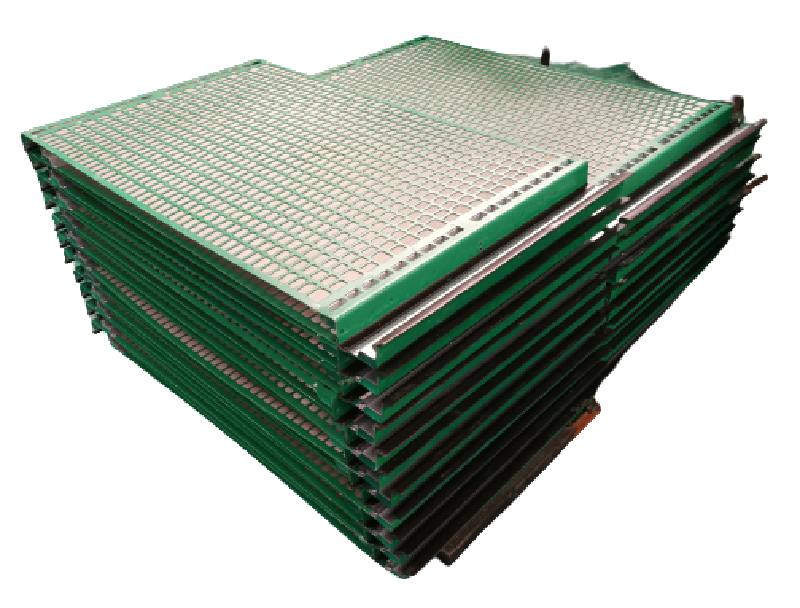

Title: Advancing Workover Drilling with GN Solids Control's Cutting-Edge Mud SystemIntroduction:As the global energy demands continue to rise, the drilling industry has witnessed a significant boost in workover operations to enhance production capabilities. To ensure the smooth execution of these drilling activities, China Drilling Company, a prominent player in the industry, turned to the expertise of GN Solids Control. With their cutting-edge workover drilling rig mud system, GN Solids Control is revolutionizing the industry, delivering exceptional separation efficiency and advanced technology. This blog post aims to delve deeper into the details of this groundbreaking system while discussing the importance of the China Drill Shale Shaker and Drilling Rig.GN Solids Control: A Leading Separation Equipment ManufacturerGN Solids Control has cemented its position as a world-leading manufacturer and supplier of solids and liquid separation equipment. With their commitment to customer satisfaction and relentless pursuit of innovation, GN Solids Control has successfully deployed numerous systems globally. The recent success in developing another set of workover drilling rig mud system highlights their dedication to delivering top-notch solutions tailored to specific customer requirements.Enhancing Workover Efficiency with GN Solids Control's Mud SystemThe workover process involves interventions in an existing well to optimize production by addressing various well-related issues. To maximize efficiency and minimize downtime during these operations, a well-designed mud system plays a crucial role. GN Solids Control's workover drilling rig mud system has been engineered to deliver outstanding performance, ensuring uninterrupted drilling operations.1. China Drill Shale Shaker:Among the essential components of GN Solids Control's mud system is the China Drill Shale Shaker. This innovative equipment applies mechanical separation to remove solid particles from drilling fluids. By efficiently separating the cuttings, the China Drill Shale Shaker not only minimizes wastage but also extends the lifespan of downstream equipment. This ensures a reduction in overall operational costs and boosts workover efficiency.2. Advanced Drilling Rig:In conjunction with the China Drill Shale Shaker, GN Solids Control's workover drilling rig mud system incorporates advanced drilling rig technology. The drilling rig serves as the core component of the system, facilitating the extraction of oil or gas reserves effectively. With enhanced features such as real-time monitoring, precise control system, and automation, these drilling rigs optimize overall workover performance.Unmatched Features and Benefits of GN Solids Control's Mud System:1. Higher Separation Efficiency:The cutting-edge technology incorporated in GN Solids Control's mud system enables efficient removal of solid particles from drilling fluids. This ensures consistent and reliable separation, leading to improved drilling performance and enhanced workover efficiency.2. Customized Design:GN Solids Control understands the unique requirements of each drilling project. Therefore, they offer tailor-made solutions to match specific operational demands. From system capacity to control mechanism, each component can be customized, providing China Drilling Company with the ideal workover drilling rig mud system.3. Increased Equipment Lifespan:GN Solids Control's mud system, equipped with the China Drill Shale Shaker, prevents clogging and damage to downstream equipment. By effectively removing the drilled cuttings, it helps extend the lifespan of crucial components, reducing maintenance costs and enhancing the longevity of the machinery.Conclusion:In the ever-evolving drilling industry, the need for efficient workover operations has become paramount. GN Solids Control's workover drilling rig mud system, featuring the China Drill Shale Shaker and advanced drilling rig technology, is the pinnacle of innovation in this field. By incorporating cutting-edge features and customizable design, this extraordinary mud system improves separation efficiency, boosts workover productivity, and elevates the overall drilling experience. With GN Solids Control's unrivaled expertise, China Drilling Company can now unlock new levels of productivity and profitability in their workover operations.

Top Water Purifier and Treatment Solutions in China

China's leading water purification and water treatment company, with a strong focus on providing clean and safe drinking water for all, has been making waves in the industry with its innovative and high-quality products.With a reputation for excellence and a commitment to sustainability, the company has become a trusted name in the field of water purification. Their products are designed to remove impurities and contaminants from water, ensuring that it is safe for consumption and free from any harmful substances.One of the main reasons behind the company's success is its dedication to research and development. They employ a team of highly skilled and experienced professionals who are constantly working on improving their products and developing new technologies to better serve their customers.In addition to their innovative products, the company also places a strong emphasis on environmental responsibility. They strive to minimize their impact on the environment by using sustainable manufacturing practices and reducing their carbon footprint. This commitment to sustainability has earned them the respect and admiration of both customers and industry experts alike.The company's water purifiers and treatment systems are designed to meet the needs of a wide range of customers, from individual households to large-scale industrial applications. Their products are known for their reliability, efficiency, and durability, making them a popular choice for consumers and businesses alike.In recent years, the company has expanded its reach beyond the borders of China, exporting its products to countries around the world. This global expansion has further solidified their position as a leader in the water purification and treatment industry.One of the company's most notable achievements is its involvement in providing clean drinking water to areas affected by natural disasters and other humanitarian crises. Their portable water purification systems have been deployed in various disaster-stricken regions, providing vital support to communities in need.Looking ahead, the company remains committed to driving innovation and excellence in the field of water purification and treatment. They continue to invest in research and development, seeking to further improve their products and develop new solutions to address the ever-evolving challenges of water purification.In conclusion, China Water Purifier and Water Treatment is a company that has made a significant impact in the field of water purification and treatment. With their commitment to excellence, sustainability, and innovation, they have become a trusted name in the industry, both in China and around the world. As they continue to grow and expand, they are sure to set new standards for the industry and continue to provide clean and safe drinking water for all.

Effective Mud Cleaning System for Efficient Drilling Operations

Mud Cleaning System (MCS) is a revolutionary technology that is changing the game in the oil and gas industry. This innovative system is designed to remove harmful solids from the drilling mud, ensuring that the mud is clean and free from contaminants. MCS is committed to providing cost-effective solutions for the oil and gas industry, and its cutting-edge technology is setting new standards for efficiency and safety.The company behind MCS is dedicated to delivering top-quality products and services to its clients. With a team of experienced professionals and industry experts, the company has established itself as a leader in the field of mud cleaning technology. It is committed to delivering innovative solutions that are tailored to the specific needs of its clients, and its commitment to excellence has earned it a solid reputation in the industry.MCS is a game-changer for the oil and gas industry. By utilizing advanced technology and state-of-the-art equipment, MCS is able to provide a level of efficiency and effectiveness that is unprecedented in the industry. The system is designed to remove solid particles from drilling mud, ensuring that the mud is clean and free from contaminants. This not only improves the efficiency of the drilling process, but also ensures that the environment is protected from harmful pollutants.Furthermore, MCS is committed to providing cost-effective solutions for its clients. The company understands the challenges that the oil and gas industry faces, and it is dedicated to delivering solutions that are not only effective, but also affordable. By utilizing innovative technology and cutting-edge equipment, MCS is able to deliver solutions that provide maximum value for its clients.In addition to its cutting-edge technology, MCS is also dedicated to safety. The company takes the safety of its employees and clients seriously, and it has implemented strict safety protocols to ensure that its operations are conducted in a safe and responsible manner. Clients can have peace of mind knowing that MCS is committed to delivering solutions that are not only effective, but also safe for the environment and for the people involved in the drilling process.MCS is leading the way in the oil and gas industry, and its commitment to excellence has earned it a solid reputation in the field of mud cleaning technology. The company is dedicated to delivering innovative solutions that are tailored to the specific needs of its clients, and its cutting-edge technology is setting new standards for efficiency and safety. With a team of experienced professionals and industry experts, MCS is poised to continue its success and lead the industry into a new era of excellence.In conclusion, Mud Cleaning System is revolutionizing the oil and gas industry with its cutting-edge technology and commitment to excellence. The company is dedicated to providing cost-effective solutions that are tailored to the specific needs of its clients, and its commitment to safety and efficiency has earned it a solid reputation in the industry. As the industry continues to evolve, MCS is poised to lead the way with its innovative solutions and game-changing technology.

New Mixing Hopper Technology: A Game Changer in Industrial Processing

Venturi Mixing Hopper Revolutionizes Mixing Technology in Industrial ApplicationsWith the increasing demand for efficient and effective mixing technology in industrial applications, the introduction of the Venturi Mixing Hopper has been a game-changer in the industry. This innovative solution has been designed to revolutionize the way materials are mixed, offering a more effective and efficient approach to industrial mixing.The Venturi Mixing Hopper, developed by a leading company in the field of industrial equipment manufacturing, has been gaining widespread attention for its ability to significantly improve mixing processes in various industries. This cutting-edge technology has been designed to provide a solution to the challenges faced by industries when it comes to mixing materials effectively and efficiently.The company behind the Venturi Mixing Hopper is known for its commitment to innovation and excellence in the field of industrial equipment manufacturing. With a proven track record of delivering high-quality solutions to industries around the world, the company has built a reputation for pushing the boundaries of what is possible in industrial technology.The Venturi Mixing Hopper is a testament to the company's dedication to innovation and its ability to develop solutions that meet the ever-evolving needs of industries. By combining cutting-edge technology with practical industrial applications, the company has been able to create a product that is not only effective but also efficient and reliable.One of the key features of the Venturi Mixing Hopper is its ability to achieve thorough and uniform mixing of materials, regardless of their properties or characteristics. This has been a significant challenge for industries that rely on effective mixing processes to ensure the quality and consistency of their products. The Venturi Mixing Hopper has been able to address this challenge by utilizing advanced technology that is capable of achieving optimal mixing results.In addition to its exceptional mixing capabilities, the Venturi Mixing Hopper also offers a range of other benefits that make it a valuable investment for industries. Its compact design and user-friendly interface make it easy to operate and maintain, while its robust construction ensures durability and longevity. Furthermore, the Venturi Mixing Hopper is designed to be adaptable to various industrial settings, making it a versatile and flexible solution for different applications.The introduction of the Venturi Mixing Hopper has been met with a positive response from industries that have been struggling with outdated and inefficient mixing technologies. The significant improvements in mixing efficiency and quality that the Venturi Mixing Hopper offers have been a game-changer for these industries, allowing them to optimize their processes and achieve better results.The company behind the Venturi Mixing Hopper has been actively promoting the benefits and advantages of this innovative solution, working closely with industries to demonstrate its capabilities and potential impact. Through various demonstrations and case studies, the company has been able to showcase the significant improvements that the Venturi Mixing Hopper can bring to industrial mixing processes.Moving forward, the company is committed to further developing and enhancing the capabilities of the Venturi Mixing Hopper, as well as exploring new opportunities for its application in different industries. By continuing to innovate and push the boundaries of industrial mixing technology, the company aims to further solidify the position of the Venturi Mixing Hopper as a leading solution for efficient and effective mixing in industrial applications.In conclusion, the introduction of the Venturi Mixing Hopper has been a significant development in the field of industrial mixing technology. With its exceptional capabilities and numerous benefits, this innovative solution has already made a substantial impact on industries that rely on efficient and effective mixing processes. As the company behind the Venturi Mixing Hopper continues to drive innovation and excellence in industrial equipment manufacturing, the future looks promising for the continued success and evolution of this groundbreaking technology.

Unlocking the Potential of Oil Based Drilling Fluid: Insights, Benefits, and Latest Developments

[Company Name] Introduces Groundbreaking Oil Based Drilling Fluid for Enhanced Efficiency and Environmental Safety[City, Date] - Leading global energy solutions provider [Company Name] unveiled its latest innovation in the oil and gas industry - an advanced oil-based drilling fluid designed to revolutionize drilling operations while prioritizing environmental safety.Recognizing the need for cutting-edge technology in the energy sector, [Company Name] has developed a state-of-the-art drilling fluid that addresses the industry's key challenges. By utilizing their extensive expertise in oil and gas exploration, the company has successfully produced a fluid that enhances drilling efficiency, reduces environmental impact, and ensures improved overall performance.Traditional drilling fluids rely on a water-based system, which often leads to inefficiencies and environmental hazards. [Company Name]'s pioneering solution is centered around an oil-based formulation that outperforms its water-based counterparts in several critical aspects.One of the key advantages of this innovative drilling fluid is its superior lubricating properties. With its unique composition, the fluid significantly reduces friction during drilling, leading to increased drilling speeds and reduced wear and tear on drilling equipment. By enhancing the drilling process, projects can be completed more efficiently, ultimately resulting in substantial cost savings for operators.Furthermore, the new oil-based drilling fluid boasts exceptional thermal stability, making it highly resilient in extreme temperature conditions. This characteristic ensures uninterrupted operations during challenging drilling environments, eliminating costly downtime due to fluid degradation.Environmental safety has been at the forefront of [Company Name]'s research and development efforts, and this new drilling fluid reflects their commitment to sustainability. Unlike water-based fluids that often require chemical additives for optimal performance, this oil-based fluid limits the need for hazardous additives, thereby reducing potential environmental risks. Moreover, its superior lubrication properties enable operators to drill more accurately, minimizing accidental spills and potential harm to surrounding ecosystems."The development of this groundbreaking oil-based drilling fluid showcases our commitment to advancing the industry while protecting the environment," said [Company Name]'s CEO. "We believe that this development will revolutionize drilling operations and help pave the way for a more sustainable future in the oil and gas industry."To ensure seamless integration into existing drilling operations, [Company Name] has invested in comprehensive compatibility testing, ensuring that their drilling fluid can be easily incorporated with conventional equipment and procedures. This ease of adoption eliminates the need for significant upfront capital investments, allowing operators to maximize the benefits of this breakthrough technology without major disruptions to their operations.The introduction of this innovative drilling fluid comes at a time when the oil and gas industry is increasingly embracing environmentally conscious practices. By providing a solution that improves drilling efficiency while reducing environmental impact, [Company Name] is frontrunning efforts to achieve a more sustainable future in the energy sector.With this groundbreaking development, [Company Name] positions itself as a frontrunner in the oil and gas industry, promoting a greener and more efficient approach to drilling. As the demand for environmentally safe drilling solutions continues to rise, [Company Name] looks forward to partnering with operators globally, creating a more sustainable and efficient future in the energy sector.About [Company Name]:[Company Name] is a leading global energy solutions provider, specializing in innovative technologies and services for the oil and gas industry. With a commitment to sustainability and customer satisfaction, the company aims to revolutionize the energy sector by delivering cutting-edge solutions that optimize operations and reduce environmental impact. With a strong emphasis on research and development, [Company Name] continues to pioneer advancements in the energy industry, striving to propel the world towards a more sustainable future.